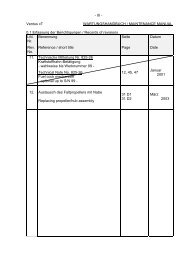

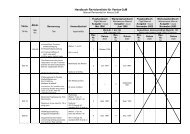

0.1 Erfassung der Berichtigungen / Record of Revisions

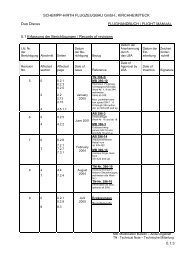

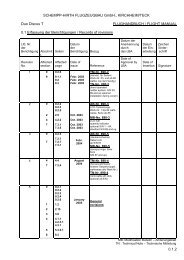

0.1 Erfassung der Berichtigungen / Record of Revisions

0.1 Erfassung der Berichtigungen / Record of Revisions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SCHEMPP -HIRTH FLUGZEUGBAU GmbH, KIRCHHEIM/TECK<br />

Ventus-2cT FLUGHANDBUCH Ausgabe Juni 1996<br />

FLIGHT MANUAL issue June 1996<br />

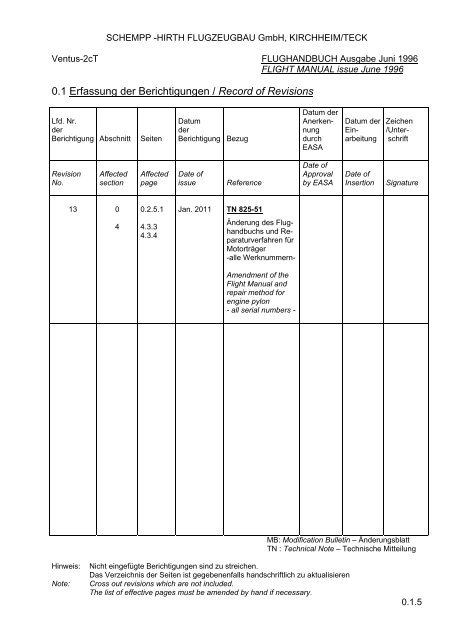

<strong>0.1</strong> <strong>Erfassung</strong> <strong>der</strong> <strong>Berichtigungen</strong> / <strong>Record</strong> <strong>of</strong> <strong>Revisions</strong><br />

Lfd. Nr.<br />

<strong>der</strong><br />

Berichtigung Abschnitt<br />

Seiten<br />

Datum<br />

<strong>der</strong><br />

Berichtigung<br />

Bezug<br />

Datum <strong>der</strong><br />

Anerkennung<br />

durch<br />

EASA<br />

Datum <strong>der</strong><br />

Einarbeitung<br />

Zeichen<br />

/Unterschrift<br />

Revision<br />

No.<br />

Affected<br />

section<br />

Affected<br />

page<br />

Date <strong>of</strong><br />

issue<br />

Reference<br />

Date <strong>of</strong><br />

Approval<br />

by EASA<br />

Date <strong>of</strong><br />

Insertion<br />

Signature<br />

13 0<br />

4<br />

0.2.5.1<br />

4.3.3<br />

4.3.4<br />

Jan. 2011 TN 825-51<br />

Än<strong>der</strong>ung des Flughandbuchs<br />

und Reparaturverfahren<br />

für<br />

Motorträger<br />

-alle Werknummern-<br />

Amendment <strong>of</strong> the<br />

Flight Manual and<br />

repair method for<br />

engine pylon<br />

- all serial numbers -<br />

MB: Modification Bulletin – Än<strong>der</strong>ungsblatt<br />

TN : Technical Note – Technische Mitteilung<br />

Hinweis:<br />

Note:<br />

Nicht eingefügte <strong>Berichtigungen</strong> sind zu streichen.<br />

Das Verzeichnis <strong>der</strong> Seiten ist gegebenenfalls handschriftlich zu aktualisieren<br />

Cross out revisions which are not included.<br />

The list <strong>of</strong> effective pages must be amended by hand if necessary.<br />

<strong>0.1</strong>.5

SCHEMPP-HIRTH FLUGZEUGBAU GmbH., KIRCHHEIM/TECK<br />

Ventus-2cT<br />

FLIGHT MANUAL<br />

(4) a) Check fuselage for damage, especially on its lower side<br />

b) Check that the STATIC pressure ports for the ASI on the<br />

tail boom (0.8 m /2.62 ft forward <strong>of</strong> the base <strong>of</strong> the fin) and<br />

below the spar stub cut-out are clear<br />

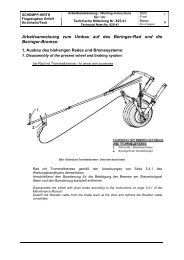

Visual inspection <strong>of</strong> the power plant<br />

CAUTION: IGNITION TO BE SWITCHED OFF !<br />

c) Check – while power plant extends – that the tip <strong>of</strong> the prop blade<br />

