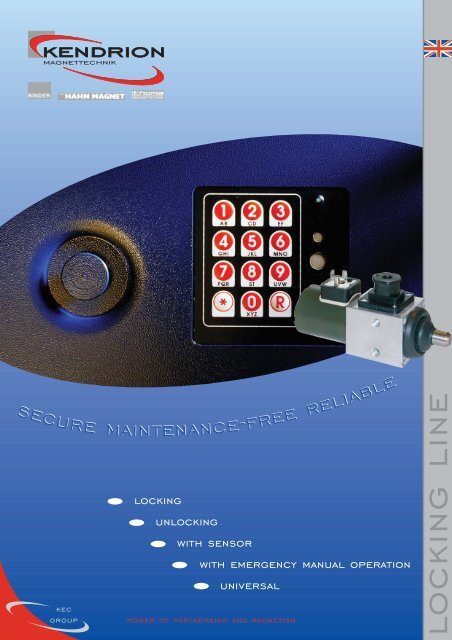

LOCKING LINE catalogue - Kendrion Binder

LOCKING LINE catalogue - Kendrion Binder

LOCKING LINE catalogue - Kendrion Binder

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BINDER<br />

secure<br />

kec<br />

group<br />

maintenance-free reliable reliable<br />

locking<br />

unlocking<br />

with sensor<br />

with emergency manual operation<br />

universal<br />

power of partnership and magnetism<br />

locking line

about us<br />

The KENDRION ELECTROMAGNETIC COMPONENTS Group<br />

(KEC Group) sees itself as a centre of excellence in the field<br />

of electromagnetism.<br />

KENDRION MAGNETTECHNIK GmbH develops and<br />

manufactures a wide range of electromagnetic products in<br />

the most diverse variations and designs for countless<br />

technical applications. The company grew out of the<br />

traditional operations of <strong>Binder</strong>, Thoma and Neue Hahn<br />

and is now Europe’s leading manufacturer of electromagnetic<br />

components.<br />

Our many years of experience in the development and<br />

manufacture of electromagnetic devices plus the skills and<br />

commitment of our employees enable us to recognise the<br />

needs of the market. And we turn those needs into highquality<br />

products in cooperation with our customers.<br />

We at KENDRION MAGNETTECHNIK achieve customerfocused<br />

solutions in all corporate divisions. Those solutions<br />

bring maximum benefits for customers and hence<br />

considerably strengthen their position in their markets.<br />

Project work is our focal point. We at KENDRION<br />

MAGNETTECHNIK take this to mean the joint development<br />

of devices together with our customers, taking into<br />

account special operating conditions, special requirements<br />

and high economic efficiency. Our objective is to provide<br />

the market with the devices it needs. With optimised costsbenefits<br />

ratios to secure the competitiveness of our<br />

customers.<br />

• Customer-centred market management,<br />

• innovative product developments,<br />

• lean, flexible logistics,<br />

• high quality standards,<br />

• affordable prices,<br />

• and the power of magnetism<br />

guarantee the success of<br />

KENDRION MAGNETTECHNIK.<br />

kendrion magnettechnik<br />

-<br />

your one-stop solution<br />

2<br />

www.kendrionmt.com

locking line<br />

Types<br />

Type LLV040002 / EMV 4002<br />

Type LLV050058 / EMV 5058<br />

Type LLV050060 / EMV 5060<br />

Type LLV050070 / EMV 5070<br />

Type LLV050080 / EMV 5080<br />

Type LLV050081 / EMV 5081<br />

Type LLV050215 / 1721503A<br />

Type LLV080215 / 1722504A<br />

Type LLV060076 / EMV 6076<br />

Functions Applications Page<br />

- locking with spring force<br />

- unlocking with magnetic force<br />

- 2-way switching status monitoring<br />

- class of protection IP 40<br />

- 8 mm stroke<br />

- safety devices<br />

- general engineering<br />

- general use in dry conditions<br />

- electrical connection via round connector<br />

- de-energised locking<br />

- locking units<br />

- 2-way switching status monitoring<br />

- materials flow controls<br />

- shut-off function<br />

- automated systems<br />

- stopper function<br />

- general machinery and apparatus<br />

- 10 mm stroke 5<br />

- locking with magnetic force<br />

- de-energised unlocking<br />

- 2-way switching status monitoring<br />

- class of protection IP 64<br />

- locking with magnetic force<br />

- de-energised unlocking<br />

- separate 1-way signal connection with plug to<br />

DIN EN 175301-803 (DIN 43650)<br />

- electromagnetic locking units for safety devices in<br />

automated systems and general engineering<br />

- electromagnetic locking units<br />

- general engineering<br />

- with GL plug for AC connection<br />

- 10 mm stroke 6+7<br />

- de-energised locking<br />

- electromagnetic locking units for machines and<br />

- unlocking with magnetic force<br />

automatic systems<br />

- 2-way switching status monitoring<br />

- with emergency manual operation<br />

- manual unlocking<br />

- general engineering<br />

- 10 mm stroke 8<br />

- de-energised locking<br />

- electromagnetic locking units for general<br />

- unlocking with magnetic force<br />

engineering<br />

- 1-way switching status monitoring with plug<br />

- with GL plug for AC connection<br />

- separate cable connections<br />

- 10 mm stroke 9<br />

- de-energised locking<br />

- electromagnetic door and window locks<br />

- signalling “open”<br />

- with pin signalling and acknowledgement signal<br />

- acknowledgement signal “locked”<br />

- general use in dry conditions<br />

- with reed contact<br />

- 15 mm stroke 10<br />

- de-energised unlocking<br />

- security element for doors and gates<br />

- magnetic locking<br />

- property security<br />

- de-energised locking<br />

- air-conditioning and ventilation systems<br />

- magnetic unlocking<br />

- 12 mm stroke 11<br />

- magnetic unlocking<br />

- locking units for safety devices with emergency<br />

- de-energised locking<br />

manual operation<br />

- class of protection IP 64<br />

- general machinery and apparatus<br />

- with emergency manual operation<br />

- 15 mm stroke 12<br />

4<br />

General instructions and accessories, plugs, sensors and strikes<br />

13-15<br />

www.kendrionmt.com 3

locking solenoids<br />

Type LLV040002/EMV 4002<br />

deep<br />

Fixings<br />

Accessories<br />

plug<br />

bellows<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

LLV040002 / EMV 4002<br />

Example of order<br />

LLV040002/EMV 4002<br />

24 VDC, 100% duty cycle<br />

de-energised locking<br />

Technical specification<br />

Insulation class F to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 40<br />

