MANUAL WAFER BONDER - SUSS MicroTec

MANUAL WAFER BONDER - SUSS MicroTec

MANUAL WAFER BONDER - SUSS MicroTec

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

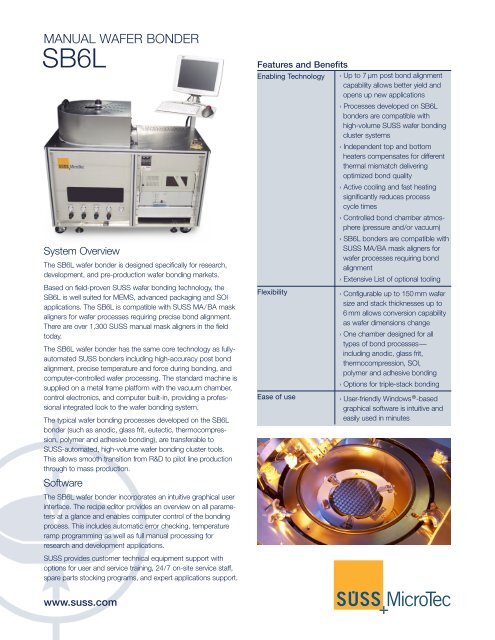

<strong>MANUAL</strong> <strong>WAFER</strong> <strong>BONDER</strong><br />

SB6L<br />

System Overview<br />

The SB6L wafer bonder is designed specifically for research,<br />

development, and pre-production wafer bonding markets.<br />

Based on field-proven <strong>SUSS</strong> wafer bonding technology, the<br />

SB6L is well suited for MEMS, advanced packaging and SOI<br />

applications. The SB6L is compatible with <strong>SUSS</strong> MA/BA mask<br />

aligners for wafer processes requiring precise bond alignment.<br />

There are over 1,300 <strong>SUSS</strong> manual mask aligners in the field<br />

today.<br />

The SB6L wafer bonder has the same core technology as fullyautomated<br />

<strong>SUSS</strong> bonders including high-accuracy post bond<br />

alignment, precise temperature and force during bonding, and<br />

computer-controlled wafer processing. The standard machine is<br />

supplied on a metal frame platform with the vacuum chamber,<br />

control electronics, and computer built-in, providing a professional<br />

integrated look to the wafer bonding system.<br />

The typical wafer bonding processes developed on the SB6L<br />

bonder (such as anodic, glass frit, eutectic, thermocompression,<br />

polymer and adhesive bonding), are transferable to<br />

<strong>SUSS</strong>-automated, high-volume wafer bonding cluster tools.<br />

This allows smooth transition from R&D to pilot line production<br />

through to mass production.<br />

Software<br />

The SB6L wafer bonder incorporates an intuitive graphical user<br />

interface. The recipe editor provides an overview on all parameters<br />

at a glance and enables computer control of the bonding<br />

process. This includes automatic error checking, temperature<br />

ramp programming as well as full manual processing for<br />

research and development applications.<br />

<strong>SUSS</strong> provides customer technical equipment support with<br />

options for user and service training, 24/7 on-site service staff,<br />

spare parts stocking programs, and expert applications support.<br />

Features and Benefits<br />

Enabling Technology › Up to 7 µm post bond alignment<br />

capability allows better yield and<br />

opens up new applications<br />

› Processes developed on SB6L<br />

bonders are compatible with<br />

high-volume <strong>SUSS</strong> wafer bonding<br />

cluster systems<br />

› Independent top and bottom<br />

heaters compensates for different<br />

thermal mismatch delivering<br />

optimized bond quality<br />

› Active cooling and fast heating<br />

significantly reduces process<br />

cycle times<br />

› Controlled bond chamber atmosphere<br />

(pressure and/or vacuum)<br />

› SB6L bonders are compatible with<br />

<strong>SUSS</strong> MA/BA mask aligners for<br />

wafer processes requiring bond<br />

alignment<br />

› Extensive List of optional tooling<br />

Flexibility<br />

Ease of use<br />

› Configurable up to 150 mm wafer<br />

size and stack thicknesses up to<br />

6 mm allows conversion capability<br />

as wafer dimensions change<br />

› One chamber designed for all<br />

types of bond processes—<br />

including anodic, glass frit,<br />

thermocompression, SOI,<br />

polymer and adhesive bonding<br />

› Options for triple-stack bonding<br />

› User-friendly Windows ® -based<br />

graphical software is intuitive and<br />

easily used in minutes<br />

www.suss.com

Technical Data: SB6L Manual Wafer Bonder<br />

Material Size Limits Standard With Special Tooling<br />

Wafer size<br />

150 mm diameter<br />

Substrate size, minimum<br />

10 mm x 10 mm<br />

Wafer or Substrate Stack Thickness, maximum<br />

6 mm<br />

Maximum Elements in stack 2 3<br />

Bond Chamber Specs<br />

Vacuum 5E-1 mbar 1E-4mbar<br />

Pressure Regulation Accuracy, 10 to 100 mbar ± 2.0 %<br />

Pressure Regulation Accuracy, 5E-4 mbar to 10 mbar ± 2.0 %<br />

Purge Time from 1 mbar to Atmosphere<br />