AquaFlex® Stainless Steel Sprinkler Fittings I-AQUAFLEX - Victaulic

AquaFlex® Stainless Steel Sprinkler Fittings I-AQUAFLEX - Victaulic

AquaFlex® Stainless Steel Sprinkler Fittings I-AQUAFLEX - Victaulic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSTALLATION INSTRUCTIONS<br />

I-<strong>AQUAFLEX</strong><br />

AquaFlex ® <strong>Stainless</strong> <strong>Steel</strong> <strong>Sprinkler</strong> <strong>Fittings</strong><br />

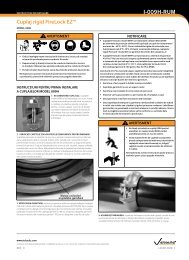

INSTALLATION FOR ASTM C645 HAT FURRING<br />

CHANNEL CEILING SYSTEMS INSTALLED IN<br />

ACCORDANCE WITH ASTM C754 STANDARDS<br />

(FM ONLY)<br />

WARNING<br />

• The flexible stainless steel hose should not be bent or<br />

fluctuated up-and-down or side-to-side when it is pressurized<br />

for test.<br />

• The flexible stainless steel hose should not be bent within<br />

2 1/2 inches/64 mm of the connection nut at both ends.<br />

Failure to follow these instructions could cause improper sprinkler<br />

operation, resulting in serious personal injury and/or property<br />

damage.<br />

3. Connect the nut of the flexible stainless steel hose to the sprinkler<br />

reducing nipple. DO NOT use pipe joint compound or Teflon*<br />

tape on the fine threads of the sprinkler reducing nipple, since the<br />

flat gasket on the end of the flexible stainless steel hose provides<br />

the leak-proof connection. Tighten the connection to a maximum<br />

torque of 15 ft-lbs/20 N•m. NOTE: To prevent damage to the seal,<br />

DO NOT exceed the specified torque on the nut.<br />

1. Apply pipe joint compound or Teflon* tape to the tapered threads<br />

of the branch line connection nipple. NOTE: DO NOT use a<br />

combination of pipe joint compound and tape. Using a pipe<br />

wrench, tighten the branch line connection nipple into the branch<br />

line.<br />

2. Connect the nut of the flexible stainless steel hose to the branch<br />

line connection nipple, as shown above. DO NOT use pipe joint<br />

compound or Teflon* tape on the threads of the branch line<br />

connection nipple, since the flat gasket on the end of the flexible<br />

stainless steel hose provides the leak-proof connection. Tighten<br />

the connection to a maximum torque of 15 ft-lbs/20 N•m. NOTE:<br />

To prevent damage to the seal, DO NOT exceed the specified<br />

torque on the nut.<br />

4. Attach the end brackets to the ASTM C645 hat furring channel<br />

ceiling system installed in accordance with ASTM C754 standards.<br />

Make sure the end brackets engage the hat furring channels,<br />

as shown above. Tighten the wing nuts loosely to maintain<br />

engagement with the hat furring channels. The wing nuts will be<br />

tightened completely in later steps.<br />

* Teflon is a registered trademark of the DuPont Company<br />

www.victaulic.com<br />

VICTAULIC AND <strong>AQUAFLEX</strong> ARE REGISTERED TRADEMARKS OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.<br />

I-<strong>AQUAFLEX</strong>_8<br />

REV_C