Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TP</strong> Series 400 pumps<br />

<strong>TP</strong>, <strong>TP</strong>D, <strong>TP</strong>E<br />

Materials<br />

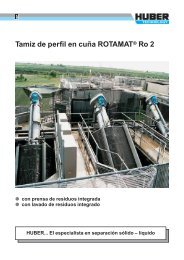

3<br />

2<br />

5<br />

4<br />

1<br />

GR7539<br />

Fig. 7 Sectional drawing of <strong>TP</strong> Series 400<br />

TM02 8492 0204<br />

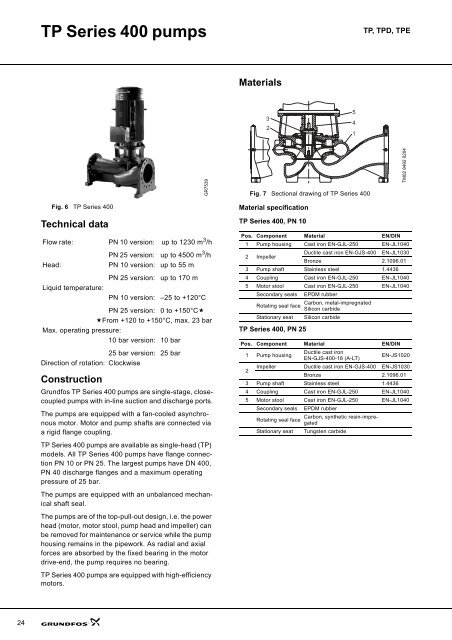

Fig. 6 <strong>TP</strong> Series 400<br />

Technical data<br />

Flow rate:<br />

Head:<br />

Liquid temperature:<br />

Construction<br />

PN 10 version:<br />

PN 25 version:<br />

PN 10 version:<br />

PN 25 version:<br />

PN 10 version:<br />

up to 1230 m 3 /h<br />

up to 4500 m 3 /h<br />

up to 55 m<br />

up to 170 m<br />

–25 to +120°C<br />

PN 25 version: 0 to +150°C<br />

From +120 to +150°C, max. 23 bar<br />

Max. operating pressure:<br />

10 bar version: 10 bar<br />

25 bar version: 25 bar<br />

Direction of rotation: Clockwise<br />

Grundfos <strong>TP</strong> Series 400 pumps are single-stage, closecoupled<br />

pumps with in-line suction and discharge ports.<br />

The pumps are equipped with a fan-cooled asynchronous<br />

motor. Motor and pump shafts are connected via<br />

a rigid flange coupling.<br />

Material specification<br />

<strong>TP</strong> Series 400, PN 10<br />

Pos. Component Material EN/DIN<br />

1 Pump housing Cast iron EN-GJL-250 EN-JL1040<br />

2 Impeller<br />

Ductile cast iron EN-GJS-400 EN-JL1030<br />

Bronze 2.1096.01<br />

3 Pump shaft Stainless steel 1.4436<br />

4 Coupling Cast iron EN-GJL-250 EN-JL1040<br />

5 Motor stool Cast iron EN-GJL-250 EN-JL1040<br />

Secondary seals EPDM rubber<br />

Rotating seal face<br />

Stationary seat<br />

<strong>TP</strong> Series 400, PN 25<br />

Carbon, metal-impregnated<br />

Silicon carbide<br />

Silicon carbide<br />

Pos. Component Material EN/DIN<br />

1 Pump housing<br />

Ductile cast iron<br />

EN-GJS-400-18 (A-LT)<br />

EN-JS1020<br />

2<br />

Impeller Ductile cast iron EN-GJS-400 EN-JS1030<br />

Bronze 2.1096.01<br />

3 Pump shaft Stainless steel 1.4436<br />

4 Coupling Cast iron EN-GJL-250 EN-JL1040<br />

5 Motor stool Cast iron EN-GJL-250 EN-JL1040<br />

Secondary seals EPDM rubber<br />

Rotating seal face<br />

Stationary seat<br />

Carbon, synthetic resin-impregated<br />

Tungsten carbide<br />

<strong>TP</strong> Series 400 pumps are available as single-head (<strong>TP</strong>)<br />

models. All <strong>TP</strong> Series 400 pumps have flange connection<br />

PN 10 or PN 25. The largest pumps have DN 400,<br />

PN 40 discharge flanges and a maximum operating<br />

pressure of 25 bar.<br />

The pumps are equipped with an unbalanced mechanical<br />

shaft seal.<br />

The pumps are of the top-pull-out design, i.e. the power<br />

head (motor, motor stool, pump head and impeller) can<br />

be removed for maintenance or service while the pump<br />

housing remains in the pipework. As radial and axial<br />

forces are absorbed by the fixed bearing in the motor<br />

drive-end, the pump requires no bearing.<br />

<strong>TP</strong> Series 400 pumps are equipped with high-efficiency<br />

motors.<br />

24