Vigilohm System - engineering site - Schneider Electric

Vigilohm System - engineering site - Schneider Electric

Vigilohm System - engineering site - Schneider Electric

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

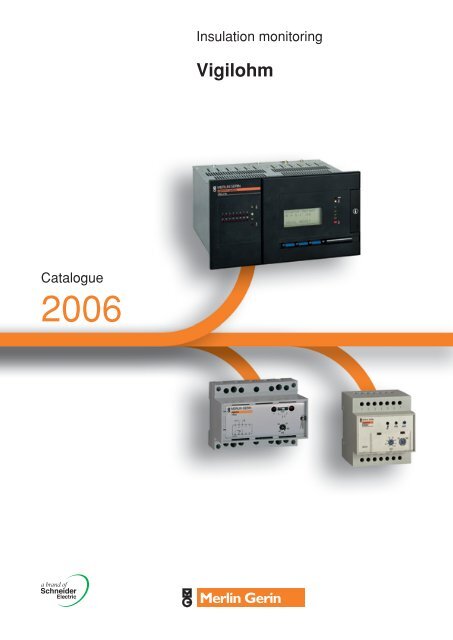

Insulation monitoring<br />

<strong>Vigilohm</strong><br />

Catalogue<br />

2006

0<br />

The Guiding <strong>System</strong>, the new way to create your<br />

electrical installations<br />

A comprehensive offer of products with consistent design<br />

The Guiding <strong>System</strong> is first and foremost a Merlin Gerin product<br />

offer covering all electrical distribution needs. However, what<br />

makes all the difference is that these products have been designed<br />

to operate togheter: mechanical and electrical compatibility,<br />

interoperability, modularity, communication.<br />

Thus the electrical installation is both optimised and more efficient:<br />

better continuity of supply, enhanced safety for people and<br />

equipment, guaranteed upgradeability, effective monitoring and<br />

control.<br />

Tools to simplify design and implementation<br />

With the Guiding <strong>System</strong>, you have a comprehensive range of tools<br />

- the Guiding Tools - that will help you increase your product<br />

knowledge and product utilisation. Of course this is in compliance<br />

with current standards and procedures.<br />

These tools include technical booklets and guides, design aid<br />

software, training courses, etc. and are regularly updated.<br />

For a genuine partnership with you<br />

Because each electrical installation is unique, there is no standard<br />

solution. With the Guiding <strong>System</strong>, the variety of combinations<br />

allows for genuine customisation solutions. You can create and<br />

implement electrical installations to meet your creative<br />

requirements and design knowledge.<br />

You and Merlin Gerin’s Guiding <strong>System</strong> form a genuine partnership.<br />

For more details on the Guiding <strong>System</strong>,<br />

consult www.merlin-gerin.com

0<br />

A consistent design of offers from<br />

Medium Voltage to Low Voltage<br />

All Merlin Gerin offers are designed according to<br />

electrical, mechanical and communication<br />

consistency rules.<br />

The products express this consistency by their<br />

overall design and shared ergonomics.<br />

<strong>Electric</strong>al consistency:<br />

Discrimination guarantees co-ordination between the operating<br />

characteristics of serial-connected circuit-breakers. Should a<br />

fault occurs downstream, only the circuit-breaker placed<br />

immediately upstream from the fault will trip.<br />

Each product complies with or enhances system performance at coordination<br />

level: breaking capacity, Isc, temperature rise, etc. for<br />

more safety, continuity of supply (discrimination) or economic<br />

optimisation (cascading).<br />

The leading edge technologies employed in Merlin Gerin’s<br />

Guiding <strong>System</strong> ensure high performance levels in discrimination<br />

