Safety & Health in the Stone Crushing Industry - Occupational ...

Safety & Health in the Stone Crushing Industry - Occupational ...

Safety & Health in the Stone Crushing Industry - Occupational ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

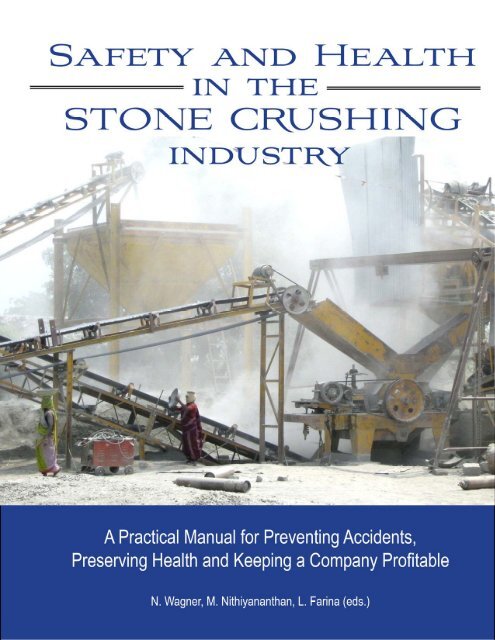

SAFETY & HEALTH<br />

IN THE<br />

STONE CRUSHING<br />

INDUSTRY<br />

A Practical Manual for Prevent<strong>in</strong>g Accidents,<br />

Preserv<strong>in</strong>g <strong>Health</strong> and Keep<strong>in</strong>g a Company Profitable<br />

Edited by<br />

Norbert Wagner<br />

University of South Florida, Tampa USA<br />

Mannarswami Nithiyananthan<br />

Sri Ramachandra University, Chennai India<br />

Laura Far<strong>in</strong>a<br />

University of South Florida, Tampa USA<br />

Published by<br />

Ecohealth Program<br />

International Development Research Centre<br />

PO Box 8500, Ottawa, ON K1G 3H9, Canada<br />

Email: ecohealth@idrc.ca<br />

Website: www.idrc.ca/ecohealth<br />

© Wagner Global Consultants, Inc. 2009<br />

This manual reports on a research project f<strong>in</strong>anced by Canada’s International Development<br />

Research Centre. It is licensed under a Creative Commons Attribution-Noncommercial-<br />

Share Alike 3.0 Unported License.

2<br />

Acknowledgements<br />

M. Nithiyananthan and N. Wagner provided almost all photos <strong>in</strong> this manual <strong>in</strong>clud<strong>in</strong>g <strong>the</strong> title page<br />

photo. Perry Gottesfeld of <strong>Occupational</strong> Knowledge International provided <strong>the</strong> photo <strong>in</strong> <strong>the</strong> chapter<br />

"Reduc<strong>in</strong>g dust where water is available"; Development Alternatives provided <strong>the</strong> photo <strong>in</strong> <strong>the</strong> chapter<br />

"Reduc<strong>in</strong>g dust where water is not available".<br />

M. Nithiyananthan created <strong>the</strong> illustrations <strong>in</strong> chapter B "Improv<strong>in</strong>g Heavy Physical Work". All o<strong>the</strong>r<br />

black & white illustrations <strong>in</strong> this manual are provided by <strong>the</strong> HESPERIAN Foundation and are<br />

repr<strong>in</strong>ted with <strong>the</strong>ir permission.<br />

You can contact <strong>the</strong> HESPERIAN Foundation at:<br />

HESPERIAN Foundation<br />

1919 Addison Street, Suite 304<br />

Berkeley, CA 94704 USA<br />

Tel: (510) 845-1447, Fax: (510) 845-9141<br />

Toll free <strong>in</strong> <strong>the</strong> US: (888) 729-1796<br />

Email: hesperian@hesperian.org

3<br />

Table of Contents<br />

Table of Contents .......................................................................................................................... 3<br />

Foreword ........................................................................................................................................ 5<br />

Eulogy............................................................................................................................................. 7<br />

Introduction.................................................................................................................................... 8<br />

A <strong>Safety</strong> & <strong>Health</strong> <strong>in</strong> <strong>Stone</strong> Crush<strong>in</strong>g ...................................................................................... 9<br />

A.1 A Word for <strong>the</strong> Owners: Manag<strong>in</strong>g <strong>Health</strong> and <strong>Safety</strong> <strong>in</strong> <strong>Stone</strong> Crush<strong>in</strong>g.................... 10<br />

A.2 Prevent<strong>in</strong>g Accidents <strong>in</strong> a <strong>Stone</strong> Crush<strong>in</strong>g Unit............................................................ 14<br />

A.2.1 Prevent<strong>in</strong>g Falls from Heights.................................................................................. 14<br />

A.2.2 Work<strong>in</strong>g Safely with Electricity................................................................................. 16<br />

A.2.3 Mach<strong>in</strong>es and Power Tools ..................................................................................... 19<br />

A.2.4 Us<strong>in</strong>g Gas Cyl<strong>in</strong>ders Safely ..................................................................................... 21<br />

A.2.5 Keep<strong>in</strong>g <strong>the</strong> Roads Safe.......................................................................................... 22<br />

A.2.6 Secur<strong>in</strong>g Access to <strong>the</strong> Plant................................................................................... 24<br />

A.3 Keep<strong>in</strong>g Workers <strong>Health</strong>y............................................................................................. 25<br />

A.3.1 Reduc<strong>in</strong>g Dust When Water is Available................................................................. 26<br />

A.3.2 Reduc<strong>in</strong>g Dust When Water is Not Available .......................................................... 28<br />

A.3.3 Protect<strong>in</strong>g Hear<strong>in</strong>g from Noise................................................................................. 32<br />

A.3.4 Us<strong>in</strong>g Personal Protective Equipment (PPE) .......................................................... 34<br />

A.3.5 Work<strong>in</strong>g Safely at Night ........................................................................................... 36<br />

A.3.6 Fight<strong>in</strong>g off <strong>the</strong> Heat................................................................................................. 37<br />

A.3.7 Tak<strong>in</strong>g care of Human Needs .................................................................................. 39<br />

A.4 Be<strong>in</strong>g Prepared for Emergencies ................................................................................. 40<br />

B Improv<strong>in</strong>g Heavy Physical Work........................................................................................ 43<br />

B.1 Ma<strong>in</strong> crusher operator .................................................................................................. 45<br />

B.2 Repair and Ma<strong>in</strong>tenance of <strong>the</strong> Ma<strong>in</strong> Crusher.............................................................. 46<br />

B.3 Align<strong>in</strong>g <strong>the</strong> portable bucket conveyor for load<strong>in</strong>g........................................................ 47<br />

B.4 Remov<strong>in</strong>g spilled stones.............................................................................................. 48<br />

B.5 Level<strong>in</strong>g <strong>the</strong> Boulder Collection Pit............................................................................... 49<br />

B.6 Clean<strong>in</strong>g work under <strong>the</strong> ma<strong>in</strong> crusher......................................................................... 50<br />

B.7 Tally clerk work station ................................................................................................. 52<br />

B.8 Ma<strong>in</strong>tenance work activities.......................................................................................... 53<br />

B.9 Clean<strong>in</strong>g and housekeep<strong>in</strong>g work around crushers ..................................................... 55<br />

B.10 Go<strong>in</strong>g to <strong>the</strong> top boulder load<strong>in</strong>g .................................................................................. 58

4<br />

B.11 Removal of Jammed Boulders <strong>in</strong> <strong>the</strong> Ma<strong>in</strong> Crusher..................................................... 59<br />

B.12 Truck load<strong>in</strong>g by bucket conveyors .............................................................................. 59<br />

C How Much Does an Accident Cost? .................................................................................. 61<br />

D Checklists and Benchmarks............................................................................................... 63<br />

D.1 Checklist: General <strong>Safety</strong> Practices, Hazards Management and Welfare Facilities.... 64<br />

D.2 Checklist: Electrical Equipment, Mach<strong>in</strong>es and Power tools........................................ 67<br />

D.3 Checklist: Ergonomic Workplace Design and Manual Handl<strong>in</strong>g of Loads ................... 69<br />

D.4 Checklist: Fire and Explosion, Gas Cyl<strong>in</strong>ders and Emergency Preparedness............. 71<br />

D.5 Checklist: Accident prevention: safe work<strong>in</strong>g and heights, road safety ....................... 73<br />

D.6 Checklist: Dust and noise reduction, personal protective equipment........................... 75

5<br />

Foreword<br />

This manual is based on f<strong>in</strong>d<strong>in</strong>gs of a research development project <strong>in</strong> stone crush<strong>in</strong>g sites <strong>in</strong> Nor<strong>the</strong>rn<br />

India (Bundelkhand). The International Development Research Centre (IDRC), Canada<br />

(http://www.idrc.ca), funded a community development project over several years which was aimed at<br />

improv<strong>in</strong>g <strong>the</strong> liv<strong>in</strong>g conditions <strong>in</strong> <strong>the</strong> villages around stone crush<strong>in</strong>g sites and <strong>the</strong> work<strong>in</strong>g conditions <strong>in</strong><br />

