PBM Sanitary Ball Valves - Tri-Canada

PBM Sanitary Ball Valves - Tri-Canada

PBM Sanitary Ball Valves - Tri-Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

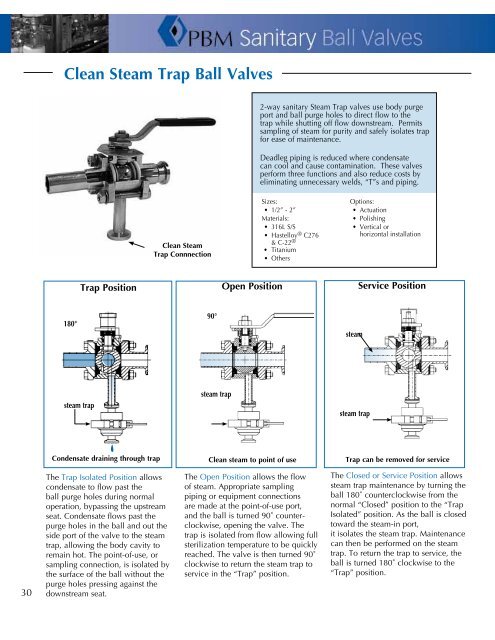

Clean Steam Trap <strong>Ball</strong> <strong>Valves</strong><br />

2-way sanitary Steam Trap valves use body purge<br />

port and ball purge holes to direct flow to the<br />

trap while shutting off flow downstream. Permits<br />

sampling of steam for purity and safely isolates trap<br />

for ease of maintenance.<br />

Deadleg piping is reduced where condensate<br />

can cool and cause contamination. These valves<br />

perform three functions and also reduce costs by<br />

eliminating unnecessary welds, “T”s and piping.<br />

Clean Steam<br />

Trap Connnection<br />

Sizes:<br />

• 1/2” - 2”<br />

Materials:<br />

• 316L S/S<br />

• Hastelloy ® C276<br />

& C-22 ®<br />

• Titanium<br />

• Others<br />

Options:<br />

• Actuation<br />

• Polishing<br />

• Vertical or<br />

horizontal installation<br />

Trap Position<br />

Open Position<br />

Service Position<br />

180°<br />

90°<br />

steam<br />

steam trap<br />

steam trap<br />

steam trap<br />

Condensate draining through trap<br />

Clean steam to point of use<br />

Trap can be removed for service<br />

30<br />

The Trap Isolated Position allows<br />

condensate to flow past the<br />

ball purge holes during normal<br />

operation, bypassing the upstream<br />

seat. Condensate flows past the<br />

purge holes in the ball and out the<br />

side port of the valve to the steam<br />

trap, allowing the body cavity to<br />

remain hot. The point-of-use, or<br />

sampling connection, is isolated by<br />

the surface of the ball without the<br />

purge holes pressing against the<br />

downstream seat.<br />

The Open Position allows the flow<br />

of steam. Appropriate sampling<br />

piping or equipment connections<br />

are made at the point-of-use port,<br />

and the ball is turned 90˚ counterclockwise,<br />

opening the valve. The<br />

trap is isolated from flow allowing full<br />

sterilization temperature to be quickly<br />

reached. The valve is then turned 90˚<br />

clockwise to return the steam trap to<br />

service in the “Trap” position.<br />

The Closed or Service Position allows<br />

steam trap maintenance by turning the<br />

ball 180˚ counterclockwise from the<br />

normal “Closed” position to the “Trap<br />

Isolated” position. As the ball is closed<br />

toward the steam-in port,<br />

it isolates the steam trap. Maintenance<br />

can then be performed on the steam<br />

trap. To return the trap to service, the<br />

ball is turned 180˚ clockwise to the<br />

“Trap” position.