Clean and soft water for business needs. - Hydrotech

Clean and soft water for business needs. - Hydrotech

Clean and soft water for business needs. - Hydrotech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Clean</strong> <strong>and</strong> <strong>soft</strong><br />

<strong>water</strong> <strong>for</strong> <strong>business</strong> <strong>needs</strong>.<br />

Commercial <strong>soft</strong>ening equipment.<br />

FAF SERIES COMMERCIAL<br />

WATER SOFTENERS

FAF Series Commercial Water Softeners<br />

Water hardness is responsible <strong>for</strong> many maintenance <strong>and</strong> process problems in commercial<br />

applications.<br />

<strong>Hydrotech</strong>’s FAF Series Automatic Commercial Water Softeners provide <strong>soft</strong> <strong>water</strong> to meet the<br />

dem<strong>and</strong>ing specifications of all types of <strong>business</strong>es <strong>and</strong> institutions with simple <strong>and</strong> reliable<br />

equipment.<br />

Regeneration Initiation Types Available<br />

Calendar Clock: Softener systems with calendar clock<br />

initiation are typically the least expensive. The regeneration is<br />

delayed <strong>and</strong> can be set <strong>for</strong> any time of day. Typically, twelve<br />

(12) day clocks are used so that the system can be regenerated<br />

at evenly spaced intervals of every 1, 2, 3, 4, 6 or 12 days. A<br />

7-day clock is an option.<br />

Metered or Volumetric: Although a meter initiated system is<br />

slightly more expensive than a calendar clock system, the<br />

metered system will easily pay <strong>for</strong> itself shortly in better salt<br />

<strong>and</strong> <strong>water</strong> consumption efficiencies. The meter measures the<br />

volume of <strong>water</strong> passing through the <strong>soft</strong>ener. The<br />

regeneration interval is based on the volume calculated to<br />

exhaust the <strong>soft</strong>ener's bed capacity. Meter initiated <strong>soft</strong>eners<br />

also have the greatest range of systems available. Single,<br />

duplex <strong>and</strong> triplex systems can be ordered with different<br />

operational characteristics <strong>and</strong> controllers.<br />

External Input (OPTIONAL): Some systems can be initiated<br />

with external inputs. This type of regeneration initiation<br />

typically requires an electronic controller. Co-ordination with<br />

our commercial engineering department is suggested to<br />

facilitate this special type of system.<br />

Controller Types Available<br />

Mechanical Timers: These are the most cost-effective type of<br />

control available <strong>for</strong> <strong>soft</strong>ener <strong>and</strong> filter systems. The program<br />

wheel of the timer allows adjustment of a regeneration in two<br />

minute increments by adding <strong>and</strong> removing pins which<br />

control the regeneration cycle times. Mechanical timers<br />

however are wired <strong>for</strong> one type of system only. They are not<br />

as flexible as an electronic control to change regeneration<br />

types or parameters <strong>and</strong> they cannot be changed to add<br />

future multiple units.<br />

3200ET Electronic Timer: The 3200ET is a much more<br />

in<strong>for</strong>mation orientated <strong>and</strong> user friendly control. The digital<br />

display will show the regeneration cycle it is in with the time<br />

remaining. It is easily changed to either immediate or delayed<br />

regeneration. Metered <strong>soft</strong>ener system capacity is adjusted by<br />

entering the <strong>water</strong> hardness. The volume of <strong>water</strong> remaining<br />

be<strong>for</strong>e regeneration is alternately displayed with the time of<br />

day continuously. Metered systems have a real time flow rate<br />

<strong>and</strong> totalizer display. The 3200ET timer also provides the<br />

customer or service technician with history displays which can<br />

assist with troubleshooting if required such as: number of days<br />

since last regeneration, prior service volume used, etc. The<br />

3200ET timer also has the following options: regeneration<br />

lockout, calendar clock override, extra regeneration cycles #5<br />

& #6 <strong>and</strong> a programmable auxiliary output during<br />

regeneration.<br />

Systemax 2000 & 2014 Electronic Controllers: Systemax<br />

2000 & 2014 controllers are meant to provide the utmost<br />

flexibility <strong>and</strong> user in<strong>for</strong>mation orientated control that a<br />