<strong>the</strong> crush<strong>in</strong>g units. Project partners were <strong>the</strong> non-governmental organization Development Alternatives,<br />

New Delhi, India (http://www.devalt.org), Dr. K. Vijaya Lakshmi (PI), and <strong>the</strong> Department of<br />

Environmental <strong>Health</strong> Eng<strong>in</strong>eer<strong>in</strong>g of Sri Ramachandra University, Chennai, India (http://www.srmcehe.org.<strong>in</strong>),<br />

Dr. Kalpana Balakrishnan (Co-PI).<br />

The late Mr. M. Nithiyananthan, <strong>the</strong> Project Leader-Industrial <strong>Safety</strong> of <strong>the</strong> project from Chennai, India,<br />

produced <strong>the</strong> majority of <strong>the</strong> f<strong>in</strong>d<strong>in</strong>gs and photos, which are presented <strong>in</strong> this manual. He tragically<br />

passed away <strong>in</strong> early 2009 before this manual could be f<strong>in</strong>ished. We publish <strong>the</strong>se f<strong>in</strong>d<strong>in</strong>gs <strong>in</strong> his<br />

memory.<br />

The editors are grateful for <strong>the</strong> support from many contributors. Special thanks go to Ana Boischio from<br />

IDRC and <strong>the</strong> project's pr<strong>in</strong>cipal <strong>in</strong>vestigators Dr. K. Vijaya Lakshmi and Dr. Kalpana Balakrishnan for<br />

mak<strong>in</strong>g this publication possible. Mr. Raghwesh Ranjan made <strong>the</strong> visits to <strong>the</strong> stone crush<strong>in</strong>g units<br />

possible. Reliable and efficient as always, Mr. D. Venkatesan researched <strong>the</strong> available documents and<br />

photos that provided <strong>the</strong> basis for this publication.<br />

The authors who contributed chapters for this manual besides <strong>the</strong> editors are: Perry Gottesfeld from<br />

<strong>Occupational</strong> Knowledge International, San Francisco USA (www.ok<strong>in</strong>ternational.org), who contributed<br />

<strong>the</strong> chapter on wet dust reduction technology; Dr. Ralf Ste<strong>in</strong>berg, an <strong>in</strong>ternational safety expert,<br />

Düsseldorf Germany, who k<strong>in</strong>dly reviewed <strong>the</strong> manuscript and contributed to several chapters and Mr.<br />

Suvankar Bose and Mr. George S Sharma from Development Alternatives, New Delhi India who<br />

developed and expla<strong>in</strong>ed <strong>the</strong> dry dust reduction systems.<br />

All black and white illustrations <strong>in</strong> this manual are from publications of <strong>the</strong> Hesperian Foundation, a<br />

non-profit health organization that k<strong>in</strong>dly granted permission to use some of <strong>the</strong>ir illustrations from two<br />

of <strong>the</strong>ir publications (http://www.hesperian.org). Their free publications "A Worker's Guide to <strong>Health</strong><br />

and <strong>Safety</strong>" and ”A Community Guide to Environmental <strong>Health</strong>" can be found on <strong>the</strong>ir website.<br />

Many of <strong>the</strong> checklists presented at <strong>the</strong> end of this manual were developed with colleagues and friends<br />

from <strong>the</strong> Department of Environmental <strong>Health</strong> Eng<strong>in</strong>eer<strong>in</strong>g of Sri Ramachandra University, Chennai,<br />

India. They <strong>in</strong>clude Dr. Joerg Arnold, S. Sankar, R. Ayyappan, Dr. Ralf Ste<strong>in</strong>berg and o<strong>the</strong>rs.<br />

The follow<strong>in</strong>g persons were part of <strong>the</strong> research project between 2006 and 2008:<br />

Dr. K. Vijaya Lakshmi (Pr<strong>in</strong>cipal Investigator)<br />

Dr. Kalpana Balakrishnan (Co-Pr<strong>in</strong>cipal Investigator)<br />

Mr. George C. Varughese (Project Advisor)<br />

Ms. Indrani Mahapatra (Research Coord<strong>in</strong>ator)<br />

Mr. Raghwesh Ranjan (Research Coord<strong>in</strong>ator/Project Leader - Social)<br />

Dr. Reetu Sogani (Consultant – Gender)<br />

Mr. Prawal Pratap S<strong>in</strong>gh (Ex-Project Staff – Social)<br />

Ms. Taru Mehta (Ex-Project Staff – Social)<br />

Dr. P Jayachandran (Project Leader-<strong>Health</strong>)<br />

Dr. M. P. S<strong>in</strong>gh (Project Staff – <strong>Health</strong>)<br />

Dr. Anandh B (Project Staff – <strong>Health</strong>)<br />

Dr. K. Mukhopadhyay (Project Leader – Environment)<br />

Mr. S. Sankar (Project Coord<strong>in</strong>ator-Environment)<br />

Mr. M. Nithiyananthan (Project Leader-Industrial <strong>Safety</strong>)<br />

Mr. R. Ayyappan (Project Staff-Environment/Air)

6<br />

Mr. Udit Mathur (Project Staff – Environment/Economics)<br />

Mr. Anand Kumar (Project Leader – GIS)<br />

Dr. Anand K Rai (Project Staff – Environment / Agro-forestry)<br />

Mr. Suvankar Bose (Project Leader – Eng<strong>in</strong>eer<strong>in</strong>g)<br />

Mr. George S Sharma (Project Staff – Eng<strong>in</strong>eer<strong>in</strong>g)<br />

Mr. Pramod Kumar (Research Assistant)<br />

Mr. S.N. Prasad (Research Assistant)<br />

Mr. D. Venkatesan (Project Technician)<br />

Mr. Rana S<strong>in</strong>gh (Research Associate)<br />

Mr. Dharmendra Kori (Field Assistant)<br />

Mr. M.Saran (Research Assistant)<br />

The International Development Research Centre (IDRC), Canada funded all activities. Without <strong>the</strong>ir<br />

support, <strong>the</strong> research project and this manual would not have been possible.<br />

Norbert Wagner<br />

Department of Environmental and <strong>Occupational</strong> <strong>Health</strong><br />

University of South Florida<br />

Tampa, USA

7<br />

Eulogy<br />

Mr. M. Nithiyananthan, <strong>the</strong> nodal <strong>in</strong>vestigator on <strong>the</strong> safety<br />

components of this project, tragically passed away <strong>in</strong><br />

January 2009, before he could see this wonderful<br />

publication <strong>in</strong> pr<strong>in</strong>t.<br />

Nithi, as he was affectionately called by his colleagues,<br />

was unusual <strong>in</strong> many ways. His ma<strong>in</strong> profession, that of a<br />

safety eng<strong>in</strong>eer at <strong>the</strong> Chennai Port Trust, was one that<br />

demanded strict enforcement often to <strong>the</strong> annoyance of his<br />

workers. He was known as a man of action dur<strong>in</strong>g his<br />

career. After his retirement, he engaged <strong>in</strong> safety<br />

assessments with such a degree of compassion that it<br />

would be hard to capture his enthusiasm <strong>in</strong> a few<br />

paragraphs. He was very gratified that all <strong>the</strong> knowledge he<br />

had pa<strong>in</strong>stak<strong>in</strong>gly acquired but yet could only use for<br />

enforcement at one organization could f<strong>in</strong>ally f<strong>in</strong>d a place <strong>in</strong><br />

<strong>the</strong> academic or awareness rais<strong>in</strong>g doma<strong>in</strong>s of safety<br />

eng<strong>in</strong>eer<strong>in</strong>g. He wanted this wealth of <strong>in</strong>formation accrued<br />

dur<strong>in</strong>g rout<strong>in</strong>e project assessments be compiled <strong>in</strong><br />

systematic ways and made available freely so that <strong>the</strong><br />

wheel doesn’t have to be re<strong>in</strong>vented repeatedly.<br />

The present f<strong>in</strong>d<strong>in</strong>gs <strong>in</strong> <strong>the</strong> stone quarry<strong>in</strong>g sector represent one of his best such efforts. He wanted to<br />

“show and tell” how th<strong>in</strong>gs could be improved at little cost but huge sav<strong>in</strong>gs for health and life. He<br />

endured extreme temperatures, sway<strong>in</strong>g temperaments of owners and workers, hazardous work place<br />

conditions with extra-ord<strong>in</strong>ary patience just so that <strong>the</strong> unsafe conditions could be showcased and<br />

eventually done away with. He has meticulously documented <strong>the</strong> hazards and listed <strong>the</strong> accompany<strong>in</strong>g<br />

solutions through a masterly photo collection.<br />

The project staff will remember his efforts with heartfelt gratitude not only for <strong>the</strong> scientific contributions<br />

but also for serv<strong>in</strong>g as a role model for human compassion and dedication. We dedicate this manual <strong>in</strong><br />

his lov<strong>in</strong>g memory.<br />

Kalpana Balakrishnan<br />

Department of Environmental <strong>Health</strong> Eng<strong>in</strong>eer<strong>in</strong>g<br />

Sri Ramachandra University<br />

Chennai, India

8<br />

Introduction<br />

<strong>Stone</strong> crush<strong>in</strong>g is necessary <strong>in</strong> order to build roads, bridges, build<strong>in</strong>gs and almost everyth<strong>in</strong>g we need<br />

