Disogrin® LSU Seals - Simrit

Disogrin® LSU Seals - Simrit

Disogrin® LSU Seals - Simrit

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

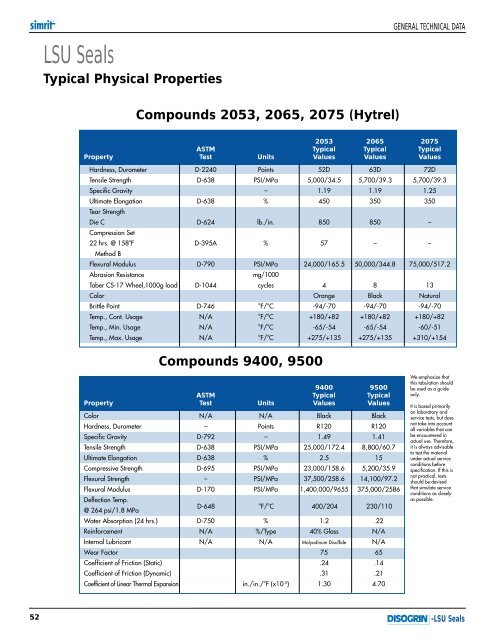

<strong>LSU</strong> <strong>Seals</strong><br />

Typical Physical Properties<br />

GENERAL TECHNICAL DATA<br />

Compounds 2053, 2065, 2075 (Hytrel)<br />

2053 2065 2075<br />

ASTM Typical Typical Typical<br />

Property Test Units Values Values Values<br />

Hardness, Durometer D-2240 Points 52D 63D 72D<br />

Tensile Strength D-638 PSI/MPa 5,000/34.5 5,700/39.3 5,700/39.3<br />

Specific Gravity – 1.19 1.19 1.25<br />

Ultimate Elongation D-638 % 450 350 350<br />

Tear Strength<br />

Die C D-624 lb./in. 850 850 –<br />

Compression Set<br />

22 hrs. @ 158 o F D-395A % 57 – –<br />

Method B<br />

Flexural Modulus D-790 PSI/MPa 24,000/165.5 50,000/344.8 75,000/517.2<br />

Abrasion Resistance<br />

mg/1000<br />

Taber CS-17 Wheel,1000g load D-1044 cycles 4 8 13<br />

Color Orange Black Natural<br />

Brittle Point D-746<br />

o F/ o C -94/-70 -94/-70 -94/-70<br />

Temp., Cont. Usage<br />

N/A<br />

o F/ o C +180/+82 +180/+82 +180/+82<br />

Temp., Min. Usage<br />

N/A<br />

o F/ o C -65/-54 -65/-54 -60/-51<br />

Temp., Max. Usage<br />

N/A<br />

o F/ o C +275/+135 +275/+135 +310/+154<br />

Compounds 9400, 9500<br />

9400 9500<br />

ASTM Typical Typical<br />

Property Test Units Values Values<br />

Color N/A N/A Black Black<br />

Hardness, Durometer – Points R120 R120<br />

Specific Gravity D-792 – 1.49 1.41<br />

Tensile Strength D-638 PSI/MPa 25,000/172.4 8,800/60.7<br />

Ultimate Elongation D-638 % 2.5 15<br />

Compressive Strength D-695 PSI/MPa 23,000/158.6 5,200/35.9<br />

Flexural Strength – PSI/MPa 37,500/258.6 14,100/97.2<br />

Flexural Modulus D-170 PSI/MPa 1,400,000/9655 375,000/2586<br />

Deflection Temp.<br />

@ 264 psi/1.8 MPa<br />

D-648<br />

o F/ o C 400/204 230/110<br />

Water Absorption (24 hrs.) D-750 % 1.2 .22<br />

Reinforcement N/A %/Type 40% Glass N/A<br />

Internal Lubricant N/A N/A Molyodinum Disulfide N/A<br />

Wear Factor 75 65<br />

Coefficient of Friction (Static) .24 .14<br />

Coefficient of Friction (Dynamic) .31 .21<br />

Coefficient of Linear Thermal Expansion in./in./ o F (x10 -5 ) 1.30 4.70<br />

We emphasize that<br />

this tabulation should<br />

be used as a guide<br />

only.<br />

It is based primarily<br />

on laboratory and<br />

service tests, but does<br />

not take into account<br />

all variables that can<br />

be encountered in<br />

actual use. Therefore,<br />

it is always advisable<br />

to test the material<br />

under actual service<br />

conditions before<br />

specification. If this is<br />

not practical, tests<br />

should be devised<br />

that simulate service<br />

conditions as closely<br />

as possible.<br />

* Reference page 6 for Part Numbering Nomenclature<br />

52 -<strong>LSU</strong> <strong>Seals</strong>