Parameters specific to product<br />

starting force/locking bolt F S = 5 N<br />

holding force/locking bolt F H = 17 N<br />

restoring force/locking bolt F R = 10 N<br />

response time<br />

t 1 = 45 ms<br />

release time<br />

t 2 = 30 ms<br />

radial force/stationary 1200 N<br />

Circuit diagram and pin assignment at plug<br />

(solenoid de-energised)<br />

Locking solenoid<br />

type LLV040002/EMV 4002<br />

This is an electromagnetic locking unit specially designed<br />

for use in all kinds of safety devices on machines and<br />

automatic systems. During its development special<br />

attention was given to ensuring a compact design,<br />

universal fixing options and an integral acknowledgement<br />

signal for the locking function. These devices comply<br />

fully with the requirements of Germany’s Accident<br />

Prevention Regulations – and with a large factor of<br />

safety. The solenoid plunger and locking bolt are<br />

guided separately in highly wear-resistant, maintenancefree<br />

bearings. To avoid stray magnetic fields in the<br />

object to be locked, the locking bolt is made from rustproof,<br />

non-magnetic stainless steel. The microswitches<br />

integrated into the aluminium housing for the locking<br />

bolt signal the respective position of the locking bolt<br />

approx. 0.5-1 mm after it leaves the initial position or<br />

before it reaches the end position. The locking<br />

function, i.e. the extending of the locking bolt into the<br />

locked position, is achieved by means of an integral<br />

spring. The unlocking function, i.e. the retracting of<br />

the locking bolt, on the other hand, is achieved by<br />

applying an electromagnetic force.<br />

In order to achieve a quick and reliable electrical<br />

connection, a common integral plug with screw fastener<br />

to DIN 43651 is used for the linear solenoid<br />

and the acknowledgement signal.<br />

When operating the locking units with voltages exceeding<br />

48 VDC, the linear solenoid is connected via<br />

an additional device connector (to DIN EN 175301-803<br />

– DIN 43650) mounted on the solenoid housing.<br />

The magnetic forces given are reached at operating<br />

temperature and 90% of the rated voltage according<br />

to DIN VDE 0580 (July 2000), and are valid for a 24<br />

VDC supply voltage. When operating at 100% rated<br />

voltage, the magnetic forces increase by approx. 20%.<br />

Different supply voltages may lead to magnetic forces<br />

higher or lower than the specified values owing to the<br />

changing copper factor. The release times are based on<br />

switching on the DC side. With a rectifier in series and<br />

switching on the AC side, the release times are 2 to 3<br />

times higher.<br />

Device connectors are not included in the scope of<br />

supply and must be ordered separately.<br />

Surface finish: solenoid galvanised<br />

Locking bolt housing: aluminium<br />

Special versions on request.<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A<br />

H E<br />

Weight<br />

[kg]<br />

LLV040002<br />

locked<br />

8<br />

12.8<br />

10<br />

x<br />

x<br />

0.6<br />

4 www.kendrionmt.com

locking solenoids<br />

Type LLV050058/EMV 5058<br />

Fixings<br />

deep<br />

LLV050058 / EMV5058<br />

Locking solenoid<br />

type LLV050058<br />

This is an electromagnetic locking unit specially designed<br />

for use in all kinds of safety devices on machines and<br />

automatic systems. During its development special<br />

attention was given to ensuring a compact design,<br />

universal fixing options and an integral acknowledgement<br />

signal for the locking function. These devices comply<br />

fully with the requirements of Germany’s Accident<br />

Prevention Regulations – and with a large factor of<br />

safety. The solenoid plunger and locking bolt are<br />

guided separately in highly wear-resistant, maintenancefree<br />

bearings. The integral microswitch signals the<br />

respective position of the locking bolt approx.<br />

0.5-1 mm after it leaves the initial position or before<br />

it reaches the end position. The locking function, i.e.<br />

the extending of the locking bolt into the locked position,<br />

is achieved by means of an integral spring. The<br />

unlocking function, i.e. the retracting of the locking<br />

bolt, on the other hand, is achieved by applying an<br />

electromagnetic force.<br />

In order to guarantee a trouble-free and reliable<br />

electrical connection, a common integral DIN 43651<br />

plug is used for the linear solenoid and the<br />

acknowledgement signal.<br />

When operating the locking units with voltages<br />

exceeding 48 VDC, the linear solenoid is connected via<br />

an additional device connector (to DIN EN 175301-803<br />

– DIN 43650) mounted on the solenoid housing.<br />

The magnetic forces given are reliably reached at<br />

operating temperature and 90% of the rated voltage<br />

according to DIN VDE 0580 (July 2000), and are valid<br />

for a 24 VDC supply voltage. When operating at 100%<br />

rated voltage, the magnetic forces increase by approx.<br />

20%. Different supply voltages may lead to magnetic<br />

forces higher or lower than the specified values owing<br />

to the changing copper factor. The release times are<br />

based on switching on the DC side. With a rectifier in<br />

series and switching on the AC side, the release times<br />

are 2 to 3 times higher.<br />

Device connectors are not included in the scope of<br />

supply and must be ordered separately.<br />

Surface finish: solenoid galvanised<br />

Locking bolt housing: aluminium<br />

Special versions on request.<br />

Accessories<br />

round plug<br />

bellows<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

Example of order<br />

LLV050058/EMV 5058<br />

24 VDC, 100% duty cycle<br />

de-energised unlocking<br />

Technical specification<br />

Insulation class F to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 64<br />

Parameters specific to product<br />

starting force/locking bolt F S = 7 N<br />

holding force/locking bolt F H = 35 N<br />

restoring force/locking bolt F R = 20 N<br />

response time<br />

t 1 = 120 ms<br />

release time<br />

t 2 = 100 ms<br />

radial force/stationary 3000 N<br />

Circuit diagram and pin assignment at plug<br />

(solenoid de-energised)<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A<br />

H E<br />

Weight<br />

[kg]<br />

LLV050058<br />

locked<br />

10<br />

18.5<br />

14<br />

x<br />

x<br />

1.25<br />

www.kendrionmt.com<br />

5

locking solenoids<br />

Type LLV050060/EMV 5060<br />

Fixings<br />

deep<br />

Accessories<br />

plug<br />

bellows<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

LLV050060 / EMV 5060<br />

Example of order<br />

LLV050060/EMV 5060<br />

24 VDC, 100% duty cycle<br />

de-energised locking<br />

Technical specification<br />

Insulation class F to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 64<br />