pointing to the front has sufficient clearance to the rim <strong>of</strong><br />

the engine compartment (blade must not get jammed below the<br />

rim)<br />

d) Check propeller for damage and ease <strong>of</strong> movements.<br />

Being in the lowermost position, each blade must unfold automatically,<br />

otherwise the bolt at the blade root should be lubricated<br />

e) Check power plant for loose bolts and nuts, check all locks and<br />

stops<br />

f) Check exhaust system and engine pylon for damage and cracks,<br />

especially at the welding joints. The area around the lower engine<br />

suspension must be checked thoroughly, see picture below. If<br />

necessary, the engine pylon should be cleaned with a cloth in this<br />

area. If necessary a torch should be used for the check.<br />

Check this area also<br />

from the rear side<br />

Check the vertical<br />

tube from every side<br />

Note: For better illustration the front plug connector is removed.<br />

January 2011 TN 825-51 approved<br />

Revision 13 4.3.3

SCHEMPP-HIRTH FLUGZEUGBAU GmbH., KIRCHHEIM/TECK<br />

Ventus-2cT<br />

FLIGHT MANUAL<br />

(4) a) Check fuselage for damage, especially on its lower side<br />

b) Check that the STATIC pressure ports for the ASI on the<br />

tail boom (0.8 m /2.62 ft forward <strong>of</strong> the base <strong>of</strong> the fin) and<br />

below the spar stub cut-out are clear<br />

Visual inspection <strong>of</strong> the power plant<br />

Completely extend the power plant with the manual operation switch<br />

CAUTION: IGNITION TO BE SWITCHED OFF !<br />

c) Check – while power plant extends – that the tip <strong>of</strong> the prop blade<br />

pointing to the front has sufficient clearance to the rim <strong>of</strong><br />

the engine compartment (blade must not get jammed below the<br />

rim)<br />

d) Check propeller for damage and ease <strong>of</strong> movements.<br />

Being in the lowermost position, each blade must unfold automatically,<br />

otherwise the bolt at the blade root should be lubricated<br />

e) Check power plant for loose bolts and nuts, check all locks and<br />

stops<br />

f) Check exhaust system and engine pylon for damage and cracks,<br />

especially at the welding joints. The area around the lower engine<br />

suspension must be checked thoroughly, see picture below. If<br />

necessary, the engine pylon should be cleaned with a cloth in this<br />

area. If necessary a torch should be used for the check.<br />

Check this area also<br />

from the rear side<br />

Check the vertical<br />

tube from every side<br />

Note: For better illustration the front plug connector is removed.<br />

January 2011 TN 825-51 approved<br />

Revision 13 TN 825-42 4.3.3

SCHEMPP-HIRTH FLUGZEUGBAU GmbH., KIRCHHEIM/TECK<br />

Ventus-2cT<br />

FLIGHT MANUAL<br />

(4) (continued)<br />

g) Check components, lines, hoses, pipes and wires etc. for<br />

chafing marks<br />

h) Check condition, function and tension <strong>of</strong> engine arresting cables,<br />

engine door operating cables and door actuating mechanism<br />

i) Check that the retaining springs are hooked up to the engine<br />

arresting wires<br />

j) Pull back decompression handle and hold – prop must rotate freely.<br />

Release handle and check that the actuating lever on the pylon<br />

returns to its stop.<br />

The gap between the decompression valve interconnecting link and<br />

the actuating lever on the pylon must be at least 2.0 mm (0.08 in.)<br />

(5) a) Check condition <strong>of</strong> tail skid or wheel. If the latter is installed,<br />

check tire pressure:<br />

2.0 bar / 29 psi (see placard)<br />

b) Should a total energy compensation probe be used, mount it<br />

and check the line (when blowing gently from the front to the probe<br />

with pneumatic valve for the TEK probe set at “Power <strong>of</strong>f”, the<br />

variometer(s) connected should read “climb”)<br />

c) Check that the fin-mounted PITOT tube is clear.<br />

When blowing gently into this probe, the ASI must register<br />

(with pneumatic valve for the pitot pressure set at “Power <strong>of</strong>f”)<br />

d) Check that the opening for the fuel tank vent line<br />

(at the upper end <strong>of</strong> the fin) is clear<br />

Should a water ballast fin tank be installed (option):<br />

e) Check that the fin tank spill holes are clear<br />

f) Check water ballast level in fin tank (in case <strong>of</strong> doubt,<br />

discharge ballast)<br />

g) Check that the dump hole for the fin tank in the tail wheel<br />

fairing (if installed) is clear<br />

January 2011 TN 825-51 approved<br />

Revision 13 4.3.4