and cascading of protection devices, electrodynamic withstand of<br />

switches and current distributors, heat loss of devices, distribution<br />

blocks and enclosures.<br />

Likewise, inter-product ElectroMagnetic Compatibilty (EMC) is<br />

guaranteed.<br />

Mechanical consistency:<br />

Each product adopts dimensional standards simplifying and<br />

optimising its use within the system.<br />

It shares the same accessories and auxiliaries and complies with<br />

global ergonomic choices (utilisation mode, operating mode, setting<br />

and configuration devices, tools, etc.) making its installation and<br />

operation within the system a simpler process.<br />

Direct connection of the Canalis KT busbar trunking on the<br />

Masterpact 3200 A circuit breaker.<br />

Communication consistency:<br />

Thanks to the use of standard Web technologies, you can offer<br />

your customers intelligent Merlin Gerin switchboards allowing<br />

easy access to information: follow-up of currents, voltages,<br />

powers, consumption history, etc.<br />

Each product complies with global choices in terms of<br />

communication protocols (Modbus, Ethernet, etc.) for simplified<br />

integration in the management, supervision and monitoring<br />

systems.<br />

Guiding Tools<br />

for more efficient design<br />

and implementation<br />

of your installations.<br />

1

0<br />

SM6<br />

Medium voltage switchboard<br />

system from 1 to 36 kV<br />

Sepam<br />

Protection relays<br />

Masterpact<br />

Protection switchgear<br />

from 100 to 6300 A<br />

Trihal<br />

MV/LV dry cast resin<br />

transformer<br />

from 160 to 5000 kVA<br />

Evolis<br />

MV vacuum<br />

switchgear and<br />

components<br />

from 1 to 24 kV.<br />

The Technical guide<br />

These technical guides help you comply with<br />

installation standards and rules i.e.:<br />

The electrical installation guide, the<br />

protection guide, the switchboard<br />

implementation guide, the technical booklets<br />

and the co-ordination tables all form genuine<br />

reference tools for the design of highperformance<br />

electrical installations.<br />

For example, the LV protection co-ordination<br />

guide - discrimination and cascading -<br />

optimises choice of protection and<br />

connection devices while also increasing<br />

markedly continuity of supply in the<br />

installations.<br />

CAD software and tools<br />

The CAD software and tools enhance<br />

productivity and safety.<br />

They help you create your installations<br />

by simplifying product choice through<br />

easy browsing in the Guiding <strong>System</strong><br />

offers.<br />

Last but not least, they optimise<br />

use of our products while also complying<br />

with standards and proper procedures.<br />

2

0<br />

Compact<br />

Protection switchgear system<br />

from 100 to 630 A<br />

Multi 9<br />

Modular protection switchgear<br />

system up to 125 A<br />

Prisma Plus<br />

Functional system for electrical<br />

distribution switchboards<br />

up to 3200 A<br />

Pragma<br />

Enclosures for<br />

distribution<br />

switchboards<br />

up to 160 A<br />

Canalis<br />

Prefabricated Busbar<br />

Trunking<br />

from 25 to 4000 A<br />

PowerLogic<br />

Power<br />

management<br />

Training<br />

Training allows you to acquire the Merlin<br />

Gerin expertise (installation design, work<br />

with power on, etc.) for increased<br />

efficiency and a guarantee of improved<br />

customer service.<br />

The training catalogue includes beginner’s<br />

courses in electrical distribution,<br />

knowledge of MV and LV switchgear,<br />

operation and maintenance of<br />

installations, design of LV installations to<br />

give but a few examples.<br />

merlin-gerin.com<br />

This international <strong>site</strong> allows you to access<br />

all the Merlin Gerin products in just 2 clicks<br />

via comprehensive range data-sheets, with<br />

direct links to:<br />

b complete library: technical documents,<br />

catalogs, FAQs, brochures…<br />

b selection guides from the e-catalog<br />

b product discovery <strong>site</strong>s and their Flash<br />

animations.<br />

You will also find illustrated overviews,<br />

news to which you can subscribe, the list<br />

of country contacts…<br />

3

insulation monitoring<br />

monitoring<br />

<strong>Vigilohm</strong><br />

page<br />

1/ presentation 6<br />

2/ functions and 17<br />

characteristics<br />

3/ installation and 45<br />

connection<br />

4/ catalogue numbers 55<br />

5

<strong>Vigilohm</strong>: presentation<br />

insulation monitoring and associated functions<br />

continuity of supply<br />

Continuity of supply is a need that must<br />

always be satisfied by electrical installations,<br />

along with the protection of life and property.<br />

The IT system provides the best guarantee<br />

in terms of continuity of supply. Even when a<br />

first insulation fault is present, the installation<br />

can continue to supply power without<br />

endangering human life. The first fault must<br />

however be detected and repaired before a<br />

second fault occurs.<br />

IO316_123<br />

principle<br />

Insulation monitoring is provided on IT<br />

systems to detect and indicate insulation<br />

faults as soon as they occur.<br />

The basic function is carried out by an<br />

Insulation Monitoring Device (IMD), also<br />

referred to in certain documentation as a<br />

permanent or continuous insulation monitor<br />

(PIM or CIM respectively). The monitoring<br />

device injects a DC or low-frequency<br />

AC voltage between the installation and<br />

earth. The insulation resistance is determined<br />

from the resulting current. This technique can<br />

be used on all types of installations: AC, DC,<br />

rectified, mixed AC/DC, etc.<br />

DB100664<br />

measuring, indicating and<br />

locating insulation faults<br />

<strong>Vigilohm</strong> <strong>System</strong>, with or without a<br />

communication bus, fulfils the following<br />

basic functions:<br />

c measurement of insulation level on all<br />

types of installations<br />

c manual or automatic locating of insulation<br />

faults.<br />

<strong>Vigilohm</strong> <strong>System</strong> with a<br />

communication bus<br />

The communication bus adds the following<br />

possibilities:<br />

c measurement of the insulation resistance<br />

and earth leakage capacitance of each<br />

circuit<br />

c centralisation of fault locating<br />

measurements on the IMD display units<br />

c communication with a supervisor<br />

(transmission of measurements and<br />

reception of settings).<br />

6

vigilohm system<br />

XD301<br />

50507<br />

vigirex - vigidix<br />

M<br />

M<br />

MERLIN GERIN<br />

test<br />

reset<br />

XAS<br />

XML316<br />

1 2 3 4 5 6 7 8<br />

9 10 11 12 13 14 15 16<br />

d faut<br />

MERLIN GERIN<br />

vigirex - vigidix<br />

1 2 3<br />

4 5 6<br />

7 8 9<br />

10 11 12<br />

vigilohm system<br />

XD312<br />

50536<br />

MERLIN GERIN<br />

vigirex - vigidix<br />

M<br />

M<br />

test<br />

reset<br />

test<br />

P50<br />

on P12 P1 0<br />

vigidix<br />

RM 10N<br />

XLI300<br />

d faut<br />

XD308c<br />

1 2 3 4 5 6 7 8<br />

test<br />

reset<br />

test<br />

on<br />

GO<br />

XM300c<br />

XTU300<br />

XL316<br />

P O<br />

d faut<br />

MERLIN GERIN<br />

test<br />

1 2 3 4 5 6 7 8<br />

9 10 11 12 13 14 15 16<br />

S1<br />

S2<br />

test/reset<br />

test<br />

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong> with or without a communication bus<br />

<strong>Vigilohm</strong> <strong>System</strong> without a<br />

communication bus<br />

<strong>Vigilohm</strong> <strong>System</strong> with a<br />

communication bus<br />

supervision and event logging<br />

DB100662<br />

DB100955<br />

supervisor<br />

printer<br />

interfaces<br />

XAS XAS<br />

XLI300 XTU300<br />

MERLIN GERIN<br />

vigilohm system<br />

MERLIN GERIN<br />

vigilohm system<br />

MERLIN GERIN<br />

vigilohm system<br />

insulation monitoring<br />

XML308/316<br />

XM300c<br />

MERLIN GERIN<br />

vigilohm system<br />

MERLIN GERIN<br />

vigilohm system<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

insulation fault detection and locating<br />

XD301<br />

XD312<br />

XRM<br />

XD308c<br />

XL308 / 316<br />

MERLIN GERIN<br />

vigilohm system<br />

MERLIN GERIN<br />

vigilohm system<br />

MERLIN GERIN<br />

MERLIN GERIN<br />

MERLIN GERIN<br />

sensors<br />

MERLIN GERIN<br />

S1<br />

S2<br />

7

vigilohm<br />

TR 22A<br />

test<br />

K<br />

MERLIN GERIN<br />

vigilhom<br />

SM21<br />

50761<br />

0,75<br />

1,0 1,25<br />

1,5<br />

1,75 1,0<br />

0,5<br />

0,25 2,0<br />

Sa<br />

MΩ<br />

1,5<br />

AL. REL. test<br />

OK<br />

3,0 2,0 o f on<br />

7,5<br />

5,0<br />

0,5 10<br />

Sp<br />

AL. REL.<br />

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong> without a communication bus<br />

<strong>Vigilohm</strong> <strong>System</strong> without a<br />

communication bus<br />

This solution offers:<br />

c automatic fault detection;<br />

c accurate measurements of the insulation<br />

level for all types of installations.<br />

DB100650<br />

insulation monitoring<br />

Insulation monitoring devices inject a DC or<br />

low-frequency AC voltage between the<br />

installation and earth. The insulation<br />

resistance is determined by measuring the<br />

resulting leakage current.<br />

c <strong>Vigilohm</strong> EM9 devices use an indicator<br />

light to signal the presence of an insulation<br />

fault within the installation. They are<br />

modular devices (Multi 9 format) designed<br />

for small installations or sub-systems<br />

isolated from earth;<br />

c the TR22A and TR22AH (for hospitals)<br />

devices detect insulation faults and, in<br />

addition, continuously indicate the value of<br />

the insulation resistance on a digital display;<br />

c the XM200 is part of the <strong>Vigilohm</strong> <strong>System</strong><br />

range and can be associated with automatic<br />

fault locating devices.<br />

E18812<br />

MERLIN GERIN<br />

TR22A<br />

off-line insulation<br />

monitoring<br />

The failure of a motor to start can have<br />

serious consequences. This is especially<br />

true in the following applications:<br />

c safety equipment (fire pumps, smoke<br />

extractors, etc.);<br />

c production (glass works, cement plants,<br />

etc.);<br />

c manufacturing processes (rolling mills, etc.).<br />

Motors often fail to start due to insulation<br />

problems caused by the humidity that<br />

accumulates in the microscopic cracks of the<br />

insulation during periods when the motor is<br />

not running. The SM21 device monitors the<br />

insulation of critical motors while they are<br />

off-line. Insulation faults give rise to an<br />

alarm or motor starting lock-out.<br />

E27136<br />

E27112<br />

1 2 3 4 5 6 7<br />

8 9 10<br />

11<br />

12<br />

13<br />

14<br />

SM21<br />

8

on P12<br />

MERLIN GERIN<br />

vigidix<br />

RM 10N<br />

P50<br />

P1 0<br />

P50¥<br />

on P12 P1 0<br />

MERLIN GERIN<br />

vigidix<br />

RM 10N<br />

1 2 3<br />

4 5 6<br />

7 8 9<br />

10 11 12<br />

MERLIN GERIN<br />

MERLIN GERIN<br />

vigilohm system<br />

XD312<br />

50536<br />

vigilohm system<br />

XM200<br />

R C Sp Sa<br />

M<br />

M<br />

S<br />

test<br />

reset<br />

MERLIN GERIN<br />

vigilohm system<br />

XM100<br />

menu ok test<br />

test<br />

test<br />

on P12<br />

MERLIN GERIN<br />

vigidix<br />

RM 10N<br />

P50<br />

P1 0<br />

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong> without a communication bus<br />

fault locating<br />

Once detected, an insulation fault must be<br />

located and eliminated in order to guarantee<br />

maximum continuity of supply.<br />

Manual fault locating<br />

The fault is located by testing different points<br />

in the installation, one after another, using a<br />

<strong>Vigilohm</strong> <strong>System</strong> XRM mobile receiver and a<br />

