Motors - TEA Machine Components Inc.

Motors - TEA Machine Components Inc.

Motors - TEA Machine Components Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MOTOREN<br />

NECKAR<br />

Technology<br />

Brushless Direct current <strong>Motors</strong><br />

The series M and MH electronically commutated<br />

direct current motors are of similar<br />

construction to induction motors. The 12-<br />

slot stator is equipped with a 4-pole winding.<br />

Adjustment of the winding to the voltage<br />

and operating conditions is possible.<br />

In comparison to the induction motor a rotor<br />

is used here with high-quality Neodymium<br />

magnets instead of the “simple” squirrel-cage.<br />

Rotor position detection is integrated in the<br />

motor. This consists of a magnetic disk rotating<br />

with the rotor and three Hall sensors<br />

arranged at 120°.<br />

The signals from the rotor position detection<br />

are evaluated by the control electronics<br />

required for operation. According to<br />

the position of the rotor the winding<br />

strands are streamed according to the following<br />

control scheme.<br />

Properties:<br />

The series M electronically commutated<br />

direct current motors are characterised by<br />

extreme reversing and acceleration properties.<br />

Series M is to some degree<br />

replaceable with other current types of<br />

similar size.<br />

While the service life of mechanically<br />

commutated direct current motors depends<br />

on that of the brushes, lying at approx.<br />

3,000–5,000 hours, the service life of an<br />

electronically commutated direct current<br />

motor only depends on the service life expectancy<br />

of the ball bearings, lying at<br />

over 20,000, presuming professional installation.<br />

The electronically commutated<br />

motor combines the known advantages of<br />

the 3-phase motor and the special features<br />

of the MH-motor in an almost exemplary<br />

fashion.<br />

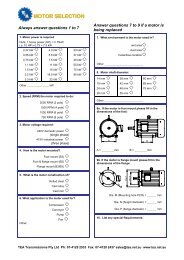

The connection between speed, number of poles and number of slots on the stator can<br />

be seen in the following table.<br />

Rated speed No. of poles No. of slots<br />

3000 min –1 4 12<br />

750 min –1 8 24<br />

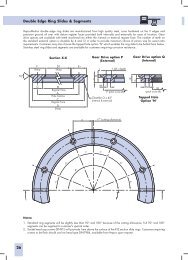

Standard control scheme<br />

left-hand rotation right-hand rotation<br />

Control scheme<br />

1 Revolution<br />

Besonderheiten des MH-<strong>Motors</strong><br />

As already mentiones, external control<br />

electronics are required for operation of<br />

the M-motors. With the development of<br />

integrated electronics we have been able<br />

to integrate a complete 1-Q-Controller into<br />

the motor. A lot of new ideas had to be<br />

used for this. The advantages of this solution<br />

are numerous:<br />

Sensor 1<br />

Sensor 2<br />

Sensor 3<br />

Commutation<br />

phase<br />

Motor phase A<br />

Motor phase B<br />

Motor phase C<br />

Motor phase A<br />

Motor phase B<br />

Motor phase C<br />

– The sensitive rotor position detection<br />

leads do not have to be led out anymore.<br />

– Damage caused by rotor position detector<br />

wiring faults can not occur.<br />

– The control of complex machines is<br />

simplified.<br />

– Continuous power as with motors with<br />

external electronics<br />

– Control range 30:1<br />

– Rotation reversal, fault signal output,<br />

impulse output (all SPS (Stored programme<br />

controller) level), short circuit<br />

braking and smooth starting with terminal<br />

box K4 integrated as standard.<br />

– Optional plug-and-socket connection.<br />

– “Stand-Alone-Operation“ possible.<br />

22 ■