- Page 1 and 2: Edition: October 17, 2006 Lexmark

- Page 3 and 4: 5056-XXX Table of contents Notices

- Page 5 and 6: 5056-XXX 983 - Black Gear Sensor Er

- Page 7 and 8: 5056-XXX Par 3 Strobe Adj . . . . .

- Page 9 and 10: 5056-XXX Paper tray lift motor remo

- Page 11 and 12: 5056-XXX Finisher locations . . . .

- Page 13 and 14: 5056-XXX Notices and safety informa

- Page 15 and 16: 5056-XXX Huomautus laserlaitteesta

- Page 17 and 18: 5056-XXX Safety information • The

- Page 19 and 20: 5056-XXX Informació de Seguretat

- Page 21 and 22: 5056-XXX 1. General information Ove

- Page 23 and 24: 5056-XXX Technical specifications T

- Page 25 and 26: 5056-XXX Performance The Lexmark C9

- Page 27 and 28: 5056-XXX Paper and media specificat

- Page 29 and 30: 5056-XXX 500-sheet input Multipurpo

- Page 31 and 32: 5056-XXX Standard output Bin 1 Fini

- Page 33 and 34: 5056-XXX Input capacity by media an

- Page 35 and 36: 5056-XXX Media guidelines Print are

- Page 37 and 38: 5056-XXX Power and electrical speci

- Page 39 and 40: 5056-XXX Maintenance approach The d

- Page 41 and 42: 5056-XXX Acronyms ASIC BUD CMYK CPU

- Page 43 and 44: 5056-XXX 2. Diagnostic information

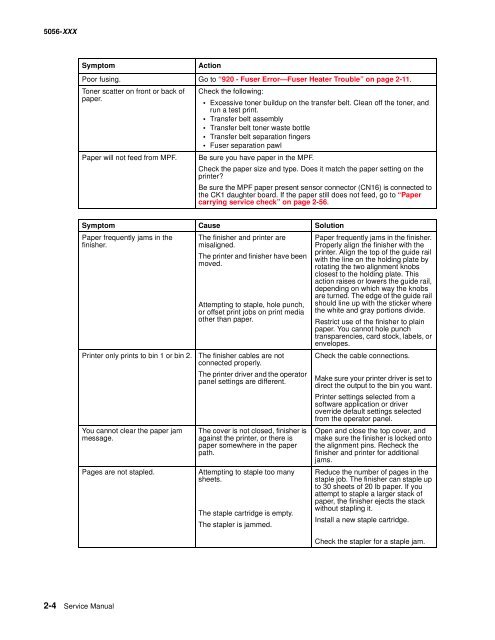

- Page 45: 5056-XXX Symptom table Symptom You

- Page 49 and 50: 5056-XXX .04 04 Objstore The 900 er

- Page 51 and 52: 5056-XXX .90 90 Lxkfax .91 91 Faxcn

- Page 53 and 54: 5056-XXX 920 - Fuser Error-Fuser He

- Page 55 and 56: 5056-XXX 930 - Yellow Printhead Err

- Page 57 and 58: 5056-XXX 934 - Color Drum Sensor Er

- Page 59 and 60: 5056-XXX 946 - Printer/Printhead Co

- Page 61 and 62: 5056-XXX 950 - Mirror Mismatch Step

- Page 63 and 64: 5056-XXX 976 - Unrecoverable Softwa

- Page 65 and 66: 5056-XXX 982 - Sensor Controller Er

- Page 67 and 68: 5056-XXX 991 - Service Paper Option

- Page 69 and 70: 5056-XXX 995 - Finisher Main Feed M

- Page 71 and 72: 5056-XXX 999 - Stapler Motor Error

- Page 73 and 74: 5056-XXX Message Meaning Action Col

- Page 75 and 76: 5056-XXX Message Meaning Action Inv

- Page 77 and 78: 5056-XXX Message Meaning Action Rea

- Page 79 and 80: 5056-XXX Message Meaning Action Ser

- Page 81 and 82: 5056-XXX Message Meaning Action 40

- Page 83 and 84: 5056-XXX Message Meaning Action 63

- Page 85 and 86: 5056-XXX Message Stapler Missing In

- Page 87 and 88: 5056-XXX Map 6 - False Print Unit

- Page 89 and 90: 5056-XXX Map 10 - Unrecoverable Che

- Page 91 and 92: 5056-XXX Map 12 - Unable to print f

- Page 93 and 94: 5056-XXX Paper feed unit service ch

- Page 95 and 96: 5056-XXX High-capacity feeder (HCF)

- Page 97 and 98:

5056-XXX Marks on paper service che

- Page 99 and 100:

5056-XXX Paper has stopped at the r

- Page 101 and 102:

5056-XXX Paper jammed in finisher (

- Page 103 and 104:

5056-XXX Photodeveloper missing ser

- Page 105 and 106:

5056-XXX Image quality troubleshoot

- Page 107 and 108:

5056-XXX Problem Color fades with f

- Page 109 and 110:

5056-XXX Black print Possible cause

- Page 111 and 112:

5056-XXX This service check is the

- Page 113 and 114:

5056-XXX 3. Diagnostic aids Note: W

- Page 115 and 116:

5056-XXX Button Display panel Funct

- Page 117 and 118:

5056-XXX Diagnostics Enter diagnost

- Page 119 and 120:

5056-XXX Alignment Auto Alignment 1

- Page 121 and 122:

5056-XXX Button Test The Button Tes

- Page 123 and 124:

5056-XXX If a test fails, one of th

- Page 125 and 126:

5056-XXX Output Bin Tests Feed Test

- Page 127 and 128:

5056-XXX The sensor tests are divid

- Page 129 and 130:

5056-XXX Printer Setup Defaults The

- Page 131 and 132:

5056-XXX When you are finished sett

- Page 133 and 134:

5056-XXX Configuration menu To ente

- Page 135 and 136:

5056-XXX Jobs on disk This setting

- Page 137 and 138:

5056-XXX As the photodeveloper rota

- Page 139 and 140:

5056-XXX After completing the fusin

- Page 141 and 142:

5056-XXX Paper feeding The paper fe

- Page 143 and 144:

5056-XXX Belt unit The transfer bel

- Page 145 and 146:

5056-XXX Paper weight Purpose: This

- Page 147 and 148:

5056-XXX 8. Slowly pull the paper o

- Page 149 and 150:

5056-XXX 241—244 Paper Jam Note:

- Page 151 and 152:

5056-XXX Tray up/down mechanism The

- Page 153 and 154:

5056-XXX Size detection mechanism T

- Page 155 and 156:

5056-XXX Maintenance Mode DIP switc

- Page 157 and 158:

5056-XXX Finisher cross section Upp

- Page 159 and 160:

5056-XXX Inverting paper path (exit

- Page 161 and 162:

5056-XXX Jogging / offset mechanism

- Page 163 and 164:

5056-XXX Elevator sequence The wire

- Page 165 and 166:

5056-XXX 6. Tighten the guide rail

- Page 167 and 168:

5056-XXX 3. Open the stapler door.

- Page 169 and 170:

1 2 3 4 5 6 7 8 9 0 # 5056-XXX 10.

- Page 171 and 172:

7 8 9 0 # 1 2 3 4 5 6 5056-XXX Alig

- Page 173 and 174:

5056-XXX 4. Roll the finisher towar

- Page 175 and 176:

5056-XXX 2. Rotate the rear adjustm

- Page 177 and 178:

5056-XXX 3. Rotate the locking knob

- Page 179 and 180:

5056-XXX Power cable 1. Unplug the

- Page 181 and 182:

5056-XXX Hole punch adjustment You

- Page 183 and 184:

5056-XXX 4. Repair information Hand

- Page 185 and 186:

5056-XXX Check finisher alignment w

- Page 187 and 188:

5056-XXX Transfer belt If you repla

- Page 189 and 190:

5056-XXX Front door / operator pane

- Page 191 and 192:

5056-XXX Cover, rear removal 1. Ope

- Page 193 and 194:

5056-XXX Cover, RIP board removal W

- Page 195 and 196:

5056-XXX Cassette guide removal 1.

- Page 197 and 198:

5056-XXX Density sensor removal/Sep

- Page 199 and 200:

5056-XXX Face up paper exit assembl

- Page 201 and 202:

5056-XXX Gear cover removal/Multipu

- Page 203 and 204:

5056-XXX 5. Disconnect the affected

- Page 205 and 206:

5056-XXX Main drive unit removal 1.

- Page 207 and 208:

5056-XXX Main unit fan removal 1. R

- Page 209 and 210:

5056-XXX 6. Remove the paper feed g

- Page 211 and 212:

5056-XXX Paper carrying frame remov

- Page 213 and 214:

5056-XXX Relay roller removal Note:

- Page 215 and 216:

5056-XXX 3. Remove the rear cover.

- Page 217 and 218:

5056-XXX 8. Remove the exit roller.

- Page 219 and 220:

5056-XXX Power switch removal 1. Re

- Page 221 and 222:

5056-XXX Left slide rail removal 1.

- Page 223 and 224:

5056-XXX Sub-frame removal Importan

- Page 225 and 226:

5056-XXX Top unit removal 1. Open t

- Page 227 and 228:

5056-XXX 5. Loosen the thumbscrews

- Page 229 and 230:

5056-XXX Turn guide cover sensor re

- Page 231 and 232:

5056-XXX Expansion feeder removals

- Page 233 and 234:

5056-XXX Paper feed assembly remova

- Page 235 and 236:

5056-XXX Duplex removals Duplex uni

- Page 237 and 238:

5056-XXX Duplex pressure roller and

- Page 239 and 240:

5056-XXX Duplex paper carrying moto

- Page 241 and 242:

5056-XXX HCF call roller, paper fee

- Page 243 and 244:

5056-XXX 8. Remove the top cover sw

- Page 245 and 246:

5056-XXX Finisher removals Note: Ch

- Page 247 and 248:

5056-XXX Elevator motor removal 1.