current probe. The receiver captures the<br />

low-frequency fault locating signal.<br />

Two cases may be encountered:<br />

c the installation is equipped with an XM200<br />

or XM300C insulation monitoring device<br />

(<strong>Vigilohm</strong> <strong>System</strong>).<br />

In this case, the manual system is used to<br />

fine-tune the results of the automatic<br />

locating system<br />

c the installation (relatively small or an<br />

isolated sub-system) is equipped with an<br />

insulation monitoring device for DC injection.<br />

In this case, a <strong>Vigilohm</strong> XGR portable<br />

generator is used together with an XRM<br />

receiver.<br />

Automatic locating:<br />

For easy locating of insulation faults, the<br />

<strong>Vigilohm</strong> <strong>System</strong> makes it possible to<br />

combine the XM200 insulation monitoring<br />

device with:<br />

c XD301/XD312 fault detectors to monitor<br />

the different circuits of the installation;<br />

c XRM receivers for mobile fault locating.<br />

DB110935<br />

E27110 DB100950<br />

Manual fault locating<br />

XRM<br />

XRM<br />

valeur d'isolement<br />

040 K<br />

TEST MENU<br />

Automatic fault locating<br />

XM200<br />

XGR<br />

XM300C<br />

XD312<br />

XRM<br />

9

MERLIN GERIN<br />

vigilohm system<br />

XD301<br />

50507<br />

vigirex - vigidix<br />

M<br />

M<br />

MERLIN GERIN<br />

test<br />

reset<br />

MERLIN GERIN<br />

vigilohm system<br />

XAS<br />

défaut<br />

MERLIN GERIN<br />

vigirex - vigidix<br />

MERLIN GERIN<br />

vigirex - vigidix<br />

1 2 3<br />

4 5 6<br />

7 8 9<br />

10 11 12<br />

MERLIN GERIN<br />

vigilohm system<br />

XD312<br />

50536<br />

MERLIN GERIN<br />

vigilohm system<br />

XML316<br />

1 2 3 4 5 6 7 8<br />

9 10 11 12 13 14 15 16<br />

M<br />

M<br />

test<br />

reset<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

test<br />

P50<br />

on P12 P1 0<br />

RM 10N<br />

MERLIN GERIN<br />

vigidix<br />

MERLIN GERIN<br />

vigilohm system<br />

XLI3 0<br />

défaut<br />

MERLIN GERIN<br />

vigilohm system<br />

XD308c<br />

test<br />

1 2 3 4 5 6 7 8<br />

on<br />

test<br />

reset<br />

MERLIN GERIN<br />

vigilohm system<br />

XTU3 0<br />

GO<br />

défaut<br />

MERLIN GERIN<br />

MERLIN GERIN<br />

vigilohm system<br />

XM3 0c<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

MERLIN GERIN<br />

vigilohm system<br />

XL316<br />

S1<br />

S2<br />

MERLIN GERIN<br />

P O<br />

test<br />

test<br />

1 2 3 4 5 6 7 8<br />

9 10 11 12 13 14 15 16<br />

S1<br />

S2<br />

test/reset<br />

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong> with a communication bus<br />

<strong>Vigilohm</strong> <strong>System</strong> with a<br />

communication bus<br />

The communication bus adds the following<br />

possibilities:<br />

c communication with a supervisor<br />

(transmission of measurements and<br />

reception of settings)<br />

c measure the insulation resistance and<br />

earth leakage capacitance of each circuit<br />

c centralisation of the locator measurements<br />

on the insulation monitoring device displays.<br />

DB100956<br />

supervision and event logging<br />

supervisor<br />

printer<br />

interfaces<br />

XAS XLI200/XLI300 XTU300<br />

insulation monitoring<br />

XML308/316<br />

XM300c<br />

insulation fault detection and locating<br />

XD301 XD312 XRM XD308c XL308 / 316<br />

sensors<br />

insulation monitoring and associated functions<br />

communication features<br />

In addition to displaying the insulation values<br />

it measures for the installation as a whole, an<br />

insulation monitoring device can also provide<br />

a centralised display for information<br />

concerning specific circuits. It receives this<br />

information from communicating insulation<br />

fault locators and detectors distributed<br />

throughout the installation. All this information<br />

may also be transmitted to a remote<br />

supervisory system.<br />

These communication features satisfy the<br />

operating requirements of modern electrical<br />

installations. All information concerning the<br />

insulation can be transmitted via a<br />

communication bus for display on a<br />

centralised insulation monitoring device or to<br />

a supervision system for centralised<br />

processing and management.<br />

E17057<br />

centralisation on a supervisor<br />

centralisation on an IMD<br />

local display<br />

measurements<br />

prevention of insulation<br />

faults<br />

E17059<br />

Prevention is the best way to ensure the<br />

continuity of supply of electrical installations.<br />

It may be applied in two ways:<br />

c the insulation monitoring device signals a<br />

drop in the insulation resistance below a<br />

non-critical prevention threshold determined<br />

by the user;<br />

c the measurements are transmitted to a<br />

supervisor, which can then process them to<br />

predict insulation faults on ageing cables.<br />

These indications can be used to schedule<br />

preventive maintenance.<br />

fault prevention<br />

preventive level<br />

fault level<br />

10

MERLIN GERIN<br />

vigilohm system<br />

XM300c<br />

test<br />

MERLIN GERIN<br />

vigilohm system<br />

XLI300<br />

défaut<br />

MERLIN GERIN<br />

vigilohm system<br />

XL308c<br />

vigilohm system<br />

XM200<br />

1 2 3 4 5 6 7 8<br />

9 10 11 12 13 14 15 16<br />

R C Sp Sa<br />

test/reset<br />

1 2 3<br />

4 5 6<br />

7 8 9<br />

10 11 12<br />

test<br />

S<br />

menu ok test<br />

vigilohm system<br />

XD312<br />

50536<br />

M<br />

M<br />

test<br />

test<br />

reset<br />

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong>:<br />

general information<br />

easier operation of<br />

IT systems<br />

An installation implementing the IT system,<br />

i.e. isolated from earth or connected to earth<br />

through a sufficiently high impedance, gives<br />

top priority to continuity of supply.<br />

Today, the operation of such installations<br />

can be greatly facilitated by the use of<br />

devices that offer functions going far beyond<br />

the simple fault signalling imposed by<br />

standards.<br />

... with <strong>Vigilohm</strong> <strong>System</strong><br />

<strong>Vigilohm</strong> <strong>System</strong> is a range of Merlin Gerin<br />

