the Farm Journal Test Plot Narrow Row Corn Report - AgWeb

the Farm Journal Test Plot Narrow Row Corn Report - AgWeb

the Farm Journal Test Plot Narrow Row Corn Report - AgWeb

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

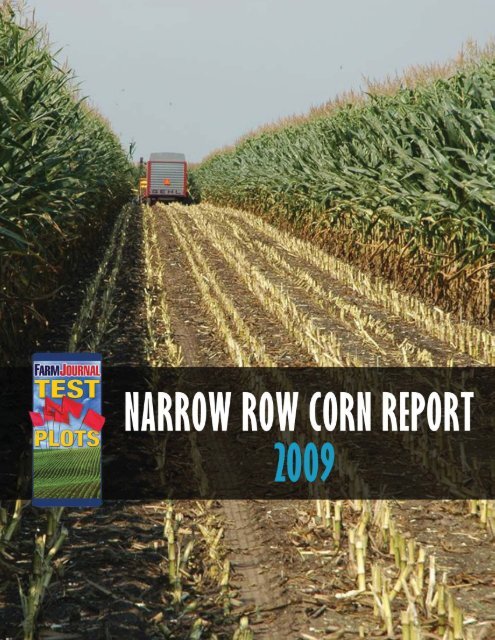

2009 <strong>Narrow</strong> <strong>Row</strong> <strong>Corn</strong> <strong>Report</strong>INTRODUCTIONThe <strong>Farm</strong> <strong>Journal</strong> <strong>Test</strong> <strong>Plot</strong>s were founded by Charlene Finck and Ken Ferrie in 1991. At <strong>the</strong> time, Finck was cropsand production editor for FARM JOURNAL magazine and Ferrie was starting his business as an independentagronomist in central Illinois. Toge<strong>the</strong>r, <strong>the</strong>ir mission was to conduct third-party research to help farmers increasecrop yields and profitability. A critical part of <strong>the</strong> <strong>Test</strong> <strong>Plot</strong>s was developing <strong>the</strong> core criteria and comprehensiveplot protocol used in each of <strong>the</strong> efforts.PROGRAM CRITERIASince its inception, <strong>the</strong> <strong>Test</strong> <strong>Plot</strong>s program’s rigorous criteriahave been applied to every plot taken to yield and published inFARM JOURNAL. Each plot is overseen by <strong>Farm</strong> <strong>Journal</strong> FieldAgronomist Ken Ferrie, who develops additional, more specificprocedures for individual plots. Ferrie, a trained agronomist, hasa strong background in fertility, soils, machinery, chemistry,diseases, insects and herbicides.An extensive field history is compiled for each field before itis selected to be in <strong>the</strong> plot program. This history includes:■ Soil types■ Fertility and soil tests■ A record of manure applications, when applicable■ Crop rotations■ A record of past herbicide applications■ Assessment of disease, insect and o<strong>the</strong>r factors■ Soil density status■ Yield recordsBefore planting <strong>the</strong> plot, all equipment is checked for wear,mechanical soundness and accuracy. Meters are calibrated to <strong>the</strong>seed to be used; insecticide applicators are also calibrated. Allequipment is operated and set to conditions before <strong>the</strong> plotbegins. All companies participating in <strong>the</strong> plot have <strong>the</strong>opportunity to set <strong>the</strong>ir equipment or product before <strong>the</strong> plot isplanted. Throughout <strong>the</strong> study full access to <strong>the</strong> plots is availableto participating <strong>Test</strong> <strong>Plot</strong>s Partners.When row spacings are a part of <strong>the</strong> plot or various plantingtechnologies are being used, great care is taken to make sure allmechanical factors that can impact yields are fair and/or equal.At planting, seeds are dug multiple times to make sure <strong>the</strong>machine(s) are performing correctly. The planting date,conditions, seed varieties, replications and o<strong>the</strong>r variables arerecorded. The plot is flagged as it is established to mark <strong>the</strong> fieldpositions. A map of <strong>the</strong> field is also drawn and filed.Emergence is monitored and multiple counts are taken atvarious crop stages. The field is scouted throughout <strong>the</strong> seasonfor insects and disease. In nutrient-related plots, nitrate tests aretaken. Rainfall and temperatures are monitored and recorded.Ear counts are taken before harvest. Each plot is harvestedwith a combine equipped with a calibrated yield monitor. Inaddition, <strong>the</strong> grain from each plot is weighed to verify <strong>the</strong>accuracy of <strong>the</strong> monitor and make sure <strong>the</strong> accurate, ra<strong>the</strong>r