Whale® 12V Pumps Set-up and user guide - Waterra-In-Situ

Whale® 12V Pumps Set-up and user guide - Waterra-In-Situ

Whale® 12V Pumps Set-up and user guide - Waterra-In-Situ

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Warranty <strong>In</strong>formation<br />

<strong>Waterra</strong> <strong>In</strong>-<strong>Situ</strong> will warranty all Whale 12 volt DC Submersible <strong>Pumps</strong> to be free from material defects in design,<br />

workmanship <strong>and</strong> material under normal use for a period of 30 days from the date of purchase.<br />

Exclusions <strong>and</strong> Conditions<br />

The use of any pump with replacement parts or accessories, which are not s<strong>up</strong>plied by <strong>Waterra</strong> <strong>In</strong>-<strong>Situ</strong> <strong>and</strong> which affect<br />

product safety or performance, shall render this warranty <strong>and</strong> all other warranties, whether express or implied, null <strong>and</strong><br />

void. Should any failure to conform to this warranty appear within the term of initial sale, the manufacturer shall <strong>up</strong>on<br />

notification thereof <strong>and</strong> substantiation that the pump has been maintained, correct such defects by suitable repair or<br />

replacement at its own expense, purchaser being responsible for shipping <strong>and</strong> h<strong>and</strong>ling charges only.<br />

The warranty does not include shipping or an obligation to provide another unit while the original Whale 12 volt<br />

submersible pump is being repaired or replaced. This warranty does not apply to any 12 volt submersible pump used as<br />

rental equipment or to submersible pumps contaminated by materials harmful to such products.<br />

This warranty does not apply to parts failure due to neglect in cleaning or unauthorized servicing the Whale 12 Volt DC<br />

Submersible Pump nor does it cover failure of a part caused by misuse or inappropriate use of the Whale 12 Volt DC<br />

Submersible Pump.<br />

Returning a 12 Volt Submersible Pump<br />

<strong>Waterra</strong> <strong>In</strong>-<strong>Situ</strong> requires that all customers notify <strong>Waterra</strong> <strong>In</strong>-<strong>Situ</strong> prior to returning a defective Whale 12 Volt DC<br />

Submersible Pump under this warranty program. The 12 Volt DC Submersible Pump will only be accepted if it has been<br />

thoroughly cleaned <strong>and</strong> decontaminated. Please contact <strong>Waterra</strong> <strong>In</strong>-<strong>Situ</strong> for a return form.<br />

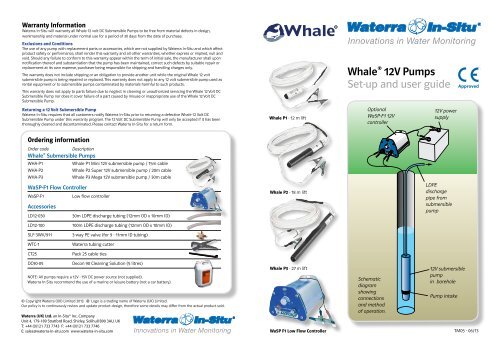

Whale P1 - 12 m lift<br />

Whale® <strong>12V</strong> <strong>Pumps</strong><br />

<strong>Set</strong>-<strong>up</strong> <strong>and</strong> <strong>user</strong> <strong>guide</strong><br />

Optional<br />

WaSP-F1 <strong>12V</strong><br />

controller<br />

<strong>12V</strong> power<br />

s<strong>up</strong>ply<br />

Approved<br />

Ordering information<br />

Order code<br />

Description<br />

Whale® Submersible <strong>Pumps</strong><br />

WHA-P1<br />

Whale P1 Mini <strong>12V</strong> submersible pump / 15m cable<br />

WHA-P2<br />

Whale P2 S<strong>up</strong>er <strong>12V</strong> submersible pump / 20m cable<br />

WHA-P3<br />

Whale P3 Mega <strong>12V</strong> submersible pump / 30m cable<br />

WaSP-F1 Flow Controller<br />

WaSP-F1<br />

Low flow controller<br />

Accessories<br />

LD12-030<br />

30m LDPE discharge tubing (12mm OD x 10mm ID)<br />

Whale P2 - 18 m lift<br />

LDPE<br />

discharge<br />

pipe from<br />

submersible<br />

pump<br />

LD12-100<br />

SLF-3WV/911<br />

WTC-1<br />

CT25<br />

100m LDPE discharge tubing (12mm OD x 10mm ID)<br />

3-way PE valve (for 9 - 11mm ID tubing)<br />

<strong>Waterra</strong> tubing cutter<br />

Pack 25 cable ties<br />

DC90-05<br />

Decon 90 Cleaning Solution (5 litres)<br />

NOTE: All pumps require a <strong>12V</strong> - 15V DC power source (not s<strong>up</strong>plied).<br />

