osterkamp dairy milk quality program - AgWeb

osterkamp dairy milk quality program - AgWeb

osterkamp dairy milk quality program - AgWeb

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WORKING AS A TEAM TO IMPLEMENT MILK QUALITY PROGRAMS:<br />

OSTERKAMP DAIRY MILK QUALITY PROGRAM<br />

Mark Osterkamp 1 , Eduardo Garbarino 2<br />

1 Osterkamp Dairy, Hereford, Texas, USA<br />

2 Progressive Dairy Health Services, Clovis, New Mexico, USA<br />

Osterkamp Dairy is a 2500 cow dry lot <strong>dairy</strong> located in Hereford, TX. It is a family<br />

owned and operated <strong>dairy</strong> that started with about 100 <strong>milk</strong> cows in 1922 in Bellflower,<br />

CA, which is a half hour south of Los Angeles. Soon after the <strong>dairy</strong> began, an outbreak of<br />

foot and mouth disease occurred and the entire herd was depopulated. The family restarted<br />

the <strong>dairy</strong> in Santa Anna, CA shortly after, and in 1961 Joe Osterkamp moved 300 <strong>milk</strong> cows to<br />

Chino, CA. Tom Osterkamp took over Osterkamp Dairy and moved to Hereford Texas in<br />

2003, <strong>milk</strong>ing about 1700 cows. Over the last six years we have been able to increase the<br />

herd size to 2500 with very little animal purchasing. Along with Veterinarian Eduardo<br />

Garbarino of Progressive Dairy Health Services in Clovis, NM, we have been working as a<br />

team to implement a <strong>milk</strong> <strong>quality</strong> <strong>program</strong> since 2005. The ability to control and manage<br />

mastitis outbreaks and the uses of specifically designed protocols (treatments, routines, animal<br />

handling, etc.) has been a contributing factor to that end. In addition, having a <strong>milk</strong> <strong>quality</strong><br />

<strong>program</strong> in place has allowed the <strong>dairy</strong> to maximize income per cwt of <strong>milk</strong> sold.<br />

Dairy Layout and Overview<br />

The <strong>dairy</strong> currently <strong>milk</strong>s approximately 2500 Holstein cows which are housed in nine<br />

<strong>milk</strong>ing pens of 275 cows/pen. An additional 3 pens with capacity for 40-50 cows are used<br />

for hospital, fresh and special needs cows. In addition, there is also a single 20 hospital<br />

barn where all fresh cows and hospital cows are <strong>milk</strong>ed by the fresh and hospital manager<br />

and his assistant. Cows are fed a TMR delivered twice a day. Currently <strong>milk</strong> production is about<br />

78 lbs, Fat 3.7%, Protein 3.3%, SCC 175,000 cells/ml, Pregnancy Rate is 21%, Culls before 30<br />

days in <strong>milk</strong> is 3% and overall culling rate is 25.2%.<br />

Environment<br />

Cows are housed in double sloped dry lot pens with shades and head locks.(Figure 1)<br />

Weather permitting, pens are groomed on a daily basis with a box scraper.(Figure 2) On<br />

occasion a honey wagon will run after a rain, drizzle, or snow. As part of regular<br />

maintenance, holes in the pens are filled with dirt trying to keep an even walking surface<br />

for the cows. See below the scraping schedule and a sketch of the pen and how the dirt is<br />

moved.<br />

NMC Annual Meeting Proceedings (2010)<br />

83

Pen layout example. Figure 1.<br />

cement<br />

water water water<br />

dry manure for bedding 1/2 to 1 in.<br />

Shade is also included<br />

shade<br />

wet manure for drying 1/2 to 1 in.<br />

Scraping schedule. Figure 2.<br />

Mon. Tues. Wed. Thurs. Fri. Sat. Sun.<br />

Valentin (Day) Milk xxxxxxxx Milk p8 - p15 Milk xxxxxxxx xxxxxxxx<br />

p1 - p5 All Pens Hef All Pens<br />

p8 - p15<br />

Dry<br />

Hugo (Night) Milk xxxxxxxx Milk xxxxxxxx xxxxxxxx Milk Milk<br />

p6 - p7 p1 - p4 p1 - p4 p23 - p7<br />

Milking Equipment<br />

The <strong>milk</strong>ing equipment consists of standard stainless steel DeLaval claws with Milk Right<br />