commercial customer could ask <strong>for</strong>. These controllers are set<br />

up <strong>for</strong> one to three units <strong>and</strong> multiple controllers can be<br />

interlocked together. The Systemax controllers also have<br />

multiple flow rate, regeneration cycle <strong>and</strong> historical displays<br />

similar to the 3200ET timers as well as up to two auxiliary<br />

outputs per unit. In addition, Systemax 2000 has the flexibility<br />

of changing system types <strong>and</strong> combining two systems together.<br />

Expansion of a Systemax controller is very simple from a single<br />

or duplex to a triplex (Note: 3200ET systems are only<br />

available as singles or duplexes). Systemax controllers also<br />

have some unique options such as the 2014 controller or<br />

System 14 Dem<strong>and</strong> Recall Program <strong>and</strong> Remote Monitoring<br />

to an on site personal computer or off site via the on site PC<br />

<strong>and</strong> a modem.<br />

3200NT Network Controller: The 3200NT uses on-board<br />

common reactions capabilities to link multiple valves via<br />

st<strong>and</strong>ard off-the-shelf telephone cables. This controller is an<br />

option <strong>for</strong> all valve types.

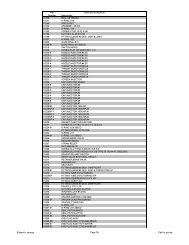

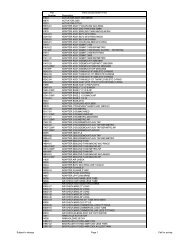

Capacity per Resin Critical<br />

TankVolume Application<br />

Model grains CU.FT. Maximum<br />

@ 15 lb-salt/cf (CU.M.) Flowrate<br />

@ 10 lb-salt/cf USGPM (LPS)<br />

2750 - 1” Valve Units 2850 - 1.5” Valve Units 2900 - 2” Valve Units<br />

Flowrate per Tank at 15 psi <strong>and</strong> 25 psi Pressure Drops<br />

15psi @ 25psi @ 15psi @ 25psi @ 15psi @ 25psi<br />

USGPM (LPS) USGPM (LPS) USGPM (LPS)<br />

3150 - 2” Valve Units 3900 - 3” Valve Units<br />

@ 15psi @ 25 psi @ 15 psi @ 25 psi<br />

USGPM (LPS) USGPM (LPS)<br />

Backwash Mineral Tank Brine Tank Shipping<br />

Flowrate Dimensions Dimension Weight<br />

Single<br />

USGPM (LPS) inches (mm) inches (mm) lbs (kg)<br />

FAF 45 45,000 1.5 7.5 17 23 2.4 10 x 54 21 x 36 180<br />

40,500 (0.04) (0.47) (1.07) (1.45) (0.15) (533x914) (533x914) (82)<br />

FAF 60 60,000 2 10 22 29 36 49 50 75 5.0 14 x 50 21 x 36 270<br />

54,000 (0.06) (0.63) (1.39) (1.83) (2.27) (3.09) (3.15) (4.73) (0.32) (356x1270) (533x914) (122)<br />

FAF 90 90,000 3 15 20 27 32 44 41 60 5.0 14 x 65 21 x 36 330<br />

84,000 (0.08) (0.95) (1.26) (1.70) (2.02) (2.78) (2.59) (3.79) (0.32) (356x1651) (533x914) (150)<br />

FAF 120 120,000 4 20 21 29 35 49 49 70 7.0 16 x 65 21 x 36 390<br />

108,000 (0.11) (1.26) (1.32) (1.83) (2.21) (3.09) (3.09) (4.42) (0.44) (406x1651) (533x914) (177)<br />