Parameters specific to product<br />

starting force/locking bolt F S = 7 N<br />

holding force/locking bolt F H = 35 N<br />

restoring force/locking bolt F R = 20 N<br />

response time<br />

t 1 = 120 ms<br />

release time<br />

t 2 = 100 ms<br />

radial force/stationary 3000 N<br />

Circuit diagram and pin assignment at plug<br />

(solenoid de-energised)<br />

Locking solenoid<br />

type LLV050060/EMV 5060<br />

This is an electromagnetic locking unit specially designed<br />

for use in all kinds of safety devices on machines and<br />

automatic systems. During its development special<br />

attention was given to ensuring a compact design,<br />

universal fixing options and an integral acknowledgement<br />

signal for the locking function. These devices comply<br />

fully with the requirements of Germany’s Accident<br />

Prevention Regulations – and with a large factor of<br />

safety. The solenoid plunger and locking bolt are<br />

guided separately in highly wear-resistant, maintenancefree<br />

bearings. The integral microswitches signal the<br />

respective position of the locking bolt approx.<br />

0.5-1 mm after it leaves the initial position or before<br />

it reaches the end position. The return movement of<br />

the locking bolt into the locked position is achieved by<br />

means of an integral spring.<br />

In order to achieve a quick and reliable electrical<br />

connection, a common integral DIN 43651 plug is used<br />

for the linear solenoid and the acknowledgement<br />

signal.<br />

When operating the locking units with voltages<br />

exceeding 48 VDC, the linear solenoid is connected via<br />

an additional device connector (to DIN EN 175301-803<br />

– DIN 43650) mounted on the solenoid housing.<br />

The magnetic forces given are reached at operating<br />

temperature and 90% of the rated voltage according<br />

to DIN VDE 0580 (July 2000), and are valid for a<br />

24 VDC supply voltage. When operating at 100% rated<br />

voltage, the magnetic forces increase by approx. 20%.<br />

Different supply voltages may lead to magnetic forces<br />

higher or lower than the specified values owing to the<br />

changing copper factor. The release times are based on<br />

switching on the DC side. With a rectifier in series and<br />

switching on the AC side, the release times are 2 to 3<br />

times higher.<br />

Device connectors are not included in the scope of<br />

supply and must be ordered separately.<br />

Surface finish: solenoid galvanised<br />

Locking bolt housing: aluminium<br />

Special versions on request.<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A<br />

H E<br />

Weight<br />

[kg]<br />

LLV050060<br />

unlocked<br />

10<br />

18.5<br />

14<br />

x<br />

x<br />

1.4<br />

6 www.kendrionmt.com

locking solenoids<br />

Fixings<br />

Type LLV050070/EMV 5070<br />

deep<br />

can be rotated through 4 x 90°<br />

LLV050070 / EMV5070<br />

Locking solenoid<br />

type LLV050070/EMV 5070<br />

This is an electromagnetic locking unit specially designed<br />

for use in all kinds of safety devices on machines and<br />

automatic systems. During its development special<br />

attention was given to ensuring a compact design,<br />

universal fixing options and an integral acknowledgement<br />

signal for the locking function. These devices comply<br />

fully with the requirements of Germany’s Accident<br />

Prevention Regulations – and with a large factor of<br />

safety. The solenoid plunger and locking bolt are<br />

guided separately in highly wear-resistant, maintenancefree<br />

bearings. The integral microswitch signals the<br />

correct engagement of the locking bolt approx.<br />

0.5-1 mm before it reaches the end position. The<br />

return movement of the locking bolt is achieved by<br />

means of an integral spring.<br />

In order to achieve a quick and reliable electrical<br />

connection, non-interchangeable plug-in connections of<br />

different sizes are used for the linear solenoid and the<br />

acknowledgement signal.<br />

The linear solenoid is connected via a device connector<br />

(to DIN EN 175301-803 – DIN 43650), the<br />

acknowledgement signal via a slim device connector<br />

which can be rotated through 4 x 90°.<br />

When using a device connector with an integral<br />

rectifier, the locking unit can be operated directly from<br />

an AC supply.<br />

The magnetic forces given are reliably reached at<br />

operating temperature and 90% of the rated voltage<br />

according to DIN VDE 0580 (July 2000), and are valid<br />

for a 24 VDC supply voltage. When operating at 100%<br />

rated voltage, the magnetic forces increase by approx.<br />

20%. Different supply voltages may lead to magnetic<br />

forces higher or lower than the specified values owing<br />

to the changing copper factor. The release times are<br />

based on switching on the DC side. With a rectifier in<br />

series and switching on the AC side, the release times<br />

are 2 to 3 times higher.<br />

Device connectors are not included in the scope of<br />

supply and must be ordered separately.<br />

Surface finish: solenoid galvanised<br />

Locking bolt housing: aluminium<br />

Special versions on request.<br />

Accessories<br />

small and large plugs<br />

bellows<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

Example of order<br />

LLV050070/EMV 5070<br />

24 VDC, 100% duty cycle<br />

de-energised unlocking<br />

Technical specification<br />

Insulation class F to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 64<br />

Parameters specific to product<br />

starting force/locking bolt F S = 7 N<br />

holding force/locking bolt F H = 35 N<br />

restoring force/locking bolt F R = 20 N<br />

response time<br />

t 1 = 120 ms<br />

release time<br />

t 2 = 100 ms<br />

radial force/stationary 3000 N<br />

Circuit diagram and pin assignment at plug<br />

(solenoid de-energised)<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A H E<br />

Weight<br />

[kg]<br />

LLV050070<br />

unlocked<br />

10<br />

18.5<br />

14<br />

x -<br />

1.4<br />

www.kendrionmt.com<br />

7

locking solenoids<br />

Type LLV050080/EMV 5080<br />

Fixings<br />

Manual unlocking<br />

deep<br />

Accessories<br />

round plug<br />

bellows<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

LLV050080 / EMV 5080<br />

Example of order<br />

LLV050080/EMV 5080<br />

24 VDC, 100% duty cycle<br />

de-energised locking<br />

Technical specification<br />

Insulation class F to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 64<br />

Parameters specific to product<br />

starting force/locking bolt F S = 7 N<br />

holding force/locking bolt F H = 35 N<br />

restoring force/locking bolt F R = 20 N<br />

response time<br />

t 1 = 120 ms<br />

release time<br />

t 2 = 100 ms<br />

radial force/stationary 3000 N<br />

Circuit diagram and pin assignment at plug<br />

(solenoid de-energised)<br />

Locking solenoid<br />

type LLV050080/EMV 5080<br />

This is an electromagnetic locking unit specially designed<br />

for use in all kinds of safety devices on machines and<br />

automatic systems. During its development special<br />

attention was given to ensuring a compact design,<br />

fixing options and an integral acknowledgement signal<br />

for the locking function. These devices comply fully<br />

with the requirements of Germany’s Accident<br />

Prevention Regulations – and with a large factor of<br />

safety. The solenoid plunger and locking bolt are<br />

guided separately in maintenance-free bearings. The<br />

integral microswitches signal the respective position of<br />

the locking bolt approx. 0.5-1 mm after it leaves the<br />

initial position or before it reaches the end position.<br />

The locking function, i.e. the extending of the locking<br />

bolt into the locked position, is achieved by means of<br />

an integral spring. The unlocking function, i.e. the<br />

retracting of the locking bolt, on the other hand, is<br />

achieved by applying an electromagnetic force. In<br />

addition, this locking unit is fitted with a manual<br />

unlocking feature which can be used to unlock the unit<br />

also when the supply voltage is switched off.<br />

In order to guarantee a trouble-free and reliable<br />

electrical connection, a common integral DIN 43651<br />

plug is used for the linear solenoid and the<br />

acknowledgement signal.<br />

When operating the locking units with voltages exceeding<br />

48 VDC, the linear solenoid is connected via an<br />

additional device connector (to DIN EN 175301-803 –<br />

DIN 43650) mounted on the solenoid housing. The<br />

magnetic forces given are reached at operating<br />

temperature and 90% of the rated voltage according<br />

to DIN VDE 0580 (July 2000), and are valid for a<br />

24 VDC supply voltage. When operating at 100% rated<br />

voltage, the magnetic forces increase by approx. 20%.<br />

Different supply voltages may lead to magnetic forces<br />

higher or lower than the specified values owing to the<br />

changing copper factor. The release times are based on<br />

switching on the DC side. With a rectifier in series and<br />

switching on the AC side, the release times are 2 to 3<br />

times higher.<br />

Device connectors are not included in the scope of<br />

supply and must be ordered separately.<br />

Surface finish: solenoid galvanised<br />

Locking bolt housing: aluminium<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A<br />