thanrelative, yield data is recorded. Harvest losses are checkedbehind <strong>the</strong> combine.The yields are ground-tru<strong>the</strong>d by Ferrie to attempt todetermine <strong>the</strong> agronomic reasons behind yield fluctuations anddocument what has happened. When <strong>the</strong> yield monitor resultsare scaled to match <strong>the</strong> weigh wagon results, <strong>the</strong> data is analyzedby soil type or yield zone. Any corrupt data is discarded.Every effort is made to position <strong>the</strong> plots in multiple locationsfor each year. All plots are planned as multi-year efforts.Spreading out <strong>the</strong> plots geographically and across crop yearsreduces <strong>the</strong> wea<strong>the</strong>r variability that a single location and yearmay present.The topics studied in <strong>the</strong> plots are sourced from numerousvoices in <strong>the</strong> industry–questions from farmers, reader requests,Ferrie himself and agricultural companies. The fertility, seedbed,inputs, planter operation, scouting and timeliness have to be ontarget to get all <strong>the</strong> details to add up to increased yields.NARROW ROW CORN TEST PLOTSTo date, for more than two decades Ferrie has worked withnarrow rows in row-crop production. The <strong>Farm</strong> <strong>Journal</strong> <strong>Test</strong><strong>Plot</strong>s effort to learn more about narrow row corn was launchedin 1999. Ferrie recognized narrow row corn’s potential to pushplanting populations without in-row crowding.“When adopting a new production practice, farmers need aTwo tractors equipped with automated steering madeplanting <strong>the</strong> replications faster and easier at TerryFerguson’s farm near Clinton, Ill. The tractors pulleda Great Plains precision drill and a custom-built GreatPlains twin-row plot planter for <strong>the</strong> variety plot.Conventional 30" row corn heads do not need any modifiationsto be used to harvest twin rows.<strong>Narrow</strong> <strong>Row</strong> <strong>Corn</strong> <strong>Report</strong> 01

clear goal of what <strong>the</strong>y’re trying toaccomplish,” Ferrie says. “Theiragronomic base needs to be rocksolid, and <strong>the</strong>y need to go about itcarefully.”1999 to 2002 The drive toplant narrow row corn withoutplacing <strong>the</strong> seed in tire tracks orhaving a tire run over <strong>the</strong> row led<strong>the</strong> first year’s effort (“<strong>Test</strong> <strong>Plot</strong>Roundup,” FARM JOURNAL, April2000). The test plot planter used wasspecially built by Great PlainsManufacturing and was able to plant30", 15" and 7" twin rows.Great care was taken to match <strong>the</strong>sprockets so <strong>the</strong> three row spacingswere planted at <strong>the</strong> same populations.To ensure accuracy, <strong>the</strong> plot crewcalibrated <strong>the</strong> finger-pickup meter for <strong>the</strong> seed, speed and rowspacing being used (“Two of a Kind,” Mid-February 2001).Since <strong>the</strong> planter used placed four of <strong>the</strong> 15" rows in tractorwheel tracks, <strong>the</strong> row spacing was taken out of <strong>the</strong> test plot(“Two by Two,” March 2002). Those rows resulted in reducedyield due to <strong>the</strong> unfair planting conditions.Within <strong>the</strong> 30" and twin rows, <strong>the</strong> study evaluated fourplanting populations: 28,000, 30,000, 32,000 and 36,000 plants peracre (ppa). Four sidedress rates were also evaluated: 0 lb., 60 lb.,90 lb. and 120 lb. on a base rate of 130 lb. of nitrogen. Ferrienoted his recommendation would be to increase <strong>the</strong> optimumpopulation for 30" rows by at least 2,000 plants per acre ifmoving from 30" rows to narrow rows. With nitrogen, <strong>the</strong> narrowrows were more efficient. The same amount of nitrogen producedmore bushels in <strong>the</strong> twins, which used 1.2 lb. of applied nitrogenper bushel, compared with 1.5 lb. for 30" rows.Wrapping up <strong>the</strong> initial three years of test plots, o<strong>the</strong>rdifferences in <strong>the</strong> row spacings included:■ The twins outyielded <strong>the</strong> 30" spacing by 6 bu. to 22 bu. peracre compared with three-year average.