canopy - Schempp-Hirth Flugzeugbau GmbH

canopy - Schempp-Hirth Flugzeugbau GmbH

canopy - Schempp-Hirth Flugzeugbau GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

WARTUNGSHANDBUCH / MAINTENANCE MANUAL<br />

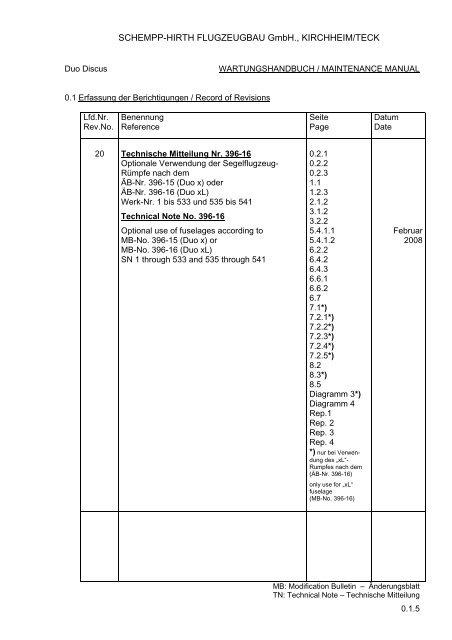

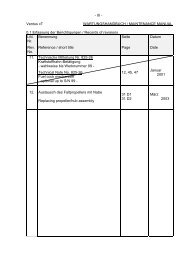

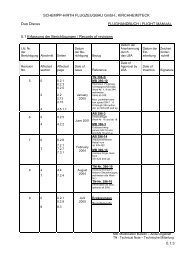

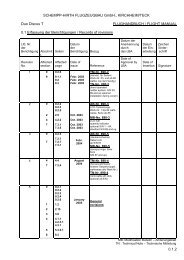

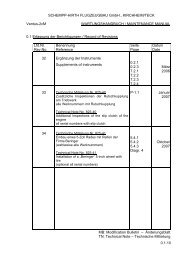

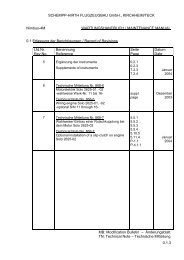

0.1 Erfassung der Berichtigungen / Record of Revisions<br />

Lfd.Nr.<br />

Rev.No.<br />

Benennung<br />

Reference<br />

Seite<br />

Page<br />

Datum<br />

Date<br />

20 Technische Mitteilung Nr. 396-16<br />

Optionale Verwendung der Segelflugzeug-<br />

Rümpfe nach dem<br />

ÄB-Nr. 396-15 (Duo x) oder<br />

ÄB-Nr. 396-16 (Duo xL)<br />

Werk-Nr. 1 bis 533 und 535 bis 541<br />

Technical Note No. 396-16<br />

Optional use of fuselages according to<br />

MB-No. 396-15 (Duo x) or<br />

MB-No. 396-16 (Duo xL)<br />

SN 1 through 533 and 535 through 541<br />

0.2.1<br />

0.2.2<br />

0.2.3<br />

1.1<br />

1.2.3<br />

2.1.2<br />

3.1.2<br />

3.2.2<br />

5.4.1.1<br />

5.4.1.2<br />

6.2.2<br />

6.4.2<br />

6.4.3<br />

6.6.1<br />

6.6.2<br />

6.7<br />

7.1*)<br />

7.2.1*)<br />

7.2.2*)<br />

7.2.3*)<br />

7.2.4*)<br />

7.2.5*)<br />

8.2<br />

8.3*)<br />

8.5<br />

Diagramm 3*)<br />

Diagramm 4<br />

Rep.1<br />

Rep. 2<br />

Rep. 3<br />

Rep. 4<br />

*) nur bei Verwendung<br />

des „xL“-<br />

Rumpfes nach dem<br />

(ÄB-Nr. 396-16)<br />

only use for „xL“<br />

fuselage<br />

(MB-No. 396-16)<br />

Februar<br />

2008<br />

MB: Modification Bulletin – Änderungsblatt<br />

TN: Technical Note – Technische Mitteilung<br />

0.1.5

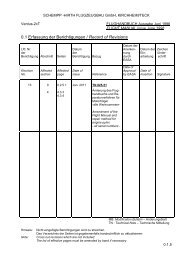

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

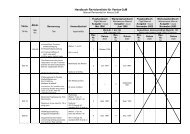

1. Description of components and systems<br />

Further descriptions and assembly are provided on sections 1.4, 1.5, 4.2 and<br />