<strong>in</strong> our modern life. There are an estimated 12000 stone crush<strong>in</strong>g units with about 500.000 workers <strong>in</strong><br />

India. One can presume that several million workers are work<strong>in</strong>g <strong>in</strong> stone crush<strong>in</strong>g all over Asia.<br />

<strong>Stone</strong> crush<strong>in</strong>g provides <strong>in</strong>come for families but <strong>the</strong> work<strong>in</strong>g conditions of employees are often<br />

unhealthy and dangerous. Major concerns <strong>in</strong> stone crush<strong>in</strong>g are accidents and <strong>in</strong>juries, hear<strong>in</strong>g loss,<br />

dust-related lung diseases. All of <strong>the</strong>se diseases can be prevented, <strong>the</strong> work<strong>in</strong>g conditions can be<br />

improved with simple means and m<strong>in</strong>imal cost.<br />

The purpose of this manual is to provide <strong>in</strong>formation and guidance to improve work<strong>in</strong>g conditions and<br />

safety <strong>in</strong> stone crush<strong>in</strong>g units for owners, workers, governmental and non-governmental <strong>in</strong>stitutions,<br />

trade unions and <strong>in</strong>terested persons. It will help stone crush<strong>in</strong>g unit owners to improve <strong>the</strong>ir bus<strong>in</strong>ess<br />

by avoid<strong>in</strong>g unnecessary cost.<br />

The above-mentioned research and development project was funded by The International<br />

Development Research Centre (IDRC), Canada and <strong>in</strong>cluded a thorough assessment of <strong>the</strong> situation,<br />

specifically <strong>the</strong> safety situation <strong>in</strong> stone crush<strong>in</strong>g units and <strong>the</strong> work<strong>in</strong>g conditions. It used observations,<br />

walk-throughs, discussions with owners and workers as well as measurements of dust and noise levels<br />

to analyze <strong>the</strong> situation. F<strong>in</strong>d<strong>in</strong>gs were documented with checklists, photos and data sheets.<br />

Based on <strong>the</strong>se f<strong>in</strong>d<strong>in</strong>gs, recommendations for immediate and low-cost solutions were formulated.<br />

Long-term, sometimes more costly <strong>in</strong>terventions were added. The project team presented All solutions<br />

to <strong>the</strong> unit owners and discussed <strong>the</strong>ir feasibility with <strong>the</strong>m.<br />

Part A " <strong>Safety</strong> & <strong>Health</strong> <strong>in</strong> <strong>the</strong> <strong>Stone</strong> Crush<strong>in</strong>g <strong>Industry</strong>" we look at solutions to prevent accidents<br />

and to keep workers and <strong>the</strong>ir families healthy. The last section discusses <strong>the</strong> elements of emergency<br />

preparedness for <strong>the</strong> <strong>in</strong>dustry.<br />

Part B "Improv<strong>in</strong>g heavy physical work" describes long-term effects of heavy physical work and<br />

suggests solutions to reduce fatigue and prevent illness.<br />

Part C "How Much Does an Accident Cost?" <strong>in</strong>troduces a short and simple table to calculate, better:<br />

estimate, <strong>the</strong> real cost of an accident. It should help to keep <strong>the</strong> right perspective on <strong>the</strong> f<strong>in</strong>ancial side<br />

of accidents and <strong>the</strong> monetary benefits of prevention.<br />

In Part D " Checklists and Benchmarks", we added checklists to make it easier to assess <strong>the</strong><br />

work<strong>in</strong>g conditions. They help <strong>in</strong> analyz<strong>in</strong>g a situation and <strong>in</strong> f<strong>in</strong>d<strong>in</strong>g <strong>the</strong> appropriate measures to<br />

improve. These checklists can be used as benchmarks to document and compare <strong>the</strong> level of <strong>the</strong><br />

safety and health performance of a company. Over time, progress and improvements can <strong>the</strong>n be<br />

documented and experiences shared.<br />

On <strong>the</strong> long run, we hope that such a "safety performance score" for crush<strong>in</strong>g units helps <strong>in</strong> achiev<strong>in</strong>g<br />

better safety performances <strong>in</strong> <strong>the</strong> <strong>in</strong>dustry. We hope that <strong>in</strong> <strong>the</strong> future such a "score" will be <strong>in</strong>cluded <strong>in</strong><br />

tender processes as one of several selection criteria so that <strong>the</strong> order goes to <strong>the</strong> stone crush<strong>in</strong>g units<br />

with <strong>the</strong> best protection for <strong>the</strong>ir workers..

9<br />

A <strong>Safety</strong> & <strong>Health</strong> <strong>in</strong> <strong>Stone</strong> Crush<strong>in</strong>g<br />

Picture 1: typical dust cloud around <strong>the</strong> crusher and sorter<br />

From reports and <strong>in</strong>terviews with owners and workers, we know that <strong>the</strong> ma<strong>in</strong> causes of <strong>in</strong>jury and<br />

days-lost-for-work <strong>in</strong> <strong>the</strong> stone crush<strong>in</strong>g <strong>in</strong>dustry are:<br />

• Falls from heights<br />

• Slips and trips<br />

• Traffic accidents <strong>in</strong>side and outside <strong>the</strong> plant<br />

• Injury by heavy physical work and manual handl<strong>in</strong>g of heavy loads<br />

• Accidents with electricity<br />

We identified <strong>the</strong> follow<strong>in</strong>g causes of long-term ill health and days-lost for-work <strong>in</strong> stone crush<strong>in</strong>g:<br />

• Dust caus<strong>in</strong>g chronic lung diseases such as chronic obstructive (asthmatic) bronchitis or silicarelated<br />

lung scar<strong>in</strong>g (silicosis)<br />

• Noise caus<strong>in</strong>g noise-<strong>in</strong>duced hear<strong>in</strong>g loss<br />

• Chronic diseases of <strong>the</strong> movement apparatus (jo<strong>in</strong>ts, bones, muscles, ligaments) caused by<br />

heavy physical work and manual handl<strong>in</strong>g of heavy loads or hand-arm vibration by power tools

10<br />

In <strong>the</strong> follow<strong>in</strong>g chapters we will take up <strong>the</strong>se topics one by one. We will discuss and describe<br />

solutions to reduce <strong>the</strong> risk of gett<strong>in</strong>g sick <strong>in</strong> stone crush<strong>in</strong>g. We have to keep <strong>in</strong> m<strong>in</strong>d <strong>the</strong> ALL of <strong>the</strong>se<br />

causes can essentially be reduced and controlled. But first, we look at <strong>the</strong> management side of safety<br />

and health. The unit owner has a very important role <strong>in</strong> f<strong>in</strong>d<strong>in</strong>g <strong>the</strong> risks, decid<strong>in</strong>g where improvements<br />

are necessary and feasible as well as <strong>in</strong> manag<strong>in</strong>g <strong>the</strong> improvement process and <strong>the</strong> role.<br />

A.1 A Word for <strong>the</strong> Owners: Manag<strong>in</strong>g <strong>Health</strong> and <strong>Safety</strong><br />

<strong>in</strong> <strong>Stone</strong> Crush<strong>in</strong>g<br />

Ralf Ste<strong>in</strong>berg, health & safety manager, Düsseldorf Germany<br />

Manag<strong>in</strong>g health and safety is little different from manag<strong>in</strong>g any o<strong>the</strong>r aspect of your bus<strong>in</strong>ess. You<br />

need to assess risks beforehand <strong>in</strong> your workplace, put sensible and cost-effective measures <strong>in</strong> place<br />

to reduce risks, and make sure <strong>the</strong>y stay low. This booklet will provide you with relevant <strong>in</strong>formation<br />

concern<strong>in</strong>g hazards and <strong>the</strong>ir control for operations <strong>in</strong> stone crush<strong>in</strong>g.<br />

What is a "risk assessment"?<br />

In order to reduce health risk and prevent<br />

accidents, you first have to assess risk. It helps<br />

you understand <strong>the</strong> nature of hazards, how your<br />

employees could be harmed and how you can<br />

prevent that from happen<strong>in</strong>g. It is noth<strong>in</strong>g more<br />

than a careful exam<strong>in</strong>ation of work<strong>in</strong>g conditions<br />

and <strong>the</strong> way workers could be harmed. It is a<br />

practical exercise, aimed at gett<strong>in</strong>g practical<br />

results. At <strong>the</strong> end, it helps you to focus on <strong>the</strong><br />

greatest risks first and set priorities for your<br />

actions. Most often, it means that simple, cheap<br />

Hazard?<br />

and effective measures are feasible to ensure<br />

your most valuable asset – your workforce – is<br />

protected. The step-by-step guidance below<br />

shows you how to assess health and safety risks<br />

with m<strong>in</strong>imum fuss.<br />

Five steps of risk assessment<br />

Operation<br />

Workplace =<br />

Equipment +<br />

Environment<br />

People<br />

Step 1: Identify <strong>the</strong> hazards<br />

Step 2: Decide who might be harmed<br />

and how<br />

Step 3: Evaluate <strong>the</strong> risks and decide on precautions<br />

Step 4: Record your f<strong>in</strong>d<strong>in</strong>gs and implement <strong>the</strong>m<br />