FAF 150 150,000 5 25 24 31 43 58 76 103 12 21 x 54 24 x 48 500<br />

135,000 (0.14) (1.58) (1.51) (1.96) (2.71) (3.66) (4.79) (6.50) (0.75) (533x1372) (610x1219) (227)<br />

FAF 180 180,000 6 30 24 31 42 57 72 98 12 21 x 54 24 x 48 560<br />

162,000 (0.17) (1.89) (1.51) (1.96) (2.65) (3.60) (4.54) (6.18) (0.75) (533x1372) (610x1219) (255)<br />

FAF 210 210,000 7 35 23 31 41 55 67 93 12 21 x 69 24 x 48 640<br />

189,000 (0.20) (2.21) (1.45) (1.96) (2.59) (3.47) (4.23) (5.87) (0.75) (533x1753) (610x1219) (291)<br />

FAF 240 240,000 8 40 23 30 40 54 63 89 12 21 x 69 24 x 48 690<br />

216,000 (0.23) (2.52) (1.45) (1.89) (2.42) (3.41) (3.97) (5.62) (0.75) (533x1753) (610x1219) (314)<br />

FAF 270 270,000 9 45 24 31 42 57 75 104 15 24 x 72 30 x 48 820<br />

243,000 (0.25) (2.84) (1.51) (1.96) (2.65) (3.60) (4.73) (6.56) (0.94) (610x1829) (762x1219) (373)<br />

FAF 300 300,000 10 50 23 31 42 57 73 102 15 24 x 72 30 x 48 880<br />

270,000 (0.28) (3.15) (1.45) (1.96) (2.65) (3.60) (4.61) (6.44) (0.94) (610x1829) (762x1219) (399)<br />

FAF 330 330,000 11 55 23 31 42 56 71 99 15 24 x 72 30 x 48 930<br />

297,000 (0.31) (3.47) (1.45) (1.96) (2.65) (3.53) (4.48) (6.25) (0.94) (610x1829) (762x1219) (423)<br />

FAF 360 360,000 12 60 46 61 84 † 116 † 80 108 156 215 25 30 x 72 30 x 48 1130<br />

324,000 (0.34) (3.79) (2.90) (3.85) (5.30) (7.32) (5.03) (6.80) (9.84) (13.56) (1.57) (762x1829) (762x1219) (514)<br />

FAF 390 390,000 13 65 46 61 82 † 114 † 79 108 152 210 25 30 x 72 30 x 48 1180<br />

351,000 (0.37) (4.10) (2.90) (3.85) (5.17) (7.19) (4.98) (6.80) (9.59) (13.25) (1.57) (762x1829) (762x1219) (536)<br />

FAF 450 450,000 15 75 45 60 80 † 112 † 78 105 142 200 25 30 x 72 30 x 48 1340<br />

405,000 (0.42) (4.73) (2.84) (3.79) (5.05) (7.07) (4.91) (6.61) (8.96) (12.62) (1.57) (762x1829) (762x1219) (609)<br />

FAF 510 510,000 17 85 45 59 79 † 109 † 76 103 138 190 25 30 x 72 36 x 48 1440<br />

459,000 (0.48) (5.36) (2.84) (3.72) (4.98) (6.88) (4.79) (6.48) (8.71) (11.99) (1.57) (762x1829) (914x1219) (655)<br />

FAF 570 570,000 19 95 85 112 180 247 35 36 x 72 36 x 48 1580<br />

513,000 (0.54) (5.99) (5.36) (7.05) (11.36) (15.58) (2.20) (914x1829) (914x1219) (718)<br />

FAF 600 600,000 20 100 84 111 177 245 35 36 x 72 42 x 48 1648<br />

540,000 (0.57) (6.31) (5.30) (6.98) (11.17) (15.46) (2.20) (914x1829) (1067x1219) (748)<br />