7 of the Flight Manual.<br />

1.1 Airframe<br />

The “Duo Discus ” is a two-seat sailplane for advanced training and crosscountry<br />

flying, constructed from fiber reinforced plastic (FRP), featuring a<br />

T-tail (with fixed horizontal stabilizer and elevator).<br />

Wing<br />

The wing shells are a glass and carbon fiber/foam-sandwich with spar<br />

flanges made from carbon fiber rovings and shear webs constructed as a<br />

glass fiber/foam-sandwich.<br />

Fuselage<br />

This is a pure carbon fiber (CFRP) lay-up with a aramid fiber reinforcement in<br />

the cockpit area for high energy absorbtion.<br />

Horizontal tailplane<br />

The horizontal tailplane consists of a fixed stabilizer with elevator.<br />

The stabilizer is a GFRP/CFRP/foam-sandwich, the elevator halves are a<br />

pure carbon fiber lay-up.<br />

Vertical tail<br />

Both fin and rudder are constructed as a glass fiber/foam-sandwich.<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-15 (x / xL) 1.1

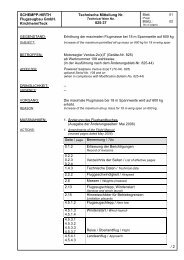

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

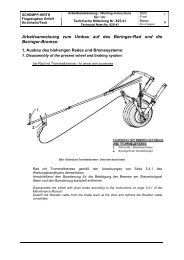

Undercarriage with wheel brake<br />

Steel push-pull tubes connect the u/c operating handles in the cockpit (which<br />

are guided in a gate) to the actuating arm on the rear pivot shaft of the u/c<br />

assembly. A gas strut on the u/c assists in retracting the wheel.<br />

For “wheel up”, the travel of the u/c operating tube in the cockpit is restricted<br />

by the actuating arm resting against the steel tube center frame; for “wheel<br />

down”, the extension stop is the overcentering of the rear u/c struts.<br />

Additionally the travel of the u/c operating tube in the cockpit is restricted by<br />

the gate guiding the front operating handle.<br />

The hydraulic main wheel disc brake is actuated by steel cables (running in a<br />

bowden conduit), connecting the stick mounted brake handles to the wheel<br />

brake master cylinder.<br />

A view of the undercarriage is provided in diagram 4.<br />

Water ballast system(s)<br />

For a description of the water ballast system(s) refer to section 7.9 of the<br />

Flight Manual.<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-15 (x / xL) 1.2.3

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus MAINTENANCE MANUAL<br />

170 mm<br />

[6.69 in.]<br />

TAILPLANE INCIDENCE:<br />

-2.65°<br />

WING INCIDENCE:<br />

1.5°<br />

410 mm [16.14 in.]<br />

176 mm<br />

[6.93 in.]<br />

AILERONS:<br />

Up:<br />

71 ± 5 mm<br />

[2.80 ± 0.20 in.]<br />

Down:<br />

36 ± 5 mm<br />

[1.42 ± 0.20 in.]<br />

WING SWEEPBACK:<br />

Negative sweepback of leading edge<br />

on trapezoidal inboard wing section<br />

228 ± 20 mm<br />

[8.98 ± 0.79 in.]<br />

RIGGING DATA AND<br />

CONTROL SURFACE DEFLECTIONS<br />

February 2008 MB 396-15<br />

Revision 20 TN 396-16 (x) 2.1.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus MAINTENANCE MANUAL<br />

170 mm<br />

[6.69 in.]<br />

TAILPLANE INCIDENCE:<br />

-2.65°<br />

WING INCIDENCE:<br />

1.5°<br />

410 mm [16.14 in.]<br />

176 mm<br />

[6.93 in.]<br />

AILERONS:<br />

Up:<br />

71 ± 5 mm<br />

[2.80 ± 0.20 in.]<br />

Down:<br />

36 ± 5 mm<br />

[1.42 ± 0.20 in.]<br />

WING SWEEPBACK:<br />

Negative sweepback of leading edge<br />

on trapezoidal inboard wing section<br />

228 ± 20 mm<br />

[8.98 ± 0.79 in.]<br />

RIGGING DATA AND<br />

CONTROL SURFACE DEFLECTIONS<br />

February 2008 TN 396-12 / MB 396-15<br />

Revision 20 TN 396-16 (x) 2.1.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

• Tow release mechanism(s)<br />

Checks should be carried out in accordance with the<br />

“Operating & Maintenance Instructions for the TOST tow Release Mechanism(s)”<br />