Step 5: Review your assessment and update if necessary<br />

Don’t overcomplicate <strong>the</strong> process. You probably already know whe<strong>the</strong>r, for example, you have<br />

employees who move heavy loads and so could harm <strong>the</strong>ir backs, or where people are most likely to<br />

slip or trip. If so, check that you have taken reasonable precautions to avoid <strong>in</strong>jury.<br />

You can do <strong>the</strong> assessment yourself. We provide you with checklists at <strong>the</strong> end of this manual to help<br />

you <strong>in</strong> this process (see chapter Checklists). You do not have to be a health and safety expert. If you<br />

are not confident, get help from someone who is competent. In all cases, you should make sure that<br />

you <strong>in</strong>volve your staff or <strong>the</strong>ir representatives <strong>in</strong> <strong>the</strong> process. They will have useful <strong>in</strong>formation about

11<br />

how <strong>the</strong> work is done and how <strong>the</strong>y see <strong>the</strong> possible solution to problems. It will make your<br />

assessment of <strong>the</strong> risk more thorough and effective.<br />

When th<strong>in</strong>k<strong>in</strong>g about your risk assessment, remember:<br />

• a hazard is anyth<strong>in</strong>g that may cause harm, such as chemicals, electricity, work<strong>in</strong>g from<br />

ladders, exposure to dust etc;<br />

• <strong>the</strong> risk is <strong>the</strong> chance, high or low, that somebody will be harmed by <strong>the</strong>se and o<strong>the</strong>r hazards,<br />

toge<strong>the</strong>r with an <strong>in</strong>dication of how serious <strong>the</strong> harm could be; e.g. <strong>in</strong>jury, fatality etc.<br />

Step 1 Identify <strong>the</strong> hazards<br />

First, you need to see what <strong>the</strong> hazards are and how people can be harmed. It is easy to overlook<br />

hazards, so here some tips to help you identify <strong>the</strong> ones that matter:<br />

• Walk around your workplace and look at what could cause harm.<br />

• Ask your employees or <strong>the</strong>ir representatives what <strong>the</strong>y th<strong>in</strong>k. They may have noticed th<strong>in</strong>gs<br />

that are not immediately obvious to you.<br />

• If you are a member of a professional association, contact <strong>the</strong>m. Many associations produce<br />

helpful guidance.<br />

• Check manufacturers’ <strong>in</strong>structions or data sheets for chemicals and equipment. These can<br />

be helpful f<strong>in</strong>d<strong>in</strong>g <strong>the</strong> hazards and putt<strong>in</strong>g <strong>the</strong>m <strong>in</strong> perspective.<br />

• Have a look at your accident and ill-health records – <strong>the</strong>se often help to identify hazards.<br />

• Remember to <strong>in</strong>clude long-term hazards to health (e.g. high levels of noise or exposure to<br />

harmful substances) besides <strong>the</strong> immediate safety hazards.<br />

Step 2 Decide who might be harmed and how<br />

When you know which group of workers might be<br />

harmed you can identify <strong>the</strong> best way of reduc<strong>in</strong>g <strong>the</strong><br />

risk. It helps to write down how <strong>the</strong>y might be harmed,<br />

i.e. what type of <strong>in</strong>jury or ill health might occur; for<br />

example, ‘Workers who move heavy stones may<br />

suffer back <strong>in</strong>jury from repeated lift<strong>in</strong>g.<br />

Remember that some workers have particular needs,<br />

e.g. new and young workers, new or expectant<br />

mo<strong>the</strong>rs and people with disabilities or elderly workers.<br />

They might be at particular risk. You can also ask your<br />

staff if <strong>the</strong>y can th<strong>in</strong>k of anyone you may have missed.<br />

Step 3 Evaluate <strong>the</strong> risks and decide on precautions<br />

Hav<strong>in</strong>g spotted <strong>the</strong> hazard, you <strong>the</strong>n have to decide what to do about it. You can work this out for<br />

yourself, but one easier way is to look for good practices <strong>in</strong> <strong>the</strong> <strong>in</strong>dustry. The present booklet shows<br />

such good practices and provides an overview of hazards and controls.<br />

You can start by compar<strong>in</strong>g your present work<strong>in</strong>g practices with examples from o<strong>the</strong>r <strong>in</strong>dustries (good<br />

practices) and see if <strong>the</strong>re is more you could be do<strong>in</strong>g to make your workplaces safe.

12<br />

Picture 2: women collect<strong>in</strong>g dust under <strong>the</strong> conveyer belts<br />

The "Hierarchy of Controls"<br />

When th<strong>in</strong>k<strong>in</strong>g about solutions, consider <strong>the</strong> pr<strong>in</strong>ciples below, if possible <strong>in</strong> order, <strong>the</strong> so-called<br />

hierarchy of controls:<br />

1. try a less risky option (e.g. switch to us<strong>in</strong>g a less hazardous chemical);<br />

2. prevent access to <strong>the</strong> hazard (e.g. by guards around mach<strong>in</strong>ery or rails);<br />

3. organize work better to reduce exposure to <strong>the</strong> hazard (e.g. don't allow on-lookers dur<strong>in</strong>g<br />

unload<strong>in</strong>g or stop runn<strong>in</strong>g <strong>the</strong> crusher while clean<strong>in</strong>g up to reduce dust exposure);<br />

4. provide personal protective equipment (e.g. cloth<strong>in</strong>g, footwear, goggles etc); and provide<br />

welfare facilities (e.g. first aid and wash<strong>in</strong>g facilities for removal of contam<strong>in</strong>ation).<br />

Improv<strong>in</strong>g health and safety often does not cost a lot. For <strong>in</strong>stance, plac<strong>in</strong>g a mirror on a dangerous<br />

bl<strong>in</strong>d corner to help prevent vehicle accidents is a low-cost precaution consider<strong>in</strong>g <strong>the</strong> risks. Failure to<br />

take simple precautions can cost you a lot more if an accident does happen (you will f<strong>in</strong>d a cost<br />

calculation <strong>in</strong> chapter How much does an Accident Cost?). We can only encourage you to <strong>in</strong>volve your<br />

workers <strong>in</strong> this discussion, so that you can be sure that what you propose will work <strong>in</strong> practice and will<br />

not <strong>in</strong>troduce new hazards.<br />

Step 4 Record your f<strong>in</strong>d<strong>in</strong>gs and implement <strong>the</strong>m<br />

Putt<strong>in</strong>g <strong>the</strong> results of your risk assessment <strong>in</strong>to practice will make a difference when look<strong>in</strong>g after<br />

people and your bus<strong>in</strong>ess. Writ<strong>in</strong>g down <strong>the</strong> results of your risk assessment, and shar<strong>in</strong>g <strong>the</strong>m with<br />

your staff, encourages you and <strong>the</strong>m to follow your solutions correctly, for <strong>in</strong>stance your new work<br />

practices and work orders. If you have only few employees, you do not have to write anyth<strong>in</strong>g down.<br />

However, notes are useful so that you can review <strong>the</strong>m later when someth<strong>in</strong>g changes.

13<br />

When writ<strong>in</strong>g down your results, you can keep it simple, for example<br />

−<br />

−<br />

‘Tripp<strong>in</strong>g over unused tools: conta<strong>in</strong>er provided, staff <strong>in</strong>structed, weekly housekeep<strong>in</strong>g checks<br />

conducted’, or<br />

‘Glare from weld<strong>in</strong>g: anti-UV goggles provided, workers <strong>in</strong>structed and regularly checked’.<br />

Nobody expects a risk assessment to be perfect, but it should be suitable and sufficient. You need to<br />

be able to show that:<br />

a. a proper check was made;<br />

b. you asked who might be affected;<br />

c. you dealt with all <strong>the</strong> significant hazards;<br />

d. <strong>the</strong> precautions are reasonable, and <strong>the</strong> rema<strong>in</strong><strong>in</strong>g risk is low.<br />

Like many bus<strong>in</strong>esses, you f<strong>in</strong>d that <strong>the</strong>re are quite a lot of improvements that you can implement.<br />

Don’t try to do everyth<strong>in</strong>g at once. Make a "plan of action" to deal with <strong>the</strong> most important th<strong>in</strong>gs first.<br />

Authorities, staff and community usually acknowledge all efforts of bus<strong>in</strong>esses that are try<strong>in</strong>g clearly to<br />

make improvements.<br />

A good plan of action often <strong>in</strong>cludes a mixture of different th<strong>in</strong>gs such as:<br />

• easy improvements that can be done quickly, perhaps as a temporary solution until more<br />

reliable controls are <strong>in</strong> place;<br />

• long-term solutions to those risks that most likely cause accidents or ill health;<br />

• a tra<strong>in</strong><strong>in</strong>g of employees on rema<strong>in</strong><strong>in</strong>g major risks and how <strong>the</strong>y can be reduced;<br />

• regular checks to make sure that <strong>the</strong> control measures stay <strong>in</strong> place; and<br />

• clear responsibilities that state who will do which action, and when.<br />

Remember, prioritize and tackle <strong>the</strong> most important th<strong>in</strong>gs first! As you complete each action, tick it off<br />

your plan.