H E<br />

Weight<br />

[kg]<br />

LLV050080<br />

locked<br />

10<br />

18.5<br />

14<br />

x<br />

x<br />

1.4<br />

8<br />

www.kendrionmt.com

locking solenoids<br />

Type LLV050081/EMV 5081<br />

Fixings<br />

deep<br />

LLV050081 / EMV5081<br />

Locking solenoid<br />

type LLV050081/EMV 5081<br />

This is an electromagnetic locking unit specially designed<br />

for use in all kinds of safety devices on machines and<br />

automatic systems. During its development special<br />

attention was given to ensuring a compact design,<br />

universal fixing options and an integral acknowledgement<br />

signal for the locking function. These devices comply<br />

fully with the requirements of Germany’s Accident<br />

Prevention Regulations – and with a large factor of<br />

safety. The solenoid plunger and locking bolt are<br />

guided separately in highly wear-resistant, maintenancefree<br />

bearings. The integral microswitch signals the<br />

correct engagement of the locking bolt approx.<br />

0.5-1 mm before it reaches the home position. The<br />

locking function, i.e. the extending of the locking bolt<br />

into the locked position, is achieved by means of an<br />

integral spring. The unlocking function, i.e. the<br />

retracting of the locking bolt, on the other hand, is<br />

achieved magnetically.<br />

In order to achieve a quick and reliable electrical<br />

connection, non-interchangeable plug-in connections of<br />

different sizes are used for the linear solenoid and the<br />

acknowledgement signal. The linear solenoid is connected<br />

via a device connector (to DIN EN 175301-803 – DIN<br />

43650), the acknowledgement signal via a slim device<br />

connector which can be rotated through 4 x 90°.<br />

When using a device connector with an integral<br />

rectifier, the locking unit can be operated directly from<br />

an AC supply.<br />

The magnetic forces given are reached at operating<br />

temperature and 90% of the rated voltage according<br />

to DIN VDE 0580 (July 2000), and are valid for a<br />

24 VDC supply voltage. When operating at 100% rated<br />

voltage, the magnetic forces increase by approx. 20%.<br />

Different supply voltages may lead to magnetic forces<br />

higher or lower than the specified values owing to the<br />

changing copper factor. The release times are based on<br />

switching on the DC side. With a rectifier in series and<br />

switching on the AC side, the release times are 2 to 3<br />

times higher.<br />

Device connectors are not included in the scope of<br />

supply and must be ordered separately.<br />

Surface finish: solenoid galvanised<br />

Locking bolt housing: aluminium<br />

Special versions on request.<br />

Accessories<br />

small and large plugs<br />

bellows<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

Example of order<br />

LLV050081/EMV 5081<br />

24 VDC, 100% duty cycle<br />

de-energised locking<br />

Technical specification<br />

Insulation class F to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 64<br />

Parameters specific to product<br />

starting force/locking bolt F S = 7 N<br />

holding force/locking bolt F H = 35 N<br />

restoring force/locking bolt F R = 20 N<br />

response time<br />

t 1 = 120 ms<br />

release time<br />

t 2 = 100 ms<br />

radial force/stationary 3000 N<br />

Circuit diagram and pin assignment at plug<br />

(solenoid de-energised)<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A H E<br />

Weight<br />

[kg]<br />

LLV050081<br />

locked<br />

10<br />

18.5<br />

14<br />

x -<br />

1.2<br />

www.kendrionmt.com 9

locking solenoids<br />

Type LLV050...<br />

Accessories<br />

mating piece with pin signalling<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

1) Concealed cable connection<br />

2) Holes for fixings<br />

Example of order<br />

LLV050215<br />

24 VDC, 100% duty cycle<br />

de-energised locking<br />

Technical specification<br />

Insulation class B to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 40<br />

Type LLV050225/17 22503A00<br />

“de-energised unlocking”<br />

- compact design<br />

- pin signalling “locked”<br />

- mating piece included<br />

- locking only possible with “door closed”<br />

Type LLV050215/17 21503A00<br />

“de-energised locking”<br />

- compact design<br />

- pin signalling “open”<br />

- mating piece included<br />

- acknowledgement signal “closed”<br />

Parameters specific to product<br />

starting force/locking bolt F S = 4 N<br />

holding force/locking bolt F H = 1 N/14 N<br />

restoring force/locking bolt F R = 3 N<br />

response time<br />

t 1 = 55 ms<br />

release time<br />

t 2 = 40 ms<br />

Switch positions shown in de-energised state.<br />

Solenoid<br />

Reed contact<br />

In order to meet the increasingly stringent requirements for building<br />

and room security, locking solenoids are being preferred as security<br />

elements. Locking solenoids are electromagnetically operated door bolts<br />

providing interlocking mechanisms which are used in addition to the<br />

existing mechanical locks. Two types of locking solenoids are available<br />

to suit different requirements:<br />

1. De-energised unlocking devices (LLV050225/17 22503A00) in which<br />

the return movement of the locking bolt is achieved by means of a<br />

spring.<br />

2. De-energised locking devices (LLV050215/17 21503A00) in which<br />

the return movement of the locking bolt is achieved by applying an<br />

electromagnetic force. The pin signalling provides extra security and<br />

enables remote inquiry.<br />

These locking solenoids are fitted in an (anodised) aluminium housing,<br />

have a locking bolt made from rustproof steel, and include LEDs.<br />

F C = Closing force (bolt extended)<br />

F O = Opening force<br />

F M = Magnetic force<br />

F Sh = Shear force up to 1000 N<br />

F Sp = Spring force<br />

G = Weight of locking bolt<br />

Solenoid<br />

Plunger<br />

Locking bolt (hardened)<br />

Spring<br />

Housing<br />

Contact piece<br />

F C = F Sp + G<br />

F O = F M - G - F Sp<br />

Microswitch for remote inquiry<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A<br />

