(To be inserted under Schedule-T - GMP) - amam-ayurveda.org

(To be inserted under Schedule-T - GMP) - amam-ayurveda.org

(To be inserted under Schedule-T - GMP) - amam-ayurveda.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

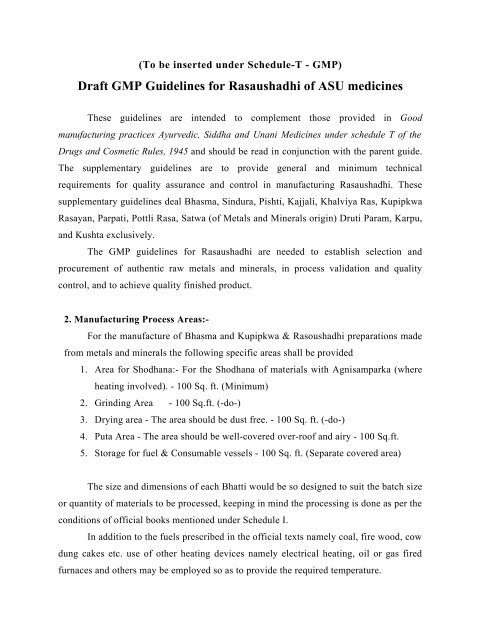

(<strong>To</strong> <strong>be</strong> <strong>inserted</strong> <strong>under</strong> <strong>Schedule</strong>-T - <strong>GMP</strong>)<br />

Draft <strong>GMP</strong> Guidelines for Rasaushadhi of ASU medicines<br />

These guidelines are intended to complement those provided in Good<br />

manufacturing practices Ayurvedic, Siddha and Unani Medicines <strong>under</strong> schedule T of the<br />

Drugs and Cosmetic Rules, 1945 and should <strong>be</strong> read in conjunction with the parent guide.<br />

The supplementary guidelines are to provide general and minimum technical<br />

requirements for quality assurance and control in manufacturing Rasaushadhi. These<br />

supplementary guidelines deal Bhasma, Sindura, Pishti, Kajjali, Khalviya Ras, Kupipkwa<br />

Rasayan, Parpati, Pottli Rasa, Satwa (of Metals and Minerals origin) Druti Param, Karpu,<br />

and Kushta exclusively.<br />

The <strong>GMP</strong> guidelines for Rasaushadhi are needed to establish selection and<br />

procurement of authentic raw metals and minerals, in process validation and quality<br />

control, and to achieve quality finished product.<br />

2. Manufacturing Process Areas:-<br />

For the manufacture of Bhasma and Kupipkwa & Rasoushadhi preparations made<br />

from metals and minerals the following specific areas shall <strong>be</strong> provided<br />

1. Area for Shodhana:- For the Shodhana of materials with Agnisamparka (where<br />

heating involved). - 100 Sq. ft. (Minimum)<br />

2. Grinding Area - 100 Sq.ft. (-do-)<br />

3. Drying area - The area should <strong>be</strong> dust free. - 100 Sq. ft. (-do-)<br />

4. Puta Area - The area should <strong>be</strong> well-covered over-roof and airy - 100 Sq.ft.<br />

5. Storage for fuel & Consumable vessels - 100 Sq. ft. (Separate covered area)<br />

The size and dimensions of each Bhatti would <strong>be</strong> so designed to suit the batch size<br />

or quantity of materials to <strong>be</strong> processed, keeping in mind the processing is done as per the<br />

conditions of official books mentioned <strong>under</strong> <strong>Schedule</strong> I.<br />

In addition to the fuels prescri<strong>be</strong>d in the official texts namely coal, fire wood, cow<br />

dung cakes etc. use of other heating devices namely electrical heating, oil or gas fired<br />

furnaces and others may <strong>be</strong> employed so as to provide the required temperature.

Depending on the formulation <strong>be</strong>ing manufactured, manufacturers may adopt aerobic<br />

or anaerobic process. Properly baked and clean earthen pots and glass containers of<br />

appropriate design should <strong>be</strong> used.<br />

The manufacturing area should <strong>be</strong> designed with special attention to processing of<br />

products that generate toxic fumes like SO2, arsenic and mercury vapor etc. When heating<br />

and boiling of the materials is necessary suitable air exhaustion mechanism should <strong>be</strong><br />

provided to prevent accumulation of unintended fumes and vapors. Such areas may <strong>be</strong><br />

provided with properly designed chimneys or ducts fitted with exhaust system and suitable<br />

scrubbing system to remove fumes and smoke, so that safety of personnel and environment is<br />

taken care of.<br />

Since processing of Rasaushadhi may generate heavy metal contamination and cross<br />

examination, cleaning of equipment is particularly important.<br />

Records shall <strong>be</strong> maintained specially for temperatures attained during the entire<br />

process of Bhasmikaran while employing furnaces using oil, gas or electricity. Appropriate<br />

temperature measuring instrument should <strong>be</strong> employed such as pyrograph for manual<br />

reading/recording or heat sensors connected to computer as the case may <strong>be</strong>.<br />

personal.<br />

Access to manufacturing areas shall <strong>be</strong> restricted to minimum num<strong>be</strong>r of authorized<br />