14<br />

Step 5 Review your risk assessment and update if necessary<br />

Few workplaces stay <strong>the</strong> same. Eventually, you will br<strong>in</strong>g <strong>in</strong> new equipment, change procedures or<br />

simply shift to ano<strong>the</strong>r place. This can lead to new hazards. It makes sense, <strong>the</strong>refore, to take time to<br />

review <strong>the</strong> situation on an ongo<strong>in</strong>g basis. Every year, you should review how th<strong>in</strong>gs are, where <strong>the</strong>re is<br />

room for improvements and if your former improvements are still work<strong>in</strong>g.<br />

Look at your risk assessment aga<strong>in</strong>: Have <strong>the</strong>re been any changes? Are <strong>the</strong>re improvements you still<br />

need to make? Have your workers spotted a problem? Can you learn anyth<strong>in</strong>g from accidents or near<br />

misses? It is best to th<strong>in</strong>k about this risk assessment while you are plann<strong>in</strong>g your change – that way<br />

you are ahead of any surprises. If <strong>the</strong>re is a significant change dur<strong>in</strong>g <strong>the</strong> year, do not wait. Just look at<br />

your risk assessment and, where necessary, correct it. The benefits of plann<strong>in</strong>g are enormous.<br />

Prevent<strong>in</strong>g just one accident is usually three or four times cheaper than pay<strong>in</strong>g for <strong>the</strong> subsequent cost<br />

of an accident.<br />

You will f<strong>in</strong>d more <strong>in</strong>formation on hazards and risks at work at <strong>the</strong>se<br />

websites:<br />

http://www.osha.gov<br />

http://www.hse.co.uk<br />

http://www.cdc.gov/niosh/homepage.html<br />

http://www.ccohs.ca/<br />

A.2 Prevent<strong>in</strong>g Accidents <strong>in</strong> a <strong>Stone</strong> Crush<strong>in</strong>g Unit<br />

A.2.1 Prevent<strong>in</strong>g Falls from Heights<br />

Accidents are always bad for <strong>the</strong> victim and for bus<strong>in</strong>ess. Some of <strong>the</strong> most common causes of<br />

accidents <strong>in</strong> a stone crush<strong>in</strong>g unit are:<br />

−<br />

−<br />

−<br />

Hands and f<strong>in</strong>gers or toes be<strong>in</strong>g crushed by stones<br />

Body parts such as hands or arms be<strong>in</strong>g caught <strong>in</strong> mach<strong>in</strong>es<br />

Traffic accidents <strong>in</strong>side <strong>the</strong> unit<br />

− Fall<strong>in</strong>g and slipp<strong>in</strong>g from heights<br />

There are many occasions where stone crush<strong>in</strong>g workers are at a specific risk for falls.<br />

Location/Workplace<br />

−<br />

−<br />

−<br />

Work<strong>in</strong>g on top of <strong>the</strong> primary crusher, for <strong>in</strong>stance dur<strong>in</strong>g boulder off load<strong>in</strong>g when boulders are<br />

brought <strong>in</strong> by trailers from quarries and fed <strong>in</strong> to <strong>the</strong> receiv<strong>in</strong>g pit<br />

At <strong>the</strong> primary crusher area when stones are stuck and need to be shoved to undo <strong>the</strong> jam<br />

On work platforms, for <strong>in</strong>stance dur<strong>in</strong>g repair and ma<strong>in</strong>tenance work on <strong>the</strong> crusher itself

15<br />

Picture 3: worker at <strong>the</strong> primary crusher chute<br />

Common unsafe conditions or acts<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

Too many workers are too close when dangerous work is done<br />

Workers need to work on <strong>the</strong> high wall of <strong>the</strong> bolder pit with no fall protection<br />

Workers need to access <strong>the</strong> top of <strong>the</strong> platform by climb<strong>in</strong>g through support<strong>in</strong>g poles or up <strong>the</strong><br />

stone piles<br />

There is no set and separated path for vehicular and persons’ movement<br />

There is no guard around <strong>the</strong> bolder pits<br />

Work is performed on work platforms which are not guarded and have no rail<strong>in</strong>gs<br />

Ma<strong>in</strong>tenance work at heights (i.e. portable conveyors) is performed without secur<strong>in</strong>g <strong>the</strong> work<strong>in</strong>g<br />

persons<br />

Hazards and health risks<br />

− Fall from heights or <strong>in</strong>to pits with severe <strong>in</strong>juries such as fractures, head <strong>in</strong>jury, or even death<br />

Solutions to protect health<br />

Attach a bund wall or raised steel girder to entire length of pit to prevent falls; curb wall can be<br />

constructed from available boulders at site<br />

Movement on <strong>the</strong> top of <strong>the</strong> reta<strong>in</strong><strong>in</strong>g wall should be avoided<br />

No person should be allowed to walk on <strong>the</strong> parapet of <strong>the</strong> load<strong>in</strong>g pit<br />

Provide <strong>in</strong>dicat<strong>in</strong>g alarms to sound when rocks are be<strong>in</strong>g loaded <strong>in</strong>to <strong>the</strong> crusher

16<br />

Provide stable ladders that are <strong>in</strong> good<br />

condition<br />

<strong>Safety</strong> belts and harnesses should be<br />

provided for all those who work at heights<br />

Stop us<strong>in</strong>g <strong>the</strong> conveyor belt to climb to <strong>the</strong><br />

top and do not use broken or make-shift<br />

ladders<br />

Provide steps and ladders where<br />

unconsolidated material slopes are currently<br />

used for climb<strong>in</strong>g up and down. Steps can be<br />

carved to prevent <strong>the</strong> trip and fall hazard due<br />

to slippery and loose soil<br />

Provide ladders that are <strong>in</strong> good condition<br />

(preferably wooden) <strong>in</strong> places where <strong>the</strong>re are<br />

electrical overhead l<strong>in</strong>es runn<strong>in</strong>g across and<br />

metal ladders <strong>in</strong> o<strong>the</strong>r places<br />

The ladders should be long enough to reach<br />

<strong>the</strong> top and also have an extra length of 75-90<br />

cm for hold<strong>in</strong>g after reach<strong>in</strong>g <strong>the</strong> top<br />

Provide ladders at 70-75 degree slopes<br />

Ladders should not be used as a platform to<br />

work<br />

Picture 4: repair<strong>in</strong>g <strong>the</strong> conveyer belts without<br />

safety harness or fall protection<br />

A.2.2 Work<strong>in</strong>g Safely with Electricity<br />

Electrical equipment makes <strong>the</strong> work and <strong>the</strong> stone crush<strong>in</strong>g possible. However, electricity can be<br />

dangerous to people. They might even die from an electrical shock. Failure of electrical equipment can<br />

cause fires <strong>in</strong> a workshop, damage to mach<strong>in</strong>es, destroy products and seriously or fatally <strong>in</strong>jure people.<br />

We need to prevent any direct contact of workers with electrical power and tension. That is <strong>the</strong> goal of<br />

prevent<strong>in</strong>g accidents with electrical equipment.<br />

Location/Workplace<br />

Electrical power is used <strong>in</strong> <strong>the</strong> entire stone crush<strong>in</strong>g unit. Specifically critical locations are:<br />

−<br />

The transformer yard and distribution panel room where <strong>the</strong> ma<strong>in</strong> <strong>in</strong>com<strong>in</strong>g supply from <strong>the</strong> state's<br />

power grid is received through a transformer at <strong>the</strong> site and subsequently transformed to <strong>the</strong> bus<br />

bar panel <strong>in</strong> <strong>the</strong> panel room from where <strong>the</strong> supply to various facilities, mach<strong>in</strong>es, locations is<br />

taken via <strong>the</strong> various cables and circuits<br />

− Control switches and distribution p<strong>in</strong>ts throughout <strong>the</strong> unit and <strong>the</strong> crusher mach<strong>in</strong>e<br />

Common Unsafe Conditions/Acts<br />

− Damaged electrical cords, for <strong>in</strong>stance wires lay<strong>in</strong>g on <strong>the</strong> ground where trucks frequently drive<br />

over <strong>the</strong>m. This leads to <strong>in</strong>adequate ground<strong>in</strong>g and possible contact of workers with <strong>the</strong> power l<strong>in</strong>e<br />

−<br />

Bare wires are used <strong>in</strong> sockets and plugs to draw current, as correct plugs are not provided by <strong>the</strong><br />

company or broken connectors are not repaired

17<br />

Picture 5: electrical room used for storage and rest<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

Damaged electrical equipment, mach<strong>in</strong>es and tools are used so that <strong>the</strong> surface of <strong>the</strong> tool actually<br />

carries electrical power.<br />

Insufficient or no ground<strong>in</strong>g of electrical equipment and mach<strong>in</strong>es lead to electrically charged<br />

mach<strong>in</strong>e parts<br />

Extension cords are used one after <strong>the</strong> o<strong>the</strong>r because of miss<strong>in</strong>g fixed <strong>in</strong>stallations<br />