■ Doubles resulted in aborted ears in all row spacings.■ Late-emerging plants ran into trouble in all row spacings.■ Being on 30" centers meant <strong>the</strong> twin rows could besidedressed, sprayed and harvested without special equipment.Yields at Peak Bro<strong>the</strong>rs <strong>Farm</strong> 2004Bu./Acre20520019519018518028,70029,90032,00033,600In <strong>the</strong> first year of twin rows at Peak Bro<strong>the</strong>rs, for thishybrid and plot conditions, yields climbed with <strong>the</strong> populationto 38,000 ppa and <strong>the</strong>n started to trend down.<strong>Narrow</strong> <strong>Row</strong> <strong>Corn</strong> <strong>Report</strong> 02Planting PopulationThe Peak Bro<strong>the</strong>rs <strong>Farm</strong> near Springfield, Ill., provided <strong>the</strong> opportunity to comparetwin rows planted by a new Great Plains Yield-Pro planter with 16 paired rows andcorn planted by <strong>the</strong> farm’s 16-row, 30" planter.Twins36,00038,00040,00042,00044,00046,00048,000■ Both row spacings were harvested with a 30" corn head,and combine losses were checked for each plot.■ The ear counts for <strong>the</strong> twin and 30" corn were within 500 to600 for each population, but <strong>the</strong> twin-row ears filled better.■ The twin rows were seven days ahead of <strong>the</strong> 30" rows inclosing <strong>the</strong> canopy. Closing <strong>the</strong> canopy quicker helps retainmore soil moisture, but on <strong>the</strong> flip side it restricts air movementand can lead to a disease-prone environment.After <strong>the</strong> first three years, <strong>the</strong> effort built on <strong>the</strong> baseline data(“Twin <strong>Row</strong>s Take to <strong>the</strong> Field,” Mid-March 2003). A 60-mphwind and 3" of rain driving sideways at pollination nixed <strong>the</strong>chance for authoritative yield results. The wind laid flat alltreatments—30" rows and twins. Even though yields wereshortchanged, we harvested <strong>the</strong> plots—to salvage what waspossible for <strong>the</strong> cooperating farmer and to get a hint of overallperformance. The down twin rows were no more difficult than<strong>the</strong> 30" rows to pick up with <strong>the</strong> corn head.2003 The fourth year of <strong>the</strong> narrow row corn effort examinedplanting populations and variety responses (“Twin <strong>Row</strong> Success,”January 2004). In <strong>the</strong> population plots, all plots were replicatedand carefully tracked. Although twin row yield boosts can rangeas high as 22 bu. per acre, <strong>the</strong>y averaged only 7 to 10 bu. per acre.The population plot made it clear again that twin rows have <strong>the</strong>capacity for more plants per acre. We returned to <strong>the</strong> FergusonYields at Peak Bro<strong>the</strong>rs <strong>Farm</strong> 2005In 2005, <strong>the</strong> Peak Bro<strong>the</strong>rs plot, compared 30" rows andtwin rows, spaced 7½" apart on 30" rows in a corn-oncornenvironment. In <strong>the</strong> drought conditions of this year,<strong>the</strong> twin rows had more effiecient water managementand edged out <strong>the</strong> 30" rows in yield.

