OPTIMA System - Isover

OPTIMA System - Isover

OPTIMA System - Isover

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

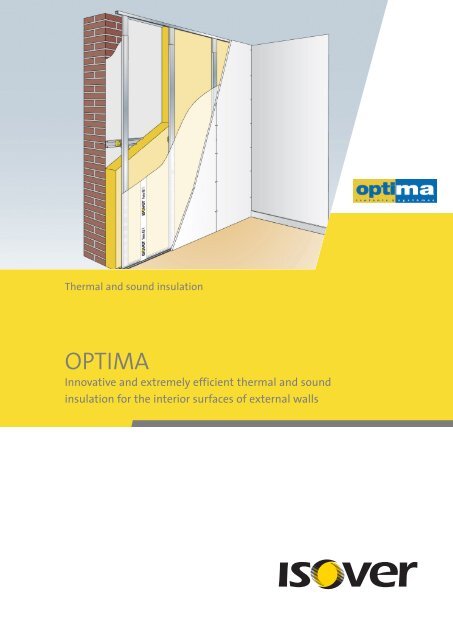

Thermal and sound insulation<br />

<strong>OPTIMA</strong><br />

Innovative and extremely efficient thermal and sound<br />

insulation for the interior surfaces of external walls

2<br />

Contents<br />

<strong>OPTIMA</strong> – THE INNOVATIVE SOLUTION 4<br />

<strong>OPTIMA</strong> – SYSTEM COMPONENTS 5<br />

I. METAL FRAME 6<br />

II. INSULATION 8<br />

III. VAPOUR RETARDER AND AIR TIGHTNESS LAYER 9<br />

IV. FACING 11<br />

<strong>OPTIMA</strong> SYSTEM – HIGH LEVEL THERMAL PERFORMANCES 12<br />

<strong>OPTIMA</strong> SYSTEM – SOLUTIONS FOR HIGH ENERGY EFFICIENCY HOUSES 13<br />

<strong>OPTIMA</strong> SYSTEM – AN EFFICIENT SOUND INSULATION 14<br />

A DRY SYSTEM, EASY TO INSTALL 15<br />

DEALING WITH SPECIFIC ISSUES 18<br />

<strong>OPTIMA</strong> SYSTEM – ADVANTAGE AFTER ADVANTAGE 19<br />

<strong>OPTIMA</strong> SYSTEM – A COMPLETE RANGE 20

High energy costs but a low comfort level – a growing problem.<br />

Most of the houses in the European Union are more than 30 years old and do not offer the levels of<br />

comfort we expect today. We speak of "thermal comfort" when it is neither too cold nor too warm – in<br />

summer and winter.<br />

Perception of a “comfortable temperature” results from a small difference between interior ambient air<br />

temperature and that of the interior surfaces of the outer walls and windows. In these conditions, one<br />

can enjoy a homogeneous air temperature throughout the whole house or flat and the absence of<br />

annoying drafts.<br />

Older houses were built at a time when the building mentality was very different from that of today,<br />

and when there were no efficient thermal insulation materials readily available.<br />

Although a lot of energy is used to heat old houses or flats, they are overheated in summer and yet<br />

rarely become warm in winter. Despite occupants having to pay high energy bills, for cooling in summer<br />

and heating in winter, thermal comfort is nevertheless not achieved very often.<br />

In view of rapidly increasing energy prices, living in older houses may well become a very expensive<br />

"pleasure", notwithstanding the high consumption of natural resources and the emissions that burden<br />

our environment.<br />

ISOVER dry wall solution – The <strong>OPTIMA</strong> <strong>System</strong><br />

Everyone looking for an efficient, yet easy and quick solution for renovating their own four walls needs<br />

look no further than the <strong>OPTIMA</strong> <strong>System</strong> from ISOVER.<br />

<strong>OPTIMA</strong> is a modern system for easy and rapid renovation or improvement of thermal and sound insulation.<br />

The system solution, with its superbly matched components make assembly simple and easy.<br />

When it is not possible to install facade or wall-cavity insulation, whether for technical, economic or<br />

social reasons (shared ownership), then insulating inside the building is strongly recommended.<br />

The <strong>OPTIMA</strong> <strong>System</strong> offers ideal solutions for the renovation and insulation of external walls from the<br />

inside.<br />

3

4<br />

1<br />

2<br />

3<br />

4<br />

<strong>OPTIMA</strong> – The Innovative Solution<br />

For installing thermal and sound insulation on the inside of outer walls<br />

The Technique<br />

The <strong>OPTIMA</strong> <strong>System</strong> consists of simple standard and economical elements:<br />

I. Metal frame (the mechanical structure; Picture 1)<br />

II. Insulation (the thermal and sound layer; Picture 2)<br />

III. Vapour retarder and air tightness layer (Picture 3)<br />

IV. Facing (the finished wall; Picture 4)<br />

The dry lining system is very quick to install and guarantees maximum comfort. In addition, it<br />

can be easily adapted to fit the structural complexity of a building (e.g. tall supporting walls).<br />

Applications<br />

• Thermal and sound insulation of walls in residential or commercial buildings (council housing,<br />

private apartments, individual houses, hotels, hospitals, offices, …) new or for renovation work.<br />

