1 - ericssonhistory.com

1 - ericssonhistory.com

1 - ericssonhistory.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The curves show that the small-diameter coaxial cable standardized by<br />

C.C.I.T.T. with the diameter ratio 1.18/4.43 mm has an optimal system size<br />

of N ~ 900 channels when the annual costs are considered. On the basis<br />

solely of first cost, the nearest optimal system size will be about 2700<br />

channels.<br />

For purposes of conversion a 2700-channel system will under all circumstances<br />

be economically advantageous <strong>com</strong>pared with the installation of new<br />

cable.<br />

The saving in per cent of the first cost for three sizes of system through the<br />

use of small-diameter coaxial cable instead of the heavier 2.6/9.5 mm cable has<br />

been calculated below. The costs of laying of the cable have not been included<br />

since they are virtually independent of the diameter of the coaxial tubes.<br />

System<br />

Saving<br />

300<br />

50%<br />

960<br />

20%<br />

1700<br />

0<br />

Another factor which makes small-diameter coaxial cable attractive also<br />

on heavy-traffic routes is that the cost of standby equipment in a multitube<br />

small-diameter coaxial system is small <strong>com</strong>pared with the conditions in a<br />

normal coaxial cable system with small number of tubes.<br />

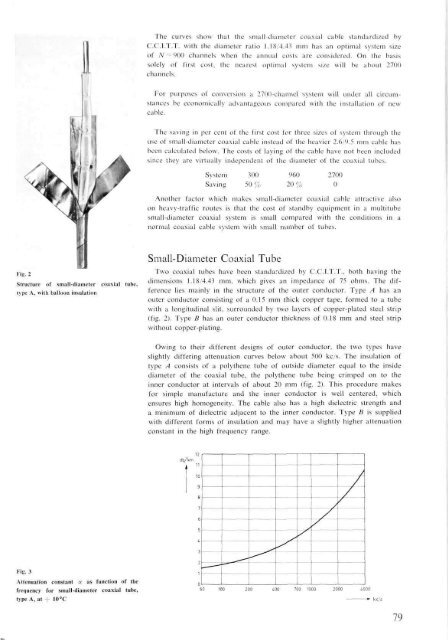

Fig. 2<br />

Structure of small-diameter<br />

type A, with balloon insulation<br />

coaxial tube,<br />

Small-Diameter Coaxial Tube<br />

Two coaxial tubes have been standardized by C.C.I.T.T., both having the<br />

dimensions 1.18/4.43 mm, which gives an impedance of 75 ohms. The difference<br />

lies mainly in the structure of the outer conductor. Type A has an<br />

outer conductor consisting of a 0.15 mm thick copper tape, formed to a tube<br />

with a longitudinal slit, surrounded by two layers of copper-plated steel strip<br />

(fig. 2). Type B has an outer conductor thickness of 0.18 mm and steel strip<br />

without copper-plating.<br />

Owing to their different designs of outer conductor, the two types have<br />

slightly differing attenuation curves below about 500 kc/s. The insulation of<br />

type A consists of a polythene tube of outside diameter equal to the inside<br />

diameter of the coaxial tube, the polythene tube being crimped on to the<br />

inner conductor at intervals of about 20 mm (fig. 2). This procedure makes<br />

for simple manufacture and the inner conductor is well centered, which<br />

ensures high homogeneity. The cable also has a high dielectric strength and<br />

a minimum of dielectric adjacent to the inner conductor. Type B is supplied<br />

with different forms of insulation and may have a slightly higher attenuation<br />

constant in the high frequency range.<br />

Fig. 3<br />

Attenuation constant y. as function of the<br />

frequency for small-diameter coaxial tube,<br />

type A, at + 10°C<br />

79