Yields at Covel Creek <strong>Farm</strong>s 2006This plot shows <strong>the</strong> yield impact of disease even though<strong>the</strong> plot was sprayed with fungicide. Disease pressure,and <strong>the</strong> amount of down corn, increased at <strong>the</strong> higherpopulations, especially in <strong>the</strong> twin rows.Located near Leroy, Ill., McLaughlin-Dooley <strong>Farm</strong>soffered a second location to compare 30" rows with twinrows on 30" centers. The corn followed soybeans. Thislocation was short on moisture but had <strong>the</strong> most rainof all of <strong>the</strong> six locations. However, uniform soil densitywas <strong>the</strong> key for <strong>the</strong> field’s ability to capture <strong>the</strong> rain thatarrived largely in surprise pop-up storms.farm to plant four populations (30,000, 32,000, 34,000 and 37,000ppa) with <strong>the</strong> custom-built plot planter in 30" and twin rows andan additional Great Plains drill set up for twin rows.Yields for both sets of twin rows continued to climb—even at<strong>the</strong> 37,000 planting population. While <strong>the</strong> twins were postingyield gains as <strong>the</strong> population climbed, <strong>the</strong> 30" rows were doingwhat we expected based on previous plots and for <strong>the</strong> plotconsiderations and hybrid selection—peaking at 32,000 to 34,000ppa and <strong>the</strong>n declining.In <strong>the</strong> variety plots, our initial work with six popular numbersfor <strong>the</strong> area clearly showed that some varieties take to twin rowsbetter than o<strong>the</strong>rs. In 2003, three of <strong>the</strong> corn varieties yieldedA team effort from three operations near Grand Ridge, Ill., made this plot possible.They were R & D Walter, Hybrid Service and Covel Creek <strong>Farm</strong>s.<strong>Narrow</strong> <strong>Row</strong> <strong>Corn</strong> <strong>Report</strong> 03A team effort involving R & D Walter <strong>Farm</strong>s, Hybrid Serviceand John Thomas provided <strong>the</strong> chance to test 20", 30"and twin rows in a high-yield, longtime continuous cornsetting. High Illinois Soil N <strong>Test</strong> (ISNT) values point to <strong>the</strong>yield potential of <strong>the</strong> field.best in twin rows, two did worse, and yields for one were about<strong>the</strong> same as in <strong>the</strong> 30" rows.2004 to 2005 In <strong>the</strong> next years, <strong>the</strong> focus was on <strong>the</strong>elements needed to make narrow rows successful: plantingpopulations, hybrid selection, and <strong>the</strong> rates and placement forstarter, insecticide and nitrogen. Each variable was tested in awide range of soils and growing conditions (“Make Twin <strong>Row</strong>sCount,” Mid-February 2005). The effort continued to reveal <strong>the</strong>best way to go about growing narrow rows and on how twinscompare with 20" rows, ano<strong>the</strong>r narrow-row route to bumpingcorn yields.For <strong>the</strong> next couple of years, <strong>the</strong> test plots involved six Illinoislocations, spanning from near Springfield north to Grand Ridge,just south of Chicago. In general, <strong>the</strong> plot data repeated <strong>the</strong>population results of previous plots, showing that some hybridsare more suited for narrow rows and indicating that <strong>the</strong> hybridsgood for 20" rows also work well for twin rows.At <strong>the</strong> Peak Bro<strong>the</strong>rs plot near Springfield, starter wasapplied and FMC supplied a liquid applicator for Captureinsecticide (using <strong>the</strong> Great Plains tanks and FMC nozzles). TheGreat Plains Yield-Pro twin-row planter was compared with <strong>the</strong>Peak’s 16-row, 30" Kinze planter,outfitted with Precision Plantingmeters set for <strong>the</strong> seed size. Twelvefingermeters were used for <strong>the</strong> 30"rows and six-finger meters wereused for <strong>the</strong> twins, so <strong>the</strong> meterscould run at <strong>the</strong> same revolutionsper minute. In 2004, <strong>the</strong> Peak plotslooked at twin-row populationsranging from 28,700 to 48,000 ppa.For this hybrid in those plotconditions, yields climbed with <strong>the</strong>population until 38,000 ppa and <strong>the</strong>nstarted to trend down (see chart:Yields at Peak Bro<strong>the</strong>rs <strong>Farm</strong> 2004).

