APP Sustainability Report 2008-2009 - Asia Pulp and Paper

APP Sustainability Report 2008-2009 - Asia Pulp and Paper

APP Sustainability Report 2008-2009 - Asia Pulp and Paper

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Sustainable Products<br />

Sustainable Products<br />

Hazardous Waste<br />

Solid hazardous waste decreased markedly in<br />

<strong>2009</strong>, as additional useful outlets were found<br />

for many of the materials. Oil-based liquid<br />

hazardous wastes can now be routinely<br />

disposed of by incineration on-site, resulting<br />

in a 67 percent reduction in the quantity<br />

of these materials in <strong>2009</strong>, which would<br />

otherwise require licensed off-site disposal.<br />

Our range of solid hazardous wastes, <strong>and</strong><br />

their reuse <strong>and</strong>/or disposal pathways are<br />

indicated below.<br />

Environmental Expenditures<br />

Ongoing investment in environmental<br />

programs supports our pursuit of continual<br />

improvement in the operation <strong>and</strong><br />

maintenance. Environmental expenditures<br />

decreased from <strong>2008</strong> to <strong>2009</strong>, from US$7.7<br />

million to US$3.7 million, thanks to the<br />

elimination of aluminium sulfate usage in a<br />

newly installed wastewater treatment plant.<br />

Plant Efficiency <strong>and</strong> Plant<br />

Improvement Programmes<br />

Improvement programmes for the period<br />

<strong>2008</strong> / <strong>2009</strong> included new air flotation<br />

systems to enhance the backwater <strong>and</strong> pulp<br />

recovery <strong>and</strong> new projects to reduce water,<br />

steam, power <strong>and</strong> chemical consumption.<br />

Additional efforts are being made on<br />

waste minimisation projects <strong>and</strong> increased<br />

utilisation – rather than disposal – of waste<br />

streams.<br />

Lontar Papyrus <strong>Pulp</strong> & <strong>Paper</strong> Industry<br />

No significant spillages of either hazardous<br />

or non-hazardous waste were recorded at<br />

either Indah Kiat Perawang mill during <strong>2008</strong><br />

or <strong>2009</strong>.<br />

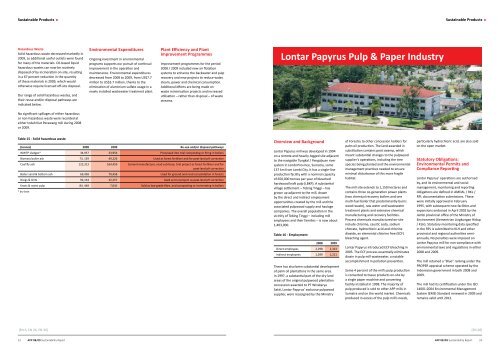

Table 15 - Solid hazardous waste<br />

(tonnes) <strong>2008</strong> <strong>2009</strong> Re-use <strong>and</strong>/or disposal pathways<br />

WWTP sludges* 34,957 33,956 Processed into trial composting or firing in boilers<br />

Biomass boiler ash 73, 139 49,226 Used as forest fertiliser <strong>and</strong> for peat-l<strong>and</strong> pH correction<br />

Coal fly ash 122,313 164,459 Cement manufacture, road sub-base, trial project as forest fertiliser <strong>and</strong> for<br />

peat-l<strong>and</strong> pH correction<br />

Boiler s<strong>and</strong> & bottom ash 69,458 70,458 Used for ground <strong>and</strong> road consolidation in forests<br />

Dregs & Grits 92,134 32,257 Used as trial project as peat-l<strong>and</strong> pH correction<br />

Knots & reject pulp 84, 448 7,041 Sold as low-grade fibre, <strong>and</strong> composting or incinerating in boilers<br />