H E<br />

Weight<br />

[kg]<br />

Electrical connection is accessible after removing cover.<br />

Connection via side with fixings!<br />

LLV050215<br />

LLV050225<br />

locked<br />

unlocked<br />

15<br />

15<br />

10.8<br />

10.8<br />

16<br />

16<br />

x<br />

x<br />

x<br />

x<br />

0.72<br />

0.72<br />

10<br />

www.kendrionmt.com

locking solenoids<br />

Dimensions (mm)<br />

Type LLV055...<br />

Locking solenoid<br />

Type LLV055001, de-energised locking<br />

Type LLV055002, de-energised unlocking<br />

Stroke function<br />

Circuit diagram, stroke detection<br />

with cable grip<br />

2 No. sealing rings C 60 x 10,<br />

DIN 7603 (supplied)<br />

Fixing options<br />

Accessories<br />

- box strike with sensor<br />

- angle strike (see p. 15)<br />

Example of operation<br />

(de-energised locking)<br />

F C = F Sp + G<br />

F O = F M - G - F Sp<br />

Solenoid<br />

Anker<br />

Plunger<br />

Spring<br />

Housing<br />

Contact piece<br />

F C = Closing force (bolt extended)<br />

F O = Opening force<br />

F M = Magnetic force<br />

F Sh = Shear force up to 1500 N<br />

F Sp = Spring force<br />

G = Weight of locking bolt<br />

Circuit diagram and pin assignment at plug<br />

Size<br />

(de-energised locking)<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Supply<br />

[V]<br />

Determining the opening or closing force taking<br />

into account the installation position<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Magnetic force F M<br />