FAF 630 630,000 21 105 83 111 173 242 35 36 x 72 42 x 48 1700<br />

567,000 (0.59) (6.62) (5.22) (6.98) (10.91) (15.27) (2.20) (914x1829) (1067x1219) (773)<br />

FAF 660 660,000 22 110 88 116 202 273 45 42 x 72 42 x 48 1850<br />

594,000 (0.62) (6.94) (5.55) (7.32) (12.74) (17.22) (2.83) (1047x1829) (1067x1219) (841)<br />

FAF 720 720,000 24 120 88 116 201 269 45 42 x 72 42 x 48 2650<br />

648,000 (0.68) (7.57) (5.55) (7.32) (12.68) (16.97) (2.83) (1047x1829) (1067x1219) (1202)<br />

FAF 780 780,000 26 130 87 115 197 266 45 42 x 72 42 x 48 2860<br />

702,000 (0.74) (8.20) (5.49) (7.26) (12.43) (16.78) (2.83) (1047x1829) (1067x1219) (1300)<br />

FAF 900 900,000 30 150 89 117 213 284 60 48 x 72 48 x 48 3330<br />

810,000 (0.85) (9.46) (5.56) (7.37) (13.44) (17.92) (3.77) (1291x1829) (1219x1219) (1510)<br />

FAF 1020 1,020,000 34 170 88 116 208 280 60 48 x 72 48 x 48 3540<br />

918,000 (0.96) (10.73) (5.55) (7.32) (13.12) (17.67) (3.77) (1291x1829) (1219x1219) (1606)<br />

FAF 1080 1,080,000 36 180 88 116 205 276 60 48 x 72 48 x 48 3640<br />

972,000 (1.02) (11.36) (5.55) (7.32) (12.93) (17.41) (3.77) (1291x1829) (1219x1219) (1655)<br />

FAF 1740 1,740,000 58 220 87 116 220 295 95 63 x 86 70 x 58 6740<br />

1,508,000 (1.64) (13.88) (5.48) (7.32) (13.88) (18.61) (5.99) (1600x2185) (1778x1474) (3064)<br />

Shipping Weights:<br />

• Single units shipping weights shown are<br />

maximums <strong>for</strong> each unit size.<br />

• Valve type, multiple unit systems <strong>and</strong> additional<br />

options may alter this figure.<br />

• Please consult customer service or a system<br />

specification drawing <strong>for</strong> actual shipping weights.<br />

Additional Notes:<br />

• Critical applications refer to <strong>soft</strong>ening prior to<br />

equipment such as: Boiler makeup <strong>water</strong>, heat<br />

exchangers <strong>and</strong> other equipment sensitive to<br />

hardness scaling.<br />

• Depending on the valve used in each system,<br />

critical application flowrates are decreased if the<br />

pressure drop is 15psig or greater.<br />

† Must have 60 psi minimum to regenerate<br />

units properly.

