Architect 2014-07.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

82<br />

ARCHITECT JULY <strong>2014</strong> WWW.ARCHITECTMAGAZINE.COM<br />

DESIGNLABWORKSHOP FOUNDER<br />

BRIAN PETERS BRINGS THE SIMPLE BRICK<br />

INTO THE AGE OF DIGITAL MODELING<br />

AND PARAMETRIC SCRIPTING.<br />

Three-dimensional printing has proven useful at model<br />

scale, but what about at building scale? Brian Peters, an<br />

assistant professor at Kent State University and the founder<br />

of DesignLabWorkshop, in Kent, Ohio, is tackling full-scale<br />

printing one clay brick at a time with a desktop 3D printer.<br />

Building Bytes is a project that goes beyond using new tools<br />

to make old products. Instead, it follows the additive logic<br />

of the printing path—rather than the conventional molding<br />

or extrusion process—to make bricks that are otherwise<br />

impractical or impossible to make.<br />

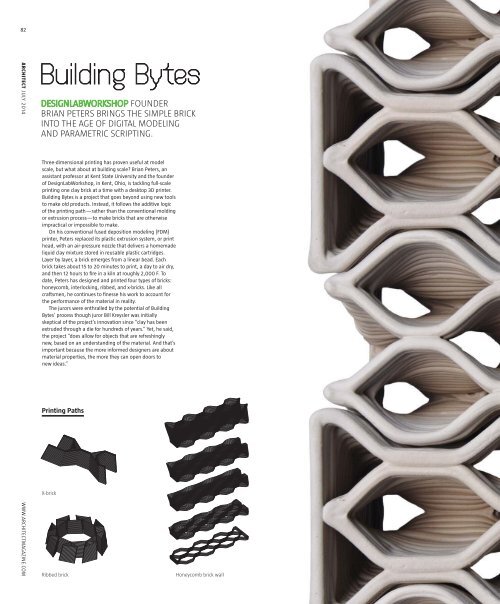

On his conventional fused deposition modeling (FDM)<br />

printer, Peters replaced its plastic extrusion system, or print<br />

head, with an air-pressure nozzle that delivers a homemade<br />

liquid clay mixture stored in reusable plastic cartridges.<br />

Layer by layer, a brick emerges from a linear bead. Each<br />

brick takes about 15 to 20 minutes to print, a day to air dry,<br />

and then 12 hours to fire in a kiln at roughly 2,000 F. To<br />

date, Peters has designed and printed four types of bricks:<br />

honeycomb, interlocking, ribbed, and x-bricks. Like all<br />

craftsmen, he continues to finesse his work to account for<br />

the performance of the material in reality.<br />

The jurors were enthralled by the potential of Building<br />

Bytes’ process though juror Bill Kreysler was initially<br />

skeptical of the project’s innovation since “clay has been<br />

extruded through a die for hundreds of years.” Yet, he said,<br />

the project “does allow for objects that are refreshingly<br />

new, based on an understanding of the material. And that’s<br />

important because the more informed designers are about<br />

material properties, the more they can open doors to<br />

new ideas.”<br />

Printing Paths<br />

X-brick<br />

Ribbed brick<br />

Honeycomb brick wall