• Dry installation on all types of substrate, including most irregular or uneven surfaces<br />

In short – The Advantages of the <strong>OPTIMA</strong> <strong>System</strong>.<br />

• A dry, time-saving solution, which needs no glue mixing and no drying times<br />

• Improved air tightness compared to traditional solutions (joints, thermal bridging/cabling that<br />

compromises the insulation layer etc.)<br />

• Easy cabling and ducting<br />

All advantages of the <strong>OPTIMA</strong> <strong>System</strong> at a glance on Page 19

<strong>OPTIMA</strong> – <strong>System</strong> components<br />

4<br />

3<br />

2<br />

6<br />

5<br />

8<br />

1<br />

1<br />

A dry, high performance system<br />

I. Metal frame<br />

1. <strong>OPTIMA</strong> Bottom and Ceiling Stud<br />

2. <strong>OPTIMA</strong> 240 Stud<br />

3. <strong>OPTIMA</strong> 30 or 50 Stud<br />

4. <strong>OPTIMA</strong>2 Support (new) or<br />

<strong>OPTIMA</strong>2 Support Reno (renovation)<br />

II. Insulation<br />

5. ISOVER glass wool with<br />

�d = 0.035 W/mK or 0.032 W/mK<br />

What you would need to install the <strong>OPTIMA</strong> <strong>System</strong> on five metres of wall – an example:<br />

<strong>OPTIMA</strong> Floor and Ceiling Stud 10 m (5 studs)<br />

<strong>OPTIMA</strong> 240 Stud 24 m (10 studs)<br />

<strong>OPTIMA</strong> 30 Stud 10 studs<br />

VARIO KB1 13 m (1 roll)<br />

VARIO DB 10 m (1 roll)<br />

<strong>OPTIMA</strong>2 Support 10 pieces (1 bucket)<br />

VARIO KM/KM Duplex UV 16.8 m2 (1 roll)<br />

7<br />

This table gives an indication of the materials needed based on a maximum<br />

wall height of 2.6 m and spacing of vertical studs at 600 mm centres.<br />

6<br />

9<br />

III. Vapour retarder and air tightness layer<br />

6. VARIO DB sealing tape<br />

7. VARIO KM or VARIO KM Duplex UV air tightness layer<br />

8. VARIO KB1 one-sided adhesive tape<br />

IV. Facing<br />

9. Plaster board or other interior facings<br />

(e.g. wooden panels)<br />

5

6<br />

1<br />

2<br />

3<br />

I. Metal Frame<br />

The mechanical structure<br />

The standard elements that make up the frame ensure the system is both economical and mechanically<br />

stable. The structure can be adapted to fit virtually every architectural situation, producing a<br />

final superbly flat and straight wall surface by ‘absorbing’ unevenness in the original wall.<br />

Intermediate Supports (Item 4 in the illustration on Page 5)<br />

The intermediate supports consist of a spacer bar clipped onto a horizontal stud (OTPIMA2 Support;<br />

Picture 2) or anchored directly to the wall (OTPIMA2 Support Reno; Picture 3). A polyamide key fastens<br />

the insulation material and secures the vertical studs, allowing thickness adjustment with millimetre<br />

precision.<br />

In short – The Advantages of the <strong>OPTIMA</strong>2 Intermediate Supports.<br />

• Reduced thermal bridges<br />

• Easy and quick to install<br />

• Adjustment possible after installation of insulation material and horizontal studs<br />

All advantages of the <strong>OPTIMA</strong> <strong>System</strong> at a glance on Page 19<br />

Intermediate<br />

Supports<br />

4

Floor and Ceiling Studs (Item 1 in the illustration on Page 5)<br />

<strong>OPTIMA</strong><br />

Ceiling Stud<br />

<strong>OPTIMA</strong><br />

Floor Stud<br />

<strong>OPTIMA</strong> Floor and Ceiling Studs (Pictures 2 & 3) allow the<br />

embedding and the adjusting of the vertical stud positioning.<br />

Facing Support (Item 2 & 3 in the illustration on Page 5)<br />

For the facing support, the <strong>OPTIMA</strong> 240 Stud (a 2.40 m metal section) can be jointed and adjusted to<br />

match the length as required. <strong>OPTIMA</strong> 30 and 50 Studs can be used to join or link <strong>OPTIMA</strong> 240 Studs<br />

(Picture 5).<br />

<strong>OPTIMA</strong><br />

30 a 50 Stud<br />

<strong>OPTIMA</strong><br />

240 Stud<br />

1<br />

4<br />

In short – The Advantages of <strong>OPTIMA</strong> Studs.<br />

Joints between <strong>OPTIMA</strong> 240 Stud and <strong>OPTIMA</strong> 30 or 50 Studs must overlap at least 10 cm. With an<br />

OTPIMA 240 Stud and an intermediate support fixed at 1.35 m height, the maximum heights to<br />

ceiling are 2.60 m and 2.80 m by adding an <strong>OPTIMA</strong> 30 Stud or <strong>OPTIMA</strong> 50 Stud respectively.<br />

• The clip fastener ensures studs are firmly secured in position and will not shake loose<br />