- see also section 9 “Service Instructions”.<br />

• Instruments<br />

In the case of all installed instruments and equipment, the instructions of<br />

the relevant manufacturer should be followed.<br />

• Safety harness<br />

At present the service time of the webbing on the restraint systems<br />

available is limited to twelve (12) years including the time of storage.<br />

See also the service instructions provided by the relevant manufacturer.<br />

• Gas strut<br />

A tension gas strut is attached to the U/C.<br />

The rod of the gas strut must always be perfectly clean and must not be<br />

damaged in any way whatsoever.<br />

If oil has escaped through the seal, the gas strut must be replaced.<br />

February 2008<br />

Revision 20 TN-No. 396-16 (x / xL) 3.1.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

After cleaning the entire aircraft, the following checks should be made:<br />

• Check the aircraft externally for damage such as cracks, holes, scratches,<br />

buckling and delamination.<br />

If the outer layer(s) of a component, constructed as a sandwich, has been<br />

damaged, then the inner skin must be checked as well.<br />

It is recommended to call upon expert assistance.<br />

• All fittings which are mounted on GFRP (CFRP) structures must be<br />

checked to confirm there has been no movement.<br />

Check also the CFRP (GFRP) structure at the fittings for cracks, white<br />

spots and delamination.<br />

• Check all accessible metal parts for damage.<br />

It is generally found, however, that if the aircraft is operated correctly, no<br />

damage will have occured.<br />

If repairs are necessary, then the manufacturer’s recommendations<br />

should be followed.<br />

• Check all accessible metal parts such as fittings, control rods (push/pull<br />

tubes) and actuating levers for corrosion.<br />

If necessary, remove the rust, clean thoroughly and apply a fresh corrosion<br />

protection.<br />

The special primer and paint for this surface protection may be obtained<br />

from <strong>Schempp</strong>-<strong>Hirth</strong> <strong>Flugzeugbau</strong> <strong>GmbH</strong>.<br />

• Linkage for attaching and locking the <strong>canopy</strong><br />

Check linkage attaching/detaching and locking/opening the <strong>canopy</strong> for<br />

any damage.<br />

Check guides for locking rod on <strong>canopy</strong> frame, locating pins on fuselage<br />

and front GFRP hinge for delamination/cracks. Check rear metal hinge for<br />

deformation.<br />

February 2008<br />

Revision 20 TN-No. 396-16 (x / xL) 3.2.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

5.4 Main wheel with hydraulic disc brake<br />

Main wheel TOST:<br />

When removing the main wheel to clean and grease it, first remove the two<br />

bolts attaching the brake back plate to the brake cylinder, then remove brake<br />

calliper (hydraulic pressure hose remains attached).<br />

Disassemble the attachment bolt of the brake shield on the inner side of the<br />

swinging arm.<br />

Next remove cotter pin and castle nut from one side of the wheel axle and<br />

withdraw the latter. Take out spacer on the ride side of the wheel and remove<br />

the wheel (take care that no washers, spacers or bushings get lost).<br />

Prior to re-assembly, clean all parts and lubricate bearings, bushings and the<br />

axle.<br />

Observe the instructions provided by the supplier of the wheel,<br />

TOST company, Munich, Germany<br />

Main wheel BERINGER<br />

Observe the instructions provided by the supplier of the wheel,<br />

BERINGER company, Chǎtelneuf, France.<br />

NOTE: Do not disconnect the hydraulic pressure hose from the brake<br />

cylinder and do not actuate the wheel brake while brake calliper is<br />

removed from the brake disc.<br />

The hydraulic wheel brake may be actuated by the handle provided at the<br />

control sticks.<br />

Front wheel-brake:<br />

The Bowden cable is directly connected with the actuating segment of the<br />

brake master cylinder.<br />

Rear wheel-brake:<br />

The Bowden cable is connected to the attachment of the brake master<br />

cylinder. The tube of the Bowden cable fits to the actuating segment of the<br />

brake master cylinder and actuates the actuating segment when the rear<br />

wheel brake is applied.<br />

Whenever a reduced effectiveness of the wheel brake is observed,<br />

see page 5.4.1.2.<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-16 (x / xL) 5.4.1.1

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

In case of reduced effectiveness of the wheel brake<br />

1. Check brake pads:<br />

If the thickness of the brake pads is less then 1.5 to 2mm replace brake pads.<br />