<strong>Waterra</strong> <strong>In</strong>-<strong>Situ</strong> recommend the use of a marine or leisure battery (not a car battery).<br />

© Copyright <strong>Waterra</strong> (UK) Limited 2013. ® Logo is a trading name of <strong>Waterra</strong> (UK) Limited.<br />

Our policy is to continuously review <strong>and</strong> <strong>up</strong>date product design, therefore some details may differ from the actual product sold.<br />

<strong>Waterra</strong> (UK) Ltd. an <strong>In</strong>-<strong>Situ</strong>® <strong>In</strong>c. Company<br />

Unit 4, 179-189 Stratford Road, Shirley, Solihull B90 3AU, UK<br />

T: +44 (0)121 733 7743 F: +44 (0)121 733 7746<br />

E: sales@waterra-in-situ.com www.waterra-in-situ.com<br />

Whale P3 - 27 m lift<br />

WaSP F1 Low Flow Controller<br />

Schematic<br />

diagram<br />

showing<br />

connections<br />

<strong>and</strong> method<br />

of operation.<br />

<strong>12V</strong> submersible<br />

pump<br />

in borehole<br />

Pump intake<br />

TM05 - 06/13

Caution - beam section to be<br />

laced <strong>and</strong> braced on the<br />

ground (as shown in Section<br />

A-A) before craned into<br />

position<br />

Caution - beam section to be<br />

laced <strong>and</strong> braced on the<br />

ground (as shown in Section<br />

A-A) before craned into<br />

position<br />

Caution - beam section to be<br />

laced <strong>and</strong> braced on the<br />

ground (as shown in Section<br />

A-A) before craned into<br />

position<br />

Caution - beam section to be<br />

laced <strong>and</strong> braced on the<br />

ground (as shown in Section<br />

A-A) before craned into<br />

position<br />

Caution - beam section to be<br />

laced <strong>and</strong> braced on the<br />

ground (as shown in Section<br />

A-A) before craned into<br />

position<br />

<strong>In</strong>troduction<br />

This <strong>guide</strong> is designed to help you through the initial set-<strong>up</strong><br />

<strong>and</strong> use of Whale <strong>12V</strong> Submersible <strong>Pumps</strong>. Please read through<br />

these instructions carefully before using the pump.<br />

Further information - visit www.waterra-in-situ.com<br />

For more detailed information the following is accessible via our website Resources page<br />

Downloads<br />

PR23 - Whale 12 Volt Submersible <strong>Pumps</strong><br />

PR11 - WaSP 12 Volt Low Flow Controller<br />

Using a Whale <strong>12V</strong> pump in a borehole<br />

Attach discharge tubing<br />

l Prior to inserting the pump into the well, you will need to connect the pump to a<br />

length of 10mm ID tubing. We recommend LDPE (low-density polyethylene) as it<br />

is softer <strong>and</strong> easier to connect to the pump.<br />

TIPS<br />

l If medium-density tubing is used, it is recommended the end of the tubing be softened<br />

with heat, or stretched prior to attaching it to the pump.<br />

l For additional security, use a hose clamp to secure tubing over the discharge outlet.<br />

Do not use high density tubing! This will break the discharge outlet.<br />

<strong>In</strong>stall to pumping depth in your monitoring borehole or well<br />

l Lower the pump into the well so that the pump intake is submerged.<br />

TIPS<br />

l Submerge the pump as deep as possible to obtain best flow rates.<br />

Technical Manual<br />

TM05 - Whale <strong>12V</strong> <strong>Pumps</strong> - <strong>Set</strong>-<strong>up</strong> <strong>and</strong> <strong>user</strong> <strong>guide</strong><br />