In 30" rows plot at McLaughlin-Dooley <strong>Farm</strong>s, you cansee <strong>the</strong> sunlight is able to reach <strong>the</strong> ground in between<strong>the</strong> canopyAt <strong>the</strong> same plot as shown to <strong>the</strong> left, <strong>the</strong> twin rows havea tighter canopy, which led to conserving water by shading<strong>the</strong> ground.In 2005, <strong>the</strong> second year at Peaks farm also showed consistentperformance by <strong>the</strong> twins (see chart: Yields at Peak Bro<strong>the</strong>rs<strong>Farm</strong> 2005). Populations were compared for <strong>the</strong> twins and 30"rows at five levels ranging from 28,700 to 36,000 ppa. The entireplot was sprayed with fungicide for disease. Even so, <strong>the</strong> twinrows suffered more disease pressure than <strong>the</strong> 30" rows. Whencomparing year-to-year results, it became apparent <strong>the</strong>re arecertain hybrids and certain soils that can and need to be pushedwith higher populations. Inconsistency in response to populationcan be attributed to <strong>the</strong> hybrid’s characteristics of being flex- orfixed-ear type. To find <strong>the</strong> upper limit in pushing populations,<strong>the</strong> first consideration should be <strong>the</strong> hybrid’s capabilities and<strong>the</strong>n <strong>the</strong> growing conditions.McLaughlin-Dooley <strong>Farm</strong>s near Leroy offered a secondopportunity to compare 30" rows with twin rows. The same rigused at Peaks put in <strong>the</strong> twins, and <strong>the</strong> 30" treatments went inwith <strong>the</strong> farm’s John Deere 7200 vacuum planter. The twinsoutpaced <strong>the</strong> 30" at every planting population above 28,000 ppa(see chart: Yields at McLaughlin-Dooley <strong>Farm</strong>s).At Gregg Sauder’s farm near Tremont, <strong>the</strong> twin rows werecompared to 20" rows. The Great Plains Yield-Pro planterplanted <strong>the</strong> twins, and Sauder’s 36-row Kinze planter put in <strong>the</strong>20" rows. Precision Planting meters were used in both machines,and care was again taken for <strong>the</strong> meters to operate at <strong>the</strong> samespeed. <strong>Plot</strong>s were put in both corn-on-cornand corn/soybean rotations. The back-tobackcorn yielded 10 bu. to 15 bu. per acrehigher than <strong>the</strong> corn following beans. In2004 <strong>the</strong>re was a slight advantage to <strong>the</strong> twinrows, and in 2005 <strong>the</strong>re was an advantage to<strong>the</strong> 20" rows. The data showed that twinrows and 20" rows have similar yieldadvantages compared with 30" rows.Near Grand Ridge, test plot cooperatorJohn Thomas put in twin-row plots in cornon-cornand corn-on-bean fields. He built aplanter for <strong>the</strong> job. A hitch, called a planterpull arm, built by Meteer Manufacturing inA<strong>the</strong>ns, Ill., links two 12-row, 30" plantersinto one rig. Thomas and son Rob set it upso that <strong>the</strong> rear machine runs 7½" to <strong>the</strong> leftof <strong>the</strong> front planter. He used Bt-rootwormhybrids so insecticide wasn’t an issue andcompared twins with 30" rows. The plots<strong>Narrow</strong> <strong>Row</strong> <strong>Corn</strong> <strong>Report</strong> 04Bu. per acre compared to 30” yield +/-20151050-5were impacted by disease to <strong>the</strong> extent that <strong>the</strong> yield resultswere compromised (see chart: 2006 Yields at Covel Creek<strong>Farm</strong>s).Thomas took his planter to R & D Walter <strong>Farm</strong>s, GrandRidge, to help put in a plot comparing twins, 30" and 20" rows.Ralph and Don Walter used <strong>the</strong>ir 30" planter and 20" planter,and Hybrid Service provided <strong>the</strong> 20" combine head andcombine. Both corn-on-corn and corn-on-bean plots wereplanted. Two varieties were used with a split-planter setup. Onehybrid barely showed a response to row spacing or population,while <strong>the</strong> o<strong>the</strong>r responded aggressively. The Grand Ridge groupplanted <strong>the</strong>ir