Therefore both parts of the brake calliper have to be removed.<br />

2. Check leak tightness of the hydraulic-system.<br />

3. Check brake fluid:<br />

a) Remove front seat pan<br />

b) Remove cover of brake fluid-container<br />

c) If necessary refill missing brake fluid and bleed the braking system as<br />

described on page 5.4.2<br />

d) Check effectiveness of the wheel brake. Afterwards reassemble the<br />

disassembled parts<br />

4. Readjustment of the Bowden cables:<br />

Note:<br />

a) The Bowden cables may be readjusted at the adjustment<br />

point at the control stick until the gap between the<br />

actuating segment on the brake master cylinder and the<br />

cylinder case is about 1.0 mm (0.04 in). To do this the<br />

wheel brake has to be relieved.<br />

To check the readjustment pull the brake handle several<br />

times. With relieved wheel brake:<br />

i) the wheel can still be rotated by hand<br />

ii)<br />

it has still to be possible to push the brake<br />

calliper back in direction to the wheel by hand<br />

b) Check the function of the wheel brake after assembling<br />

the seat pan<br />

Normally the brake system has to be bleeded, if the fuselage is stored inverted!<br />

If the brake handle is fixed in pulled position during the inverted storage of the<br />

fuselage, the bleeding of the brake system usually is not necessary<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-16 (x / xL) 5.4.1.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

Datum plane:<br />

Aircraft attitude:<br />

Wing leading edge at root rib<br />

Tail jacked up such that a wedge-shaped<br />

block, 100 : 4.5, placed on the rear top<br />

fuselage, is horizontal along its upper<br />

edge.<br />

Distance main wheel: a = 8 mm (0.31 in.)<br />

Distance tail wheel:<br />

Distance skid:<br />

b = 5322 mm (209.53 in.)<br />

b = 5357 mm (210.91 in.)<br />

Empty mass c/g position:<br />

x =<br />

W 2<br />

x b<br />

W<br />

+ a<br />

C/G position in flight:<br />

(just given for the case that the “c/g position in flight” is to be determined by<br />

weighing rather than by computing it on the basis of the empty mass c/g position)<br />

The aircraft is to be weighed fully equipped (crew with parachutes and<br />

complete outfit incl. barograph, cushions, cameras etc.) Seat back and rudder<br />

pedals should be correctly adjusted for this purpose.<br />

x =<br />

W 2 loaded<br />

x b<br />

W empty<br />

+ W disposable<br />

+ a<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-16 (x / xL) 6.2.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

Forward c/g limits: With a maximum seat load of 110 kg (242.5 lb)<br />

on either seat and with maximum permitted water<br />

ballast<br />

Rearward c/g limits: With various minimum loads on the front seat<br />

(allowance for 5.0 kg / 11.02 lb baggage already<br />

made)<br />

To facilitate the checking of the empty mass center of gravity, the table<br />

below shows – at different empty mass values – the maximum permissible<br />

load on the tail wheel, with various loads on the front seat and in<br />

relation to the most rearward c/g position.<br />

The actual load on the tail wheel is determined with the aircraft in<br />

weighing attitude, i.e. main wheel on the ground and tail jacked up as<br />

described on page 6.2.1.<br />

If the load on the tail wheel does not exceed the corresponding value in<br />

the table, the center of gravity is within the permitted range.<br />

Empty mass<br />

Load on tail wheel (or skid) with a minimum seat load of:<br />

70 154 75 165 80 176 85 187 90 198<br />

kg lb kg lb kg lb kg lb kg lb kg lb<br />

410 904 39.7 87.5 41.2 90.8 42.8 94.4 44.3 97.7 45.9 101.2<br />

420 926 40.1 88.4 41.7 91.9 43.2 95.3 44.8 98.8 46.3 102.1<br />

430 948 40.6 89.5 42.1 92.8 43.7 96.4 45.2 99.7 46.8 103.2<br />

440 970 41.1 90.6 42.6 93.9 44.2 97.5 45.7 100.8 47.3 104.3<br />

450 992 41.5 91.5 43.1 95.0 44.6 98.3 46.2 101.9 47.7 105.2<br />

460 1014 42.0 92.6 43.5 95.9 45.1 99.4 46.6 102.8 48.2 106.3<br />

470 1036 42.4 93.5 44.0 97.0 45.5 100.3 47.1 103.9 48.6 107.2<br />

480 1058 42.9 94.6 44.4 97.9 46.0 101.4 47.5 104.7 49.1 108.3<br />

490 1080 43.3 95.5 44.9 99.0 46.4 102.3 48.0 105.8 49.5 109.1<br />

500 1103 43.8 96.6 45.3 99.9 46.9 103.4 48.4 106.7 50.0 110.3<br />

Note:<br />

Should a tail skid be fitted (instead of a tail wheel), the above values are<br />

to be multiplied by a factor of 0.993).<br />

February 2008 MB-No. 396-15<br />

Revision 20 TN-No. 396-16 (x) 6.4.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

