industrial wireless book special edition - Networking ...

industrial wireless book special edition - Networking ...

industrial wireless book special edition - Networking ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>industrial</strong> <strong>wireless</strong><br />

48<br />

Wireless makes inroads across<br />

the process automation sector<br />

Wireless technology is commonplace and WirelessHART, using the IEEE 802.15.4 radio operating at 2.4GHz,<br />

is providing tangible benefits in the process industries. The network range has been extended and redundant<br />

communication routes provide the crucial 99.9% reliability, reports David Walker who covers integration,<br />

device diagnostics, security and standardisation on HART IP as part of his working brief.<br />

WIRELESS NETWORKS have been around for<br />

about 10 years in the process industries. w-<br />

HART is a widely recognised standard that<br />

provides a process industry application that,<br />

arguably, is as easy to use as a Bluetooth<br />

connection to a mobile phone.<br />

WirelessHART (w-HART) was developed specifically<br />

to meet the needs of process sector users,<br />

who demanded coexistence, reliability, security,<br />

multi-vendor interoperability and long battery<br />

life. Crucially, power consumption is limited<br />

such that process devices can be batterypowered<br />

for up to 10 years. The HART<br />

Communication Foundation (HCF) worked with<br />

process equipment vendors and experts on radio<br />

frequency and <strong>wireless</strong> communications, and<br />

came up with a scheme that satisfied all parties.<br />

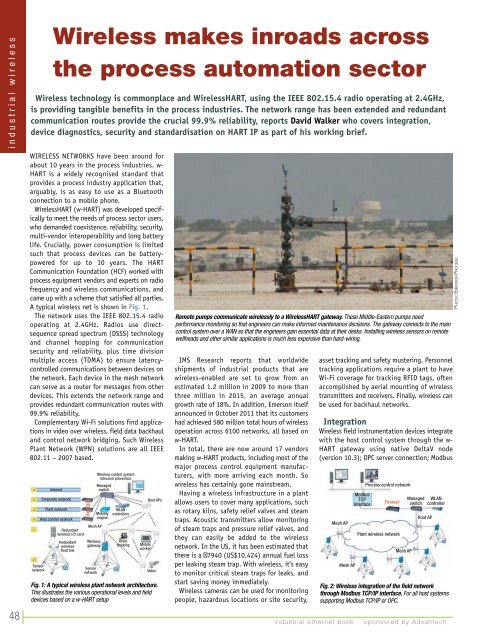

A typical <strong>wireless</strong> net is shown in Fig. 1.<br />

The network uses the IEEE 802.15.4 radio<br />

operating at 2.4GHz. Radios use directsequence<br />

spread spectrum (DSSS) technology<br />

and channel hopping for communication<br />

security and reliability, plus time division<br />

multiple access (TDMA) to ensure latencycontrolled<br />

communications between devices on<br />

the network. Each device in the mesh network<br />

can serve as a router for messages from other<br />

devices. This extends the network range and<br />

provides redundant communication routes with<br />

99.9% reliability.<br />

Complementary Wi-Fi solutions find applications<br />

in video over <strong>wireless</strong>, field data backhaul<br />

and control network bridging. Such Wireless<br />

Plant Network (WPN) solutions are all IEEE<br />

802.11 – 2007 based.<br />

Sensor<br />

network<br />

Internet<br />

Corporate network<br />

Plant network<br />

Area control network<br />

Redundant<br />

<strong>wireless</strong> I/O card<br />

Redundant<br />

<strong>wireless</strong><br />

field link<br />

Firewalls<br />

Mesh AP<br />

Wireless<br />

gateway<br />

Sensor<br />

network<br />

Wireless control system<br />

intrusion prevention<br />

Managed<br />

switch<br />

Mobility<br />

engine<br />

WLAN<br />

controllers<br />

Asset<br />

tracking<br />

Mobile<br />

worker<br />

Root APs<br />

Video<br />

Fig. 1: A typical <strong>wireless</strong> plant network architecture.<br />

This illustrates the various operational levels and field<br />

devices based on a w-HART setup<br />

Remote pumps communicate <strong>wireless</strong>ly to a WirelessHART gateway. These Middle-Eastern pumps need<br />

performance monitoring so that engineers can make informed maintenance decisions. The gateway connects to the main<br />

control system over a WAN so that the engineers gain essential data at their desks. Installing <strong>wireless</strong> sensors on remote<br />

wellheads and other similar applications is much less expensive than hard-wiring.<br />

IMS Research reports that worldwide<br />

shipments of <strong>industrial</strong> products that are<br />

<strong>wireless</strong>-enabled are set to grow from an<br />

estimated 1.2 million in 2009 to more than<br />

three million in 2015, an average annual<br />

growth rate of 18%. In addition, Emerson itself<br />

announced in October 2011 that its customers<br />

had achieved 580 million total hours of <strong>wireless</strong><br />

operation across 6100 networks, all based on<br />

w-HART.<br />

In total, there are now around 17 vendors<br />

making w-HART products, including most of the<br />

major process control equipment manufacturers,<br />

with more arriving each month. So<br />

<strong>wireless</strong> has certainly gone mainstream.<br />

Having a <strong>wireless</strong> infrastructure in a plant<br />

allows users to cover many applications, such<br />

as rotary kilns, safety relief valves and steam<br />

traps. Acoustic transmitters allow monitoring<br />

of steam traps and pressure relief valves, and<br />

they can easily be added to the <strong>wireless</strong><br />

network. In the US, it has been estimated that<br />

there is a 7940 (US$10,424) annual fuel loss<br />

per leaking steam trap. With <strong>wireless</strong>, it’s easy<br />

to monitor critical steam traps for leaks, and<br />

start saving money immediately.<br />

Wireless cameras can be used for monitoring<br />

people, hazardous locations or site security,<br />

<strong>industrial</strong> ethernet <strong>book</strong><br />

asset tracking and safety mustering. Personnel<br />

tracking applications require a plant to have<br />

Wi-Fi coverage for tracking RFID tags, often<br />

accomplished by aerial mounting of <strong>wireless</strong><br />

transmitters and receivers. Finally, <strong>wireless</strong> can<br />

be used for backhaul networks.<br />

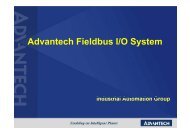

Integration<br />

Wireless field instrumentation devices integrate<br />

with the host control system through the w-<br />

HART gateway using native DeltaV node<br />

(version 10.3); OPC server connection; Modbus<br />

Mesh AP<br />

Mesh AP<br />

Modbus<br />

TCP<br />

interface<br />

Process control network<br />

Firewall<br />

Plant <strong>wireless</strong> network<br />

Mesh AP<br />

Managed<br />

switch<br />

Root AP<br />

WLAN<br />

controller<br />

Fig. 2: Wireless integration of the field network<br />

through Modbus TCP/IP interface. For all host systems<br />

supporting Modbus TCP/IP or OPC.<br />

sponsored by Advantech<br />

PHOTO: EMERSON PROCESS