TM07 - WaSP F1 Low Flow Controller <strong>user</strong> manual<br />

l Avoid placing pump too close to the base of the well to avoid ingress of silt or other debris.<br />

l Whale 12 Volt <strong>Pumps</strong> can pump with only 25 to 50mm of the pump submerged beneath<br />

the water.<br />

Connect to power s<strong>up</strong>ply<br />

l Connect the pump’s negative alligator clamp securely to the negative terminal<br />

on your power s<strong>up</strong>ply, <strong>and</strong> then connect the positive pump clamp to the positive<br />

terminal. The pump will start immediately.<br />

l Alternatively, <strong>and</strong> for greater control of your Whale pump, connect the pump<br />

terminals via the WaSP F1 Flow Controller - see diagram on front cover <strong>and</strong> refer<br />

to <strong>user</strong> manual TM07.<br />

TIPS<br />

Remove pump from borehole<br />

l When pumping is completed, remove the pump from the well.<br />

l When removed, hold the pump in the <strong>up</strong>right position so that all water drains<br />

from the unit.<br />

WARNINGS<br />

Do not allow water to freeze inside the pump! Frozen water will exp<strong>and</strong> <strong>and</strong> damage the unit.<br />

S<strong>and</strong> <strong>and</strong> silt, if allowed to build <strong>up</strong>, can cause the pump to fail.<br />

<strong>In</strong>take<br />

l For best results we recommend use of a <strong>12V</strong> marine battery or a leisure battery with at least 40 amp-hour rating. If<br />

a vehicle battery is being used, it is important that the vehicle is turned on <strong>and</strong> run for 2 minutes every 30 minutes in<br />

order to maintain the charge in the vehicle’s battery. Failure to do this may result in damage to the battery <strong>and</strong> being<br />

unable to start the vehicle. Running the vehicle while the pump is running will not damage the pump.<br />

Do not run dry! This will damage the motor.<br />

A cool down period of 5 minutes is required after every 15 minutes of running time.<br />

Cleaning <strong>and</strong> Decontamination<br />

Whale 12 Volt Submersible <strong>Pumps</strong> can only be partially decontaminated. There is no decontamination procedure<br />

that can ensure that all contaminants are completely removed from the pump. The best way to ensure that you<br />

will not incur cross contamination between wells is to use a different pump for each well.<br />

l Immerse the Whale <strong>12V</strong> pump <strong>and</strong> discharge tubing in a bucket of warm water<br />

with a non-phosphate detergent (e.g. diluted Decon 90).<br />

l Attach a short section of tubing to the pump outlet to re-circulate the cleaning<br />

solution back into the bucket.<br />

l Attach the pump to your power s<strong>up</strong>ply <strong>and</strong> allow the cleaning solution to circulate<br />

through the pump. The amount of time that is required for this will vary depending<br />

on the concentration <strong>and</strong> type of contaminant the unit was exposed to.<br />

l Repeat the procedure with clean water.<br />

l For reassurance, check the decontamination by passing a rinse blank sample<br />

through the pump<br />

Technical<br />

specifications<br />

Choose the pump that<br />

best suits your pumping<br />

requirements.<br />

Note:<br />

Performance data is for<br />

guidance only. Actual<br />

performance will depend<br />

on the conditions in the<br />

borehole being pumped.<br />

Technical<br />

specification<br />

Pumping rate (litres/min)<br />

0<br />

0<br />

www.waterra-in-situ.com<br />

15<br />

10<br />

5<br />

5<br />

Whale P1<br />

Whale P2<br />

Whale P3<br />

Whale Pump rating<br />

curves (approx)<br />

10 15 20 25 30 35<br />

Head (Depth) - metres<br />

Technical Units Whale P1 Whale P2 Whale P3<br />

Material<br />

ABS / Nylon / Nitrile / Stainless Steel<br />

Maximum Head (Lift) m 12 18 27<br />

Maximum Flow l/min 12 11 13<br />

Duty cycle<br />

<strong>In</strong>termittent (15 mins on / 5 mins off)<br />

Pump diameter mm 43 43 43<br />

Pump body length mm 130 260 400<br />

Max. Voltage V 12 - 15<br />

Max. Amps amp 5 12 15<br />

Motor life hours Approx 100 hours duty cycle<br />

S<strong>up</strong>plied cable length m 15 20 30<br />

Cable gauge Multi-str<strong>and</strong> 3.96 mm 2<br />

Cable insulating material<br />

PVC<br />

Discharge Tube (ID) mm 8 or 10 mm (adaptor s<strong>up</strong>plied)