Empty mass c/g range<br />

in. mm<br />

23.62 600<br />

23.23 590<br />

22.83 580<br />

22.44 570<br />

22.05 560<br />

21.65 550<br />

21.26 540<br />

20.87 530<br />

20.47 520<br />

90kg<br />

198lb<br />

85kg<br />

187lb<br />

20.08 510<br />

19.69 500<br />

19.29 490<br />

18.90 480<br />

18.50 470<br />

80kg<br />

176lb<br />

75kg<br />

165lb<br />

70kg<br />

154lb<br />

18.11 460<br />

17.72 450<br />

17.32 440<br />

FOREMOST EMPTY<br />

MASS C/G POS.<br />

16.93 430<br />

EMPTY MASS (kg / lb)<br />

500<br />

1103<br />

kg<br />

lb<br />

February 2008 MB-No. 396-15<br />

Revision 20 TN-No. 396-16 (x) 6.4.3

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

6.6 Useful load<br />

Load on the seats<br />

a) Water ballast fin tank not installed<br />

Note:<br />

(*) Depending on its equipment and the installation of fixed trim ballast, the actual<br />

minimum and/or maximum seat loads of this “Duo Discus” (to which this manual<br />

refers) may differ from the above typical weights.<br />

The placards in the cockpit must always show the actual weights, which are also<br />

to be entered in the log chart – see flight manual, page 6.2.3.<br />

Neither the maximum permitted all-up mass nor the maximum mass of the non-lifting<br />

parts must be exceeded.<br />

Determination of the maximum permitted load on the seats:<br />

Flown solo:<br />

Two occupants:<br />

SEAT<br />

LOAD<br />

front<br />

seat load<br />

rear<br />

seat load<br />

LOAD ON THE SEATS<br />

(crew incl. parachutes)<br />

TWO PERSONS<br />

min. max.<br />

70* kg<br />

154* lb<br />

at choice<br />

Maximum cockpit seatload<br />

110* kg<br />

243* lb<br />

110* kg<br />

243* lb<br />

Always 110 kg (242.5 lb)<br />

ONE PERSON<br />

min. max.<br />

70* kg<br />

154* lb<br />

110* kg<br />

243* lb<br />

Maximum cockpit load (load on both seats) may not be<br />

exceeded. For seat loads below the placarded minimum<br />

refer to Flight manual - section 6.2<br />

The total of the loads on front and rear seat has to be lower<br />

than the maximum cockpit seatload.<br />

At the same time pay attention, that the load on each seat<br />

stays below 110 kg (242.5 lb)<br />

Maximum seat load: This is the difference between the maximum permitted mass of<br />

the non-lifting parts (440 kg / 970 lb) and their actual mass<br />

(refer to last weighing report).<br />

b) Water ballast fin tank installed<br />

Note:<br />

SEAT<br />

LOAD<br />

front<br />

seat load<br />

rear<br />

seat load<br />

LOAD ON THE SEATS<br />

(crew incl. parachutes)<br />

TWO PERSONS<br />

min. max.<br />

100 **<br />

220 kg 100 **<br />

*<br />

** lb 110*<br />

243* kg 220 *<br />

kg<br />

** lb<br />

( 70* kg)<br />

lb ( 70* kg)<br />

(154* lb)<br />

(154* lb)<br />

110*<br />

at choice<br />

243* kg<br />

lb<br />

Maximum cockpit seatload<br />

ONE PERSON<br />

min. max.<br />

110*<br />

243* kg<br />

lb<br />

Maximum cockpit load (load on both seats) may not be<br />

exceeded. For seat loads below the placarded minimum refer<br />

to Flight manual - section 6.2. The value shown in parenthesis<br />

may be used after having thoroughly checked the ballast<br />

quantity in the fin tank and the appropriate loading chart.<br />

(*) Depending on its equipment and the installation of fixed trim ballast, the actual<br />

minimum and/or maximum seat loads of this “Duo Discus” (to which this manual<br />

refers) may differ from the above typical weights.<br />

If so, the log charts and the placards must be altered accordingly.<br />

(**) 1. For safety reasons the minimum seat load for flights with empty fin tank must<br />

be increased by 30 kg (66 lb) so as to allow for an unnoticed filled fin tank.<br />