• Time saving during installation<br />

• Adjustment to the nearest millimetre<br />

All advantages of the <strong>OPTIMA</strong> <strong>System</strong> at a glance on Page 19<br />

2<br />

3<br />

5<br />

7

8<br />

II. Insulation<br />

The thermal and sound layer<br />

In short – The Advantages of the Insulation Material.<br />

• High performing thermal and acoustic insulation<br />

• Compressed products – easy to handle and install<br />

• Improved acoustics, non-combustible<br />

All advantages of the <strong>OPTIMA</strong> <strong>System</strong> at a glance on Page 19<br />

1<br />

2<br />

The glass wool product has to be installed between the wall and the vertical studs<br />

(Item 5 in the illustration on Page 5). As the system guarantees a continuous layer of<br />

insulation material thermal bridges are reduced to a minimum. Pipes and electric<br />

cables can be integrated without degrading the insulation.<br />

Using light weight glass wool insulation material, available in a wide range of thicknesses,<br />

it is possible to gain optimal thermal resistance with minimum use of space.<br />

The material’s flexibility and stiffness ensure the cavity is completely filled.<br />

Products with the lowest thermal conductivity, λd= 0.032 W/(mK) or 0.035 W/(mK), are<br />

preferable as they provide maximum thermal performance with minimum loss of room<br />

area.

III. Vapour retarder and air tightness layer<br />

To avoid condensation damage in the structure, the vapour retarder and air tightness<br />

layer needs to be installed on the inner facing surface of the insulation layer (= the<br />

warm side; Items 6, 7 & 8 in the illustration on Page 5). This barrier prevents water<br />

vapour passing from the room into the construction.<br />

VARIO KM & VARIO KM Duplex UV –<br />

The intelligent vapour retarder and air tightness membrane<br />

outside inside<br />

In winter, ambient relative humidity outside is lower than inside<br />

a building. VARIO KM / KM Duplex UV closes up to prevent the<br />

penetration of water vapour into the construction (Picture 2).<br />

In short – The Advantages of VARIO KM / KM Duplex UV.<br />

In summer, ambient relative humidity outside is greater than<br />

inside a building. In this case VARIO KM/KM Duplex UV opens up.<br />

In this way any moisture in the construction can move into the<br />

interior of the building (Picture 3).<br />

• Dual functionality – humidity regulation: improved and faster drying out in summer, and secure<br />

barrier in winter<br />

• Reliable functionality with matched components<br />

• Vario KM Duplex UV – ease of work: printed guidelines for easy accurate cutting, and fleece surface for<br />

better adhesion to substrate<br />

All advantages of the <strong>OPTIMA</strong> <strong>System</strong> at a glance on Page 19<br />

outside inside<br />

2 3<br />

1<br />

9

10<br />

1<br />

VARIO – <strong>System</strong> Components<br />

To ensure minimal energy costs and a comfortable living environment requires not only that a building<br />

should be well insulated but also the building envelope is air tight. The breathable active VARIO KM/<br />

KM Duplex UV membrane represents a new milestone in building technology. The result of its special<br />

structure, the polyamide film boasts a property unique worldwide: In winter when humidity is<br />

relatively low, the pores close, preventing interior water vapour penetrating into the construction.<br />

In summer, with relatively high humidities, the pores open, allowing any moisture that might have<br />

found its way into the structure to dry out. There is no risk of mould formation.<br />

Whereas, standard films do not allow drying out, trapping moisture in the construction, VARIO KM/<br />

KM Duplex UV film is clearly ideal for creating air tight sealing in wall constructions.<br />

Perfectly matched – VARIO <strong>System</strong> Components<br />

Climate membrane<br />

VARIO KM Duplex UV<br />

VARIO KM<br />

Adhesive and sealing products<br />

VARIO KB1<br />

VARIO KB3<br />

VARIO DB<br />

VARIO DS<br />

VARIO ProTape<br />

VARIO MultiTape<br />

VARIO MultiTape SL<br />

VARIO TightTec<br />

Mangete Passelec<br />

VARIO Stos<br />

Properties<br />

non-woven, reinforced, water vapour<br />

regulating climate membrane. variable sd value 0.3 m to 5.0 m. highly tear resistant<br />

