Safety & Health in the Stone Crushing Industry - Occupational ...

Safety & Health in the Stone Crushing Industry - Occupational ...

Safety & Health in the Stone Crushing Industry - Occupational ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

19<br />

−<br />

−<br />

−<br />

The transformers are positioned at least 2.50 meters above ground level<br />

All workers are tra<strong>in</strong>ed <strong>in</strong> <strong>the</strong> hazards and <strong>the</strong> safety measures when work<strong>in</strong>g with electricity<br />

In every shift, <strong>the</strong>re is one person tra<strong>in</strong>ed <strong>in</strong> basic life support (such as cardio-pulmonary<br />

resuscitation, CPR) <strong>in</strong> case of an accident with electricity<br />

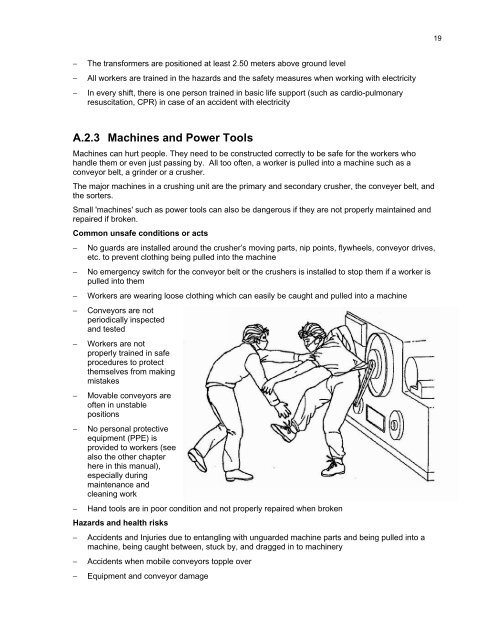

A.2.3 Mach<strong>in</strong>es and Power Tools<br />

Mach<strong>in</strong>es can hurt people. They need to be constructed correctly to be safe for <strong>the</strong> workers who<br />

handle <strong>the</strong>m or even just pass<strong>in</strong>g by. All too often, a worker is pulled <strong>in</strong>to a mach<strong>in</strong>e such as a<br />

conveyor belt, a gr<strong>in</strong>der or a crusher.<br />

The major mach<strong>in</strong>es <strong>in</strong> a crush<strong>in</strong>g unit are <strong>the</strong> primary and secondary crusher, <strong>the</strong> conveyer belt, and<br />

<strong>the</strong> sorters.<br />

Small 'mach<strong>in</strong>es' such as power tools can also be dangerous if <strong>the</strong>y are not properly ma<strong>in</strong>ta<strong>in</strong>ed and<br />

repaired if broken.<br />

Common unsafe conditions or acts<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

−<br />

No guards are <strong>in</strong>stalled around <strong>the</strong> crusher’s mov<strong>in</strong>g parts, nip po<strong>in</strong>ts, flywheels, conveyor drives,<br />

etc. to prevent cloth<strong>in</strong>g be<strong>in</strong>g pulled <strong>in</strong>to <strong>the</strong> mach<strong>in</strong>e<br />

No emergency switch for <strong>the</strong> conveyor belt or <strong>the</strong> crushers is <strong>in</strong>stalled to stop <strong>the</strong>m if a worker is<br />

pulled <strong>in</strong>to <strong>the</strong>m<br />

Workers are wear<strong>in</strong>g loose cloth<strong>in</strong>g which can easily be caught and pulled <strong>in</strong>to a mach<strong>in</strong>e<br />

Conveyors are not<br />

periodically <strong>in</strong>spected<br />

and tested<br />

Workers are not<br />

properly tra<strong>in</strong>ed <strong>in</strong> safe<br />

procedures to protect<br />

<strong>the</strong>mselves from mak<strong>in</strong>g<br />

mistakes<br />

Movable conveyors are<br />

often <strong>in</strong> unstable<br />

positions<br />

No personal protective<br />

equipment (PPE) is<br />

provided to workers (see<br />

also <strong>the</strong> o<strong>the</strong>r chapter<br />

here <strong>in</strong> this manual),<br />

especially dur<strong>in</strong>g<br />

ma<strong>in</strong>tenance and<br />

clean<strong>in</strong>g work<br />

Hand tools are <strong>in</strong> poor condition and not properly repaired when broken<br />

Hazards and health risks<br />

−<br />

−<br />

−<br />

Accidents and Injuries due to entangl<strong>in</strong>g with unguarded mach<strong>in</strong>e parts and be<strong>in</strong>g pulled <strong>in</strong>to a<br />

mach<strong>in</strong>e, be<strong>in</strong>g caught between, stuck by, and dragged <strong>in</strong> to mach<strong>in</strong>ery<br />

Accidents when mobile conveyors topple over<br />

Equipment and conveyor damage