products meeting the needs of IT systems in<br />

terms of performance, practical operation<br />

and continuity of supply.<br />

This range features modular design. It is<br />

made up of Insulation Monitoring Devices<br />

(IMDs) and fault detection and locating<br />

devices. Some of these devices make<br />

independent measurements of the insulation<br />

resistance on each circuit.<br />

In addition, the <strong>Vigilohm</strong> <strong>System</strong> can<br />

communicate with a supervisor or PLC.<br />

principle and functions<br />

The basic device is the Insulation<br />

Monitoring Device (IMD). It injects a lowfrequency<br />

AC voltage between earth and the<br />

installation. Based on a measurement of the<br />

resulting current, the <strong>Vigilohm</strong> <strong>System</strong><br />

accurately determines the true insulation<br />

resistance of the installation and its earth<br />

coupling capacitance. This technique can be<br />

used on all types of installations: AC, DC,<br />

rectified, mixed, etc.<br />

Fault locating is the main function<br />

associated with insulation monitoring.<br />

Toroids placed on the various circuits<br />

capture a signal proportional to the current<br />

injected by the insulation monitoring device.<br />

This signal is transmitted to fault detection<br />

and locating devices which automatically<br />

identify any faulty circuit.<br />

Distributed measurements of the<br />

insulation resistance and the earth leakage<br />

capacitance are possible on each circuit via<br />

the toroids used for fault locating.<br />

Centralisation on a supervisor. Via a<br />

communication bus using JBUS protocol,<br />

the <strong>Vigilohm</strong> <strong>System</strong> can forward all<br />

measurements, information and events to a<br />

supervisor. In this way, the supervisor<br />

maintains full knowledge on the insulation<br />

status of the overall installation and the<br />

individually monitored circuits. The<br />

supervisor (or PLC) can be connected to a<br />

printer to log all events occurring on the<br />

installation, complete with location and<br />

timestamp.<br />

Adaptation to variable installation<br />

configurations. The system automatically<br />

excludes all but one insulation monitoring<br />

device connected to the same set of<br />

busbars.<br />

E20123<br />

Other functions<br />

c measurement of the true insulation<br />

resistance<br />

c measurement of the earth leakage<br />

capacitance<br />

c indication of transient faults<br />

c prevention alarm when the insulation<br />

resistance falls below a non-critical<br />

threshold determined by the user;<br />

c remote interrogation and display, from the<br />

insulation monitoring device, of faults<br />

detected by the fault locators<br />

c setting of alarm thresholds from a<br />

supervisor<br />

c ...<br />

The system evolves with the needs of the<br />

installation. New devices can be added at<br />

any time to adapt to installation<br />

modifications or provide higher levels of<br />

monitoring.<br />

insensitivity to electrical<br />

disturbances<br />

The <strong>Vigilohm</strong> <strong>System</strong> offers both<br />

measurement accuracy and insensitivity to<br />

electrical disturbances. Designed to operate<br />

on modern installations, it is not affected by<br />

the harmonics generated by loads such as<br />

variable speed drives, UPSs and switchmode<br />

power supplies.<br />

valeur d'isolement<br />

TEST MENU<br />

... to distributed measurements with centralised display<br />

1,5 K<br />

E20122<br />

insulation resistance<br />

1.5 KΩ<br />

TEST MENU<br />

XM300c<br />

MERLIN GERIN<br />

From automatic fault locating with local display ...<br />

XLI300<br />

supervisor<br />

insulation<br />

resistance<br />

1.5 KΩ<br />

valeur<br />

d'isolement<br />

1,5 K<br />

XL316<br />

XM200<br />

XD312<br />

MERLIN GERIN<br />

11

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong>:<br />

choosing the system architecture<br />

what devices make up the<br />

system?<br />

c XM200 and XM300C insulation monitoring<br />

devices inject a signal that is used by the<br />

detection and locating devices;<br />

c XL308 and XL316 locators, connected to 8<br />

or 16 toroids, measure the insulation<br />

resistance of each circuit (distributed<br />

measurements) and, in the event of a fault,<br />

automatically identify the faulty circuit.<br />

They can transmit this information to a<br />

supervisor;<br />

c XML308 and XML316 monitoring-locating<br />

devices combine the monitoring and locating<br />

functions in a single unit;<br />

c the XD308C communicating insulation<br />

fault detector automatically identifies the<br />

faulty circuit and transmits this information to<br />

a supervisor;<br />

c XD301 and XD312 non-communicating<br />

insulation fault detectors automatically<br />

identify the faulty circuit;<br />

c the XRM mobile receiver can be used to<br />

fine-tune the automatic locating results by<br />

identifying the faulty circuit at the final<br />

distribution level;<br />

c XLI200, XLI300 and XTU300 interfaces<br />

make communication possible between the<br />

<strong>Vigilohm</strong> <strong>System</strong> and a supervisor;<br />

c the XAS interface is used to supply power<br />

to the communication bus.<br />

1 level of performance<br />

12<br />

2 locating and measurement devices<br />

XRM XD301/302 XD308C XL308/316<br />

receiver detector detector locator<br />

manual fault locating<br />

c<br />

automatic fault locating c v v<br />

with local display<br />

automatic fault locating c v<br />

with centralised display<br />

distributed measurements<br />

c<br />

with local display<br />

distributed measurements<br />

c<br />

with centralised display<br />

3 insulation monitoring device<br />

XM200 c c<br />

XM300c v v c c<br />

XML308/316 v v v c<br />

4 XAS, XLI200, XLI300, XTU300<br />

interfaces c c<br />

c device providing only the required function<br />

v device offering additional possibilities or higher performance.<br />

how to choose the right<br />

system?<br />

The right system can be chosen in four<br />

steps, described in detail below:<br />

1. define the required level of locating and<br />

measurement performance.<br />

2. select the corresponding locating and<br />

measurement devices.<br />

3. select the insulation monitoring devices<br />

compatible with the locating and<br />

measurement devices.<br />

4. check whether or not an interface is<br />

required.<br />

Note: connect the insulation monitoring<br />

device to a PHT1000 subassembly if the<br />

installation voltage U is:<br />

c 760 < U < 1700 V AC (neutral distributed);<br />

c 440 < U < 1000 V AC (neutral not<br />

distributed);<br />

c 550 < U < 1200 V DC (DC or rectified<br />

voltage).<br />

1 level of locating and measurement<br />

performance<br />

According to your need, select one of the<br />

five possibilities listed in part 1 of the table.<br />

The choice depends on:<br />

c the required performance of the locating<br />

system to be associated with the fault<br />

detection function;<br />

c the need for independent insulation<br />

measurements on each circuit.<br />

The five possibilities are (in increasing order<br />

of performance):<br />

v manual fault locating<br />

The fault is located using a mobile receiver<br />

connected to a current probe placed at<br />

different points in the installation one after<br />

another. This type of system is<br />

recommended as an enhancement to the<br />

automatic system in order to determine the<br />

faulty portion of a circuit on which an<br />

insulation fault has been detected.<br />

v automatic fault locating with local<br />

display<br />

The faulty circuit is identified and indicated<br />

on the front face of the fault detector.<br />

A contact is provided for remote indications,<br />

v automatic fault locating with<br />

centralised display<br />

The faulty circuit is identified and indicated<br />

on the front face of the fault detector. The<br />

information is also transmitted to a<br />

supervisor or a PLC,<br />

v distributed measurements with local<br />

display<br />

The devices measure the insulation<br />

resistance on each circuit independently.<br />

These measurements can be read on the<br />

front face of the device.<br />

Faults are located and displayed locally. A<br />

contact is provided for remote indications,<br />

v distributed measurements with<br />

centralised display<br />

The insulation measurement for each circuit<br />

and the indication of the faulty circuit are<br />

displayed on the front of the device and<br />

transmitted to a supervisor or PLC.<br />

2 selection of the locating and<br />

measurement devices<br />

On the line selected in part 1, select the fault<br />

locating or distributed measurement device<br />

in part 2 of the table.<br />

3 selection of the insulation monitoring<br />

device<br />

Similarly, determine the insulation monitoring<br />

devices, in part 3 of the table, that are<br />

compatible with the selected locating and<br />

measurement devices.<br />

4 necessity of an interface<br />

For the column selected in part 2 of the<br />

table, part 4 indicates whether or not an<br />

interface is required. If required, the<br />

interface will be selected according to the<br />

installation and the devices making up the<br />

system. See the page entitled "choosing the<br />

communication interface".

1 2 3<br />

4 5 6<br />

7 8 9<br />

10 11 12<br />

MERLIN GERIN<br />

vigilohm system<br />

XM200<br />

MERLIN GERIN<br />

vigilohm system<br />

XAS<br />

R C Sp Sa<br />

MERLIN GERIN<br />

vigilohm system<br />

XD312<br />

50536<br />

MERLIN GERIN<br />

défaut<br />

vigilohm system<br />

XL316<br />

MERLIN GERIN<br />

XD312<br />

M<br />

M<br />

S<br />

menu ok test<br />

test<br />

reset<br />

test<br />

reset<br />

1<br />

9<br />

2<br />

10<br />

3<br />

11<br />

4<br />

12<br />

test<br />

5<br />

13<br />

6<br />

14<br />

7<br />

15<br />

8<br />

16<br />

test/reset<br />

test<br />

MERLIN GERIN<br />

vigilohm system<br />

XM300c<br />

040 K<br />

test<br />

MERLIN GERIN<br />

RM 10N<br />

P50<br />

P12 P1 0<br />

MERLIN GERIN<br />

RM 10N<br />

P12<br />

P50<br />

P1 0<br />

MERLIN GERIN<br />

vigilohm system<br />

XAS<br />

MERLIN GERIN<br />

vigilohm system<br />

XAS<br />

défaut<br />

défaut<br />

MERLIN GERIN<br />

RM 10N<br />

P50<br />

P12 P1 0<br />

MERLIN GERIN<br />

MERLIN GERIN<br />

vigilohm system<br />

XD308c<br />

vigilohm system<br />

XL308c<br />

1 2 3 4 5 6 7 8<br />

test<br />

reset<br />

MERLIN GERIN<br />

XD312<br />

test<br />

on<br />

1 2 3 4 5 6 7 8<br />

9 10 11 12 13 14 15 16<br />

MERLIN GERIN<br />

XD308c<br />

test<br />

reset<br />

test/reset<br />

test<br />

MERLIN GERIN<br />

vigilohm system<br />

XML316<br />

1 2 3 4 5 6 7 8<br />

9 10 11 12 13 14 15 16<br />

MERLIN GERIN<br />

vigilohm system<br />

XM300c<br />

040 K<br />

MERLIN GERIN<br />

vigilohm system<br />

XD308c<br />

RM 10N<br />

1 2 3 4 5 6 7 8<br />

test<br />

MERLIN GERIN<br />

reset<br />

P50<br />

P12 P1 0<br />

test<br />

on<br />

MERLIN GERIN<br />

XD312<br />

test<br />

test<br />

test<br />

reset<br />

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong>:<br />

choosing the fault locating system<br />

The <strong>Vigilohm</strong> <strong>System</strong> offers four fault<br />

locating performance levels.<br />

level 1: automatic fault detection and<br />

locating.<br />

level 2: automatic fault detection and<br />

locating with transmission to a supervisor.<br />

level 3: automatic fault detection, locating<br />

and measurement.<br />

level 4: automatic fault detection, locating<br />

and measurement with transmission to a<br />

supervisor.<br />

Manual fault locating with the XRM mobile<br />

receiver is generally used to fine-tune the<br />

automatic locating results.<br />

E24547<br />

XM200<br />

E24548<br />

interface<br />

supervisor<br />

printer<br />

IMD<br />

valeur d'isolement<br />

TEST MENU<br />

XRM<br />

XD312<br />

XD308c<br />

XD308c<br />

level 1: automatic fault detection and locating<br />

XRM<br />

XD312<br />

level 2: automatic fault detection and locating with transmission to a supervisor.<br />