and easy to lay, thanks to guideline markings<br />

moisture-regulating climate membrane.<br />

variable sd value, 0.2 m to 5.0 m<br />

Properties<br />

single-sided adhesive tape with high<br />

bonding strength<br />

single-sided, highly flexible adhesive tape<br />

self-adhesive, rollable compressed tapes<br />

durable elastic, self-adhesive sealant in a<br />

cartridge or sausage bag<br />

durable elastic, self-adhesive sealant on a roll.<br />

50 % quicker to apply than with a cartridge<br />

Flexible and ductile adhesive tape with high<br />

bonding strength<br />

Flexible adhesive tape with split release strip<br />

Advanced design and with pre-marked<br />

membrane panels 200 x 400 mm<br />

120 x 400 mm<br />

Strongly adhesive, tear-resistant sleeve,<br />

60 x 60 cm<br />

Flexible pre-forms with strongly adhesive<br />

tape, 195 x 195 mm and 285 x 285 mm<br />

Uses<br />

For sealing the insulation layer in all building elements<br />

(floors, walls and roofs). Excellent moisture protection<br />

for new buildings and renovation work, of solid and<br />

lightweight construction<br />

Uses<br />

Extra-wide for airtight bonding of seam overlaps in<br />

VARIO KM / VARIO KM Duplex UV climate membranes<br />

For wind and airtight bonding of all joints and<br />

penetrations in VARIO KM / VARIO KM Duplex UV<br />

climate membranes<br />

To ensure air tight junctions between <strong>OPTIMA</strong><br />

construction Floor and Ceiling Studs<br />

For producing perfect wind and airtight joints in<br />

VARIO KM / VARIO KM Duplex UV climate membrane<br />

For durable airtight joints in VARIO KM / VARIO KM<br />

Duplex UV climate membrane around roof windows,<br />

pipes, roof penetrations and at membrane overlaps<br />

For airtight seals of all types of corners, such as outer<br />

walls, outer walls, window, door, and inner corners<br />

For airtight penetration joints for all types of<br />

installation, conduits through VARIO KM / VARIO KM<br />

Duplex UV

IV. Facing<br />

The finishing wall<br />

The <strong>OPTIMA</strong> <strong>System</strong> allows a wide choice of different finishes and ensures high thermal and<br />

acoustic comfort in the interior living area. The system can be adapted to meet the tastes of even<br />

the most creative interior decorator, with today’s numerous types of covering allowing expression of<br />

the personal touch. Plaster board, high stiffness, pre-painted, water repellent, or wood panelling,<br />

PVC, melamine, solid, perforated, or even simple plywood – everything is possible.<br />

Facing with plaster board (Item 9 in the illustration on Page 5)<br />

Whatever or wherever you want to insulate, Gyproc plaster board enjoys a number of significant<br />

advantages, such as rapid installation, a superbly smooth, even surface that can be adapted to the<br />

virtual every type of interior.<br />

In short – The Advantages of Plaster Board.<br />

• Superbly smooth, even surface<br />

• Rapid installation<br />

• Can be adapted to all architectural designs (ribbed walls, great height …)<br />

All advantages of the <strong>OPTIMA</strong> <strong>System</strong> at a glance on Page 19<br />

1<br />

11

<strong>OPTIMA</strong> <strong>System</strong> – High level thermal performance for renovation<br />

The following calculations demonstrate thermal insulation performance one can expect using the <strong>OPTIMA</strong> <strong>System</strong> with different types of<br />

wall construction. When insulating an outer wall, VARIO KM /KM Duplex UV has to be installed as vapor retarder and airtightness layer.<br />

In all the examples cited here, accessory <strong>OPTIMA</strong>2 Supports Reno and a standard plaster board (12.5 mm) are applied to different<br />

types of supporting wall and insulation materials.<br />

* Calculations were made with TRISCO software, version 10.0w ©2002 PHYSIBEL, conform with existing standards.<br />

** Air gap of 7.5 mm; the insulation material is compressed flush to the vertical studs.<br />

12<br />

Supporting wall 16 cm concrete (R = 0.21) 20 cm hollow concrete blocks (R=0.31) 20 cm bricks (R = 0.63)<br />

Facing 12.5 mm plaster board 12.5 mm plaster board 12.5 mm plaster board<br />

ISOVER Glass Thickness: 120 mm Thickness: 120 mm Thickness: 120 mm<br />

Wool Product R = 3.75 m 2 K/W R = 3.75 m 2 K/W R = 3.75 m 2 K/W<br />

λd = 0.032 W/(mK) λd = 0.032 W/(mK) λd = 0.032 W/(mK)<br />

U-Value* 0.24 W/(m 2 .K) 0.24 W/(m 2 .K) 0.22 W/(m 2 .K)<br />

Total thickness<br />

of system<br />

140 mm** 140 mm** 140 mm**<br />

ISOVER Glass Thickness: 140 mm Thickness: 140 mm Thickness: 140 mm<br />

Wool Product R = 4.35 m 2 K/W R = 4.35 m 2 K/W R = 4.35 m 2 K/W<br />

λd = 0.032 W/(mK) λd = 0.032 W/(mK) λd = 0.032 W/(mK)<br />

U-Value* 0.21 W/(m 2 .K) 0.21 W/(m 2 .K) 0.19 W/(m 2 .K)<br />

Total thickness<br />

of system<br />

160 mm** 160 mm** 160 mm**<br />

ISOVER Glass Thickness: 160 mm Thickness: 160 mm Thickness: 160 mm<br />

Wool Product R = 5 m 2 K/W R = 5 m 2 K/W R = 5 m 2 K/W<br />

λd = 0.032 W/(mK) λd = 0.032 W/(mK) λd = 0.032 W/(mK)<br />

U-Value* 0.19 W/(m 2 .K) 0.18 W/(m 2 .K) 0.17 W/(m 2 .K)<br />

Total thickness<br />

of system<br />

180 mm** 180 mm** 180 mm**

<strong>OPTIMA</strong> <strong>System</strong> – Solutions for ISOVER Multi-Comfort House*<br />