* dry base<br />

Overview <strong>and</strong> Background<br />

Lontar Papyrus mill was developed in 1994<br />

on a remote <strong>and</strong> heavily-logged site adjacent<br />

to the navigable Tungkal / Pengabuan river<br />

system in Jambi Province, Sumatra, some<br />

137 km from Jambi City. It has a single-line<br />

production facility with a nominal capacity<br />

of 650,000 tonnes per year of bleached<br />

hardwood kraft pulp (LBKP). A substantial<br />

village settlement – Tebing Tinggi – has<br />

grown up adjacent to the mill, drawn<br />

by the direct <strong>and</strong> indirect employment<br />

opportunities created by the mill <strong>and</strong> the<br />

associated pulpwood supply <strong>and</strong> haulage<br />

companies. The overall population in the<br />

vicinity of Tebing Tinggi – including mill<br />

employees <strong>and</strong> their families – is now about<br />

1,403,000.<br />

Table 16 - Employment<br />

<strong>2008</strong> <strong>2009</strong><br />

Direct employees 2,298 2,323<br />

Indirect employees 1,399 1,211<br />

There has also been substantial development<br />

of palm oil plantations in the same area.<br />

In 1997, a substantial part of the dry l<strong>and</strong><br />

areas of the original pulpwood plantation<br />

concession awarded to PT Wirakarya<br />

Sakti, Lontar Papyrus’ exclusive pulpwood<br />

supplier, were reassigned by the Ministry<br />

of Forestry to other concession holders for<br />

palm oil production. The l<strong>and</strong> awarded in<br />

substitution contains peat swamp, which<br />

meant substantial changes to the pulpwood<br />

supplier’s operations, including the tree<br />

species being planted <strong>and</strong> the environmental<br />

management practices needed to ensure<br />

minimal disturbance of this more fragile<br />

habitat.<br />

The mill site extends to 1,150 hectares <strong>and</strong><br />

contains three co-generation power plants<br />

(two chemical recovery boilers <strong>and</strong> one<br />

multi-fuel boiler that predominantly burns<br />

wood-waste), raw water <strong>and</strong> wastewater<br />

treatment plants <strong>and</strong> extensive chemical<br />

manufacturing <strong>and</strong> recovery facilities.<br />

Process chemicals manufactured on-site<br />

include chlorine, caustic soda, sodium<br />

chlorate, hydrochloric acid <strong>and</strong> chlorine<br />

dioxide, an elemental chlorine free (ECF)<br />

bleaching agent.<br />

Lontar Papyrus introduced ECF bleaching in<br />

2005. The ECF process essentially eliminates<br />

dioxin in pulp mill wastewater, a notable<br />

accomplishment in pollution prevention.<br />

Some 4 percent of the mill’s pulp production<br />

is converted to tissue products on-site by<br />

a single paper machine <strong>and</strong> converting<br />

facility installed in 1998. The majority of<br />

pulp produced is sold to other <strong>APP</strong> mills in<br />

Sumatra <strong>and</strong> on the world market. Chemicals<br />

produced in excess of the pulp mill’s needs,<br />

particularly hydrochloric acid, are also sold<br />

on the open market.<br />

Statutory Obligations:<br />

Environmental Permits <strong>and</strong><br />

Compliance <strong>Report</strong>ing<br />

Lontar Papyrus’ operations are authorised<br />

by, <strong>and</strong> its environmental <strong>and</strong> social<br />

management, monitoring <strong>and</strong> reporting<br />

obligations are defined in AMDAL / RKL /<br />

RPL documentation submissions. These<br />

were initially approved in February<br />

1995, with subsequent new facilities <strong>and</strong><br />

expansions endorsed in April 2002 by the<br />

Jambi provincial office of the Ministry of<br />

Environment (Kementrian Lingkungan Hidup<br />

/ KLH). Statutory monitoring data specified<br />

in the RPL is submitted to KLH <strong>and</strong> other<br />

provincial <strong>and</strong> regional authorities semiannually.<br />

No penalties were imposed on<br />

Lontar Papyrus mill for non-compliance with<br />

environmental laws <strong>and</strong> regulations in either<br />

<strong>2008</strong> <strong>and</strong> <strong>2009</strong>.<br />

The mill retained a “Blue” ranking under the<br />

PROPER appraisal scheme operated by the<br />

Indonesian government in both <strong>2008</strong> <strong>and</strong><br />

<strong>2009</strong>.<br />

The mill had its certification under the ISO<br />

14001:2004 Environmental Management<br />

System (EMS) St<strong>and</strong>ard renewed in <strong>2009</strong> <strong>and</strong><br />

remains valid until 2012.<br />

[EN 6, EN 26, EN 30]<br />

[EN 28]<br />

32 <strong>APP</strong> 08/09 <strong>Sustainability</strong> <strong>Report</strong> <strong>APP</strong> 08/09 <strong>Sustainability</strong> <strong>Report</strong> 33