Disogrin® LSU Seals - Simrit

Disogrin® LSU Seals - Simrit

Disogrin® LSU Seals - Simrit

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

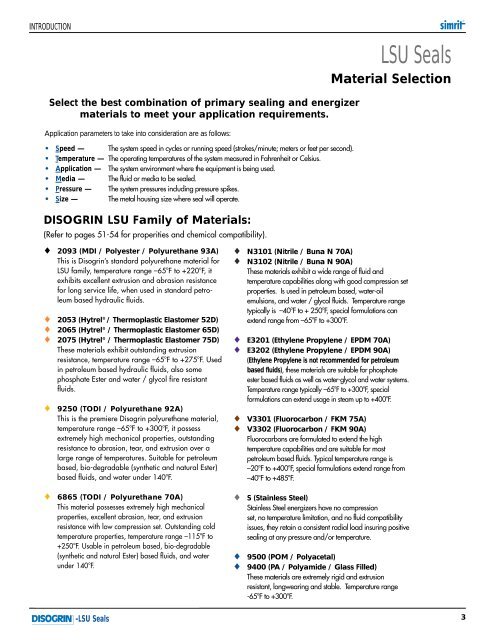

INTRODUCTION<br />

<strong>LSU</strong> <strong>Seals</strong><br />

Material Selection<br />

Select the best combination of primary sealing and energizer<br />

materials to meet your application requirements.<br />

Application parameters to take into consideration are as follows:<br />

• Speed — The system speed in cycles or running speed (strokes/minute; meters or feet per second).<br />

• Temperature — The operating temperatures of the system measured in Fahrenheit or Celsius.<br />

• Application — The system environment where the equipment is being used.<br />

• Media — The fluid or media to be sealed.<br />

• Pressure — The system pressures including pressure spikes.<br />

• Size — The metal housing size where seal will operate.<br />

DISOGRIN <strong>LSU</strong> Family of Materials:<br />

(Refer to pages 51-54 for properities and chemical compatibility).<br />

◆ 2093 (MDI / Polyester / Polyurethane 93A)<br />

This is Disogrin’s standard polyurethane material for<br />

<strong>LSU</strong> family, temperature range –65 o F to +220 o F, it<br />

exhibits excellent extrusion and abrasion resistance<br />

for long service life, when used in standard petroleum<br />

based hydraulic fluids.<br />

◆ 2053 (Hytrel ® / Thermoplastic Elastomer 52D)<br />

◆ 2065 (Hytrel ® / Thermoplastic Elastomer 65D)<br />

◆ 2075 (Hytrel ® / Thermoplastic Elastomer 75D)<br />

These materials exhibit outstanding extrusion<br />

resistance, temperature range –65 o F to +275 o F. Used<br />

in petroleum based hydraulic fluids, also some<br />

phosphate Ester and water / glycol fire resistant<br />

fluids.<br />

◆ 9250 (TODI / Polyurethane 92A)<br />

This is the premiere Disogrin polyurethane material,<br />

temperature range –65 o F to +300 o F, it possess<br />

extremely high mechanical properties, outstanding<br />

resistance to abrasion, tear, and extrusion over a<br />

large range of temperatures. Suitable for petroleum<br />

based, bio-degradable (synthetic and natural Ester)<br />

based fluids, and water under 140 o F.<br />

◆ N3101 (Nitrile / Buna N 70A)<br />

◆ N3102 (Nitrile / Buna N 90A)<br />

These materials exhibit a wide range of fluid and<br />

temperature capabilities along with good compression set<br />

properties. Is used in petroleum based, water-oil<br />

emulsions, and water / glycol fluids. Temperature range<br />

typically is –40 o F to + 250 o F, special formulations can<br />

extend range from –65 o F to +300 o F.<br />

◆ E3201 (Ethylene Propylene / EPDM 70A)<br />

◆ E3202 (Ethylene Propylene / EPDM 90A)<br />

(Ethylene Propylene is not recommended for petroleum<br />

based fluids), these materials are suitable for phosphate<br />

ester based fluids as well as water-glycol and water systems.<br />

Temperature range typically –65 o F to +300 o F, special<br />

formulations can extend usage in steam up to +400 o F.<br />

◆ V3301 (Fluorocarbon / FKM 75A)<br />

◆ V3302 (Fluorocarbon / FKM 90A)<br />

Fluorocarbons are formulated to extend the high<br />

temperature capabilities and are suitable for most<br />

petroleum based fluids. Typical temperature range is<br />

–20 o F to +400 o F, special formulations extend range from<br />

–40 o F to +485 o F.<br />

◆ 6865 (TODI / Polyurethane 70A)<br />

This material possesses extremely high mechanical<br />

properties, excellent abrasion, tear, and extrusion<br />

resistance with low compression set. Outstanding cold<br />

temperature properties, temperature range –115 o F to<br />

+250 o F. Usable in petroleum based, bio-degradable<br />

(synthetic and natural Ester) based fluids, and water<br />

under 140 o F.<br />

* Reference page 6 for Part Numbering Nomenclature<br />

◆<br />

◆<br />

◆<br />

S (Stainless Steel)<br />

Stainless Steel energizers have no compression<br />

set, no temperature limitation, and no fluid compatibility<br />

issues, they retain a consistent radial load insuring positive<br />

sealing at any pressure and/or temperature.<br />

9500 (POM / Polyacetal)<br />

9400 (PA / Polyamide / Glass Filled)<br />

These materials are extremely rigid and extrusion<br />

resistant, longwearing and stable. Temperature range<br />

-65 o F to +300 o F.<br />

-<strong>LSU</strong> <strong>Seals</strong><br />

3