Today’s modern housing needs to provide much more than basic shelter from the elements – it must offer high standards of quality and<br />

safety throughout. Just as high standards of energy efficiency have now become the norm, families today require a comfortable thermal<br />

environment all year round, and excellent acoustic protection from both internally and externally generated noise. Equally important are<br />

issues such as fire protection and the longevity of the property – and, of course the quality of the internal air within the building.<br />

To address these challenges, ISOVER has developed and refined its Multi-Comfort House concept to offer the ultimate combination of<br />

solutions to meet the demands of modern living.<br />

Supporting wall 25 cm cellular concrete with Wood frame house**** 20 cm glued bricks with 14 cm<br />

8 cm existing insulation (R = 4.8) composite thermal insulation system<br />

(wall R = 4.4) (R = 4.6)<br />

Facing 12.5 mm plaster board 12.5 mm plaster board 12.5 mm plaster board<br />

ISOVER Glass Thickness: 160 mm Thickness: 160 mm Thickness: 160 mm<br />

Wool Product R = 5 m 2 K/W R = 5 m 2 K/W R = 5 m 2 K/W<br />

λd = 0.032 W/(mK) λd = 0.032 W/(mK) λd = 0.032 W/(mK)<br />

U-Value* 0.10 W/(m 2 .K) 0.10 W/(m 2 .K) 0.10 W/(m 2 .K)<br />

Total thickness wall + lining = 510 mm*** wall + lining = 380 mm*** wall + lining = 520 mm***<br />

of construction<br />

* The shown examples of the U-values fullfil criteria of ISOVER Multi-Comfort House for single family houses in moderate climate.<br />

** Calculations were made with TRISCO software, version 10.0w ©2002 PHYSIBEL, conform with existing standards.<br />

*** Air gap of 7.5 mm; the insulation material is compressed flush to the vertical studs.<br />

**** U-value calculation takes wooden frame into account.<br />

13

14<br />

1<br />

<strong>OPTIMA</strong> <strong>System</strong> – An efficient sound insulation<br />

For acoustic comfort indoors, a house needs to be well insulated against the noise outside. The<br />

<strong>OPTIMA</strong> <strong>System</strong>, based on the mass-spring-mass principle, achieves ISOVER Acoustic Comfort<br />

Classes, which generally exceed standard requirements for sound insulation. The <strong>OPTIMA</strong> <strong>System</strong><br />

safeguards personal privacy in the home, maintaining the well-being of its occupants.<br />

Acoustic insulation of a construction is determined by the (weighted) sound reduction index Rw,<br />

expressed in dB: the higher the Rw, the better the sound insulation.<br />

The table below shows some examples of sound reduction for different types of support walls,<br />

insulation and facing materials. Important: sound reduction of 10 dB causes 50% reduction of the<br />

parceived noise!<br />

Thickness of ISOVER Support +<br />

Support glass wool with Facing Support only <strong>OPTIMA</strong> Gain<br />

AFr ≥ 5 kPa.s/m 2 Rw (C;Ctr) in dB Rw (C;Ctr) in dB Rw+C in dB<br />

Hollow concrete<br />

blocks 200 mm + glue<br />

100 mm Wood panelling 53 (-1 ; -2) 71 (-4 ; -11) 15<br />

Hollow concrete<br />

blocks 200 mm + glue<br />

100 mm PVC panelling 53 (-1 ; -2) 67 (-3 ; -11) 12<br />

Hollow concrete<br />

blocks 200 mm + glue<br />

100 mm<br />

12.5 mm<br />

Plaster board<br />

53 (-1 ; -2) 76 (-4 ; -11) 20<br />

Hollow concrete<br />

blocks 200 mm + glue<br />

75 mm<br />

12.5 mm<br />

Plaster board<br />

54 (-2 ; -4) 68 (-3 ; -10) 13<br />

Concrete 160 mm 85 mm<br />

12.5 mm<br />

Plaster board<br />

58 (-1 ; -4) 71 (-2 ; -6) 12<br />

Hollow bricks 200 mm<br />

+ glue<br />

100 mm<br />

12.5 mm<br />

Plaster board<br />

42 (0 ; -2) 68 (-2 ; -9) 24<br />

Hollow bricks 200 mm<br />

+ glue<br />

75 mm<br />

12.5 mm<br />

Plaster board<br />

50 (-5 ; -7) 66 (-3 ; -8) 18<br />

Plaster tile 70 mm 85 mm<br />

In multi-family buildings<br />

12.5 mm<br />

Plaster board<br />

35 (-1 ; -3) 57 (-1 ; -6) 22<br />

Sound absorbing elements installed on the walls (Picture 1) and ceilings can significantly reduce echo<br />

in hallways. The <strong>OPTIMA</strong> <strong>System</strong>, with a perforated facing is ideal for such situations.