Breakers and circuits are miss<strong>in</strong>g or overloaded for <strong>in</strong>stance, <strong>the</strong> power connection to <strong>the</strong> mobile<br />

load<strong>in</strong>g belt with bucket conveyor has no circuit breakers<br />

Sub-station, pillar boxes, junction boxes, etc. are not clearly marked as DANGEROUS. Anyone<br />

can easily access it. Often <strong>the</strong>se rooms are used for storage and as social rooms by workers<br />

There is no regular check and ma<strong>in</strong>tenance of electrical <strong>in</strong>stallations and equipment<br />

Electrical rooms be<strong>in</strong>g used as rest areas for workers<br />

Fire ext<strong>in</strong>guishers or <strong>in</strong>sulation materials such as rubber mats are miss<strong>in</strong>g. If available, no one is<br />

tra<strong>in</strong>ed to properly use fire ext<strong>in</strong>guishers.<br />

Hazards and health risks<br />

−<br />

−<br />

−<br />

Electrical short circuits and fire<br />

Tripp<strong>in</strong>g of <strong>the</strong> entire power supply to <strong>the</strong> plant, which stops <strong>the</strong> entire production<br />

Contact of electrical power by workers which can result <strong>in</strong> serious <strong>in</strong>jury, electrocution, burns or<br />

even death

18<br />

Solutions to protect health<br />

Install Earth Leakage Circuit Breakers<br />

(ELCB) <strong>in</strong> all circuits to protect <strong>the</strong><br />

operators from electrical hazards<br />

Keep <strong>the</strong> ma<strong>in</strong> switch box <strong>in</strong> good<br />

condition, protected from <strong>the</strong> wea<strong>the</strong>r <strong>in</strong><br />

a separate room. Install an appropriately<br />

sized ELCB<br />

Provide good earth or ground connection<br />

for all <strong>in</strong>stallations<br />

Electrical cables should be laid <strong>in</strong>to <strong>the</strong><br />

ground <strong>in</strong> shock-proof material or taken<br />

over head. Cables should be run <strong>in</strong> extra<br />

plastic conduits<br />

Provide <strong>in</strong>sulation materials for work on<br />

electrical equipment such as approved<br />

rubber mats <strong>in</strong> front of <strong>the</strong> distribution<br />

boards and ma<strong>in</strong> switches. This will help<br />

to <strong>in</strong>sulate <strong>the</strong> worker and prevent a<br />

dangerous current from go<strong>in</strong>g through<br />

his body<br />

Log, and tag all <strong>in</strong>stallations which are<br />

under ma<strong>in</strong>tenance or repair, to prevent<br />

o<strong>the</strong>rs from switch<strong>in</strong>g on <strong>the</strong> mach<strong>in</strong>es<br />

while ano<strong>the</strong>r worker is repair<strong>in</strong>g it<br />

All distribution po<strong>in</strong>ts should be marked<br />

legibly <strong>in</strong> an understandable language,<br />

mark<strong>in</strong>g <strong>the</strong> feed<strong>in</strong>g po<strong>in</strong>t, voltage, and identification number. This will help to Log-Out and<br />

make shutdown quicker <strong>in</strong> case of emergency<br />

Provide fire buckets filled with sand or portable-size fire ext<strong>in</strong>guishers for use <strong>in</strong> case of fire<br />

Provide necessary personal protective equipment like shoes and rubber gloves for those<br />

deployed <strong>in</strong> electrical work<br />

Good practices when work<strong>in</strong>g with electricity<br />

− All electrical connections are <strong>in</strong> good order with ELCB attached<br />

−<br />

−<br />

−<br />

−<br />

−<br />

All switch boards are enclosed and protected from wea<strong>the</strong>r and dust<br />

All panel boards are equipped with ELCB and all hand and power tools are run on circuits<br />

protected by ELCBs<br />

Dur<strong>in</strong>g electrical ma<strong>in</strong>tenance, a lockout/tagout system is mandatory and workers are tra<strong>in</strong>ed to<br />

follow <strong>the</strong>se <strong>in</strong>structions<br />

Electrical conductors such as cables are of sufficient size and load carry<strong>in</strong>g capacity<br />

The transformer where <strong>the</strong> <strong>in</strong>com<strong>in</strong>g electricity supply is received from <strong>the</strong> grid is isolated and<br />

cordoned off to prevent free access of <strong>the</strong> public and animals. A fence with or without barbed wire<br />

can enclose it. The compound is sufficiently large (around 2 meters each direction form <strong>the</strong><br />

transformer), its surface is clear of green and dry vegetation to prevent fire

19<br />

−<br />

−<br />

−<br />

The transformers are positioned at least 2.50 meters above ground level<br />

All workers are tra<strong>in</strong>ed <strong>in</strong> <strong>the</strong> hazards and <strong>the</strong> safety measures when work<strong>in</strong>g with electricity<br />

In every shift, <strong>the</strong>re is one person tra<strong>in</strong>ed <strong>in</strong> basic life support (such as cardio-pulmonary<br />

resuscitation, CPR) <strong>in</strong> case of an accident with electricity<br />

A.2.3 Mach<strong>in</strong>es and Power Tools<br />

Mach<strong>in</strong>es can hurt people. They need to be constructed correctly to be safe for <strong>the</strong> workers who<br />

handle <strong>the</strong>m or even just pass<strong>in</strong>g by. All too often, a worker is pulled <strong>in</strong>to a mach<strong>in</strong>e such as a<br />

conveyor belt, a gr<strong>in</strong>der or a crusher.<br />

The major mach<strong>in</strong>es <strong>in</strong> a crush<strong>in</strong>g unit are <strong>the</strong> primary and secondary crusher, <strong>the</strong> conveyer belt, and<br />

<strong>the</strong> sorters.<br />

Small 'mach<strong>in</strong>es' such as power tools can also be dangerous if <strong>the</strong>y are not properly ma<strong>in</strong>ta<strong>in</strong>ed and<br />

repaired if broken.<br />

Common unsafe conditions or acts<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

No guards are <strong>in</strong>stalled around <strong>the</strong> crusher’s mov<strong>in</strong>g parts, nip po<strong>in</strong>ts, flywheels, conveyor drives,<br />

etc. to prevent cloth<strong>in</strong>g be<strong>in</strong>g pulled <strong>in</strong>to <strong>the</strong> mach<strong>in</strong>e<br />

No emergency switch for <strong>the</strong> conveyor belt or <strong>the</strong> crushers is <strong>in</strong>stalled to stop <strong>the</strong>m if a worker is<br />

pulled <strong>in</strong>to <strong>the</strong>m<br />

Workers are wear<strong>in</strong>g loose cloth<strong>in</strong>g which can easily be caught and pulled <strong>in</strong>to a mach<strong>in</strong>e<br />

Conveyors are not<br />

periodically <strong>in</strong>spected<br />

and tested<br />

Workers are not<br />

properly tra<strong>in</strong>ed <strong>in</strong> safe<br />

procedures to protect<br />

<strong>the</strong>mselves from mak<strong>in</strong>g<br />

mistakes<br />

Movable conveyors are<br />

often <strong>in</strong> unstable<br />

positions<br />

No personal protective<br />

equipment (PPE) is<br />

provided to workers (see<br />

also <strong>the</strong> o<strong>the</strong>r chapter<br />

here <strong>in</strong> this manual),<br />

especially dur<strong>in</strong>g<br />

ma<strong>in</strong>tenance and<br />

clean<strong>in</strong>g work<br />

Hand tools are <strong>in</strong> poor condition and not properly repaired when broken<br />

Hazards and health risks<br />

−<br />

−<br />

−<br />

Accidents and Injuries due to entangl<strong>in</strong>g with unguarded mach<strong>in</strong>e parts and be<strong>in</strong>g pulled <strong>in</strong>to a<br />

mach<strong>in</strong>e, be<strong>in</strong>g caught between, stuck by, and dragged <strong>in</strong> to mach<strong>in</strong>ery<br />

Accidents when mobile conveyors topple over<br />

Equipment and conveyor damage

20<br />

Picture 6: repair<strong>in</strong>g <strong>the</strong> primary crusher, boulder chute on right<br />

Solutions to protect health<br />

Tra<strong>in</strong> employees on safe work methods, avoid wear<strong>in</strong>g loose cloth<strong>in</strong>g when work<strong>in</strong>g near<br />

mov<strong>in</strong>g mach<strong>in</strong>ery and conveyors<br />

Work<strong>in</strong>g near conveyors and mov<strong>in</strong>g mach<strong>in</strong>ery should be avoided as much as possible<br />

Install mach<strong>in</strong>e guards that are needed on and around all mov<strong>in</strong>g parts<br />

Repair and ma<strong>in</strong>ta<strong>in</strong> all hand and power tools<br />

Only work with power tools when <strong>the</strong>y are connected to a circuit, which is protected by an<br />

ELCB <strong>in</strong>terrupter (see chapter on "Work<strong>in</strong>g Safely with Electricity")<br />

Use a so-called "Lock out – Tag out" system for safe lock<strong>in</strong>g of power sources, so that no one<br />

can accidentally switch on <strong>the</strong> mach<strong>in</strong>e while o<strong>the</strong>rs are work<strong>in</strong>g on it<br />

