APP Sustainability Report 2008-2009 - Asia Pulp and Paper

APP Sustainability Report 2008-2009 - Asia Pulp and Paper

APP Sustainability Report 2008-2009 - Asia Pulp and Paper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sustainable Products<br />

Sustainable Products<br />

Energy Inputs<br />

Both Pindo Deli mills operate co-generation<br />

plants, fueled predominantly by natural<br />

gas, with coal used as a supplementary<br />

fuel. Aggregate energy input – including the<br />

thermal value of purchased electrical energy<br />

– was 8,760,507 GJ in <strong>2008</strong>, 9,224,200 GJ in<br />

<strong>2009</strong>, the 5.3 percent increase being broadly<br />

in line with the increase in overall paper<br />

production. Problems with the combinedcycle<br />

gas turbine unit in <strong>2009</strong>, led to a<br />

substantial increase in coal usage.<br />

Energy Generation & Efficiency<br />

Electricity generated at both sites was<br />

758,405 MWh in aggregate in <strong>2008</strong>, 625,875<br />

MWh in <strong>2009</strong>; gas turbine engineering<br />

problems necessitated a large increase in<br />

purchased electricity, from 98,270 MWh in<br />

<strong>2008</strong> to 266,822 MWh in <strong>2009</strong>. Aggregate<br />

power usage was 742,037 MWh in <strong>2008</strong>,<br />

672,534 MWh in <strong>2009</strong>.<br />

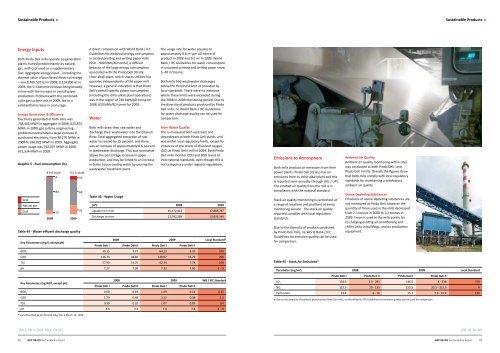

Graphic 5 - Fuel consumption (%)<br />

Grid<br />

Natural gas<br />

Coal<br />

8.8 G Joule 9.2 G Joule<br />

4<br />

10<br />

84 65<br />

25<br />

12<br />

<strong>2008</strong> <strong>2009</strong><br />

Table 44 - Water effluent discharge quality<br />

Key Parameters (mg/l, except pH)<br />

A direct comparison with World Bank / IFC<br />

Guidelines for electrical energy consumption<br />

in coated printing <strong>and</strong> writing paper mills<br />

(650 – 900 kWh/AD tonne) is difficult<br />

because of the large energy consumption<br />

associated with the Pindo Deli (II) site<br />

chlor-alkali plant, which shares utilities but<br />

operates independently of the paper mill.<br />

However, a general indication is that Pindo<br />

Deli’s overall specific power consumption<br />

(including the chlor-alkali plant operations)<br />

was in the region of 740 kWh/AD tonne for<br />

<strong>2008</strong>, 620 kWh/AD tonne for <strong>2009</strong>.<br />

Water<br />

Both mills draw their raw water <strong>and</strong><br />

discharge their wastewater into the Citarum<br />

River. Total aggregated extraction of raw<br />

water increased by 15 percent, <strong>and</strong> there<br />

was an increase of approximately 8.6 percent<br />

in wastewater discharge. This was somewhat<br />

above the percentage increase in paper<br />

production, <strong>and</strong> may be linked to an increase<br />

in boiler house cooling water by-passing the<br />

wastewater treatment plant.<br />

Table 43 - Water Usage<br />

The usage rate for water equates to<br />

approximately 8.6 m 3 per AD tonne of<br />

product in <strong>2008</strong> <strong>and</strong> 9.1 m 3 in <strong>2009</strong>. World<br />