- Page 249 and 250:

5056-XXX Inverter paper exit discha

- Page 251 and 252:

5056-XXX Path select gate removal 1

- Page 253 and 254:

5056-XXX 8. Remove the tension spri

- Page 255 and 256:

5056-XXX Registration roller remova

- Page 257 and 258:

5056-XXX Straight paper exit discha

- Page 259 and 260:

5056-XXX Timing belts 1 and 2 remov

- Page 261 and 262:

5056-XXX 8. Remove the tractor belt

- Page 263 and 264:

5056-XXX 5. Locations Covers diagra

- Page 265 and 266:

5056-XXX Sensor and switch location

- Page 267 and 268:

5056-XXX Printer controller board L

- Page 269 and 270:

5056-XXX Print controller board con

- Page 271 and 272:

5056-XXX CK1 board connectors Conn

- Page 273 and 274:

5056-XXX RIP board RIP board connec

- Page 275 and 276:

5056-XXX LVPS 2 board connectors Co

- Page 277 and 278:

5056-XXX Expansion paper feeder con

- Page 279 and 280:

5056-XXX Size sensor board Location

- Page 281 and 282:

5056-XXX High-capacity feeder (HCF)

- Page 283 and 284:

5056-XXX Finisher locations Locatio

- Page 285 and 286:

5056-XXX Finisher Face Up Bin (Tray

- Page 287 and 288:

5056-XXX 6. Preventive maintenance

- Page 289 and 290:

5056-XXX 7. Parts catalog How to us

- Page 291 and 292:

5056-XXX Assembly 1: Covers 1 Index

- Page 293 and 294:

5056-XXX Assembly 3: Covers 3 1 2 I

- Page 295 and 296:

5056-XXX Assembly 5: Covers 5 Index

- Page 297 and 298:

5056-XXX Assembly 6: Upper unit Ind

- Page 299 and 300:

5056-XXX Assembly 7: Paper feed Ind

- Page 301 and 302:

5056-XXX Assembly 8: Base 2 Index P

- Page 303 and 304:

5056-XXX Assembly 9: Base 3 Index P

- Page 305 and 306:

5056-XXX Assembly 10: Electrical A

- Page 307 and 308:

5056-XXX Assembly 10 (continued): E

- Page 309 and 310:

5056-XXX Assembly 11: Electrical B

- Page 311 and 312:

5056-XXX Assembly 13: Fuser unit 1

- Page 313 and 314:

5056-XXX Assembly 14: Cassette Inde

- Page 315 and 316:

5056-XXX Assembly 15: Expansion fee

- Page 317 and 318:

5056-XXX Assembly 16: Expansion fee

- Page 319 and 320:

5056-XXX Assembly 17: Duplex Unit 1

- Page 321 and 322:

5056-XXX Assembly 18: Duplex unit 2

- Page 323 and 324:

5056-XXX Assembly 19: High-capacity

- Page 325 and 326:

5056-XXX Assembly 20: High-capacity

- Page 327 and 328:

5056-XXX Assembly 21: High-capacity

- Page 329 and 330:

5056-XXX Assembly 22: High-capacity

- Page 331 and 332:

5056-XXX Assembly 23: High-capacity

- Page 333 and 334:

5056-XXX Assembly 24: High-capacity

- Page 335 and 336:

5056-XXX Assembly 25: Finisher cove

- Page 337 and 338:

5056-XXX Assembly 26: Finisher fram

- Page 339 and 340:

5056-XXX Assembly 27: Finisher feed

- Page 341 and 342:

5056-XXX Assembly 29: Finisher elev

- Page 343 and 344:

5056-XXX Assembly 31: Finisher dock

- Page 345 and 346:

5056-XXX Assembly 33: Miscellaneous

- Page 347 and 348:

5056-XXX Assembly 34: Parts packets

- Page 349 and 350:

5056-XXX Assembly 34: Parts packets

- Page 351 and 352:

5056-XXX Index Numerics 1565 Emul E

- Page 353 and 354:

5056-XXX parts catalog 7-23 removal

- Page 355 and 356:

5056-XXX paper end sensor 4-60 pape

- Page 357 and 358:

5056-XXX Part number index P/N Desc

- Page 359 and 360:

5056-XXX 40X1116 Cable, MPF clutch

- Page 361 and 362:

5056-XXX 40X1259 Operator panel - -

- Page 363 and 364:

5056-XXX 56P9407 Belt, timing 60S2M

- Page 365 and 366:

1 2 3 STEPPING MOTOR ASSEMBLY Paper