Air-operated oil pump Oilmatic DP 11 - Hallbauer Viernheim

Air-operated oil pump Oilmatic DP 11 - Hallbauer Viernheim

Air-operated oil pump Oilmatic DP 11 - Hallbauer Viernheim

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Hallbauer</strong> Industries GmbH<br />

P.O. Box 1340 68503 <strong>Viernheim</strong><br />

Industriestraße 18 68519 <strong>Viernheim</strong><br />

Germany<br />

Parts and technical service guide<br />

Pneumatic <strong>oil</strong> <strong>pump</strong> „<strong>Oilmatic</strong>” <strong>DP</strong> 1:1<br />

Part nos.: 80633/ 40623<br />

Description<br />

Installation<br />

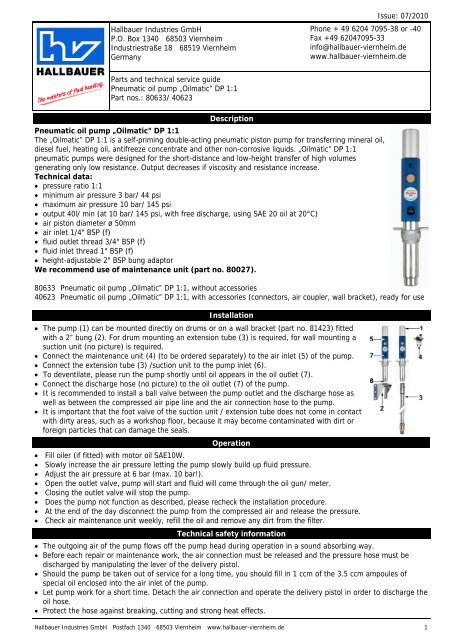

�� The <strong>pump</strong> (1) can be mounted directly on drums or on a wall bracket (part no. 81423) fitted<br />

with a 2” bung (2). For drum mounting an extension tube (3) is required, for wall mounting a<br />

suction unit (no picture) is required.<br />

�� Connect the maintenance unit (4) (to be ordered separately) to the air inlet (5) of the <strong>pump</strong>.<br />

�� Connect the extension tube (3) /suction unit to the <strong>pump</strong> inlet (6).<br />

�� To deventilate, please run the <strong>pump</strong> shortly until <strong>oil</strong> appears in the <strong>oil</strong> outlet (7).<br />

�� Connect the discharge hose (no picture) to the <strong>oil</strong> outlet (7) of the <strong>pump</strong>.<br />

�� It is recommended to install a ball valve between the <strong>pump</strong> outlet and the discharge hose as<br />

well as between the compressed air pipe line and the air connection hose to the <strong>pump</strong>.<br />

�� It is important that the foot valve of the suction unit / extension tube does not come in contact<br />

with dirty areas, such as a workshop floor, because it may become contaminated with dirt or<br />

foreign particles that can damage the seals.<br />

Operation<br />

�� Fill <strong>oil</strong>er (if fitted) with motor <strong>oil</strong> SAE10W.<br />

�� Slowly increase the air pressure letting the <strong>pump</strong> slowly build up fluid pressure.<br />

�� Adjust the air pressure at 6 bar (max. 10 bar!).<br />

�� Open the outlet valve, <strong>pump</strong> will start and fluid will come through the <strong>oil</strong> gun/ meter.<br />

�� Closing the outlet valve will stop the <strong>pump</strong>.<br />

�� Does the <strong>pump</strong> not function as described, please recheck the installation procedure.<br />

�� At the end of the day disconnect the <strong>pump</strong> from the compressed air and release the pressure.<br />

�� Check air maintenance unit weekly, refill the <strong>oil</strong> and remove any dirt from the filter.<br />

Issue: 07/2010<br />

Phone + 49 6204 7095-38 or -40<br />

Fax +49 62047095-33<br />

info@hallbauer-viernheim.de<br />

www.hallbauer-viernheim.de<br />

Pneumatic <strong>oil</strong> <strong>pump</strong> „<strong>Oilmatic</strong>” <strong>DP</strong> 1:1<br />

The „<strong>Oilmatic</strong>” <strong>DP</strong> 1:1 is a self-priming double-acting pneumatic piston <strong>pump</strong> for transferring mineral <strong>oil</strong>,<br />

diesel fuel, heating <strong>oil</strong>, antifreeze concentrate and other non-corrosive liquids. „<strong>Oilmatic</strong>” <strong>DP</strong> 1:1<br />

pneumatic <strong>pump</strong>s were designed for the short-distance and low-height transfer of high volumes<br />

generating only low resistance. Output decreases if viscosity and resistance increase.<br />

