Motors - TEA Machine Components Inc.

Motors - TEA Machine Components Inc.

Motors - TEA Machine Components Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MOTOREN<br />

Technology<br />

Induction <strong>Motors</strong><br />

NECKAR<br />

All induction motors operate according to<br />

a uniform principle: The mechanically stationary<br />

“Stator“ produces a rotating magnetic<br />

field which is synchronised exactly<br />

with the frequency of the power supply.<br />

The rotor is made of low-loss magnetic<br />

steel which is surrounded by a cage made<br />

of short-circuited metal bars, (therefore also<br />

the name “squirrel-cage rotor “).<br />

During operation the stator induces a<br />

(therefore “induction motor“) torque produced<br />

magnetic field in the rotor, as long<br />

as this turns more slowly than the stator<br />

magnetic field. The difference in the speed<br />

of rotation between stator and rotor is<br />

called “slip“. The greater the slip, the<br />

greater also the induction and therefore<br />

the torque of the motor.<br />

This behaviour leads to a stabilisation near<br />

the nominal point, which with the right design<br />

leads to stable behaviour without the<br />

assistance of electronic controls.<br />

Induction motors are an important part of<br />

the NECKAR-MOTOREN- Programme. A<br />

single-phase capacitor motor normally has<br />

a lower starting torque as the rated torque.<br />

This should be taken into consideration<br />

during design.<br />

This is just the opposite to 3-phase current<br />

motors. Therefore the 3-phase current motor<br />

is preferred for applications with difficult<br />

start up.<br />

The following table shows the relationship of the starting torque to the rated torque.<br />

Single-phase motor<br />

3-phase motor<br />

2pole 0.60 x M rated 1.2 x M rated<br />

4pole 0.70 x M rated 1.3 x M rated<br />

8pole 0.85 x M rated 1.6 x M rated<br />

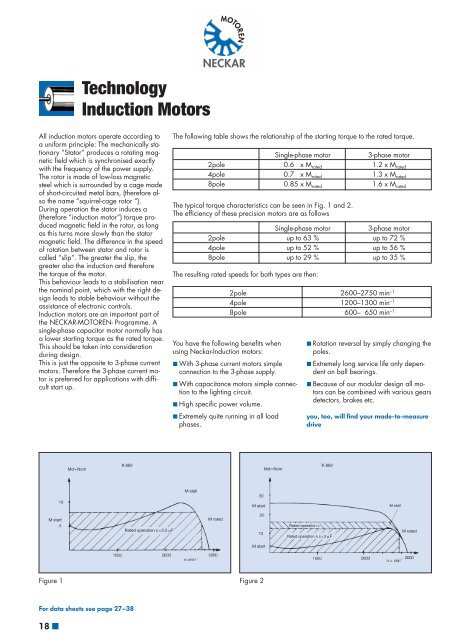

The typical torque characteristics can be seen in Fig. 1 and 2.<br />

The efficiency of these precision motors are as follows<br />

Single-phase motor<br />

3-phase motor<br />

2pole up to 63 % up to 72 %<br />

4pole up to 52 % up to 56 %<br />

8pole up to 29 % up to 35 %<br />

The resulting rated speeds for both types are then:<br />

You have the following benefits when<br />

using Neckar-Induction motors:<br />

With 3-phase current motors simple<br />

connection to the 3-phase supply.<br />

With capacitance motors simple connection<br />

to the lighting circuit.<br />

High specific power volume.<br />

2pole 2600–2750 min –1<br />

4pole 1200–1300 min –1<br />

8pole 600– 650 min –1<br />

Rotation reversal by simply changing the<br />

poles.<br />

Extremely long service life only dependent<br />

on ball bearings.<br />

Because of our modular design all motors<br />

can be combined with various gears<br />

detectors, brakes etc.<br />

Extremely quite running in all load<br />

phases.<br />

you, too, will find your made-to-measure<br />

drive<br />

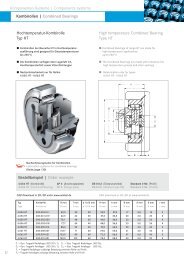

Md=Ncm<br />

K 662<br />

Md=Ncm<br />

K 662<br />

M stall<br />

M start<br />

M stall<br />

M start<br />

M rated<br />

Rated operation c=2.5 µF<br />

Rated operation λ<br />

Rated operation ∆ c=3 µF<br />

M rated<br />

M start<br />

Figure 1 Figure 2<br />

For data sheets see page 27–38<br />

18 ■