System Selection<br />

The following example explains how the model number works:<br />

FAF<br />

FAF St<strong>and</strong>ard<br />

Softener<br />

240 - 2 D 7 0<br />

Softener Size<br />

indicates grain<br />

capacity of single<br />

unit x 1000 (@15<br />

lbs salt setting)<br />

Valve Type<br />

1 = 2750-1”<br />

1.5 = 2850-1.5”<br />

2 = 2900-2”<br />

2.0 = 3150-2”<br />

3 = 3900-3”<br />

Number of<br />

Mineral Tanks<br />

S = Single<br />

D = Duplex<br />

T = Triplex<br />

Q = Quadraplex<br />

F = Fiveplex<br />

Special Option Number<br />

0 - St<strong>and</strong>ard Mechanical Unit<br />

1 - Systemax Unit without Special Options<br />

2 - 3200ET Unit without Special Options<br />

4 - Systemax 2014 Dem<strong>and</strong> Recall System<br />

7 - Systemax 2000 Alternating System<br />

8 - 3200NT Network Controller without<br />

Special Options<br />

X - Non-St<strong>and</strong>ard Unit<br />

System<br />

C = Calendar Clock<br />

4 = Meter Initiated Single<br />

5 = Meter Initiated System 5<br />

6 = Meter Initiated System 6<br />

7 = Meter Initiated System 7<br />

System Controls & Configurations<br />

(Available with optional 3200ET, Systemax or 3200NT Controllers)<br />

1. System 4 - Single meter initiated unit with st<strong>and</strong>ard hard<br />

<strong>water</strong> bypass piston.<br />

2. System 5 - Duplex meter initiated system with all units in<br />

parallel service. Each unit has its own meter <strong>and</strong> brine tank.<br />

Regeneration is immediately at end of service run <strong>and</strong> an<br />

electrical interlock prevents regeneration of a unit while<br />

another is in regeneration. No hard <strong>water</strong> bypass pistons<br />

are st<strong>and</strong>ard.<br />

3. System 6 - Sequential dem<strong>and</strong> system with all tanks in<br />

service <strong>and</strong> all <strong>water</strong> flow is monitored by one meter. The<br />

tanks regenerate sequentially, on dem<strong>and</strong> with one tank off<br />

line any time.<br />

4. System 7 - Duplex alternating (service/st<strong>and</strong>-by) system<br />

with one unit on line <strong>and</strong> the other in regeneration or<br />

st<strong>and</strong>-by. Hard <strong>water</strong> bypass is prevented with no hard<br />

<strong>water</strong> bypass pistons (2900 or 3900 valve) <strong>and</strong> automatic<br />

diaphragm isolation valves on all other types.<br />

5. 3200ET Controller - a precise electronic control available<br />

with all of our commercial control valves. A bright 7 digit<br />

display shows flow <strong>and</strong> totalizer in<strong>for</strong>mation <strong>and</strong><br />

programming is easy with the simple touchpad design. The<br />

Technical Specifications & Features<br />

Main Control Valve<br />

• Meter initiated regeneration is st<strong>and</strong>ard<br />

• Valve body constructed of lead-free brass*<br />

• Main piston constructed of Teflon coated lead-free brass*<br />

with no hard <strong>water</strong> bypass feature st<strong>and</strong>ard on all duplex<br />

models<br />

• St<strong>and</strong>ard cycle timer controls service, backwash, brine<br />

draw, slow rinse, fast rinse <strong>and</strong> brine tank refill<br />

• St<strong>and</strong>ard 115 volt electrical requirement<br />

• Simple threaded (NPT) service inlet <strong>and</strong> outlet connections<br />

• Valves used on FAF <strong>soft</strong>eners in Canada are CSA Certified<br />

Resin<br />

• Premium quality ion exchange <strong>soft</strong>ening resin, selected <strong>for</strong><br />

resistance to fouling <strong>and</strong> minimum salt usage<br />

• FDA Grade<br />

* as defined under Section 1417(d) of the U.S.E.P.A. Safe Drinking Water Act<br />

enclosure is hinged to allow complete access to all internal<br />

parts <strong>and</strong> has a NEMA 3R rating.<br />

6. Systemax 2000 - Electronic controller monitors <strong>and</strong><br />

controls up to three <strong>water</strong> <strong>soft</strong>eners. Featuring a bright 8<br />

digit display, the Systemax can be programmed <strong>for</strong> each<br />

<strong>soft</strong>ener individually or as a system, allowing the operator<br />

to view flow rates, flow totals <strong>and</strong> operating status of any<br />