shells and liners. Universal pulsators with pulsation rate set at 60:40 are used. Universal<br />

automatic take-off settings are described in figure 3. The vacuum is set at 12.75 "Hg at the<br />

teat end.<br />

84 NMC Annual Meeting Proceedings (2010)

Take-off settings. Figure 3.<br />

Milk Flow<br />

Lb/Min.<br />

Threshold 0.41<br />

Take-off<br />

Sec.<br />

Time 30<br />

Neutral<br />

Sec.<br />

Time 125<br />

EV Delay<br />

Sec.<br />

Time 2.5<br />

Milking Routine and Milker Meetings<br />

Milking routine<br />

Cows are <strong>milk</strong>ed twice a day in a double 35, parallel parlor. The <strong>milk</strong>ing routine is a complete<br />

routine under a territorial arrangement. Milker #1 pre-dips from cow #1 to cow #13 then goes<br />

back to cow #1 and strips to cow #13, walks back wiping from #13 to #1 and finally hangs<br />

machines from #1 to #13. See graph 1. Milker #2 does the same routine from cow #14 to cow<br />

#24 and <strong>milk</strong>er #3 repeats the same steps from cow #25 to cow #35. Milker #3 has fewer<br />

machines because he is in charge of filling the line when the pusher is not in the pit. One pusher<br />

completes the team and his responsibilities include: prepping the cloth towels, filling the post dip<br />

cups, helps filling the lane, and bringing the pens to the barn. The pusher does not help in the<br />

<strong>milk</strong>ing routine other than the post dipping process.<br />

NMC Annual Meeting Proceedings (2010)<br />

85

Milking routine. Figure 4.<br />

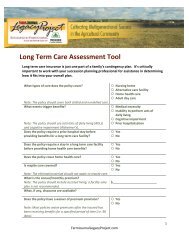

Milkers are evaluated once a month for routine compliance. This is done by the <strong>dairy</strong> manager<br />

using a standardized evaluation form. (Figure 5) The goals of the evaluations are to detect areas<br />

that need improvement in the routine, determine if the <strong>milk</strong>ers are entitled to receive the <strong>quality</strong><br />

bonus offered by the <strong>dairy</strong>, and document as well as discuss areas of improvement. Results of the<br />

evaluation are used as a basis for the subsequent <strong>milk</strong>er meeting. In addition, the <strong>milk</strong>ers need to<br />

have a satisfactory evaluation in order to receive the <strong>milk</strong> <strong>quality</strong> bonus.<br />

As an aid to stimulate parlor consistency for all the <strong>milk</strong>ers, the manager keeps track of how<br />

many cows are pulled for mastitis by each <strong>milk</strong>er. This information is posted for the <strong>milk</strong>ers to<br />

see and allows management to detect differences among employees in the parlor. If large<br />

differences exist among <strong>milk</strong>ers, they are addressed in the meetings or with the particular<br />

individual. Since we initiated this protocol, large fluctuations in bulk tank somatic cells have<br />

drastically been reduced.<br />

Milker meetings<br />

Every 3 months a 1 hour <strong>milk</strong>er meeting is scheduled with each shift (day/night). In each<br />

meeting, <strong>milk</strong> <strong>quality</strong> information (SPC, LPC, Coli and SCC) is presented for the last year to<br />

date and the previous month. The aim is to teach the <strong>milk</strong>ers how to interpret the information<br />

presented (graphs, tables, etc.) from a learning perspective and for improvement on the job. In<br />

addition, the <strong>milk</strong>ers are educated regarding the current <strong>milk</strong> <strong>quality</strong> bonus standards set by the<br />