2. Adding the mass of 30 kg (66 lb) is not required, however, if the pilot either<br />

- dumps all water ballast (prior to take off)<br />

or<br />

- determines the ballast quantity in the fin tank and ensures that it is<br />

compensated by an appropriate load in the wing tanks and/or on the<br />

aft seat.<br />

The placards in the cockpit must always show the actual weights (including those<br />

allowing for a filled fin tank **), which are also to be entered in the log chart – see<br />

flight manual, page 6.2.3.<br />

Neither the maximum permitted all-up mass nor the maximum mass of the non-lifting<br />

parts must be exceeded.<br />

February 2008 MB-No. 396-15 / TN-No. 396-13<br />

Revision 20 TN-No. 396-16 (x)<br />

6.6.1

Duo Discus<br />

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

MAINTENANCE MANUAL<br />

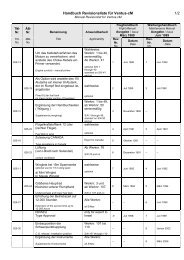

For establishing a "Weight & Balance Report" the following lever arms<br />

are to be used:<br />

Trim ballast under front instrument<br />

panel<br />

Trim ballast on right hand side of<br />

front control stick mounting frame<br />

Pilot, front seat (with parachute or<br />

back cushion)<br />

Pilot, rear seat (with parachute or<br />

back cushion)<br />

Battery at rear control stick<br />

mounting frame<br />

Center of gravity of:<br />

2055 mm forward of datum<br />

80.91 in.<br />

1855 mm forward of datum<br />

73.03 in.<br />

1400 mm forward of datum<br />

55.12 in.<br />

290 mm forward of datum<br />

11.42 in.<br />

680 mm forward of datum<br />

26.77 in.<br />

Main wheel 8 mm aft of datum<br />

0.31 in<br />

Waterballast, wings 65 mm aft of datum<br />

2.56 in.<br />

Tail wheel 5330 mm aft of datum<br />

209.84 in.<br />

Tail skid 5365 mm aft of datum<br />

211.22 in.<br />

Water ballast, fin 5320 mm aft of datum<br />

209.45 in.<br />

Baggage 1000 mm aft of datum<br />

39.37 in.<br />

February 2008 MB-No. 396-15<br />

Revision 20 TN-No. 396-16<br />

6.6.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

6.7 Mass – C/G diagram<br />

lb<br />

kg<br />

1543 700<br />

MAXIMUM ALL-UP MASS<br />

1433 650<br />

ALL - UP MASS (kg / lb)<br />

1378 625<br />

1323 600<br />

1257 570<br />

1213 550<br />

1135 515<br />

FORE MOST C/G POSITION<br />

PERMITTED<br />

RANGE<br />

REARMOST C/G POSITION<br />

1102 500<br />

1038 471<br />

mm<br />

in.<br />

X (mm / in.) aft of datum<br />

in flight<br />

February 2008 MB 396-15<br />

Revision 20 TN 396-16 (x) 6.7

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

MAINTENANCE MANUAL<br />

without fin tank<br />

LOAD ON THE SEATS<br />

(crew incl. parachutes)<br />

SEAT LOAD TWO PERSONS ONE PERSON<br />

min. max. min. max.<br />

front<br />

seat load<br />

rear<br />

seat load<br />

70* kg<br />

154* lb<br />

at<br />

choice<br />

110* kg<br />

243* lb<br />

110* kg<br />

243* lb<br />

70* kg<br />

154* lb<br />

110* kg<br />

243* lb<br />

Maximum cockpit seat load 220* kg / 485* lb<br />

Maximum cockpit load (load on both seats) may not<br />

be exceeded. For seat loads below the placarded<br />

minimum refer to Flight manual - section 6.2.<br />

(if installed)<br />

fin tank installed<br />

LOAD ON THE SEATS<br />

(crew incl. parachutes)<br />

SEAT LOAD TWO PERSONS ONE PERSON<br />

min. max. min. max.<br />

100* kg<br />

100* kg<br />

front 220* lb 110* kg 220* lb 110* kg<br />

seat load ( 70* kg) 243* lb ( 70* kg) 243* lb<br />

(154* lb)<br />

(154* lb)<br />

rear<br />

seat load<br />

at<br />

choice<br />

110* kg<br />

243* lb<br />

Maximum cockpit seat load 220* kg / 485* lb<br />

Maximum cockpit load (load on both seats) may not<br />

be exceeded. For seat loads below the placarded<br />

minimum refer to Flight manual - section 6.2.<br />

The value shown in parenthesis may be used after<br />

having thoroughly checked the ballast quantity in the<br />

fin tank and the appropriate loading chart.<br />

Placing:<br />

Cockpit inner skin on<br />

the right for either seat<br />

WHEN FLOWN SOLO, THE PLACARDED<br />

MINIMUM FRONT SEAT LOAD MAY BE<br />

REDUCED BY UP TO:<br />

NUMBER OF LEAD<br />

PLATES REQUIRED<br />

- 05 kg (11 lb) 1<br />

- 10 kg (22 lb) 2<br />

- 15 kg (33 lb) 3<br />

Cockpit inner skin on the right<br />

(front seat only)<br />

- 20 kg (44 lb) 4<br />