A dry system, easy to install<br />

The <strong>OPTIMA</strong> <strong>System</strong> is quick and easy to install, clean and dry. In contrast to traditional dry lining<br />

solutions, adhesives and glues are not needed, allowing installation in unheated rooms or during<br />

periods of frost.<br />

1. Installation of <strong>OPTIMA</strong> Floor and Ceiling Studs<br />

The position of the <strong>OPTIMA</strong> Floor and Ceiling Studs is determined by the width of the window frame<br />

(Picture 1, point T) minus the thickness of the facing. Check the frames reference points to ensure<br />

correct positioning of the <strong>OPTIMA</strong> Floor and Ceiling Studs and correct any possible misalignment.<br />

Mechanical Installation according to the support:<br />

• Pistocelling (ideal for concrete slabs)<br />

• Plugs to be hammered (screw + plug)<br />

If the ceiling is made of concrete blocks, the upper corners can be attached with expansion plugs. To<br />

ensure the joint between the <strong>OPTIMA</strong> Floor and Ceiling Studs, and the support is air tight VARIO DB<br />

band should be used (Picture 2). Installation in humid rooms requires the necessary protection for<br />

such joints.<br />

(A) <strong>OPTIMA</strong> Floor and Ceiling Studs<br />

(B) VARIO DB<br />

(C) <strong>OPTIMA</strong> 240 Stud (horizontal)<br />

2. Installation of <strong>OPTIMA</strong> 240 Studs and <strong>OPTIMA</strong>2 Support<br />

In new buildings, horizontal <strong>OPTIMA</strong> 240 Studs are installed a maximum of 1.35 m from the floor<br />

(Picture 3). Depending on the facing and on wall geometry intermediate <strong>OPTIMA</strong>2 Supports are clipped<br />

every 60 cm (Picture 4). For renovation work <strong>OPTIMA</strong>2 Supports Reno are fixed directly to the wall.<br />

B<br />

T<br />

A<br />

A<br />

C<br />

1.35 m max<br />

1<br />

2<br />

3<br />

4<br />

15

16<br />

F<br />

1<br />

2<br />

3<br />

4<br />

3. Cutting and installing the insulation material<br />

The insulation material should be cut to the height floor-ceiling plus 1 cm, and installed<br />

such that the <strong>OPTIMA</strong>2 Supports pierce the material; panels joints should be tight<br />

and flush (Picture 1).<br />

4. Installing the keys of <strong>OPTIMA</strong>2 Supports<br />

Locate the key on the projecting end of the <strong>OPTIMA</strong>2 Support or <strong>OPTIMA</strong>2 Support<br />

Reno supports (Picture 2 point F).<br />

5. Installing the vertical studs<br />

Insert the <strong>OPTIMA</strong> 240 Stud in the <strong>OPTIMA</strong> Floor Stud (Picture 3). Depending on the<br />

height required, affix either an <strong>OPTIMA</strong> 30 or 50 Stud and slide the extended stud into<br />

position in the <strong>OPTIMA</strong> Ceiling Stud from the side.<br />

Vertical studs are locked in position by the keys of <strong>OPTIMA</strong>2 Support or <strong>OPTIMA</strong>2<br />

Support Reno pieces, first making sure studs are vertical using a spirit level (Picture 4).

6. Installation of the vapour retarding and air tight layer<br />

Once the metal studs are securely located, VARIO KM or VARIO KM Duplex UV can be<br />

applied as a vapour retardant, air tight layer. VARIO accessories, such as VARIO DS,<br />

an adhesive sealing compound, and VARIO ProTape, an adhesive tape, are used to fix<br />

the membrane to the studs, floor and ceiling. The construction is only air tight if<br />

VARIO KM / KM Duplex UV are bonded well to the floor and ceiling. Each membrane<br />

seam should overlap by a least 10 cm (Picture 1).<br />

Applying single-sided VARIO KB1 tape to all membrane seams ensures a reliable, tight<br />

seal. Overlapping the seams by at least 10 cm, and the tape’s powerful bonding<br />

strength avoids leaks in the system (Picture 2).<br />

Cable penetrations are made airtight with VARIO MultiTape SL. VARIO Stos or Mangete<br />

Passelec are also ideal for sealing off various other installations (Picture 3).<br />

7. Cutting and fixing the facing<br />

The facing material should be cut to a length of the floor to ceiling height minus 1 cm.<br />

Hold the board flush to the ceiling and screw it directly to the studs (Picture 4), at<br />

30 cm intervals, leaving a minimum of 1 cm perimeter from the edge of the board.<br />

1<br />

2<br />

3<br />

4<br />

17

Dealing with specific issues<br />

Integrating ducts<br />

Standard electrical appliances, home automation and multimedia have led to an increasing in cabling<br />

and ducting that need to be included in buildings (Picture 1).<br />

The <strong>OPTIMA</strong> <strong>System</strong> allows the integration of such networks in the lining without compromising<br />

insulation. They are run between ISOVER glass wool and plaster boards. VARIO MultiTape SL is used<br />

to ensure breakout points are both vapour and air tight.<br />

The <strong>OPTIMA</strong> Connector<br />

This accessory is used to construct<br />

T-joints between <strong>OPTIMA</strong> transverse and<br />

perpendicular studs, for instance to accommodate<br />

a window frame (Picture 2).<br />

Window sill<br />

The position of the windows has to be taken into account. If it is in the inner surface of the wall,<br />

the length of <strong>OPTIMA</strong>2 Supports are chosen according to the depth of the window sill.<br />

Humid rooms<br />

In humid rooms (bathroom, garage, non-heated basement), plaster board facings have to be waterrepellent.<br />

Irrespective of whether the floor is rough or finished, an impregnated foam strip needs to<br />

be installed as a central joint (Picture 5 point A) between the bottom wall plate and floor.<br />