<strong>soft</strong>ener unit. Electrical connections are simple, prewired<br />

interlock cables supplied with the controller. Enclosure<br />

rating is NEMA 4X.<br />

7. Systemax 2014 Electronic Dem<strong>and</strong> Recall Controller -<br />

Electronic controller incorporates all the same visual<br />

displays as the st<strong>and</strong>ard Systemax. Systemax 2014 is a<br />

special multiple unit controller that puts the required<br />

number of units online to meet the current flow conditions.<br />

8. Systemax Remote Monitoring - All versions of the<br />

Systemax can be monitored with the remote option. This<br />

allows access to all front panel data from a remote location.<br />

Since the data is "read only" <strong>and</strong> has an optional password,<br />

your site is secure from unauthorized use.<br />

9. 3200NT Network Controller - Control can network up to<br />

four valves using st<strong>and</strong>ard RJ45, 6 position 4 conductor<br />

telephone cable. It can be field configured to any system<br />

type using simple programming.<br />

Softener Tanks <strong>and</strong> Internals<br />

• Seamless polyethylene liner wrapped with a continuous<br />

filament wound/epoxy resin fiberglass shell designed <strong>for</strong><br />

125 psig (862 kPa) working pressure <strong>and</strong> temperatures of<br />

110° F (43°C)<br />

• Hub/lateral flow distributor (21" tanks <strong>and</strong> larger) <strong>and</strong> riser<br />

tube with washed quartz support bed<br />

• Tanks up to <strong>and</strong> including 24" diameter are manufactured<br />

by <strong>Hydrotech</strong><br />

• Brine tanks are one piece rotationally molded polyethylene<br />

with lid, air check valve assembly, brine well <strong>and</strong> grid<br />

assembly<br />

Optional Features<br />

• Calendar clock initiation • 3200ET electronic control<br />

• Systemax 2000 electronic • Systemax 2014 electronic<br />

control<br />

control<br />

• Systemax remote monitoring • 3200NT Network Contoller<br />

• Brine tank safety float valve<br />

• Side mounted valves (2850 <strong>and</strong> larger)

Need a Drawing?<br />

Drawings can be provided <strong>for</strong> all st<strong>and</strong>ard single <strong>and</strong> duplex FAF series commercial <strong>soft</strong>eners with your quotation. Many<br />

drawings are also available <strong>for</strong> optional product setups such as 3200ET Electronic Timers, Systemax Controller, Side Mounted<br />

Piping. Please ask your area representative or customer service if you require a drawing along with your commercial equipment<br />

quotation.<br />

FAF Softener drawings are supplied with the appropriate model highlighted, <strong>and</strong> corresponding per<strong>for</strong>mance specifications<br />

automatically filled in as shown in the following example.<br />

FAF Softener drawings include all pertinent<br />

in<strong>for</strong>mation such as:<br />

• System type <strong>and</strong> operating description<br />

• Mineral <strong>and</strong> Brine Tank Dimensions<br />

• Approximate Installation Space Required (in the<br />

configuration shown)<br />

• Shipping <strong>and</strong> Operating Weight<br />

• Service Flow rates <strong>for</strong> Critical Applications,<br />

15 psi <strong>and</strong> 25 psi pressure drops<br />

• Maximum Flow rate to drain during backwash<br />

• Electrical In<strong>for</strong>mation <strong>and</strong> Controller Type<br />

• Piping layout, installation notes <strong>and</strong> accessories<br />

Highlighted<br />

Model<br />

Complete Model Number<br />

<strong>and</strong> Specifications<br />

2750 - 1” Control Valve 2850 - 1-1/2” Control Valve 2900 - 2” Control Valve<br />

3150 - 2” Control Valve<br />

3900 - 3” Control Valve 3200ET Controller<br />

3200NT Network<br />

(shown on 2900 Valve)<br />

Controller<br />

Systemax 2000<br />

Electronic Controller<br />

WATERGROUP INC. WATERGROUP COMPANIES INC.<br />

Fridley, Minnesota Cambridge, Ontario<br />

Sun Valley, Cali<strong>for</strong>nia Regina, Saskatchewan<br />

1-800-354-7867 1-877-299-5999<br />

www.hydrotech<strong>water</strong>.com<br />

Printed in Canada #57246 07/04