plot in a longtime continuous corn field with highIllinois Soil N <strong>Test</strong> (ISNT) values built by years of manureapplications and corn-on-corn production. The high-yieldenvironment is suited for higher planting populations. In 2005,<strong>the</strong> plot yielded extremely well considering that it had less rainthan any of <strong>the</strong> o<strong>the</strong>r locations included in <strong>the</strong> effort. Thedownside of <strong>the</strong> many years of continuous corn is that <strong>the</strong> fieldis a welcome mat for disease (see charts: Yields at Grand Ridgewith Fungicide and without Fungicide).The data points to 34,000 to 36,000 ppa as <strong>the</strong> top end for mosthybrids in medium to light soils. At <strong>the</strong> same time, populationsneed to be pushed more in fields with heavier soils, greaterwater-holding capacity and higher ISNT values—as seen in <strong>the</strong>Yields at Kuntz <strong>Farm</strong> 20081 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26ReplicationsThe chart shows twin row yield compared with 30" row yield (plus or minus).Overall, <strong>the</strong> twin rows averaged 7 bu. greater than <strong>the</strong> 30" rows.

Silage <strong>Plot</strong> 2008: PopulationSilage <strong>Plot</strong> 2008: Effect of Fungicidelb. milk/acre25,00024,00023,00022,00021,00020,00019,00018,00017,00016,00015,000Using <strong>the</strong> University of Wisconsin’s Milk 2006 formulation,our test plots show how 30" row silage and twin rowsilage yields in pounds of milk per acre.results from <strong>the</strong> McLaughlin-Dooley and Grand Ridge plots.In 2005, preharvest checks predicted strong yields in <strong>the</strong> <strong>Farm</strong><strong>Journal</strong> twin-row corn plots, but it was still hard to believe howstrong <strong>the</strong> final numbers were when <strong>the</strong> grain rolled into <strong>the</strong>combine. Checks with <strong>the</strong> weigh wagon verified <strong>the</strong> yields(“Tough Year <strong>Test</strong>s Twin <strong>Row</strong>s,” Mid-January 2006). Conservingwater was a key factor in <strong>the</strong> plot effort with narrow rows. Thefive Illinois plot locations posted yields as high as 240 bu. peracre; most hovered between 175 bu. and 200 bu.2006 to 2008 By 2006, twin rows had gone from a nichepractice used primarily by vegetable growers to a mainstreamoption for corn growers in less than a decade (“Dynamic Duo,”February 2007). Twin rows advanced to <strong>the</strong> point that some of<strong>the</strong> winners in <strong>the</strong> 2006 National <strong>Corn</strong> Growers Yield Contestused twins to achieve <strong>the</strong>ir big yields.In 2008, at Bob Kuntz’s farm, a plot was replicated multipletimes across one field. Having 26 replications provided datashowing a yield advantage averaging 7 bu. for <strong>the</strong> twin rows.Where twin rows yielded less than 30" rows, that yield dropcould be attributed to <strong>the</strong> sprayer tracks (see chart: Yields atKuntz <strong>Farm</strong> 2008).The opportunity to push populations and increase yields canbenefit any corn grower but is especiallyimportant to those raising corn for silage. Westarted a new effort in 2006 to examine <strong>the</strong>impact of twin rows on corn silage production.We linked up with Illinois State University andIowa State University to create replicated plotsthat compare <strong>the</strong> nutritive value of silagegrown in twin rows with that of silage from 30"rows. More plants meant more tonnage peracre (“Twin <strong>Row</strong>s Yield Tonnage,” September2007). After <strong>the</strong> first year, <strong>the</strong> study continuedat one location, Illinois State University’sresearch and teaching farm near Lexington, Ill.We compared <strong>the</strong> results from 30" and twinrows and evaluated how population and rowspacing impact silage quality. Two hybrids—onein each field—were used; <strong>the</strong> seed was providedby Pioneer Hi-Bred International Inc. and<strong>Narrow</strong> <strong>Row</strong> <strong>Corn</strong> <strong>Report</strong> 