Installations on rough floors require additional protection in the form of a polyethylene film overlapping<br />

the floor by at least 2 cm (Picture 5 point B).<br />

18<br />

Inner and outer corners<br />

An <strong>OPTIMA</strong> Floor and Ceiling<br />

Stud can replace studs at the<br />

corners (Picture 3).<br />

<strong>OPTIMA</strong>2 Support<br />

Lining Thickness<br />

(finished with standard<br />

plasterboard 1 BA 13)<br />

Length of window sill<br />

(Picture 4 point T)<br />

75 from 94 mm to 113 mm 100 mm<br />

100 from 114 mm to 133 mm 120 mm<br />

115 from 134 mm to 153 mm 140 mm<br />

2<br />

A<br />

T<br />

1<br />

3<br />

4<br />

B<br />

5

<strong>OPTIMA</strong> <strong>System</strong> – Advantage after advantage<br />

Renovating with the <strong>OPTIMA</strong> <strong>System</strong> means rapid installation of an air tight insulation layer including a finished wall. Waiting for the<br />

lengthy drying times of individual components is avoided. The <strong>OPTIMA</strong> <strong>System</strong> allows the integration of cables and ducts without compromising<br />

the insulation. All elements of the <strong>OPTIMA</strong> <strong>System</strong> are easy to transport, store and distribute on site. With ISOVER glass wool<br />

products, up to 100 mm thick, a significant improvement of the thermal insulation and a reduction of energy costs can be<br />

achieved. Furthermore, this solution improves sound properties of interior rooms and protects against noise from outside the building.<br />

<strong>OPTIMA</strong> Metal frame – light, solid, but elastic<br />

• Avoids thermal bridges, as the insulation layer is continuous<br />

• Easy and practical installation with no waste<br />

• Precise installation to the nearest millimetre<br />

• Perfectly matched components<br />

ISOVER insulation – highest insulation performance<br />

• Products with the lowest thermal conductivity λd = 0.032 W/(mK), or λd = 0.035 W/(mK) save space<br />

and increase thermal and sound insulation performance<br />

• Compressed products save space and time, both for transport and distribution on site<br />

• Excellent quality and safety – non-combustible and CE mark certified<br />

VARIO – air tightness and protection against moisture<br />

• Breathable and moisture regulatory<br />

• Excellent assurance due to a variable sd-value of 0.2–5.0 m<br />

• Ease of work: printed guidelines for easy accurate cutting, and fleece surface for better adhesion to substrate<br />

• Product is perfect for any application<br />

• Patented system based on 10 years experience and more than 15 million m2 of protected area installed<br />

Facing with plaster board – suitable for every design<br />

• Quick assembly<br />

• Smooth and level surface<br />

• Suitable for every room height or size<br />

19

20<br />

<strong>OPTIMA</strong> <strong>System</strong> – A complete range<br />

ISOVER Insulation Material<br />

ISOVER Glass Wool Product with λ d = 0,032 W/mK<br />

R thickness length width packaging unit<br />

m 2 K/W (mm) (m) (m) m 2 /packet packet/pallet m 2 /pallet<br />

3.15 100<br />

2.65 85<br />

2.35 75<br />

1.85 60<br />

ISOVER Glass Wool Product with λ d = 0,035 W/mK<br />

R thickness length width packaging unit<br />

m 2 K/W (mm) (m) (m) m 2 /packet packet/pallet m 2 /pallet<br />

3.40 120<br />

2.85 100<br />

2.40 85<br />

2.10 75<br />

1.70 60<br />

Insulation Cutter<br />

Double edge knife for cutting the insulation material.

The Accessories<br />

<strong>OPTIMA</strong> Floor and Ceiling Studs<br />

<strong>OPTIMA</strong> Floor and Ceiling Studs allow the embedding and the adjusting the vertical stud position.<br />

article packaging unit<br />

<strong>OPTIMA</strong> Stud Pallet of 12 bundles<br />

Length: 235 cm of 20 units = 564 m<br />

<strong>OPTIMA</strong> 240 Stud<br />

Metal stud of 2.40 m allowing the splicing and length adjustment.<br />

article packaging unit<br />

<strong>OPTIMA</strong> 240 Stud Pallet of 40 bundles<br />

Length: 240 cm of 10 units = 960 m<br />

<strong>OPTIMA</strong> 30 and 50 Stud<br />

Short metal stud designed for linking or lengthening the <strong>OPTIMA</strong> 240 Studs.<br />

article packaging unit<br />

<strong>OPTIMA</strong> 30 Stud Pallet of 40 bundles<br />

Length: 30 cm of 10 units = 120 m<br />

<strong>OPTIMA</strong> 50 Stud Pallet of 40 bundles<br />

Length: 50 cm of 10 units = 200 m<br />

<strong>OPTIMA</strong>2 Support<br />

A support pillar that has to be clipped onto a metal stud, with a plastic key.<br />

article packaging unit<br />

<strong>OPTIMA</strong>2 Support 75 50 pieces<br />

<strong>OPTIMA</strong>2 Support 100 50 pieces<br />

<strong>OPTIMA</strong>2 Support 115 50 pieces<br />

<strong>OPTIMA</strong>2 Support Reno<br />

A support pillar that can be attached directly to the wall, with plastic key.<br />

article packaging unit<br />

<strong>OPTIMA</strong>2 Support Reno 40 pieces<br />

<strong>OPTIMA</strong> Connector<br />

For joining <strong>OPTIMA</strong> 240 Studs at particular points.<br />

article packaging unit<br />

<strong>OPTIMA</strong> Connector 25 pieces<br />

21

The Accessories<br />

VARIO KM Duplex UV<br />

Reinforced, laminated water vapour retardant climate membrane for sealing all construction components<br />