Technical data:<br />

�� pressure ratio 1:1<br />

�� minimum air pressure 3 bar/ 44 psi<br />

�� maximum air pressure 10 bar/ 145 psi<br />

�� output 40l/ min (at 10 bar/ 145 psi, with free discharge, using SAE 20 <strong>oil</strong> at 20°C)<br />

�� air piston diameter ø 50mm<br />

�� air inlet 1/4" BSP (f)<br />

�� fluid outlet thread 3/4" BSP (f)<br />

�� fluid inlet thread 1" BSP (f)<br />

�� height-adjustable 2" BSP bung adaptor<br />

We recommend use of maintenance unit (part no. 80027).<br />

80633 Pneumatic <strong>oil</strong> <strong>pump</strong> „<strong>Oilmatic</strong>” <strong>DP</strong> 1:1, without accessories<br />

40623 Pneumatic <strong>oil</strong> <strong>pump</strong> „<strong>Oilmatic</strong>” <strong>DP</strong> 1:1, with accessories (connectors, air coupler, wall bracket), ready for use<br />

Technical safety information<br />

�� The outgoing air of the <strong>pump</strong> flows off the <strong>pump</strong> head during operation in a sound absorbing way.<br />

�� Before each repair or maintenance work, the air connection must be released and the pressure hose must be<br />

discharged by manipulating the lever of the delivery pistol.<br />

�� Should the <strong>pump</strong> be taken out of service for a long time, you should fill in 1 ccm of the 3.5 ccm ampoules of<br />

special <strong>oil</strong> enclosed into the air inlet of the <strong>pump</strong>.<br />

�� Let <strong>pump</strong> work for a short time. Detach the air connection and operate the delivery pistol in order to discharge the<br />

<strong>oil</strong> hose.<br />

�� Protect the hose against breaking, cutting and strong heat effects.<br />

<strong>Hallbauer</strong> Industries GmbH Postfach 1340 68503 <strong>Viernheim</strong> www.hallbauer-viernheim.de 1

Pneumatic <strong>oil</strong> <strong>pump</strong> „<strong>Oilmatic</strong>” <strong>DP</strong> 1:1 Part nos.: 80633/ 40623<br />

Spare parts<br />

EC declaration of conformity<br />

Declaration of Conformity<br />

according to the EC directive Machines 89/392/EEC, appendix II A<br />

Part No Includes item no.<br />

1518648 3, 4, 5, 6, 7, 8, 9, 10, <strong>11</strong>, 14<br />

1518643 2, 3<br />

1518644 3, 4, 5, 6, 7, 8, 9, 10, 13<br />

1518645 1, 3<br />

1518126 9, 18<br />

<strong>11</strong>17086 19<br />

1517189 9, 15<br />

1518129 9, 10, 16, 17, 18<br />

1518128 12<br />

Issue: 07/2010<br />

We hereby declare that HALLBAUER air-<strong>operated</strong> <strong>oil</strong> <strong>pump</strong>s <strong>DP</strong>S correspond to the general safety and health<br />

requirements of the Europen Union directives with respect to concept and type as well as to the model launched by<br />

us. When modifying something at the air-<strong>operated</strong> <strong>oil</strong> <strong>pump</strong> without our agreement, this declaration is no longer<br />

valid.<br />

Description of the product:: <strong>Air</strong>-<strong>operated</strong> <strong>oil</strong> <strong>pump</strong>s <strong>DP</strong>S 1:1<br />

Applicable EC directives: EC directive Machines 89/392/EEC<br />

i.d.F. 91/368/EEC, 93/44/EEC and 93/68/EEC<br />

Applied harmonized<br />

specification, especially: EN 292-I and EN 292-2 and EN 809<br />

Applied national and<br />

technical specification: DIN 20 022, DIN 1283 Point 2.2.1.1<br />

<strong>Viernheim</strong>, in January 1999 ________________________________<br />

Lothar <strong>Hallbauer</strong>, General Manager<br />

<strong>Hallbauer</strong> Industries GmbH Postfach 1340 68503 <strong>Viernheim</strong> www.hallbauer-viernheim.de 2