E24550<br />

interface<br />

XM300c<br />

E24549<br />

interface<br />

supervisor<br />

printer<br />

XML308/316<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

valeur d'isolement<br />

TEST MENU<br />

XL308/316<br />

XL308/316<br />

XD312<br />

XRM<br />

XD308c<br />

XRM<br />

XD312<br />

level 3: automatic fault detection, locating and<br />

measurement<br />

level 4: automatic fault detection, locating and measurement with transmission<br />

to a supervisor.<br />

13

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong>:<br />

choosing a communication interface<br />

the power of a<br />

communicating system<br />

The power of the <strong>Vigilohm</strong> <strong>System</strong> lies in the<br />

capacity it offers for communication between<br />

all its devices, thereby ensuring insulation<br />

monitoring and complementary functions<br />

such as automatic locating of faults or the<br />

anticipation of their occurrence.<br />

In addition, the <strong>Vigilohm</strong> <strong>System</strong> is capable<br />

of communicating with a supervisor or a<br />

PLC, i.e. it can both transmit data to and<br />

receive data from such units.<br />

The transfer of information takes place:<br />

c via the internal <strong>Vigilohm</strong> <strong>System</strong> bus for<br />

communication between the devices;<br />

c via the external JBUS for communication<br />

with a supervisor or PLC.<br />

In both cases, the use of an internal or<br />

external bus requires a communication<br />

interface.<br />

four interfaces<br />

The <strong>Vigilohm</strong> <strong>System</strong> offers four interfaces:<br />

