You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

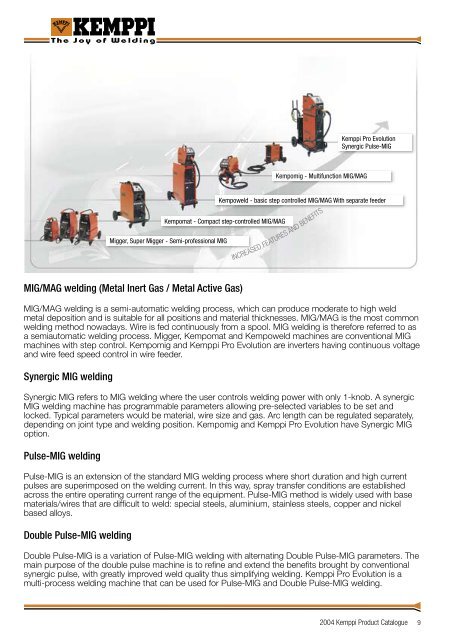

Kemppi Pro Evolution<br />

Synergic Pulse-MIG<br />

Kempomig - Multifunction MIG/MAG<br />

Kempoweld - basic step controlled MIG/MAG With separate feeder<br />

Kempomat - Compact step-controlled MIG/MAG<br />

Migger, Super Migger - Semi-professional MIG<br />

INCREASED FEATURES AND BENEFITS<br />

MIG/MAG welding (Metal Inert Gas / Metal Active Gas)<br />

MIG/MAG welding is a semi-automatic welding process, which can produce moderate to high weld<br />

metal deposition and is suitable for all positions and material thicknesses. MIG/MAG is the most common<br />

welding method nowadays. Wire is fed continuously from a spool. MIG welding is therefore referred to as<br />

a semiautomatic welding process. Migger, Kempomat and Kempoweld machines are conventional MIG<br />

machines with step control. Kempomig and Kemppi Pro Evolution are inverters having continuous voltage<br />

and wire feed speed control in wire feeder.<br />

Synergic MIG welding<br />

Synergic MIG refers to MIG welding where the user controls welding power with only 1-knob. A synergic<br />

MIG welding machine has programmable parameters allowing pre-selected variables to be set and<br />

locked. Typical parameters would be material, wire size and gas. Arc length can be regulated separately,<br />

depending on joint type and welding position. Kempomig and Kemppi Pro Evolution have Synergic MIG<br />

option.<br />

Pulse-MIG welding<br />

Pulse-MIG is an extension of the standard MIG welding process where short duration and high current<br />

pulses are superimposed on the welding current. In this way, spray transfer conditions are established<br />

across the entire operating current range of the equipment. Pulse-MIG method is widely used with base<br />

materials/wires that are difficult to weld: special steels, aluminium, stainless steels, copper and nickel<br />

based alloys.<br />

Double Pulse-MIG welding<br />

Double Pulse-MIG is a variation of Pulse-MIG welding with alternating Double Pulse-MIG parameters. The<br />

main purpose of the double pulse machine is to refine and extend the benefits brought by conventional<br />

synergic pulse, with greatly improved weld quality thus simplifying welding. Kemppi Pro Evolution is a<br />

multi-process welding machine that can be used for Pulse-MIG and Double Pulse-MIG welding.<br />

<strong>2004</strong> Kemppi Product Catalogue<br />

9