3. Quality Control:-<br />

A. Process Quality Control:-<br />

The registers as indicated <strong>be</strong>low should exclusively <strong>be</strong> maintained for ready reference:-<br />

a. Shodhan Register with following details:-<br />

1. S1.No.<br />

2. Batch No. & Size<br />

3. Name of the Raw-material with Quality reference<br />

4. Quantity of Shodhana Dravya

5. Book Reference followed<br />

6. Methodology<br />

7. Description<br />

b. Log Register with following details:-<br />

1. S1.No.<br />

2. Batch No.<br />

3. Quantity of starting materials<br />

4. Quantity of Avapa Dravya<br />

5. Quantity of Bhavana Dravya<br />

6. Date & Time of Starting of Bhavana/mardana<br />

7. Date & Time of completion of Bhavana/Mardana<br />

8. Num<strong>be</strong>r of Samputas (Quantity of material in each samputa)<br />

9. Type & Num<strong>be</strong>r of Puta<br />

10. Time and Date of ignition<br />

11. Time and Date of evacuation<br />

12. Time and Date of completion of Puta<br />

13. Obtained quantity<br />

14. Colour and texture of the product/Standards<br />

15. In process tests followed.<br />

B. Product Quality Control:-<br />

The specifications for finished Rasaushadhi are primarily intended to define the<br />

quality rather than to establish full characterization, and should focus on those characteristics<br />

found to <strong>be</strong> useful in ensuring the safety and efficacy. Consistent quality for Rasaushadhi can<br />

only <strong>be</strong> assured if the starting metals and minerals are defined in a rigorous and detailed<br />

manner. In some cases more detailed information may <strong>be</strong> needed on aspects of their<br />

collection. The manufacture will ensure in-house standards for the uniform reproducible end<br />

products.<br />

Quality testing will <strong>be</strong> carried out as per official texts namely colour, taste, varitaratwa,<br />

Rekhapurnatwa, Laghutva, Nirdhumatwa, Dntagre Kachakacha, Niruttha, Apunarbhava and<br />

Nischandratwa.

Wherever possible and applicable Particle size of the product may <strong>be</strong> tested adopting<br />

microscope fitted with micrometer or particle size analyzer or such other techniques.<br />

4. Product recalls:-<br />

The product recall procedure should <strong>be</strong> related to and depends very much on the<br />

existing regulation. Standard operating procedures (SOPs) should <strong>be</strong> included for storage of<br />

recalled Rasaushadhi in a secure segregated area, complying with the requirements<br />

specified for storage, while their fate is decided.<br />

5. Self-inspection:-<br />

At least one mem<strong>be</strong>r of the self-inspection team should possess a thorough<br />

knowledge on Rasashastra (production and quality control testing of Rasaushadhi).<br />

6. Personnel:-<br />

The release of Rasaushadhi should <strong>be</strong> <strong>under</strong> the authority of a person who has <strong>be</strong>en<br />

trained in the specific features of the processing and quality control of Rasaushadhis.<br />

Personnel dealing with the production and quality control of Rasaushadhis should have an<br />

adequate training in the specific issues of Rasaushadhis.<br />

7. Training:-<br />

The personnel should have adequate level of training in appropriate fields such as<br />

Rasa shastra- Bhaishajya Kalpana, pharmaceutical technology, mineralogy, pharmacology of<br />

metals and minerals, in<strong>org</strong>anic medicinal and pharmaceutical chemistry, Pharmacognosy,<br />

hygiene, microbiology, and related subjects (such as traditional use of herbal medicines).<br />

Training records should <strong>be</strong> maintained and periodic assessments of the effectiveness of<br />

training programmes should <strong>be</strong> made.<br />

8. Reference samples and standards:-<br />

In the case of Rasaushadhis, the reference standard may <strong>be</strong> a mineralogical sample<br />

of the minerals and metals, a sample of the prepared Rasaushadhi, processed metals and<br />

minerals e.g. Bhasma, Kajjali, etc. All reference standards should <strong>be</strong> stored <strong>under</strong>

appropriate conditions to prevent degradation. Their expiry and/or revalidation date should<br />

<strong>be</strong> determined and indicated.<br />

9. Documentation:-<br />

The system of documentation devised or adopted should have as its main objective to<br />

establish, monitor, and record quality for all aspects of the production, quality control and<br />

quality assurance.<br />

10. Stability studies:-<br />

The Rasoushadhis are descri<strong>be</strong>d as having no specific shelf life. However, inhouse<br />

validation of the product should <strong>be</strong> done once in 3 years to ensure the desired quality.<br />

Samples used for stability studies should <strong>be</strong> stored in the containers intended for marketing.<br />

11. Packaging materials and la<strong>be</strong>ling:-<br />

In addition to the Rule 161 of the Drugs & Cosmetics Rules the following<br />

information should <strong>be</strong> provided in the la<strong>be</strong>l. There should <strong>be</strong> adequate information on the<br />

la<strong>be</strong>l (or in package insert) informing the users of the composition of the product (in addition<br />

to the brand name, if any), indications or actions, directions for use, cautions and adverse<br />

reactions if any, and the expiry date.<br />

12. Dosage form of Rasoushadhi:-<br />

In order to have equal quantity of Rasoushadi having different individual doses. the<br />

Rasoushdhi may <strong>be</strong> made into an acceptable dosage form such as Tablet/Pill/Capsule after<br />

adding suitable fillers or binding agents. In such cases the la<strong>be</strong>l must indicate the quantity of<br />

medicine and filling material added in each case. The crystalline product may <strong>be</strong> grinded<br />

<strong>be</strong>fore packing in the individual size.

![[To be published in Gazette of India Part II Section 3, sub-section iii]](https://img.yumpu.com/28570283/1/190x245/to-be-published-in-gazette-of-india-part-ii-section-3-sub-section-iii.jpg?quality=85)