c the XLI200 interface, for the transmission<br />

of information from the insulation monitoring<br />

device and XD308C detectors to a<br />

supervisor or PLC via JBUS. In this way,<br />

a PC can access information concerning<br />

the presence of faults and the identification<br />

of the faulty circuit. This interface cannot be<br />

used with XL308/316 or XML308/316<br />

devices and connects only to the XM300C<br />

and XD308C (the XLI200 cannot be used<br />

with XML monitoring-locating devices or with<br />

XL locating devices).<br />

c the XLI300 interface, for the transmission<br />

of measurements and measurement<br />

parameters from the XM300C and XD308C<br />

devices to a supervisor. This interface is<br />

used on single busbar installations. The<br />

exclusion of other insulation monitoring<br />

devices found on the same installation is<br />

managed automatically;<br />

c the XTU300 interface, for communication<br />

between the <strong>Vigilohm</strong> <strong>System</strong> and a<br />

supervisor, like the XLI300 interface. This<br />

interface is required for installations with<br />

multiple busbars and bus coupler circuit<br />

breakers. It manages the exclusion of other<br />

insulation monitoring devices found on the<br />

same installation and the link between the<br />

locators and their corresponding insulation<br />

monitoring devices;<br />

c the XAS interface, indispensable for the<br />

operation of the communication bus in the<br />

absence of one of the three other interfaces.<br />

interface selection table<br />

IMD associated only one XML308/316 IMD with at least IMD with a least<br />

with XD308C device 1 locator 1 locator<br />

communicating + 1 set of busbars + several sets<br />

detectors, whatever the<br />

of busbars with<br />

installation configuration<br />

bus coupling<br />

without supervision ---- ---- XAS XTU300<br />

with supervision XLI200 XLI300 XLI300 XTU300<br />

E20791<br />

E20792<br />

MV/LV<br />

XML308<br />

One set of busbars without supervisor<br />

XM300c<br />

MV/LV<br />

XAS<br />

XL308<br />

supervisor<br />

or<br />

PLC<br />

DB100957 E20790A<br />

MV/LV<br />

XML308<br />

One set of busbars with supervisor<br />

XM300c<br />

MV/LV<br />

supervisor<br />

or<br />

PLC<br />

XLI300<br />

XL308<br />

supervisor<br />

or<br />

PLC<br />

MV/LV<br />

MV/LV<br />

MT/BT<br />

MT/BT<br />

XML308<br />

XM300c<br />

XTU300<br />

XM300C<br />

XM300C<br />

XLI200<br />

XD308C<br />

XL308<br />

XD308C<br />

Several sets of busbars with bus coupling and with or without supervisor<br />

14<br />

application of the measurement voltage<br />

internal <strong>Vigilohm</strong> <strong>System</strong> bus<br />

JBUS bus

<strong>Vigilohm</strong>: presentation<br />

<strong>Vigilohm</strong> <strong>System</strong>:<br />

two examples of installations<br />

E20786 E20788<br />

MV/LV<br />

XM200<br />

XD301<br />

MV/LV<br />

XML316<br />

XRM<br />

MV/LV<br />

XM200<br />

MV/LV<br />

XML308<br />

XD301<br />

XD312<br />

G<br />

supervisor<br />

or<br />

PLC<br />

XTU300<br />

XM300c<br />

XL308<br />

automatic fault locating<br />

with or without supervision<br />

The following examples cover two typical<br />

installation configurations with insulation<br />

monitoring and fault locating systems.<br />

Example 1:<br />

c automatic fault locating with local<br />

display.<br />

The use of an XM200 insulation monitoring<br />

device together with XD301 and XD312<br />

detectors represents the typical case<br />

providing basic detection and automatic<br />

locating of insulation faults on the main<br />

feeders as well as on certain secondary<br />

feeders.<br />

Fault locating can be fine-tuned using an<br />

XRM mobile receiver and a current probe to<br />

determine the exact location of the fault on<br />

the faulty circuit.<br />

The auto-exclusion of other XM200 insulation<br />

monitoring devices is controlled by the circuit<br />

breaker position indication contacts.<br />

Example 2:<br />

c measurement and automatic fault<br />

locating with local and centralised<br />

display, for an installation with more than<br />

one set of busbars and a bus coupling<br />

circuit breaker.<br />

The measurement of the insulation<br />

resistance on the main feeders is provided in<br />

addition to fault detection with automatic<br />

locating (XL308/316 and XML308/316).<br />

The secondary feeders are monitored simply<br />

by an XD312/301 detector or by an XD308C<br />

detector that communicates detected faults to<br />

the supervisor (via the XTU300 interface).<br />

The architecture of the installation (several<br />

sources and sets of busbars) makes it<br />

necessary to use an XTU300 interface to<br />

handle the exclusion of other insulation<br />

monitoring devices and the link between the<br />

locators and their corresponding insulation<br />

monitoring devices.<br />

XD312<br />

XD308c<br />

XRM<br />

application of the measurement voltage<br />

internal <strong>Vigilohm</strong> <strong>System</strong> bus<br />

JBUS bus<br />

15

insulation monitoring<br />

<strong>Vigilohm</strong><br />

2/ functions<br />

and characteristics<br />

page<br />

choosing an insulation monitoring device<br />

for different types of installations 18<br />

and associated functions 20<br />

Vigilhom <strong>System</strong><br />

XM300C insulation monitoring 22<br />

device<br />

XL308 and XL316 insulation 24<br />

fault locators<br />

XML308 and XML 316 monitoring- 26<br />

locating devices<br />

XD308C communicating automatic 28<br />

insulation fault detector<br />

XLI200, XLI300, XTU300, XAS 29<br />

communication interfaces<br />

XM200 insulation monitoring 30<br />

device<br />

XD301 and XD312 automatic 32<br />

insulation fault detectors<br />

XRM mobile fault locating receiver 33<br />

and current probes<br />

<strong>Vigilohm</strong><br />

TR22A and TR22AH insulation 34<br />

monitoring devices<br />

EM9 and EM9B insulation 35<br />

monitoring devices<br />

EM9BV insulation monitoring device 36<br />

EM9T insulation monitoring device 37<br />

TR5A insulation monitoring device 38<br />

SM21 insulation monitoring device 39<br />

mobile fault locating kit<br />

XGR + XRM + probes 40<br />

toroids 41<br />

auxiliaries 43<br />

17

<strong>Vigilohm</strong>: functions and characteristics<br />

choosing an insulation monitoring device<br />

for different types of installations<br />

044147 044148<br />

installation characteristics (1)<br />

device XM200 XM300C<br />

IT system for the entire installation<br />

Continuity of supply is the requirement that most often<br />

leads designers to chose the IT system for an electrical<br />

installation.<br />

This requirement may apply to the entire installation<br />

(e.g. chemical process plant, steel plant, etc.).<br />

Such an installation requires continuous monitoring of<br />

the insulation level.<br />

E27341<br />

E27336<br />

MV/LV<br />

MV/LV<br />

P1<br />

IMD<br />

PHT 1000<br />

IMD<br />

E27427<br />

L1<br />

L2<br />

L3<br />

N<br />

PHT 1000<br />

IMD<br />

440 to<br />

1000 V AC* (1)<br />

500 to<br />

1200 V DC*<br />

*with<br />

PHT 1000<br />

subassembly<br />

E27343<br />

MV/LV<br />

L1<br />

L2<br />

L3<br />

N<br />

i 440 V AC (1)<br />

i 500 V DC<br />

i 440 V AC (1)<br />

i 500 V DC<br />

IMD<br />

L-<br />

L+<br />

IT system for part of an installation<br />

The requirement for continuity of supply may apply to<br />

only a part of an installation, for example a single shop<br />

or plant, or a circuit subject to special conditions<br />

(safety lighting).<br />

In this case, it is recommended to use the IT system<br />

for this part of the installation, whatever the system<br />

used for general distribution.<br />

E27344<br />

E27345<br />

MV/LV<br />

MV/LV<br />

TN or TT<br />

LV/LV<br />

IMD<br />

TN or TT<br />

IT<br />

L1<br />

L2<br />

L3<br />

N<br />

L1<br />

L2<br />

L3<br />

N<br />

L1<br />

L2<br />

L3<br />

i 440 V AC<br />

i 440 V AC<br />

machine<br />

tool or<br />

robot<br />

LV/LV<br />

IMD<br />

IT<br />

control/monitoring<br />

IT system for DC installations<br />

In many cases, the use of direct current corresponds to<br />

a need for continuity of supply. The use of an IT<br />

system and insulation monitoring is therefore<br />

consistent with this choice.<br />

E27337<br />

500 V 500 to 1200 V TR5A<br />

IMD<br />

+<br />

–<br />

E27338<br />

PHT 1000<br />

IMD<br />

+<br />

–<br />

E27339<br />

IMD<br />

+<br />

–<br />

i 500 V DC<br />

i 500 V DC<br />

500 to<br />

1200 V DC*<br />

*with<br />

PHT 1000<br />

subassembly<br />

off-line insulation monitoring<br />

The use of motors in industrial processes creates a further<br />

need for insulation monitoring. By checking the insulation<br />

with power off, the presence of insulation faults can be<br />

determined before starting motors (fire pumps, smoke<br />

extractors, etc.). It is also possible to prevent motor starting<br />

automatically if the insulation resistance is below a certain<br />

threshold.<br />

E27346<br />

L1<br />

L2<br />

L3<br />

IMD<br />

M<br />

(1) Phase-to-phase voltage with IMD connected to one phase. Multiply these values by e if IMD is connected to neutral.<br />