Spring force F Sp<br />

Weight of locking bolt G<br />

Circuit diagram and pin assignment at plug<br />

(de-energised unlocking)<br />

Sensor<br />

H A<br />

H E<br />

Weight<br />

[kg]<br />

Example of order<br />

LLV055001<br />

24 VDC, 100% duty cycle<br />

de-energised locking<br />

Locking solenoid<br />

These locking solenoids are preferred as<br />

security elements for doors or similar<br />

closures in security, fire protection, ventilation<br />

and air-conditioning systems as well as<br />

for protecting property. The locking function<br />

is achieved either by energising the solenoid<br />

(working current principle) or by means of a<br />

spring with the coil de-energised (closedcircuit<br />

principle).<br />

The extended position of the locking bolt is<br />

detected by an integral microswitch (U max<br />

250 VDC, or with AC via integral rectifier).<br />

The DC linear solenoid, microswitch and connection<br />

terminals are fitted in a waterproof<br />

aluminium housing. The connecting cable is<br />

fed through a sealed cable gland with a<br />

cable grip, which can be fitted in one of two<br />

positions as required.<br />

Cable diameter 5-8 mm<br />

The unit can be installed in any position.<br />

Typ LLV055001 (17 21504A00)<br />

Typ LLV055002 (17 22504A00)<br />

Typ LLV055003 (17 21704A00)<br />

Typ LLV055004 (17 22704A00)<br />

locked<br />

unlocked<br />

locked<br />

unlocked<br />

12<br />

12<br />

12<br />

12<br />

24 DC<br />

24 DC<br />

230 AC<br />

230 AC<br />

17<br />

17<br />

17<br />

17<br />

16<br />

16<br />

16<br />

16<br />

x<br />

x<br />

x<br />

x<br />

1.6<br />

1.6<br />

1.6<br />

1.6<br />

www.kendrionmt.com 11

locking solenoids<br />

Type LLV060076 / EMV6076<br />

Fixings<br />

Manual unlocking<br />

Accessories<br />

round plug<br />

bellows<br />

We reserve the right to make changes<br />

to the product design.<br />

Please note ordering data!<br />

Type LLV060076 / EMV6076<br />

Example of order<br />

LLV060076/EMV 6076<br />

24 VDC, 100% duty cycle<br />

de-energised locking<br />

Technical specification<br />

Insulation class F to<br />

DIN VDE 0580 (July 2000)<br />

100% duty cycle<br />

Class of protection to IEC 60529: IP 64<br />

Parameters specific to product<br />

starting force/locking bolt F S = 12 N<br />

holding force/locking bolt F H = 50 N<br />

restoring force/locking bolt F R = 16 N<br />

response time<br />

t 1 = 45 ms<br />

release time<br />

t 2 = 30 ms<br />

radial force/stationary 1500 N<br />

Circuit diagram and pin assignment at plug<br />

(solenoid de-energised)<br />

Locking solenoid<br />

type LLV060076/EMV 6076<br />

This is an electromagnetic locking unit specially designed<br />

for use in all kinds of safety devices on machines and<br />

automatic systems. During its development special attention<br />

was given to ensuring a compact design, universal fixing<br />

options and an integral acknowledgement signal for the<br />

locking function. These devices comply fully with the<br />

requirements of Germany’s Accident Prevention<br />

Regulations – and with a large factor of safety. The<br />

solenoid plunger and locking bolt are guided separately<br />

in highly wear-resistant, maintenance-free bearings. To<br />

avoid stray magnetic fields in the object to be locked, the<br />

locking bolt is made from rustproof, non-magnetic<br />

stainless steel. The microswitches integrated into the<br />

aluminium housing for the locking bolt are positive<br />

opening types and signal the respective position of the<br />

locking bolt approx. 0.5-1 mm after it leaves the initial<br />

position or before it reaches the end position. The locking<br />

function, i.e. the extending of the locking bolt into the<br />

locked position, is achieved by means of an integral<br />

spring. The unlocking function, i.e. the retracting of the<br />

locking bolt, on the other hand, is achieved magnetically.<br />

In addition, this locking unit includes a manual unlocking<br />

function, concealed by blanking plugs, which can be<br />

operated from two sides and is intended to actuate the<br />

locking bolt when the supply voltage is switched off.<br />

In order to achieve a quick and reliable electrical connection,<br />

a common integral DIN 43651 plug with screw fastener is<br />

used for the linear solenoid and the acknowledgement<br />

signal.<br />

When operating the locking units with voltages exceeding<br />

48 VDC, the linear solenoid is connected via an additional<br />

device connector (to DIN EN 175301-803 – DIN 43650)<br />

mounted on the solenoid housing. The magnetic forces<br />

given are reliably reached at operating temperature and<br />

90% of the rated voltage according to DIN VDE 0580<br />

(July 2000), and are valid for a 24 VDC supply voltage.<br />

When operating at 100% rated voltage, the magnetic<br />

forces increase by approx. 20%. Different supply voltages<br />

may lead to magnetic forces higher or lower than the<br />

specified values owing to the changing copper factor. The<br />

release times are based on switching on the DC side. With<br />

a rectifier in series and switching on the AC side, the<br />

release times are 2 to 3 times higher. Device connectors<br />

are not included in the scope of supply and must be<br />

ordered separately.<br />

Surface finish: solenoid galvanised<br />

Locking bolt housing: aluminium<br />

Special versions on request.<br />

Size<br />

Function<br />

(de-energised)<br />

Stroke<br />

[mm]<br />

Power<br />

[Watt]<br />

Locking bolt<br />

Ø [mm]<br />

Sensor<br />

H A<br />

H E<br />

Weight<br />

[kg]<br />

LLV050080<br />

locked<br />

15<br />

30.5<br />

15<br />

x<br />

x<br />

2.4<br />

12<br />

www.kendrionmt.com

general technical information<br />

General instructions for users of KENDRION<br />

electromagnetic products<br />

CE symbol solenoids/electronics<br />

electromagnets, electromagnetic devices<br />

1. General safety advice<br />

The devices are designed, built and tested according<br />

to the acknowledged technical standards and rules, in<br />

particular according to the provisions for electromagnetic<br />

devices (DIN VDE 0580, July 2000).<br />

The devices may only be connected to the power<br />

supply type (DC or AC) and voltage as specified on<br />

the rating plate.<br />

Always make sure that the devices are disconnected<br />

from the power supply during servicing and<br />

maintenance work.<br />

Current-carrying parts, e.g. plug contacts or the<br />

energisation coil of the device, must never come into<br />

contact with water.<br />

The lead wires or cables or the plug-in connections of<br />

the devices should never be subjected to mechanical<br />

loads (pulling, squashing, etc.).<br />

The devices may not be put into operation if:<br />

- the electrical power supply cables/wires are<br />

damaged<br />

- the solenoid housing or the casing is damaged<br />

- a fault is suspected after the device has been<br />

dropped, knocked, etc.<br />

Repairs in such cases may be carried out only by<br />

specially trained personnel. Repairs carried out<br />

improperly can lead to considerable dangers for the<br />

user. If the devices are used for purposes other than<br />

those for which they are intended, or connected<br />

incorrectly, KENDRION MAGNETTECHNIK cannot accept<br />

any liability for any damages caused as a result. The<br />

user is responsible for the proper and safe use of the<br />

devices. Therefore, the installation situation, ambient<br />

conditions and similar factors must be agreed with<br />

the manufacturer of the devices in good time.<br />

The life expectancy is heavily dependent on the<br />

external conditions (installation position, type of<br />

medium, magnitude of loading), and any statements<br />

