quality assurance/gmp in avaleha paka - amam-ayurveda.org

quality assurance/gmp in avaleha paka - amam-ayurveda.org

quality assurance/gmp in avaleha paka - amam-ayurveda.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

QUALITY ASSURANCE/GMP IN AVALEHA PAKA<br />

DR.R.K.RAI<br />

PRINCIPAL SCIENTIST<br />

DRDC

Avaleha<br />

A Therapeutic preparation with high degree of<br />

Palatability and extended shelf life

Avaleha Paka<br />

A Product of Rasakriya<br />

Phanit Leha Ghana are the simultaneous<br />

stages of Rasakriya

General Methodology of Avaleha Pak<br />

1. Preparation of Decoction/Swarasa<br />

2. Preparation of Pishti<br />

3. Preparation of Syrup with decoction &<br />

Sugar/Jaggery<br />

4. Mix<strong>in</strong>g of Pishti <strong>in</strong> syrup<br />

5. Mix<strong>in</strong>g of Prakshepa Dravya

Avaleha Paka Lakshana

Steps for Quality Assurance of Avaleha Pak<br />

As per GMP requirement<br />

1. Quality of RM<br />

2. Manufactur<strong>in</strong>g Premises<br />

3. Mach<strong>in</strong>ery & Equipments<br />

4. IPQA<br />

5. Product Specification

Quality Of RM<br />

1. Use of Genu<strong>in</strong>e/Authentic RM <strong>in</strong> textual Ratio<br />

2. Validation of Specs Parameters<br />

2. Validation of Markers/Actives for Authenticity<br />

3. Green herbs should be fresh and mature

Ay. View

Manufactur<strong>in</strong>g Premises<br />

Sanitized, Hygienic and Sterile environment

Ancient Set up of Ay. Pharmacy<br />

Location and surround<strong>in</strong>g<br />

1. In the east direction of city<br />

2. Nearby to abundance availability of RM<br />

3. Area should be surrounded by orchards

Cont……<br />

Build<strong>in</strong>g of the Ayurvedic Pharmacy<br />

1. Walled campus<br />

2. Well ventilated build<strong>in</strong>g with w<strong>in</strong>dows<br />

and air outlets<br />

3. Separate blocks for different k<strong>in</strong>d of<br />

formulations<br />

4. Proper plantation <strong>in</strong> the campus

Cont…..<br />

Work<strong>in</strong>g division of the Ay. Pharmacy<br />

1. Heat<strong>in</strong>g devices <strong>in</strong> Agneya Kona<br />

2. Gr<strong>in</strong>d<strong>in</strong>g/Pulverisation <strong>in</strong> South<br />

3. Peel<strong>in</strong>g and cutt<strong>in</strong>g <strong>in</strong> Nairitya<br />

4. Clean<strong>in</strong>g and wash<strong>in</strong>g <strong>in</strong> West<br />

5. Dry<strong>in</strong>g <strong>in</strong> Vayu Kona<br />

6. Vedha Karma <strong>in</strong> North<br />

7. Storage <strong>in</strong> Ishan Kona

Cont…..<br />

Supervis<strong>in</strong>g staff<br />

1. Pharmacist<br />

2. Pharmacogonist<br />

3. L<strong>in</strong>guist<br />

4. Accountant/storekeeper

Workers<br />

1. Drug Collector<br />

2. Pharmacy Assistant<br />

3. Security Guard<br />

4. Attendants<br />

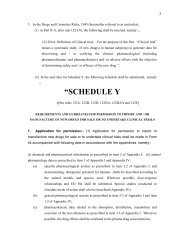

As per Schedule T<br />

– Ayurvedic Doctor<br />

– Botanist<br />

– Pharmacist(B.Pharma)<br />

Staff Cont…..

Mach<strong>in</strong>ery & Equipments<br />

1. Mach<strong>in</strong>ery made up of Sta<strong>in</strong>less.Steel. with<br />

SOP of validation and clean<strong>in</strong>g<br />

2. With Proper Lid/Cover<br />

3. Dedicated use<br />

4. With status tag

Quality Control of Water<br />

Prevents Microbial contam<strong>in</strong>ation<br />

Stable pH for the Product<br />

Prevents HM Contam<strong>in</strong>ation

What to be taken care more<br />

1. Process<strong>in</strong>g of product <strong>in</strong> a sterile condition<br />

2. Mix<strong>in</strong>g of Honey & Prakshepa at appropriate<br />

temperature<br />

3. Filtration of the product with appropriate filters.<br />

4. Immediate pack<strong>in</strong>g of the f<strong>in</strong>ished product <strong>in</strong><br />

suitable conta<strong>in</strong>ers<br />

5. Quality & Stability assessment of the f<strong>in</strong>ished<br />

product

Cont…..<br />

To check the loss of volatiles/nutrients mix<strong>in</strong>g<br />

of prakshepa (Raw herbal powder) at ambient<br />

temperature but care should be taken for<br />

microbial contam<strong>in</strong>ation

Ay. Concept for Prakshepa Mix<strong>in</strong>g

Specification of Avaleha should <strong>in</strong>clude<br />

1. Description<br />

2. pH<br />

3. LOD<br />

4. Sugar<br />

5. TLC Profile<br />

6. Heavy Metal<br />

7. Microbial Load<br />

8. Ash Values

Critical Factors In specs<br />

1. Organoleptic Characters – Acceptance criteria<br />

<strong>in</strong> the public<br />

2. Moisture Content<br />

3. Sugar Content<br />

(Both of these have a significant impact on<br />

stability)

Crystallization a major problem<br />

To m<strong>in</strong>imize the chances of crystallization<br />

boil<strong>in</strong>g of Sugar syrup on 105 – 110 0 C for 30 –<br />

45 m<strong>in</strong>utes and use of citric acid <strong>in</strong> the ratio of<br />

0.2 – 0.5%w/w to achieve the proper <strong>in</strong>version<br />

of sugar.

Pack<strong>in</strong>g<br />

1. Sterile & Appropriate conta<strong>in</strong>er<br />

2. Permit m<strong>in</strong>imum possible oxidation of the<br />

product.

Critical Factors for the Stability Assessment<br />

Tail & Ghee – One of the major <strong>in</strong>gredients<br />

Acid Value & Rancidity should be monitored<br />

dur<strong>in</strong>g shelf life assessment of the f<strong>in</strong>al product

Use of Preservatives<br />

To make sure the protection of food/drug from<br />

degradation the use of follow<strong>in</strong>g preservative<br />

should be encouraged.<br />

1. Sodium Benzoate<br />

2. Sodium Methyl Paraben<br />

+<br />

3. Sodium Propyl Paraben

Thanks

![[To be published in Gazette of India Part II Section 3, sub-section iii]](https://img.yumpu.com/28570283/1/190x245/to-be-published-in-gazette-of-india-part-ii-section-3-sub-section-iii.jpg?quality=85)