(2) Installation without frequency converter.<br />

18

044149 041850 043274<br />

042578<br />

042580<br />

042580<br />

042582 017422 051346<br />

042581<br />

XML<br />

308/316<br />

TR22A TR22AH EM9 EM9B EM9BV EM9T TR5A SM21<br />

i 1 000 V AC<br />

(1)<br />

with P1<br />

subassembly<br />

440 to<br />

1000 V AC* (1)<br />

500 to<br />

1200 V DC*<br />

*with<br />

PHT 1000<br />

subassembly<br />

i 440 V AC (1)<br />

i 500 V DC<br />

i 440 V AC (1)<br />

(2)<br />

i 440 V AC (1)<br />

(2)<br />

i 440 V AC<br />

i 440 V AC i 440 V AC i 440 V AC i 440 V AC<br />

i 440 V AC<br />

i 220 V AC<br />

i 500 V DC<br />

500 to<br />

1200 V DC*<br />

*with<br />

PHT 1000<br />

subassembly<br />

i 420 V DC<br />

i 690 V AC<br />

19

<strong>Vigilohm</strong>: functions and characteristics<br />

choosing an insulation monitoring device<br />

and associated functions<br />

044147 044148<br />

installation characteristics<br />

device<br />

XM200<br />

XM300C<br />

injected signal<br />

2.5 Hz<br />

2.5 Hz<br />

IT system for the entire installation<br />

E27328<br />

HV/MV<br />

MV/LV<br />

MV/LV<br />

voltage (1)<br />

with rectifiers<br />

440 to 1000 V AC<br />

i 400 V AC<br />

440 to 1000 V AC<br />

(2)<br />

(2)<br />

i 440 V AC<br />

for hospitals<br />

i 440 V AC<br />

IT system for part of an installation<br />

E27329<br />

MV/LV<br />

LV/LV<br />

high insulation level<br />

i 440 V AC<br />

low insulation level<br />

i 440 V AC<br />

control and<br />

monitoring<br />

of machines<br />

i 220 V AC<br />

DC installation<br />

E27330<br />

+<br />

24 to 420 V DC<br />

-<br />

i 500 V DC<br />

500 to 1200 V DC<br />

(2)<br />

off-line monitoring (LV motors)<br />

E27331<br />

M<br />

i 690 V AC<br />

E27332<br />

communication functions<br />

insulation resistance measurement<br />

kΩ<br />

measurement display<br />

prevention indication<br />

E27335<br />

E27333<br />

fault locating<br />

communication with supervisor<br />

external BUS<br />

insulation fault indication<br />

manual<br />

automatic<br />

automatic + fault measurement<br />

via JBUS communication bus (and interfaces)<br />

(1) Phase-to-phase voltage with IMD connected to one<br />

phase. Multiply these values by e if IMD is connected to<br />

neutral.<br />

(2) With PHT 1000 subassembly.<br />

(4) (4)<br />

(6) (7)<br />

(8)<br />

(3) With P1 subassembly.<br />

(4) With XRM mobile receiver.<br />

(5) With XRM mobile receiver + XGR signal generator<br />

20

044149<br />

041850 043274<br />

042578<br />

042580<br />

042580<br />

042582<br />

017422 051346<br />

042581<br />

XML<br />

308/316<br />

2.5 Hz<br />

TR22A<br />

DC<br />

TR22AH<br />

DC<br />

EM9<br />

DC<br />

EM9B<br />

DC<br />

EM9BV<br />

DC<br />

EM9T<br />

DC<br />

TR5A<br />

NONE<br />

SM21<br />

DC<br />

(2)<br />

(3)<br />

(2)<br />

(9)<br />

(2)<br />

(4)<br />

(5) (5) (5) (5) (5)<br />

(5) (5)<br />

(7)<br />

(8)<br />

(6) With XD301/312 detector.<br />

(7) With XD301/312 detector or communicating XD308C<br />

detector.<br />

(8) With XL308/316 locator.<br />

(9) Remote test possible.<br />

21

044148<br />

MERLIN GERIN<br />

v ig ilo h m s y s t e m<br />

X D 3 0 1<br />

5 0 5 0 7<br />

MERLIN GERIN<br />

v i g i r e x - v i g i d i x<br />

M<br />

M<br />

t e s t<br />

r e s e t<br />

MERLIN GERIN<br />

vigilo h m system<br />

XAS<br />

MERLIN GERIN<br />

vig ilo h m system<br />

XML316<br />

1 2 3 4 5 6 7 8<br />

9 1 0 1 1 1 2 1 3 1 4 1 5 1 6<br />

MERLIN GERIN<br />

v i g i r e x - v i g i d i x<br />

d é f a u t<br />

1 2 3<br />

4 5 6<br />

7 8 9<br />

10 11 12<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

MERLIN GERIN<br />

v ig ilo h m s y s t e m<br />

X D 3 1 2<br />

5 0 5 3 6<br />

MERLIN GERIN<br />

v i g i r e x - v i g i d i x<br />

M<br />

M<br />

t e s t<br />

r e s e t<br />

test<br />

MERLIN GERIN<br />

v i g i d i x<br />

R M 1 0 N<br />

P 1 0<br />

P 5 0<br />

o n P 1 2<br />

MERLIN GERIN<br />

vigiloh m system<br />

XLI3 0<br />

d é f a u t<br />

MERLIN GERIN<br />

vig ilo h m system<br />

X D 3 08c<br />

test<br />

1 2 3 4 5 6 7 8<br />

on<br />

test<br />

reset<br />

MERLIN GERIN<br />

G O<br />

MERLIN GERIN<br />

MERLIN GERIN<br />

vigiloh m system<br />

XTU3 0<br />

vig ilo h m system<br />

X M 3 0 c<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

MERLIN GERIN<br />

vig ilo h m system<br />

X L 3 1 6<br />

S1<br />

S2<br />

P O<br />

d é f a u t<br />

MERLIN GERIN<br />

test<br />

test<br />

1 2 3 4 5 6 7 8<br />

9 1 0 1 1 1 2 1 3 1 4 1 5 1 6<br />

S1<br />

S2<br />

test/reset<br />

<strong>Vigilohm</strong>: functions and characteristics<br />

communicating <strong>Vigilohm</strong> <strong>System</strong><br />

XM300C insulation monitoring device<br />

DB100958<br />

interfaces<br />

insulation monitoring<br />

XML308/316<br />

insulation<br />

fault detection and locating<br />

sensors<br />

XM300c<br />

basic function: overall<br />

insulation monitoring<br />

The XM300C provides overall insulation<br />

monitoring of electrical installations by<br />

injecting a low-frequency AC voltage<br />

between the installation and earth.<br />

main functions<br />

c measurement:<br />

v insulation resistance,<br />

v earth leakage capacitance;<br />

c indications:<br />

v satisfactory insulation resistance (green<br />

light on bargraph),<br />

v drop in insulation resistance:<br />

– below prevention threshold (orange light<br />

on bargraph and relay actuated),<br />

– below fault threshold (red light on bargraph<br />

and two relays actuated, including one with<br />

a failsafe feature),<br />

v transient faults (orange light);<br />

c display:<br />

v measurements,<br />

v events detected by any XL308/316<br />

locators connected.<br />

All this data is accessible locally on the LCD<br />

screen of the insulating monitoring device<br />

and remotely via the <strong>Vigilohm</strong> <strong>System</strong> bus.<br />

additional functions with<br />

other devices<br />

Locating of faulty circuits<br />

This function is obtained by using the<br />

XM300C together with:<br />

c XL308 and XL316 locators connected to 8<br />

or 16 toroids. They are linked to the<br />

XM300C by the <strong>Vigilohm</strong> <strong>System</strong> bus;<br />

c XD308C communicating detectors. They<br />

are linked to the XM300C by the <strong>Vigilohm</strong><br />

<strong>System</strong> bus, and connected to the toroids<br />

placed on the circuits to be monitored;<br />

c XD301 and XD312 detectors connected to<br />

the toroids placed on the circuits to be<br />

monitored;<br />

c an XRM mobile receiver and a current<br />

probe to fine-tune the automatic locating<br />

results.<br />

All these devices can be combined on a<br />

given installation.<br />

Distributed measurements<br />

This function is provided by combining an<br />

XM300C monitoring device (or an<br />

XML308/316 monitoring-locating device)<br />

with XL308 or XL316 locators.<br />

These locators measure the insulation<br />

resistance and the earth leakage<br />

capacitance of each of the circuits.<br />

They have a fault alarm threshold that can<br />

be set to a different levels for each channel.<br />

communication<br />

Communication with the supervision system.<br />

The XLI300 and XTU300 interfaces allow<br />

monitoring devices + locators<br />

+ communicating detectors to exchange<br />

information with a supervision system via<br />

JBUS protocol.<br />

The XLI300 and XTU300 interfaces connect<br />

to the <strong>Vigilohm</strong> <strong>System</strong> bus and allow<br />

timestamping of insulation monitoring<br />

events.<br />

configuration management<br />

On installations with a number of insulation<br />

monitoring devices installed to cover<br />

variable configurations, only one device at a<br />

time can be allowed to inject a voltage<br />

between earth and the installation<br />

downstream of the incoming circuit breaker.<br />

For this reason, the system must manage<br />

the exclusion of other connected insulation<br />

monitoring devices. In addition, each locator<br />

must identify the monitoring device from<br />

which it is to capture the signal.<br />

The exclusion of monitoring devices and<br />

their identification by the locators is handled<br />

in one of the following manners:<br />

c by the XTU300 interface for multiple<br />

busbar installations;<br />

c by the XLI300 interface for single busbar<br />

installations.<br />

In both cases, the circuit breaker position<br />

indication contacts are wired to the all-ornothing<br />

inputs of the XM300C or<br />

XML308/316.<br />

If only XD308C detectors are associated<br />

with the XM300C, monitoring device<br />

exclusion is handled by the XLI200 interface.<br />

standards<br />

The XM300C insulation monitoring device<br />

complies with the following standards:<br />

c IEC 364, parts 4 and 5;<br />

c class CPI/XA of UTE C 63-080.<br />

It is implemented in accordance with<br />

standard NF C 15-100 paragraph 413.4;<br />

c IEC 61557-8.<br />

installation and connection<br />

c horizontal flush mounting on the front face<br />

of a cubicle or enclosure;<br />

c easy mounting in Prisma enclosures using<br />

the corresponding mounting plates and front<br />

plates that come with the appropriate<br />

cut-outs;<br />

c the devices are interconnected by shielded<br />

cables (double 0.75 mm 2 twisted pairs).<br />

The resistance between the two most distant<br />

points must not exceed 12 Ω.<br />

The coupling capacitance between pairs<br />

must not exceed 250 nF;<br />

c if no XTU300 or XLI300 interface is<br />

included, operation of the <strong>Vigilohm</strong> <strong>System</strong><br />

bus will require an XAS interface.<br />

22

auxiliaries<br />

Cardew surge limiter: page 43.<br />

ZX limiting impedance to create an<br />

impedance-earthed neutral: page 44.<br />

PHT1000 subassembly if the device is to<br />

be used on 1000-1700 V installations:<br />

page 44.<br />

restrictions for use<br />

The XM300C operates by injecting lowfrequency<br />

signals (2.5 Hz). It should not be<br />

used for circuits that include variable speed<br />

drives if this equipment continuously<br />

generates a signal with a similar frequency<br />

(≤ 5 Hz).<br />

E19527<br />

MERLIN GERIN<br />

XM300C<br />

1 7 6 2 4 5 3<br />

1. display indicating:<br />

c the value of the overall insulation<br />

resistance R;<br />

c other information as selected via function<br />

keys.<br />

2. red self-test light, indicating internal<br />

XM300C faults.<br />

3. light indicating that a transient fault has<br />

occurred.<br />

4. 5 lights indicating the insulation level.<br />

5. instruction manual stored in a drawer on<br />

the front face<br />

6. sealable cover ensuring tamperproof<br />

settings.<br />

7. function keys for:<br />

c accessing earth coupling capacitance<br />

readings<br />

c setting thresholds;<br />

c accessing three last values of transient<br />

insulation faults;<br />

c remote access to faults detected by XL308<br />

or XL316 detectors;<br />

c choice of language.<br />

test<br />

i<br />

type of installation to be monitored<br />

AC or mixed<br />

phase-to phase voltage<br />

AC/DC IT systems with XM300C connected to neutral < 760 or 1700 V AC (1)<br />

with XM300C connected to phase < 440 or 1000 V AC (1)<br />

frequency<br />

45-400 Hz<br />

size of installation<br />

0 to 30 km of cable<br />

DC or rectified line voltage < 500 or 1200 V DC (1)<br />

IT systems<br />

electrical characteristics<br />

ohmmeter<br />

digital<br />

range for insulation resistance readings<br />

0.1 to 999 kΩ<br />

signalling number of thresholds 2 (sealable settings)<br />

threshold settings 1st threshold (prevent.) 1 to 299 kΩ<br />

2nd threshold (fault) 0.2 to 99.9 kΩ<br />

dielectric strength<br />

2500 V<br />

auxiliary supply voltage 50/60 Hz 115/127 V AC<br />

220/240 V AC<br />

380/415 V AC<br />

500/525 V AC<br />

auxiliary supply voltage tolerances - 15 % to + 10 %<br />

maximum device consumption<br />

30 VA<br />

measurement voltage<br />

6 V<br />

measurement current<br />

5 mA max<br />

50 Hz/DC impedance 22 kΩ<br />

device test<br />

self-test and manual test<br />

failsafe feature (2)<br />

as standard<br />

changeover output contact quantity 3 (1 failsafe)<br />

breaking capacity of output AC 400 V p. f. = 0.7 3 A<br />

contacts 230 V p. f. = 0.7 5 A<br />

DC 220 V L/R = 1 ms 0.45 A<br />

120 V L/R = 1 ms 0.65 A<br />

48 V L/R = 1 ms 2.5 A<br />

24 V L/R = 1 ms 10 A<br />

circuit breaker position indication contacts (3) : voltage supplied 24 V<br />

(voltage and current supplied by XAS max. current supplied 10 mA (short-circuit)<br />

XLI or XTU interfaces)<br />

connection cross-sections rigid conductors 1 to 1.5 mm 2<br />

flexible conductors 0.75 to 1.5 mm 2<br />

mechanical characteristics<br />

weight<br />

sheet-metal case (horizontal mounting)<br />

3.5 kg<br />

disconnectable screw terminal block<br />

degree of protection flush mounting IP 30<br />

other characteristics<br />

interfacing possible with<br />

supervisor<br />

multi-language display<br />

English/French<br />

tamperproof settings<br />

protected by access code or sealable cover<br />

temperature range operating - 5 °C to + 55 °C<br />

storage - 25 °C to + 70 °C<br />

(1) The upper limit is extended to the second value by adding a PHT1000 subassembly.<br />

