Technical Data - Hytek

Technical Data - Hytek

Technical Data - Hytek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Data</strong><br />

HYTEK PULS.800 FLOWMETER<br />

PULSE TRANSMITTER<br />

Applies to the following models only:<br />

- PULS.800<br />

Please read carefully before commencing installation<br />

Registered Office: HYTEK (GB) LIMITED, Delta House, Green Street, Elsenham, Bishop’s Stortford CM22 6DS UK.<br />

Registered in England No. 1915382<br />

Tel: +44 (0) 1279 815 600 Fax: +44 (0) 1279 812 978 email: info@hytekgb.com<br />

Web: www.hytekgb.com

ENVIRONMENTAL INFORMATION<br />

European Directives 2002/96/EC and 2003/108/EC require<br />

that the equipment bearing this symbol on the product an/or<br />

its packaging must not be disposed of with unsorted<br />

municipal waste. The symbol indicates that this product<br />

must be disposed of separately from regular household<br />

waste streams. It is your responsibility to dispose of this and<br />

other electric and electronic equipment via designated<br />

collection facilities appointed by the government or local<br />

authorities.<br />

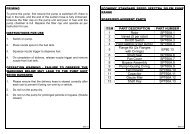

IMPORTANT WARNING NOTES<br />

1. The pulse transmitter MUST NOT be used to measure petrol<br />

or other flammable liquids.<br />

2. It is designed for use with diesel, gas oil, hydraulic oil and<br />

heating oil.<br />

3. It must not be sited adjacent to a petrol dispenser or in any<br />

other hazardous zone.<br />

4. Installation of this equipment should be carried out by a<br />

qualified fuel installation engineer.<br />

5. The installation must conform to all relevant electrical and<br />

local authority regulations and standards.<br />

PRODUCT DESCRIPTION<br />

The Pulse Transmitter utilizes advanced CMOS technology to<br />

achieve a multi-channel solution to the problems of parasitic<br />

pulsing associated with single channel pulse transmitters. The<br />

device requires minimal supply current, accepts a wide supply<br />

voltage range and has a large output current sink capacity as well<br />

as an option for volt-free output contacts via a plug in reed relay.<br />

The Pulse Transmitter has been designed to maximize the amount<br />

of disc rotation available without false generation of pulses<br />

resulting in a vast improvement over conventional single channel<br />

solutions.<br />

PULSE OUTPUT<br />

PULS.800: 10 pulses per litre<br />

S625/3<br />

2

INSTALLATION<br />

1. Remove meter front cover, dial face, register.<br />

2. Remove the bevelled pinion gear<br />

3. Place the nylon washer over the protruding gear shaft before fitting the<br />

modified bevel gear with the slotted disc fitted.<br />

4. Remove the bottom two meter bolts. See photo 1 on page 4.<br />

5. Ensure that the meter inlet/outlet ports are in the desired orientation. If<br />

not then turn the meter backplate to the desired position before<br />

proceeding.<br />

6. Fit the pulser using the M6 bolts, washers and nuts supplied. Ensure<br />

that the bracket is pushed fully downwards before tightening bolts. See<br />

photo 2 on page 4.<br />

7. Ensure the slotted disc is centrally located between the pulser emitter<br />

and receiver and does not rub on either. See photo 2 on page 4.<br />

8. Refit the register.<br />

9. Drill a 12mm hole in the meter cover in the location shown on the<br />

pulser location diagram and photo on page 5. Fit the TA.GLND as<br />

shown.<br />

10. Slide signal flex through gland leaving 140mm of flex inside the meter<br />

casing. Tighten gland and carefully refit meter front cover and dial face<br />

insuring signal flex is coiled up inside casing without being snagged or<br />

pinched.<br />

11. Connect pulser wires as per connection diagram on page 6.<br />

12. Ensure that the pulser functions correctly and check that when the<br />

meter is reset it doesn’t clock up extra pulses.<br />

S625/3<br />

3

PHOTOS<br />

PHOTO 1<br />

REMOVE METER BOLTS<br />

PHOTO 2<br />

Ensure bracket is<br />

pushed fully<br />

downwards<br />

before tightening<br />

bolts.<br />

S625/3<br />

4

PULSER LOCATION DIAGRAM<br />

PHOTO 3<br />

GLAND LOCATION<br />

S625/3<br />

5

CONNECTION DIAGRAM<br />

Black<br />

Green<br />

0V<br />

To Key System Pulse Input<br />

n<br />

Yellow<br />

Blue<br />

Screen<br />

To Key System Output OR 0V<br />

DO NOT USE<br />

Frame Ground<br />

Red<br />

V+<br />

Connect the pulse transmitter as shown in the connection diagram.<br />

The connections are rated as follows:<br />

Supply Ratings:<br />

Voltage - 5 -12V DC<br />

Current - 5 -40 mA<br />

Passive Contact Ratings:<br />

Voltage - 24V DC Max.<br />

Current - 1A Max.<br />

Power - 15W Max.<br />

NB: The pulse transmitter pulse input and output (green and<br />

yellow) wires are connected across the passive contacts of the<br />

transmitter relay. If the key system, to which the transmitter is to<br />

be connected, has only 3 wires (0 volts, +volts and “signal”) the<br />

transmitter 0V (black) and the yellow pulse wire can be linked<br />

together. The key system +volts can then be connected to +V<br />

(red), 0 volts to 0V (black) and “signal” to the green pulse wire.<br />

This will “drag” the signal down to 0 volts every pulse.<br />

S625/3<br />

6

NOTES<br />

S625/3<br />

7

E.C. DECLARATION OF CONFORMITY<br />

Date of Issue: 10 th September2009<br />

Amended: 23 rd December 2009<br />

Equipment Details:<br />

<strong>Hytek</strong> Flowmeter Pulse<br />

Transmitters<br />

PULS.800, PULS.900, PULS.FM4<br />

PULS.K33, PULS.K44<br />

Applicable Standards:<br />

Machinery Directive 2006/42/EC<br />

Waste Electrical and Electronic<br />

Equipment<br />

Regulations 2006<br />

2002/96/EC<br />

2003/108/EC<br />

Authorized By:<br />

Clive Wellings<br />

<strong>Technical</strong> Manager <strong>Hytek</strong><br />

Declaration Number:<br />

EC072<br />

S625/3<br />

8