- 25 kg (55 lb) 5<br />

- 30 kg (66 lb) 6<br />

LOCKING PIN FLUSH<br />

WITH UPPER SURFACE<br />

Locking device for outbd. wing panels<br />

Outbd. end of main wing panels<br />

February 2008 MB-No. 396-15 / TN-No. 396-13<br />

Revision 20 TN-No. 396-16 (x) 8.2

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus MAINTENANCE MANUAL<br />

Placing:<br />

Locking of <strong>canopy</strong><br />

On red locking lever on the left,<br />

provided for either seat<br />

(if installed)<br />

Ballast in fin tank is dumped<br />

simultaneously with wing tanks<br />

Operating knob for dumping<br />

ballast from wing tanks<br />

Front seat above guide slot for operating<br />

knob on cockpit inner skin on the right<br />

Air quantity<br />

Next to operating knob protruding<br />

from front instrument panel<br />

push<br />

pull<br />

Airstream direction<br />

Next to operating knob protruding<br />

from front instrument panel<br />

C A N O P Y<br />

attachment / detachment<br />

Canopy<br />

attachment/detachment<br />

Above operating handle on<br />

cockpit inner skin on the right<br />

for either seat<br />

February 2008 MB 396-15<br />

Revision 20 TN 396-16 (x) 8.5

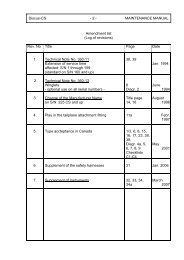

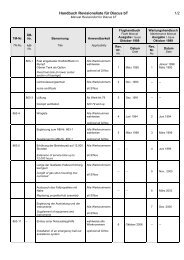

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus T MAINTENANCE MANUAL<br />

UNDERCARRIAGE WITH RETRACTING LINKAGE<br />

AND HYDRAULIC DISC BRAKE<br />

1. Front retracting linkage<br />

2. Rear retracting linkage<br />

3. Brake handle on front control stick<br />

4. Brake handle on rear control stick<br />

5. Brake master cylinder with reservoir<br />

February 2008 MB 396-15<br />

Revision 20 TN 396-16 (x) DIAGRAM 4

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

REPAIR INSTRUCTIONS<br />

REPAIR INSTRUCTIONS FOR „Duo Discus “<br />

The components of this aircraft are constructed as follows:<br />

1. Inboard wing panels<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 8 mm (0.31 in.)<br />

Wing tip extension<br />

GFRP/foam-sandwich,<br />

with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

2. Ailerons<br />

Inboard: GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 4 mm (0.16 in.)<br />

Outboard:<br />

Pure GFRP/CFRP-shell<br />

3. Fuselage<br />

Forward section: Pure CFRP/Kevlar/GFRP-shell<br />

Aft section:<br />

Pure CFRP-shell<br />

4. Fin<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

5. Rudder<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 4 mm (0.16 in.)<br />

6. Horizontal stabilizer<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

7. Elevator halves<br />

Pure CFRP-shell<br />

February 2008<br />

Revision 20 TN-No. 396-16 (x + xL) - 1 -

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

REPAIR INSTRUCTIONS<br />

REPAIR INSTRUCTIONS FOR „Duo Discus “<br />

The components of this aircraft are constructed as follows:<br />

1. Inboard wing panels<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 8 mm (0.31 in.)<br />

Wing tip extension<br />

GFRP/foam-sandwich,<br />

with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

with winglets<br />

Pure GFRP/CFRP-shell<br />

2. Ailerons<br />

Inboard: GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 4 mm (0.16 in.)<br />

Outboard:<br />

Pure GFRP/CFRP-shell<br />

3. Fuselage<br />

Forward section: Pure CFRP/Kevlar/GFRP-shell<br />

Aft section:<br />

Pure CFRP-shell<br />

4. Fin<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

5. Rudder<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 4 mm (0.16 in.)<br />

6. Horizontal stabilizer<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

7. Elevator halves<br />

Pure CFRP-shell<br />

February 2008 TN-No. 396-12<br />

Revision 20 TN-No. 396-16 (x + xL) - 1 -

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

REPAIR INSTRUCTIONS<br />

REPAIR INSTRUCTIONS FOR „Duo Discus “<br />

The components of this aircraft are constructed as follows:<br />

1. Inboard wing panels<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 8 mm (0.31 in.)<br />

Wing tip extension<br />

GFRP/foam-sandwich,<br />

with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

with winglets<br />

Pure GFRP/CFRP-shell<br />

2.a Ailerons<br />

Inboard: GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 4 mm (0.16 in.)<br />