(2) Failsafe feature: a failsafe relay operates in the event of an accidental interruption of auxiliary power or a fault.<br />

(3) This contact is an auxiliary switch mounted on the circuit breaker and used to indicate its operating status.<br />

23

044145<br />

MERLIN GERIN<br />

v ig ilo h m s y s t e m<br />

X D 3 0 1<br />

5 0 5 0 7<br />

MERLIN GERIN<br />

v i g i r e x - v i g i d i x<br />

M<br />

M<br />

t e s t<br />

r e s e t<br />

MERLIN GERIN<br />

vig ilo h m system<br />

XAS<br />

MERLIN GERIN<br />

vig ilo h m system<br />

XML316<br />

1 2 3 4 5 6 7 8<br />

9 1 0 1 1 1 2 1 3 1 4 1 5 1 6<br />

MERLIN GERIN<br />

v i g i r e x - v i g i d i x<br />

d é f a u t<br />

1 2 3<br />

4 5 6<br />

7 8 9<br />

10 11 12<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

MERLIN GERIN<br />

v ig ilo h m s y s t e m<br />

X D 3 1 2<br />

5 0 5 3 6<br />

MERLIN GERIN<br />

v i g i r e x - v i g i d i x<br />

M<br />

M<br />

t e s t<br />

r e s e t<br />

test<br />

5 0<br />

on P 1 2 P 1 0<br />

MERLIN GERIN<br />

v i g i d ix<br />

R M 1 0 N<br />

MERLIN GERIN<br />

vig ilo h m system<br />

XLI3 0<br />

d é f a u t<br />

MERLIN GERIN<br />

vigilo h m system<br />

X D 3 0 8c<br />

test<br />

1 2 3 4 5 6 7 8<br />

on<br />

test<br />

reset<br />

MERLIN GERIN<br />

G O<br />

MERLIN GERIN<br />

MERLIN GERIN<br />

vig iloh m system<br />

XTU3 0<br />

vig ilo hm system<br />

X M 3 0 c<br />

valeur d'isolement<br />

TEST MENU<br />

040 K<br />

MERLIN GERIN<br />

vig iloh m system<br />

X L31 6<br />

S1<br />

S2<br />

P O<br />

d é f a u t<br />

MERLIN GERIN<br />

test<br />

test<br />

1 2 3 4 5 6 7 8<br />

9 1 0 1 1 1 2 1 3 1 4 1 5 1 6<br />

S1<br />

S2<br />

test/reset<br />

<strong>Vigilohm</strong>: functions and characteristics<br />

communicating <strong>Vigilohm</strong> <strong>System</strong><br />

XL308 and XL316 insulation fault locators<br />

basic function: local<br />

insulation fault monitoring<br />

Used together with an XM300C or XML308/<br />

316 monitoring device, XL308 and XL316<br />

locators monitor the insulation of 8 or 16<br />

individual circuits and automatically locate<br />

any faults.<br />

main functions<br />

c measurement:<br />

v insulation resistance of each monitored<br />

circuit,<br />

v earth leakage capacitance of each<br />

monitored circuit;<br />

c indications:<br />

v satisfactory insulation resistance (green<br />

light),<br />

v drop in insulation resistance below fault<br />

threshold (red light and two relays actuated,<br />

including one with a failsafe feature). The<br />

fault threshold is adjustable for each of the 8<br />

or 16 channels corresponding to the<br />

monitored circuits,<br />

v transient faults on each of the monitored<br />

circuits;<br />

c display:<br />

v faulty circuits are indicated by the<br />

corresponding LEDs (8 or 16 depending on<br />

the model),<br />

v a flashing LED indicates a transient fault<br />

on the corresponding circuit.<br />

communication<br />

Faults detected by XL308/316 locators can<br />

be displayed on the insulation monitoring<br />

device associated with the locator.<br />

The information transmitted to the insulation<br />

monitoring device can be transmitted to a<br />

supervisor via an XLI300 or XTU300<br />

interface connect to the <strong>Vigilohm</strong> <strong>System</strong><br />

bus.<br />

standards<br />

XL308 and XL316 locators comply with the<br />

following standards:<br />

c IEC 364, parts 4 and 5;<br />

c class DLD/M of UTE C 63-080;<br />

They are implemented in accordance with<br />

standard NF C 15-100 paragraph 413.4;<br />

c IEC 61557-8.<br />

toroids<br />

XL308 and XL316 locators operate with type<br />

A and OA toroids.<br />

installation and connection<br />

c horizontal flush mounting on the front face<br />

of a cubicle or enclosure;<br />

c easy mounting in Prisma enclosures using<br />

the corresponding mounting plates and front<br />

plates that come with the appropriate<br />

cut-outs;<br />

c the devices are interconnected by shielded<br />

cables (double 0.75 mm 2 twisted pairs).<br />

The resistance between the two most distant<br />

points must not exceed 12 Ω.<br />

The coupling capacitance between pairs<br />

must not exceed 250 nF;<br />

c connection of toroids using twisted,<br />

shielded cable (1 pair);<br />

c if no XTU300 or XLI300 interface is<br />

included, operation of the <strong>Vigilohm</strong> <strong>System</strong><br />

bus will require an XAS interface.<br />

DB100959<br />

interfaces<br />

insulation monitoring<br />

insulation<br />

fault detection and locating<br />

XD301 XD312 XRM XD308c XL308 / 316<br />

sensors<br />

24

DB100954<br />

locator XL308 XL316<br />

electrical characteristics<br />

ohmmeter<br />

digital<br />

range for insulation resistance readings<br />

0.1 to 999 kΩ<br />

signalling 8 lights (1 per channel) 16 lights (1 per channel)<br />

signalling threshold and 1<br />

setting range (per channel) fault threshold 0.2 to 99.9 kΩ<br />

polling time<br />

15 seconds per channel<br />

device test<br />

self-test and manual test<br />

dielectric strength<br />

2500 V<br />

auxiliary supply voltage 50/60 Hz 115/127 V AC<br />

220/240 V AC<br />

380/415 V AC<br />

500/525 V AC<br />

auxiliary supply voltage tolerances - 15 % to + 10 %<br />

maximum device consumption<br />

30 VA<br />

indicator and output relay<br />

local or from insulation monitoring device<br />

output relays<br />

2 (1 failsafe)<br />

breaking capacity of<br />

output contacts<br />

AC 400 V p.f. = 0.7<br />

230 V p.f. = 0.7<br />

3 A<br />

5 A<br />

DC 220 V L/R = 1 ms<br />

0.45 A<br />

120 V L/R = 1 ms 0.65 A<br />

48 V L/R = 1 ms 2.5 A<br />

24 V L/R = 1 ms 10 A<br />

link with insulation monitoring device<br />

via 4-wire communication bus<br />

connection crosssections<br />

mechanical characteristics<br />

weight<br />

sheet-metal case<br />

other characteristics<br />

(1) The upper limit is extended to the second value by adding a PTH1000 subassembly.<br />

The same voltage limits apply to both the XL308 and the XL316.<br />

rigid conductors 1 to 1.5 mm 2<br />

flexible conductors 0.75 to 1.5 mm 2<br />

3.5 kg<br />

horizontal mounting<br />

disconnectable screw terminal block<br />

types of toroid to be used<br />

A and OA (XC compatible)<br />

temperature range operating - 5 °C to + 55 °C<br />

storage - 20 °C to + 70 °C<br />

MERLIN GERIN<br />

XL31<br />

6<br />

-<br />

∝<br />

+<br />

1 2 3 4 5 6 7 8<br />

9 10 1 12 13 14 15 16<br />

1<br />

∝F !<br />

/<br />

test/rese<br />

t<br />

1 2 9 7 8 5 6 4 3<br />

i<br />

1. display indicating measured insulation<br />

resistance and earth coupling capacitance<br />

value.<br />

2. light indicating measurement units for<br />

displayed value (kΩ, µF, etc.).<br />

3. red self-test light, indicating device faults.<br />

4. yellow light indicating that a transient fault<br />

has occurred.<br />

5. 2 lights indicating the insulation level:<br />

c green light: normal;<br />

c red light: insulation resistance below fault<br />

threshold on one of the circuits.<br />

6. instruction manual stored in a drawer on<br />