Emergency shut-down switches should be <strong>in</strong>stalled for all mach<strong>in</strong>es <strong>in</strong> <strong>the</strong> crush<strong>in</strong>g unit; tra<strong>in</strong><br />

workers <strong>in</strong> <strong>the</strong>ir use<br />

Avoid unauthorized operation and entry by us<strong>in</strong>g a "work permit system" for contractors, which<br />

tells <strong>the</strong>m what to do and how to protect <strong>the</strong>mselves and <strong>the</strong> o<strong>the</strong>r workers

21<br />

A.2.4 Us<strong>in</strong>g Gas Cyl<strong>in</strong>ders Safely<br />

Gases are used <strong>in</strong> a stone crush<strong>in</strong>g unit for repairs and ma<strong>in</strong>tenance work where weld<strong>in</strong>g or torch<br />

cutt<strong>in</strong>g is necessary. These gas cyl<strong>in</strong>ders are pressurized, which means that <strong>the</strong>y conta<strong>in</strong> enormous<br />

pressure. If <strong>the</strong> cyl<strong>in</strong>der is cut open, for <strong>in</strong>stance dur<strong>in</strong>g an accident, <strong>the</strong>y can explode; <strong>the</strong> gases <strong>in</strong><br />

<strong>the</strong>m can ignite and start a fire. It is clear that <strong>in</strong> such an event, workers and by-standers such as <strong>the</strong><br />

unit owner can be seriously hurt or even killed. Especially dangerous are:<br />

• cyl<strong>in</strong>ders of liquid propane or natural gas (LNG, LPG), even though <strong>the</strong>re is little pressure <strong>in</strong><br />

<strong>the</strong> cyl<strong>in</strong>der <strong>the</strong>y are highly flammable;<br />

• cyl<strong>in</strong>ders with Oxygen or Acetylene, which are pressurized and also highly flammable<br />

Prevent<strong>in</strong>g gas cyl<strong>in</strong>ders from explod<strong>in</strong>g or gases <strong>in</strong> <strong>the</strong>se cyl<strong>in</strong>ders from catch<strong>in</strong>g fire is <strong>the</strong>refore an<br />

important part of <strong>the</strong> safety of a crush<strong>in</strong>g unit.<br />

Picture 7: compressed weld<strong>in</strong>g gas cyl<strong>in</strong>der (foreground) toge<strong>the</strong>r with LPG gas tank (right side) close<br />

to a power generator on open, hand-twisted electrical cable connections (center)<br />

Location/Workplace<br />

−<br />

Store rooms of gas cyl<strong>in</strong>ders, locations of weld<strong>in</strong>g and cutt<strong>in</strong>g throughout <strong>the</strong> unit

22<br />

Activities and Processes<br />

−<br />

Stor<strong>in</strong>g materials, weld<strong>in</strong>g & cutt<strong>in</strong>g ma<strong>in</strong>tenance work<br />

Common unsafe conditions or acts<br />

−<br />

−<br />

−<br />

Gas cyl<strong>in</strong>ders are stored or placed all over unit<br />

Gas cyl<strong>in</strong>ders are not secured and protected from falls<br />

Cyl<strong>in</strong>ders are rolled, pushed, pulled or even thrown without care<br />

Hazards and health risks<br />

−<br />

−<br />

Explosion<br />

Fire<br />

Solutions to protect health<br />

Cyl<strong>in</strong>ders should be stored and used upright and secured with a cha<strong>in</strong> to prevent <strong>the</strong>m from<br />

tipp<strong>in</strong>g<br />

Cyl<strong>in</strong>ders should be stored <strong>in</strong> cool and dry place, <strong>in</strong> <strong>the</strong> shade. They should be placed <strong>in</strong> an<br />

upright position, never be left open, or exposed to sunlight<br />

Put full and empty cyl<strong>in</strong>ders <strong>in</strong> different places and mark which ones are full and which are<br />

empty<br />

Always use <strong>the</strong> protective caps on cyl<strong>in</strong>ders that are not-<strong>in</strong>-use. They protect <strong>the</strong> outlet from<br />

be<strong>in</strong>g damaged <strong>in</strong> case of a fall<br />

Simple trolleys can be used for transport<strong>in</strong>g cyl<strong>in</strong>ders <strong>in</strong> an upright position. NEVER roll or<br />

drop cyl<strong>in</strong>ders<br />

All cyl<strong>in</strong>ders are equipped with pressure gauges<br />

Color-cod<strong>in</strong>g of each cyl<strong>in</strong>der is used to <strong>in</strong>dicate <strong>the</strong> k<strong>in</strong>d of gas <strong>in</strong> <strong>the</strong> cyl<strong>in</strong>der. Please ask<br />

someone for <strong>the</strong> national color cod<strong>in</strong>g standards, so <strong>the</strong> mark<strong>in</strong>g is uniform <strong>in</strong> <strong>the</strong> entire<br />

country when cyl<strong>in</strong>ders are bought, sold and refilled<br />

No sparks should be created when work<strong>in</strong>g close to <strong>the</strong> cyl<strong>in</strong>ders. No smok<strong>in</strong>g is allowed <strong>in</strong> <strong>the</strong><br />

vic<strong>in</strong>ity of <strong>the</strong> work.<br />

A.2.5 Keep<strong>in</strong>g <strong>the</strong> Roads Safe<br />

Accidents with vehicles are some of <strong>the</strong> most common accidents, often severe and often fatal. People<br />

are run over or crushed aga<strong>in</strong>st o<strong>the</strong>r objects by mov<strong>in</strong>g trucks.<br />

Often, <strong>the</strong> drivers have not received sufficient tra<strong>in</strong><strong>in</strong>g or <strong>the</strong> company does not provide simple<br />

equipment such as mirrors.<br />

Trucks are regularly transport<strong>in</strong>g and dump<strong>in</strong>g <strong>the</strong> boulders brought from <strong>the</strong> quarry<strong>in</strong>g m<strong>in</strong>es to <strong>the</strong><br />

collection pit. Because of <strong>the</strong> dust <strong>in</strong> stone crush<strong>in</strong>g units, <strong>the</strong> visibility is often poor and, because of<br />

<strong>the</strong> noise, shout<strong>in</strong>g and warn<strong>in</strong>gs are often impossible to hear. Owners need to make special<br />

provisions to keep truck operations safe for <strong>the</strong> driver but mostly for <strong>the</strong> o<strong>the</strong>r workers.<br />

Location/Workplace<br />

−<br />

Hot spots for traffic accidents are: <strong>the</strong> approach road from <strong>the</strong> entrance to <strong>the</strong> top of <strong>the</strong> boulders<br />

unload<strong>in</strong>g pit are, and <strong>the</strong> boulders load<strong>in</strong>g po<strong>in</strong>t at top of primary crusher itself<br />

Common unsafe conditions or acts<br />

−<br />

Poor visibility for <strong>the</strong> drivers because of dust

23<br />

−<br />

−<br />

The conditions of trucks and roads are very poor, mirrors are often miss<strong>in</strong>g or not used<br />

Vehicles are mov<strong>in</strong>g freely near <strong>the</strong> work area without clear traffic lanes and park<strong>in</strong>g areas <strong>in</strong>side<br />

<strong>the</strong> unit<br />

Picture 8: unload<strong>in</strong>g boulders on top of boulder pit, workers rest<strong>in</strong>g (background)<br />

Hazards and health risks<br />

−<br />

Severe traffic accident risk for all persons <strong>in</strong>side <strong>the</strong> crush<strong>in</strong>g unit<br />

− Toppl<strong>in</strong>g of <strong>the</strong> vehicles, damag<strong>in</strong>g <strong>the</strong> vehicles as well as <strong>in</strong>jur<strong>in</strong>g <strong>the</strong> driver<br />

Solutions to protect health<br />

Ma<strong>in</strong>ta<strong>in</strong> <strong>the</strong> vehicles regularly and repair broken and miss<strong>in</strong>g mirrors<br />

Provide street light<strong>in</strong>g along <strong>the</strong> approach road<br />

Mark <strong>the</strong> roads <strong>in</strong>side <strong>the</strong> plant! This can be easily done by dipp<strong>in</strong>g <strong>the</strong> small boulders <strong>in</strong> white<br />

lime and plac<strong>in</strong>g <strong>the</strong>m along <strong>the</strong> curb of <strong>the</strong> road to provide better visibility and guidance<br />

Restrict unauthorized entry of vehicles and undue park<strong>in</strong>g <strong>in</strong>side <strong>the</strong> plant and restrict park<strong>in</strong>g<br />

of <strong>the</strong> vehicles along <strong>the</strong> road and on <strong>the</strong> slopes<br />

Drivers should not move <strong>the</strong> vehicle when persons are stand<strong>in</strong>g on <strong>the</strong> top of <strong>the</strong> truck<br />

Provide warn<strong>in</strong>g signals and also speed limit <strong>in</strong>dication for vehicles mov<strong>in</strong>g <strong>in</strong>side <strong>the</strong> crush<strong>in</strong>g<br />

unit premises<br />

Wherever truck operations are carried out, particularly <strong>in</strong> uneven surfaces and slopes, wheel<br />

chokers should be provided<br />

Try to use gravel <strong>in</strong>stead of dust for prepar<strong>in</strong>g roads to control dust emissions caused by<br />

vehicle movements<br />

The vehicles enter<strong>in</strong>g <strong>the</strong> crusher unit must have <strong>the</strong> proper validation of <strong>the</strong> vehicles and<br />

certificates of road worth<strong>in</strong>ess<br />

The driver should have <strong>the</strong> valid licenses of heavy vehicle driv<strong>in</strong>g. They should also receive<br />

proper tra<strong>in</strong><strong>in</strong>g <strong>in</strong> driv<strong>in</strong>g <strong>in</strong>clud<strong>in</strong>g some safety tra<strong>in</strong><strong>in</strong>g for safe driv<strong>in</strong>g on public roads.