(floors, walls, roof) in both lightweight and solid constructions. Moisture-variable sd of 0.3 m to<br />

5 m. Includes a practical installation guide (line markings).<br />

VARIO KM<br />

Vapour retardant climate membrane for protection against moisture in all construction components<br />

(floors, walls, roof) in both lightweight and solid constructions. Moisture-variable sd value of 0.2 m to 5 m.<br />

VARIO DB<br />

Roll of sealing tape to ensure airtight junctions between <strong>OPTIMA</strong> Floor and Ceiling Studs and their<br />

support wall.<br />

22<br />

length - width packaging unit<br />

40 m – 1.5 m 60 m2 / roll<br />

length - width packaging unit<br />

60 m – 2 m 120 m2 / roll<br />

30 m – 2 m 60 m2 / roll<br />

15 m – 2 m 30 m2 / roll<br />

length - width packaging unit<br />

8 m – 17 mm 6 rolls = 48 m<br />

VARIO DS<br />

Durable elastic sealant in a handy cartridge or sausage bag. Used for producing airtight joints<br />

and junctions between VARIO KM / VARIO KM Duplex UV climate membranes and floors, ceilings and<br />

walls, and for fixing overlapping seams in membranes.<br />

product volume packaging unit<br />

cartridge 310 ml 12 pieces<br />

sausage bag 600 ml 12 pieces<br />

VARIO Pro Tape<br />

Durably elastic and self-adhesive sealant for fixing the VARIO KM / KM Duplex UV on metal studs<br />

and for air tight joints on floor, ceiling and wall.<br />

length - width packaging unit<br />

10 m – 25 mm 5 rolls = 50 m<br />

VARIO KB 1<br />

Single-sided, extra wide adhesive tape for joining the seams of VARIO KM / KM Duplex UV at vapour<br />

retarder and air tight membranes.<br />

article packaging unit<br />

20 m – 60 mm 12 rolls = 240 m<br />

40 m – 60 mm 5 rolls = 200 m

VARIO KB3<br />

Single-sided, highly flexible adhesive tape for producing wind and airtight seals at all junctions and<br />

penetrations in VARIO KM / VARIO KM Duplex UV climate membranes.<br />

length – width packaging unit<br />

15 m – 60 mm 12 rolls = 180 m<br />

25 m – 60 mm 10 rolls = 250 m<br />

VARIO MultiTape<br />

Single-sided, flexible and ductile adhesive tape with high bonding strength. Used for producing durable<br />

airtight junctions between VARIO KM / VARIO KM Duplex UV climate membranes and flush roof windows,<br />

pipes and roof penetrations. Also suitable for sealing overlapping membrane joints (indoors and outdoors).<br />

length - width packaging unit<br />

25 m – 60 mm 10 rolls = 250 m<br />

VARIO MultiTape SL<br />

Single-sided, flexible adhesive tape with a split release strip for producing durable airtight junction seals<br />

between VARIO KM / VARIO KM Duplex UV climate membranes and roof windows, pipes and roof<br />

penetrations. The split release strip makes it easy to install in corners and difficult-to-access areas.<br />

length – width packaging unit<br />

25 m – 60 mm 10 rolls = 250 m<br />

VARIO TightTec<br />

VARIO TightTec is the easy way to produce airtight junctions with external walls, windows, doors and<br />

interior corners. It is easy to fold and the printed guidelines make matching the corner easy. Junctions<br />

with climate membrane are taped<br />

over with VARIO MultiTape.<br />

product dimensions packaging unit<br />

TightTec X 200 x 400 mm 60 pieces<br />

TightTec X 120 x 400 mm 60 pieces<br />

TightTec I 200 x 400 mm 60 pieces<br />

Mangete Passelec<br />

Strong bonding, self-adhesive and extremely tear-resistant 60 x 60 cm sleeving, for creating durable airtight<br />

seals in penetrations of different diameters through VARIO KM / VARIO KM Duplex UV climate<br />

membranes.<br />

dimensions packaging unit<br />

60 cm x 60 cm 100 pieces<br />

VARIO Stos<br />

Flexible membrane profile with a strong adhesive tape in 195 x 195 mm and 285 x 285 mm formats.<br />

Used to create durable airtight junctions around service penetrations of different diameter through<br />

VARIO KM / VARIO KM Duplex UV climate membranes.<br />

product packaging unit<br />

Stos 195 10 pieces<br />

Stos 285 5 pieces<br />

23

Saint-Gobain Insulation<br />

“Les Miroirs”<br />

92096 La Défense Cedex<br />

France<br />

www.isover.com