0530" Twin row29,000 33,000 37,000Planted Populationlb. milk/acre32,50030,00027,50025,00022,50020,00017,50015,00012,50010,000Check30"33,000Twin33,000With fungicide30"37,000Planted PopulationTwin37,000Tonnage and quality are important in silage production.Applying fungicide provided increased value of our silageyields in terms of pounds of milk per acre.Mycogen Seeds. Using RTK guidance on a New Holland tractorwith a 40' Great Plains planter, we planted <strong>the</strong> twin rows firstand returned to plant <strong>the</strong> 30" rows. To harvest <strong>the</strong> test plots, weused a six-row New Holland FX50 silage chopper, which provedto be a significant time-saver for <strong>the</strong> research farm. Whilechopping, we created data log files for each silage load on aPDA with GPS. From <strong>the</strong> field, we weighed each load beforeand after dumping. We backtracked to see where each loadcame from and its origin soil type.The plot crew harvested valuable data from <strong>the</strong> <strong>the</strong>e-yearsilage study. As population increased, tonnage followed. After<strong>the</strong> first year of data regarding <strong>the</strong> impact of row spacing andpopulation in terms of tonnage yield and relative feed value, weexpanded <strong>the</strong> study to include silage quality (“Twin <strong>Row</strong>sCutting Edge,” Mid-November 2008). The 2007 data wasanalyzed with <strong>the</strong> University of Wisconsin’s Milk 2006formulation. <strong>Corn</strong> silage provides energy from two pools in <strong>the</strong>feed—starch and digestible neutral detergent fiber—and <strong>the</strong>results using Milk 2006 take into consideration those two energypools to provide a more well-rounded perspective.<strong>Narrow</strong> row silage production increased tonnage withoutcompromising quality as measured in pounds of milk per acreUsing a 40' Great Plains planter, we planted 70 acres of silage at <strong>the</strong> IllinoisState University’s research and teaching farm near Lexington, Ill.

(“Feed Silage Success,” Summer 2009). The silage results wereevaluated with <strong>the</strong> Milk 2006 test (see chart: Silage <strong>Plot</strong> 2008:Population). The samples were taken before ensilage; <strong>the</strong>refore,<strong>the</strong> green forage equation was used in our evaluations. Thesilage harvester we used was also equipped with a kernelprocessor, which can increase <strong>the</strong> quality of test results.With an aerial application when <strong>the</strong> corn was tasselling, a plotpartner applied Bayer Stratego fungicide, which has a harvestrestriction of 30 days in silage. In twin rows, <strong>the</strong> response tofungicide was at all populations with higher pounds of milk peracre. In pounds of milk per acre, where <strong>the</strong> fungicide was appliedcompared with <strong>the</strong> control, we saw no response in 30" rows at33,000 ppa; a 16% increase in twin rows at 33,000 ppa; an 8%increase in 30" rows at 37,000 ppa; and a 23% increase in twinrows at 37,000 ppa. Comparing <strong>the</strong> two row spacings in poundsof milk per acre, without <strong>the</strong> fungicide application <strong>the</strong>re was an11% increase in <strong>the</strong> twin rows compared with <strong>the</strong> 30" rows at33,000 ppa. There was a 6% increase in twin rows compared with<strong>the</strong> 30" rows at 37,000 ppa. Where <strong>the</strong> fungicide was applied,<strong>the</strong>re was a 29% increase in twin rows compared with 30" rowsat 33,000 ppa and a 21% increase in twin rows compared with30" at 37,000 ppa (see chart: Silage <strong>Plot</strong> 2008: Effect ofFungicide). As he reviews <strong>the</strong> three-year effort, Ferrie says plan<strong>the</strong>alth and population are king in silage production.CONCLUSIONSAs we wrapped up <strong>the</strong> many years of replicated narrow rowtest plots, this summarizes what we’ve learned:Yield. Years of replicated plot data show narrow rowsoutyield 30" rows by as much as 22 bu. per acre, and <strong>the</strong> averageyield gain was 7 bu. to 10 bu. per acre. The row spacings producesimilar ear counts, but <strong>the</strong> twin and 20" rows pick up extra yieldthrough better tip fill and deeper kernel depth. The upper end of<strong>the</strong> yield response came from soils that need to be pushed andfrom lighter soils that need to hang onto water. At <strong>the</strong> same time,<strong>the</strong> average yield gains were posted in middle-of-<strong>the</strong>-road soils.In silage, twin rows result in increased tonnage withoutcompromising quality, and fungicide has a powerful effect.Populations. <strong>Narrow</strong> rows let you push populations in soilsand hybrids that can handle it. During <strong>the</strong> multiple years ofplots, we’ve used populations from 28,000 to 48,000 ppa. Theresults show that <strong>the</strong> best population for narrow row corn ishigher than what’s best for 30" rows. In silage production, <strong>the</strong>lesson is that higher populations are key.Hybrids. Seed selection is important with anyrow spacing in corn production and silageproduction. If you’re growing a racehorse hybridwithout strong defensive traits, you’ll need toprotect it. And some disease-prone fields simplyneed a hybrid with defensive genetics. As always,it is wise to plant your own variety plot to seewhat works best in your fields at what population.There are limited labels for insecticide in twinrows, and <strong>the</strong> postemergence ground applicationis more difficult. When you’re planting non-GMO crops and aerial applications aren’tavailable, take this into consideration.Disease pressure. The downside of narrowrows and high populations is that you have tomanage disease. With narrow row corn, <strong>the</strong>tighter canopy can make disease worse. As withany row spacing, growing conditions are more<strong>Narrow</strong> <strong>Row</strong> <strong>Corn</strong> <strong>Report</strong> 06Although <strong>the</strong> sidedressing window is tight, <strong>the</strong> sameequipment used for 30" rows can be used for twin rows.conducive to disease in some years than in o<strong>the</strong>rs. Scouting fordisease is especially important. <strong>Narrow</strong> rows have to be treatedlike 30" rows when it comes to weeds, although <strong>the</strong> narrow rowsclose faster and help choke back <strong>the</strong> weeds.Insect control. In particular, rootworm control in narrowrows requires <strong>the</strong> most attention. In narrow rows, it’s not <strong>the</strong> rateof insecticide per acre that needs to be calculated, but ra<strong>the</strong>r <strong>the</strong>rate per foot of row. This means a higher insecticide rate andincreased cost to reach control as compared with 30” rows.Starter fertilizer. The application rates of starter fertilizerin narrow rows should be calculated in rate per foot of row. Innarrow rows, starter application will cost more than wider rows.However, banding a greater portion of a field’s fertilizerallocation will result in more efficient nutrient pick up.Water. <strong>Narrow</strong> row corn can conserve water—because ofmore canopy and quicker closure than 30" rows—and make <strong>the</strong>most of extra moisture by maximizing higher populations.Machinery. We were nervous about harvest during our firstyear of twin-row plots, but we quickly learned that a 30" cornhead has no problem munching through <strong>the</strong> twin rows. Ofcourse, using a guidance system at planting makes it even easier.The sidedress window can be tight, and residue management canbe tough. Depending on <strong>the</strong> type of planter and crop rotationyou use for narrow rows, <strong>the</strong> tolerances for residue flow can betight between row units. You may need to shred and size <strong>the</strong>stalks in corn-on-corn. You’ll also want to make sure you’re notburying one of <strong>the</strong> rows with residue during planting.For more information, e-mail testplots@farmjournal.comHarvesting twin row silage did not require any modifications to <strong>the</strong>silage chopper and its head.