Bank / IFC Guidelines for water consumption<br />

in uncoated printing <strong>and</strong> writing paper show<br />

5- 40 m 3 /tonne.<br />

Both mills had wastewater discharges<br />

below the threshold limit as provided by<br />

local st<strong>and</strong>ards. There were no instances<br />

where these limits were exceeded during<br />

the <strong>2008</strong> to <strong>2009</strong> monitoring period. Due to<br />

the diversity of products produced by Pindo<br />

Deli mills, no World Bank / IFC Guidelines<br />

for water discharge quality can be used for<br />

comparison.<br />

River Water Quality<br />

This is measured both upstream <strong>and</strong><br />

downstream at both Pindo Deli plants, <strong>and</strong><br />

was within local regulatory limits, except for<br />

instances of low levels of dissolved oxygen<br />

(DO) at Pindo Deli I mill in <strong>2009</strong>. Both Pindo<br />

Deli mills monitor COD <strong>and</strong> BOD levels to<br />

international st<strong>and</strong>ards, even though this is<br />

not compulsory under regional regulations.<br />

(m 3 ) <strong>2008</strong> <strong>2009</strong><br />

Uptake from river 15,172,412 17,869,787<br />

Discharge to river 12,742,284 13,839,340<br />

<strong>2008</strong> <strong>2009</strong> Local St<strong>and</strong>ard*<br />

Pindo Deli I Pindo Deli II Pindo Deli I Pindo Deli II<br />

Emissions to Atmosphere<br />

Both mills produce air emissions from their<br />

power plants. Pindo Deli (II) also has air<br />

emissions from its chlor-alkali plant <strong>and</strong> this<br />

is reported semi-annually through UKL / UPL.<br />

The emitted air quality from the mill is in<br />

compliance with the national st<strong>and</strong>ard.<br />

Stack air quality monitoring is carried out at<br />

a range of locations <strong>and</strong> positions at every<br />

monitoring session. The stack air quality<br />

reported complies with local regulatory<br />

st<strong>and</strong>ards.<br />

Due to the diversity of products produced<br />

by Pindo Deli mills, no World Bank / IFC<br />

Guidelines for emission quality can be used<br />

for comparison.<br />

Ambient Air Quality<br />

Ambient air quality monitoring within sites<br />

was conducted at both Pindo Deli I <strong>and</strong><br />

Pindo Deli II mills. Overall, the figures show<br />

that both mills comply with local regulatory<br />

st<strong>and</strong>ards for maintaining a satisfactory<br />

ambient air quality.<br />

Ozone Depleting Substances<br />

Emissions of ozone-depleting substances are<br />

not monitored at Pindo Deli, however the<br />

quantity of freon used in the mills decreased<br />

from 2.3 tonnes in <strong>2008</strong> to 1.2 tonnes in<br />

<strong>2009</strong>. Freon is used in the mills purely for<br />

re-charging existing air conditioning <strong>and</strong><br />

chiller units in buildings, <strong>and</strong> on production<br />

equipment.<br />

BOD 5<br />

39.15 7.77 64.23 6.10 100<br />

COD 116.73 18.85 148.97 15.79 200<br />

TSS 57.90 14.25 62.34 7.78 100<br />

pH 7.27 7.30 7.32 7.60 6 – 9<br />

Key Parameters (kg/ADT, except pH)<br />

<strong>2008</strong> <strong>2009</strong> WB / IFC St<strong>and</strong>ard<br />

Pindo Deli I Pindo Deli II Pindo Deli I Pindo Deli II<br />

BOD 5<br />

0.60 0.19 1.09 0.14 0.25<br />

COD 1.79 0.48 2.52 0.38 1.5<br />

TSS 0.90 0.10 1.07 0.09 0.4<br />

Table 45 - Stack Air Emissions*<br />

Parameter (mg/m 3 ) <strong>2008</strong> <strong>2009</strong> Local St<strong>and</strong>ard<br />

Pindo Deli I Pindo Deli II Pindo Deli I Pindo Deli II<br />

SO 2<br />

154.5 3.5 - 281 146.5 4 - 338 750<br />

NO 2<br />

132.5 20 - 135 155.5 35.5 - 312.5 #<br />

Particulate 23.4 6 - 16 15.1 7.3 - 22.4 150<br />

• Due to the diversity of products produced by Pindo Deli mills, no World Bank / IFC Guidelines for emission quality can be used for comparison<br />

pH 7.3 7.3 7.3 7.6 6 – 9<br />

* Local St<strong>and</strong>ard as per SK-Gub Jabar No. 6 March 13, 1999<br />

[EN 3, EN 4, EN 8, EN 9, EN 21] [EN 19, EN 20}<br />

48 <strong>APP</strong> 08/09 <strong>Sustainability</strong> <strong>Report</strong> <strong>APP</strong> 08/09 <strong>Sustainability</strong> <strong>Report</strong> 49