appertaining to life expectancy shall require a special<br />

agreement.<br />

The magnetic forces specified are average values and<br />

may deviate from the values given in the tables as a<br />

result of natural scatter effects.<br />

The relevant Accident Prevention Regulations are to<br />

be observed depending on the particular application.<br />

2. General requirements for ambient<br />

conditions<br />

In the case of deviations from the specified operating<br />

and ambient conditions, appropriate measures, e.g.<br />

higher class of protection and/or special surface<br />

finish, must be taken.<br />

The class of protection to IEC 60529 is only<br />

guaranteed when the device is installed on the<br />

machine in accordance with the specification, and in<br />

conjunction with a plug-in connection by means of a<br />

connector to DIN EN 175301-803 (DIN 43650).<br />

3. General requirements concerning installation<br />

of devices<br />

Unauthorised modifications or changes of any nature,<br />

e.g. drilling into the solenoid housing, are prohibited<br />

because they can lead to operational malfunctions,<br />

e.g. interruption of the coil windings.<br />

Higher supply voltages, different operating modes,<br />

low frequencies, etc. contrary to the details given on<br />

the rating plate, or the blocking of the plunger in the<br />

case of AC solenoids, can lead to severe malfunctions,<br />

e.g. burn-out of the energisation coil.<br />

The devices must be operated with the necessary<br />

rated voltage. The voltage drop is to be kept within<br />

strict tolerances (normally 4%) when laying the lines<br />

by choosing the correct wire cross-sections. The<br />

earthing screw, if fitted, must be connected, otherwise<br />

the solenoid must be suitably earthed in some other<br />

way.<br />

Devices with class of protection I require the user to<br />

provide a PE line connection according to<br />

DIN VDE 0100.<br />

For further information on the use of electromagnetic<br />

devices please refer to the publication “Technical<br />

Explanations”.<br />

The electromagnetic products from <strong>Kendrion</strong><br />

Magnettechnik are components for incorporation and<br />

operation in electrical equipment and devices.<br />

They therefore do not fall within the remit of the<br />

Low Voltage Directive 73/23/EEC.<br />

However, the components comply with various<br />

standards for incorporation and operation in devices<br />

covered by the Low Voltage Directive, in particular<br />

DIN VDE 0580 (July 2000). The corresponding data<br />

is given on the data sheets for the individual<br />

components.<br />

The products are components in the meaning of the<br />

Machinery Directive 98/37/EC. According to this<br />

directive, such products incorporated in a machine<br />

may not be operated until said machine’s conformity<br />

with the EC directive has been established. A manufacturer’s<br />

declaration, which is not automatically<br />

supplied with the product, can be obtained on<br />

request.<br />

The user must ensure conformity with the EMC<br />

Directive 89/336/EEC by using suitable switching<br />

devices or controls. When using the recommended<br />

electronic switching devices and controls from<br />

<strong>Kendrion</strong> Magnettechnik, conformity with the EMC<br />

Directive is stated on the respective data sheets.<br />

Notes:<br />

- to DIN VDE 0580 (July 2000)<br />

ICS29.020.53.020.01<br />

(valid as manufacturer’s Declaration of Conformity)<br />

- directives 98/37/EC and 73/23/EEC<br />

- CCC certificate for China not required<br />

We reserve the right to make changes to the<br />

product design.<br />

www.kendrionmt.com<br />

13

assessories<br />

GD209<br />

RSG 6 WSK 6<br />

Plug-in connector to DIN EN 175301-803<br />

Round connector to DIN 43651<br />

Round connector to DIN 45322<br />

Material No: 314 1046<br />

Material No: 314 1048<br />

small form E<br />

large form A<br />

Material No: 314 1053<br />

Material No: 314 1054<br />

22 AF<br />

small<br />

large<br />

Plug-in connectors are detachable connections and<br />

are used for connecting the locking units of the LLV...<br />

series.<br />

The cable outlet can be rotated through 4 x 90°<br />

(GD209 through 180°) by inserting the contact<br />

carrier accordingly. After plugging the connector into<br />

the device connector it is secured with a machine<br />

screw (supplied). This guarantees an effective seal<br />

between the two and prevents the plug-in connector<br />

from becoming accidentally detached. A screwed<br />

cable gland, thread size Pg 11 (GD209: Pg 9),<br />

serves to seal the cable entry. The contact elements<br />

are fitted with screw terminals and are suitable for<br />

connecting wire cross-sections up to max. 1.5 mm 2 .<br />

When plugged in and secured, the connection meets<br />

the requirements of class of protection IP 66 to IEC<br />

60529. The permissible continuous maximum<br />

temperature is 90°C; the connection can withstand<br />

temperatures of up to 120°C briefly without<br />

suffering any damage. When using the GDSB 211<br />

plug-in connector with integral rectifier, the plug-in<br />

connector can be used as a direct connecting element<br />

between an AC mains system and a DC consumer.<br />

Four silicon diodes form a bridge circuit. A varistor<br />

connected in parallel on the AC side protects the<br />

bridge rectifier against voltage spikes from the<br />

mains.<br />

Round connectors to DIN 43651 are used for<br />

connecting the locking units of the LLV... series. The<br />

connector is a 6-pole version complete with an<br />

earthing connection. After plugging the connector into<br />

the device connector it is secured with a machine<br />

screw (supplied). This guarantees an effective seal<br />

between the two and prevents the connector from<br />

becoming accidentally detached. A screwed cable<br />

gland, thread size Pg 11, serves to seal the cable<br />

entry. The wires are attached by crimping (max. wire<br />

cross-section 1.5 mm 2 ). When plugged in and<br />

secured, the connection meets the requirements of<br />

class of protection IP 65 to IEC 60529. The permissible<br />

continuous maximum temperature is 90°C; the connection<br />

can withstand temperatures of up to 120°C<br />

briefly without suffering any damage.<br />

Round connectors with a screw fixing are used for<br />

connecting the locking units of the LLV040002 series.<br />

This connector is supplied as a 6-pole version. The<br />

mechanical fixing of the round connector to the<br />

corresponding plug, and the earthing connection, is<br />

achieved by means of the metal union nut. A flexible<br />

grommet guarantees no kinks in the outgoing<br />

connecting cable. The wires are connected by<br />

soldering (max. wire cross-section 0.75 mm 2 ). When<br />

plugged in and secured, the connection meets the<br />

requirements of class of protection IP 40 to IEC<br />

60529. The permissible continuous maximum<br />

temperature is 90°C; the connection can withstand<br />

temperatures of up to 120°C briefly without suffering<br />

any damage. The cable outlet can be turned through<br />

180° by installing the contact carrier accordingly.<br />

14<br />

www.kendrionmt.com

assessories<br />

Type 17 00004A00001<br />

Type 17 00504A00100<br />

The strikes are designed for locking solenoid types LLV05500. and LLV080...<br />

Two different strikes are available.<br />

The box strike with a sensor includes a microswitch with an operating contact. The locked state can therefore be indicated at any point in the system<br />

(Umax = 250 VDC or AC; Imax = 0.5 A).<br />

The box strike with a spring enables a door or similar closure to be engaged when the locking bolt is extended.<br />