Outboard:<br />

Pure GFRP/CFRP-shell<br />

2.b Trailing edge flap<br />

GFRP/foam-sandwich,<br />

with HEREX C 70.55,<br />

thickness 4 mm (0.16 in.)<br />

3. Fuselage<br />

Forward section: Pure CFRP/Kevlar/GFRP-shell<br />

Aft section:<br />

Pure CFRP-shell<br />

4. Fin<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

5. Rudder<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 4 mm (0.16 in.)<br />

6. Horizontal stabilizer<br />

GFRP/foam-sandwich, with HEREX C 70.55,<br />

thickness 6 mm (0.24 in.)<br />

7. Elevator halves<br />

Pure CFRP-shell<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-16 (x / xL) - 1 -

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

REPAIR INSTRUCTIONS<br />

The first stage in carrying out repairs on components constructed from fiber reinforced<br />

plastic (FRP) is to examine the construction of the component at the location<br />

in question and to proceed in accordance with the latest applicable issue of<br />

the<br />

„REPAIR INSTRUCTIONS FOR SCHEMPP-HIRTH SAILPLANES<br />

AND POWERED SAILPLANES CONSTRUCTED FROM FIBER<br />

REINFORCED PLASTIC“<br />

General considerations<br />

For repairs only the following resin systems must be used:<br />

1. For GFRP-components<br />

Resin Hardener Mixing proportion<br />

by weight<br />

L 285 286 or 287 100 : 38<br />

LY 5052 HY 5052 100 : 38<br />

L 335 335 or 340 100 : 38<br />

Curing : 15 hours at 50° C (122° F)<br />

2. For CFRP/AFRP components<br />

Resin Hardener Mixing proportion<br />

by weight<br />

L 285 286 or 287 100 : 38<br />

LY 5052 HY 5052 100 : 38<br />

L 335 335 or 340 100 : 38<br />

Curing : 15 hours at 55° C (131° F)<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-16 (x / xL) - 2 -

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

REPAIR INSTRUCTIONS<br />

MATERIALS (AND SUPPLIERS) FOR THE REPAIR OF CFRP-COMPONENTS<br />

Resin system: See page 2<br />

Carbon fiber cloth:<br />

(Yarn DIN 65184 CC 200 f 3000-F)<br />

Cloth 1/1 (warp equal weft)<br />

a) Weight 200 g/m²: e.g. Quality 98140 or 98141 from CS-Interglas AG, Ulm<br />

Sigratex KDL 8003 from SGL Carbon Group, Meitingen<br />

Style 450 from C. Cramer & Co., Heek-Nienborg<br />

b) Weight 285 g/m²: e.g. Quality 98160 from CS-Interglas AG, Ulm<br />

Style 475T from C. Cramer & Co., Heek-Nienborg<br />

Unidirectional<br />

carbon fiber cloth:<br />

Weight 140 g/m²<br />

(carbon fiber 120 g/m², glass fiber 20 g/m²), quality<br />

e.g. Style 763 from C. Cramer & Co., Heek-Nienborg or<br />

MDL 9001 from SGL Carbon Group, Meitingen<br />

Carbon fiber tape: (Yarn DIN 65184)<br />

e.g. Quality Sigratex KDU/NF6, 39-7.5<br />

Sigratex KDU -1001, width: 75 mm (2.95 in.)<br />

from SGL Carbon Group, Meitingen<br />

Carbon fiber / Aramid<br />

fiber (Kevlar) cloth: CF: Yarn DIN 65184 CC 200 f 3000-F<br />

AF: Yarn DIN 65427<br />

Linen cloth 1/1 (warp equals weft), weight 205 g/m²<br />

e.g. Quality 98355 from CS-Interglas AG, Ulm<br />

Carbon fiber rovings:<br />

(Yarn DIN 65184 CC 800 f 12000-F)<br />

e.g. Quality Tenax HTA 5131 800tex f 12000to<br />

from Tenax-Fibers, Wuppertal<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-16 (x / xL) - 3 -

SCHEMPP-HIRTH FLUGZEUGBAU <strong>GmbH</strong>., KIRCHHEIM/TECK<br />

Duo Discus<br />

REPAIR INSTRUCTIONS<br />

Surface coating: ● UP-Vorgelat, white, No. T 35<br />

● UP-Hardener No. SF 10<br />

● UP-Thinner No. SF<br />

from Scheufler, Stuttgart<br />

Mixing proportion by weight:<br />

100 parts UP-Vorgelat T 35 to 10 parts hardener SF 10<br />

February 2008 MB-No. 396-15 resp. MB-No. 396-16<br />

Revision 20 TN-No. 396-16 (x / xL) - 4 -