24<br />

All vehicles should be fitted with fog lights to drive <strong>in</strong> <strong>the</strong> dusty atmosphere at night<br />

Equip all vehicles with loud sound signals when back<strong>in</strong>g up<br />

The roads shall have <strong>the</strong> allowable slope for easy ascend<strong>in</strong>g and descend<strong>in</strong>g of <strong>the</strong> vehicle<br />

A.2.6 Secur<strong>in</strong>g Access to <strong>the</strong> Plant<br />

Access to a plant <strong>in</strong> general should be prohibited for all untra<strong>in</strong>ed persons and all persons who do not<br />

work <strong>the</strong>re. This <strong>in</strong>cludes specifically children, also after work<strong>in</strong>g hours.<br />

However, trespassers and outsiders often have free entry to any part of <strong>the</strong> unit. This poses a security<br />

problem (e.g. th<strong>in</strong>gs can get stolen) and a safety problem (e.g. person might get hurt because <strong>the</strong>y do<br />

not know <strong>the</strong> operations). Entry of unauthorized persons <strong>the</strong>refore needs to be restricted.<br />

Picture 9: access roads to crusher and boulder pit (background)<br />

Solutions to secure access and protect health<br />

Install gates at entrance po<strong>in</strong>ts, which can be controlled and locked after work<strong>in</strong>g hours<br />

Have a fence around <strong>the</strong> entire premise<br />

Vehicle movement should be controlled and documented <strong>in</strong> a log by a security guard for future<br />

reference<br />

Assign security personnel to <strong>the</strong> entry gate to control unauthorized entry <strong>in</strong>to <strong>the</strong> unit. These<br />

security guards should <strong>the</strong>n be able to assist <strong>in</strong> head counts <strong>in</strong> case of an emergency<br />

Security guards can also check on <strong>the</strong> condition of <strong>the</strong> drivers for <strong>the</strong>ir proper identification<br />

(license), credentials, and physical condition

25<br />

A.3 Keep<strong>in</strong>g Workers <strong>Health</strong>y<br />

<strong>Stone</strong> crush<strong>in</strong>g produces a lot of dust. Dust consists of particles,<br />

which are dispersed <strong>in</strong> <strong>the</strong> air and rema<strong>in</strong> <strong>the</strong>re for a while. It is<br />

generated from mechanical actions, such as stone crush<strong>in</strong>g, truck<br />

movement, etc. Although most dust particles can be seen with <strong>the</strong><br />

naked eye, some cannot be seen without <strong>the</strong> help of a microscope.<br />

These f<strong>in</strong>e dust particles can travel deep <strong>in</strong>to <strong>the</strong> lungs and have<br />

<strong>the</strong> potential to cause <strong>the</strong> most damage. A "dusty lung"<br />

(pneumoconiosis <strong>in</strong> medical terms) or severe chronic lung disease<br />

(called "chronic-obstructive pulmonary disease", COPD <strong>in</strong> medical<br />

terms) is a common hazard caused by to much exposure to dust.<br />

Several rocks such as granite and normal sand conta<strong>in</strong> a<br />

substance called "silica" <strong>in</strong> vary<strong>in</strong>g degrees, typically about 10 or<br />

20%. This substance causes even more severe lung disease when<br />

<strong>in</strong>haled as f<strong>in</strong>e, man-made particles ("silicosis" <strong>in</strong> medical terms).<br />

These f<strong>in</strong>e particles are typically found <strong>in</strong> <strong>the</strong> stone crush<strong>in</strong>g<br />

process. Scar tissue forms deep <strong>in</strong> <strong>the</strong> lungs and makes <strong>the</strong> lungs<br />

less efficient and less strong. Over time, even AFTER work <strong>in</strong> stone<br />

crush<strong>in</strong>g and <strong>the</strong> dust exposure has stopped, this destruction<br />

process <strong>in</strong> <strong>the</strong> lungs cont<strong>in</strong>ues and <strong>the</strong> worker will eventually die<br />

from <strong>the</strong> damage.<br />

Typical signs of lung damage by dust <strong>in</strong>clude difficulty breath<strong>in</strong>g,<br />

shortness of breath, wheez<strong>in</strong>g, constant cough<strong>in</strong>g, reddish or bluish<br />

color of ears and/or <strong>the</strong> lips. This difficulty <strong>in</strong> breath<strong>in</strong>g is often<br />

comb<strong>in</strong>ed with fatigue, loss of appetite, weakness.<br />

<strong>Stone</strong> dust cannot be avoided <strong>in</strong> stone crush<strong>in</strong>g. It is produced by<br />

<strong>the</strong> crush<strong>in</strong>g itself, <strong>the</strong> sort<strong>in</strong>g, <strong>the</strong> transport of gravel and also by<br />

vehicle movements over dusty roads. We can however reduce <strong>the</strong><br />

amount of dust that reaches <strong>the</strong> lungs. By eng<strong>in</strong>eer<strong>in</strong>g controls, <strong>the</strong> places where dust is generated<br />

can be encapsulated so <strong>the</strong> dust is not easily carried off by <strong>the</strong> w<strong>in</strong>d. Only after eng<strong>in</strong>eer<strong>in</strong>g and o<strong>the</strong>r<br />

controls have been used <strong>in</strong> all areas, personal protective equipment such as appropriate masks should<br />

be used. So-called Particulate Respirators Masks offer various amounts of protection depend<strong>in</strong>g on <strong>the</strong><br />

type of filter and <strong>the</strong> fit provided. Us<strong>in</strong>g a cloth to cover <strong>the</strong> nose and mouth is NOT really protect<strong>in</strong>g<br />

<strong>the</strong> worker.<br />

There is no good short-term solution to <strong>the</strong> problem.<br />

Appropriate masks that protect workers from dust are often<br />

hard to f<strong>in</strong>d <strong>in</strong> develop<strong>in</strong>g countries. Even if <strong>the</strong>y were<br />

available, <strong>the</strong> very high amount of dust would force <strong>the</strong><br />

workers to change <strong>the</strong> masks or filters several times per<br />

day. In addition, <strong>the</strong> masks are often uncomfortable,<br />

specifically when one works <strong>in</strong> a hot climate.<br />

The best solution is <strong>the</strong>refore to REDUCE <strong>the</strong> amount of<br />

dust that is be<strong>in</strong>g released <strong>in</strong>to <strong>the</strong> ambient air. This can be<br />

done by:<br />

• Enclos<strong>in</strong>g <strong>the</strong> dust sources and processes<br />

• Ventilate with a local exhaust system near <strong>the</strong><br />

generat<strong>in</strong>g source<br />

• Spray<strong>in</strong>g water at <strong>the</strong> source of dust dispersion

26<br />

We will discuss <strong>the</strong>se solutions <strong>in</strong> <strong>the</strong> next chapters. You will f<strong>in</strong>d <strong>in</strong>formation on dust reduction<br />

systems that use<br />

(a) water sprayers or<br />

(b) a ventilation system<br />

A.3.1 Reduc<strong>in</strong>g Dust When Water is Available<br />

Perry Gottesfeld, <strong>Occupational</strong> Knowledge International, San Francisco USA<br />

Water spray dust control measures are effective at reduc<strong>in</strong>g respirable crystall<strong>in</strong>e silica dust. Studies<br />

have reported significant reductions with <strong>the</strong> use of wet methods to control silica dust <strong>in</strong> various<br />

applications <strong>in</strong>clud<strong>in</strong>g stone crush<strong>in</strong>g, construction, m<strong>in</strong><strong>in</strong>g, and manufactur<strong>in</strong>g <strong>in</strong>dustries.<br />

Reductions <strong>in</strong> respirable dust <strong>in</strong> stone crusher mills can be accomplished through eng<strong>in</strong>eer<strong>in</strong>g controls<br />

<strong>in</strong>clud<strong>in</strong>g process enclosures (or conta<strong>in</strong>ment), dust collection (or local exhaust ventilation), and water<br />

spray systems. Water spray suppression systems may be pressurized or rely on available water<br />

pressure. Basic systems without pressurization can be effective at significantly reduc<strong>in</strong>g respirable<br />

silica if an adequate number of well positioned spray nozzles are used.<br />

Silica content is known to vary greatly from area to area and may help to determ<strong>in</strong>e <strong>the</strong> necessary<br />

extent of controls. Quarry and mill owners can test samples of <strong>the</strong> rock to determ<strong>in</strong>e <strong>the</strong> silica content.<br />

Water Spray System Design<br />

The spray nozzle is selected to achieve <strong>the</strong> desired spray characteristics, velocity, spray pattern and<br />