Operating contact<br />

Switching point<br />

End position<br />

2 No. sealing rings C 60 x 10, DIN 7603 (supplied)<br />

www.kendrionmt.com 15

kendrion magnettechnik worldwide<br />

<strong>Kendrion</strong> Magnettechnik GmbH<br />

August-Fischbach-Strasse 1<br />

78166 Donaueschingen<br />

Germany<br />

Tel. +49 (0) 77 1 80 09-0<br />

Fax +49 (0) 77 1 80 09-63 4<br />

www.kendrionmt.com<br />

info@kendrionmt.com<br />

Engelswies Works<br />

Fred-Hahn-Strasse 33<br />

72514 Inzigkofen-Engelswies, Germany<br />

Tel. +49 (0) 75 75 20 8-0<br />

Fax +49 (0) 75 75 20 8-1 90<br />

www.kendrionmt.com<br />

info@kendrionmt.com<br />

<strong>Kendrion</strong> <strong>Binder</strong> Magnete<br />

Ges.m.b.H.<br />

8552 Eibiswald 269, Austria<br />

Tel. +43 (0) 34 66 42 32 2-0<br />

Fax +43 (0) 34 66 42 72 2<br />

office@kendrion.com<br />

<strong>Kendrion</strong> <strong>Binder</strong> Componentes,<br />

S.L.<br />

Parque Industrial “El Poligono”<br />

c/.Rio Arba, 25<br />

50410 Cuarte de Huerva /<br />

Zaragoza, Spain<br />

Tel. +34 9 76 46 30 40<br />

Fax +34 9 76 46 30 42<br />

guadalupe.cabrera@kendrion.com<br />

Technical offices (Germany)<br />

<strong>Kendrion</strong> Magnettechnik GmbH<br />

Technisches Büro West<br />

Bottroper Strasse 15<br />

46244 Bottrop<br />

Tel. +49 (0) 20 45 41 34 34<br />

Fax +49 (0) 20 45 40 64 26<br />

www.kendrionmt.com<br />

wilhelm.martin@kendrion.com<br />

<strong>Kendrion</strong> Magnettechnik GmbH<br />

Technisches Büro Nord<br />

Delmer Bogen 71<br />

21614 Buxtehude<br />

Tel. +49 (0) 41 61 73 37 77<br />

Fax +49 (0) 41 61 60 07 39 3<br />

www.kendrionmt.com<br />

reinhard.lenser@kendrion.com<br />

Representatives (Germany)<br />

VOR-Steuerungstechnik<br />

Friedrich Rudolph GmbH<br />

Wichernstrasse 9<br />

50389 Wesseling<br />

Tel. +49 (0) 22 36 94 27 88<br />

Fax +49 (0) 22 36 84 27 86<br />

info@vor.de<br />

www.vor.de<br />

Claus Kähne<br />

Industrievertretungen GmbH<br />

Kurmainzer Str. 199a<br />

65936 Frankfurt<br />

Tel. +49 (0) 69 34 05 90 20<br />

Fax +49 (0) 69 34 05 90 27<br />

kaehne.gmbh@t-online.de<br />

RUG<br />

Regler- und Gerätebau GmbH<br />

Karl-Ehmann-Str. 50<br />

73037 Göppingen<br />

Tel. +49 (0) 71 61 85 70<br />

Fax +49 (0) 71 61 85 72 9<br />

jurenka@r-u-g.de<br />

Antriebstechnik Laipple GmbH<br />

Burgstrasse 84<br />

73614 Schorndorf<br />

Tel. +49 (0) 71 81 97 94 92<br />

Fax +49 (0) 71 81 97 94 93<br />

antriebstechnik-laipple@t-online.de<br />

Winfried Kerner GmbH<br />

Ingenieurbüro<br />

Kiebitzweg 11<br />

85375 Neufahrn<br />

Tel. +49 (0) 81 65 52 45<br />

Fax +49 (0) 81 65 62 12 8<br />

www.kerner-gmbh.de<br />

kerner-gmbh@t-online.de<br />

Hans-Christian Pilder<br />

Wirtschaftsingenieur<br />

Ablers 119<br />

88175 Scheidegg<br />

Tel. +49 (0) 17 17 23 13 31<br />

Fax +49 (0) 83 81 94 87 62<br />

www.kendrionmt.com<br />

kendrion@pilder.de<br />

Representatives (worldwide)<br />

Austria<br />

<strong>Kendrion</strong> <strong>Binder</strong> Magnete<br />

Vertriebs. GmbH<br />

Estermannstrasse 27<br />

4020 Linz<br />

Tel. +43 (0) 7 32 77 63 83<br />

Fax +43 (0) 7 32 78 35 58<br />

www.kendrion-binder.at<br />

office@kendrion-binder.at<br />

Belgium, Luxembourg<br />

Bintz technics N.V.<br />

Brixtonlaan 25<br />

1930 Zaventem<br />

Tel. +32 (0) 2 7 20 49 16<br />

Fax +32 (0) 2 7 20 37 50<br />

www.bintz-technics.be<br />

info@bintz.be<br />

Canada<br />

VL Motion Systems Inc.<br />

1105 Goodson Cres.<br />

Oakville, Ontario L6H4A7<br />

Tel. +01 905 842 0244<br />

Fax +01 905 844 1293<br />

vince@vlmotion.com<br />

Denmark<br />

Lind Jacobsen & Co. A / S<br />

Blokken 62<br />

3460 Birkerød<br />

Tel. +45 (0) 45 81 82 22<br />

Fax +45 (0) 45 82 10 22<br />

www.lind-jacobsen.dk<br />

strong@lind-jacobsen.dk<br />

Desim Elektronik APS<br />

Tasingevej 15<br />

9500 Hobro<br />

Tel. +45 (0) 70 22 00 66<br />

Fax +45 (0) 70 22 22 20<br />

www.desim.dk<br />

desim@desim.dk<br />

Farstrup & Benzon A/S<br />

Engholmvej 1, Saunte<br />

3100 Hombaek<br />

Tel. +45 (0) 49 70 40 33<br />

Fax +45 (0) 49 70 40 32<br />

www.safeline.dk<br />

f&b@safeline.dk<br />

Finland<br />

SKS-mekaniikka Oy<br />

Martinkyläntie 50<br />

P.O. Box 122<br />

01721 Vantaa<br />

Tel. +358 (0) 98 52 66 1<br />

Fax +358 (0) 98 52 68 20<br />

www.sks.fi<br />

mekaniikka@sks.fi<br />

Moeller Electric Oy<br />

Sahaajankatu 24<br />

00811 Helsinki<br />

Tel. +358 (0) 9 25 25 21 00<br />

Fax +358 (0) 9 25 25 21 77<br />

www.moeller.fi<br />

info.fin@moeller.net<br />

France<br />

<strong>Binder</strong> Magnetic<br />

1, Allée des Barbanniers<br />

92632 Gennevilliers Cedex<br />

Tel. +33 (0) 1 46 13 80 80<br />

Fax +33 (0) 1 46 13 80 99<br />

info@binder-magnetic.fr<br />

Italy<br />

SPII S.p.A<br />

Via Don Volpi 37<br />

21047 Saronno (VA)<br />

Tel. +39 (0) 2 96 22 921<br />

Fax +39 (0) 2 96 09 611<br />

www.spii.it<br />

info@spii.it<br />

Netherlands<br />

Solar Electro B. V.<br />

Effect 5<br />

6921 RG Duiven<br />

Tel. +31 (0) 26 3 65 29 11<br />

Fax +31 (0) 26 3 65 23 90<br />

www.solarelektro.nl<br />

algemeen@solarelektro.nl<br />

GTI Electroproject B.V.<br />

Grote Tocht 102<br />

1507 CE-Zaandam<br />

Tel. +31 (0) 75 68 11 11 1<br />

Fax +31 (0) 75 63 54 00 3<br />

Norway<br />

Industrielementer AS<br />

Postboks 43<br />

1556 Son<br />

Tel. +47 (0) 64 95 81 32<br />

Fax +47 (0) 64 98 29 29<br />

www.industrielementer.no<br />

post@industrielementer.no<br />

siv. ing. J.F. Knudtzen A/S<br />

Billingstadsletta 97<br />

1396 Billingstad<br />

Tel. +47 (0) 66 98 33 50<br />

Fax +47 (0) 66 98 09 55<br />

www.jfk.no<br />

firmapost@jfk.no<br />

South Africa<br />

Magnete Service <strong>Binder</strong><br />

P.O. Box 44051<br />

2104 Linden<br />

Tel. +27 (0) 11 46 2-32 08<br />

Fax +27 (0) 11 46 2-33 04<br />

info@binder.co.za<br />

Spain, Portugal<br />

<strong>Binder</strong> Magnete Iberica S.L.<br />

Apartado de Correos 116<br />

Costa Zefir 99<br />

43892 Miami-Playa (Tarragona)<br />

Tel. +34 9 77 17 27 07<br />

+34 9 77 81 04 29<br />

Fax +34 9 77 17 01 82<br />

www.binder-es.com<br />

binder@binder-es.com<br />

Sweden<br />

Industrikomponenter AB<br />

Industrivägen 12<br />

17148 Solna<br />

Tel. +46 (0) 8 51 48 44 00<br />

Fax +46 (0) 8 51 48 44 01<br />

www.inkom.se<br />

info@inkom.se<br />

Uno Gunnarsson / Höör AB<br />

Box 64<br />

24322 Höör<br />

Tel. +46 (0) 4 13 24 54 0<br />

Fax +46 (0) 4 13 23 18 3<br />

Moeller Electric AB<br />

Granitvägen 2<br />

55303 Jönköping<br />

Tel. +46 (0) 86 32 30 00<br />

Fax +46 (0) 86 32 32 99<br />

Switzerland<br />

<strong>Kendrion</strong> <strong>Binder</strong> Magnet AG<br />

Albisstrasse 26<br />

8915 Hausen a/A<br />

Tel. +41 (0) 17 64 80 60<br />

Fax +41 (0) 17 64 80 69<br />

www.kendrion.ch<br />

binder.magnet@kendrion.com<br />

United Kingdom<br />

<strong>Kendrion</strong> <strong>Binder</strong> Magnete<br />

(U.K.) Ltd.<br />

Huddersfield Road, Low Moor<br />

Bradford, West Yorkshire,<br />

BD12 0TQ<br />

Tel. +44 (0) 12 74 60 11 11<br />

Fax +44 (0) 12 74 69 10 93<br />

www.kendrion-binder.co.uk<br />

sales@kendrion-binder.co.uk<br />

USA<br />

Gradframe Inc.<br />

950 E. Baldwin Road<br />

Palatine IL 60074<br />

Tel. +01 847 991 1788<br />

Fax +01 847 991 1788<br />

gradframe@aol.com<br />

This publication is for information<br />

purposes only and should not be<br />

regarded as a binding presentation of<br />

the products, unless we expressly<br />

confirm otherwise.<br />

We reserve the right to make changes<br />

to the specification, form, price and<br />

availability of the products described<br />

herein at any time without prior notice.<br />

Each product may be used only for its<br />

intended purpose.<br />

We reserve to make changes to the<br />

product design.<br />

www.kendrionmt.com