Co-op. In order for the <strong>dairy</strong> to receive a bonus, 25% of the <strong>milk</strong> loads are tested, in which 75%<br />

of them need to be below the Co-op thresholds (SPC

addition the veterinary practice provides a <strong>milk</strong>er meeting school for all new <strong>milk</strong>ers. In this<br />

meeting we explain the <strong>milk</strong>ing routine step by step and a thorough understanding of the<br />

importance of cleanliness and consistency in the parlor. An explanation of what the <strong>dairy</strong> expects<br />

from the <strong>milk</strong>er and what the <strong>milk</strong>er should expect from the <strong>dairy</strong> is also covered. The idea is to<br />

present rules and expectations clearly and upfront with the hope that by good communication we<br />

will achieve better compliance.<br />

NMC Annual Meeting Proceedings (2010)<br />

87

Evaluation form. Figure 5.<br />

Osterkamp Dairy - Milker Evaluation<br />

Date: ____________________________<br />

Milkers Name:________________________<br />

Shift: ___________________<br />

Cow Handling V.Good Good Needs Improvement Poor Quiet with no aggressions<br />

Pre-Dip: V.Good Good Needs Improvement Poor All 4 teats completely<br />

Strip: V.Good Good Needs Improvement Poor 2-3 squirts per teat<br />

Wipe: V.Good Good Needs Improvement Poor Circular motion. Are teats clean after wipping?<br />

Timming: V.Good Good Needs Improvement Poor Time between Pre-Dip and Wipe >30 sec<br />

time between Strip and Attach 1-2min<br />

Attach: V.Good Good Needs Improvement Poor Are units align and no air allowed when attaching<br />

Re-Attach V.Good Good Needs Improvement Poor Is the <strong>milk</strong>er looking for squaks and unaligned units?<br />

Detach: V.Good Good Needs Improvement Poor Is the vacuum shut off before detaching?<br />

Post-Dip: V.Good Good Needs Improvement Poor All 4 teats completely<br />

Comments:<br />

Evaluator: _________________________ Milker Signatu__________________________<br />

Action plan for non-compliance: Each person will receive a warning if evaluation is Poor in one<br />

or more items. At the first warning the manager will address the problem with the <strong>milk</strong>er.<br />

After the second warning, the <strong>milk</strong>er looses the monthly bonus.<br />

After 3 warnings a person could be fired.<br />

88 NMC Annual Meeting Proceedings (2010)

Mastitis Control and Treatment<br />

All <strong>milk</strong> from fresh and mastitic cows is sampled and plated on blood agar and mycoplasma<br />

media. All mastitis cases are treated with a standard intramammary antimicrobial. Cows with<br />

hard quarters are also treated with an intramammary antimicrobial and an anti-inflammatory.<br />

Cows that appear to be sick are given systemic therapy, rumen drench, and intravenous fluid<br />

therapy in addition to an intramammary antimicrobial and an anti-inflammatory.<br />

Dry Cow Management<br />

All cows receive a standard dry cow tube shortly after their last <strong>milk</strong>ing on each teat. Cows are<br />

dipped with the same barrier dip used on the <strong>milk</strong> cows and moved to the dry pen. Cows are dry<br />

for 60 days.<br />

Culling Policy<br />

Cows are evaluated on an individual basis before treatment. Items like days in <strong>milk</strong>, <strong>milk</strong><br />

production at last test, times with mastitis, reproductive status (open/pregnant), other health<br />

issues (lameness) are taken into consideration to decide the future of each cow.<br />

Summary<br />

Communication between the <strong>dairy</strong> and the <strong>milk</strong>ers is the key for successfully implementing a<br />

<strong>milk</strong> <strong>quality</strong> <strong>program</strong>. Monitoring <strong>milk</strong>ers for positive and/or negative reinforcement is an<br />

important part of motivating employees. As a result of working as a team between the <strong>dairy</strong><br />

manager, veterinarian and <strong>milk</strong>ers, Osterkamp Dairy has achieved all but one (52/53) <strong>milk</strong><br />

<strong>quality</strong> bonuses from June 2005 up to November 2009. Additionally and harder to quantify,<br />

somatic cells has been consistently lower than at the start of the <strong>program</strong>, udder health has<br />

improved, and culling due to mastitis has been reduced.<br />

NMC Annual Meeting Proceedings (2010)<br />

89