Download - Hitachi Power Europe GmbH

Download - Hitachi Power Europe GmbH

Download - Hitachi Power Europe GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Hitachi</strong> <strong>Power</strong> <strong>Europe</strong> Service <strong>GmbH</strong><br />

<strong>Hitachi</strong> <strong>Power</strong> <strong>Europe</strong> Service ist ein<br />

eigen ständiges Unternehmen der <strong>Hitachi</strong><br />

Gruppe und bündelt die Service aktivitäten<br />

der <strong>Hitachi</strong> <strong>Power</strong> <strong>Europe</strong> <strong>GmbH</strong>.<br />

<strong>Hitachi</strong> <strong>Power</strong> <strong>Europe</strong> Service is an<br />

independent subsidiary of <strong>Hitachi</strong> Group<br />

and bundles the service activities of<br />

<strong>Hitachi</strong> <strong>Power</strong> <strong>Europe</strong> <strong>GmbH</strong>.<br />

›› Extremely Resilient<br />

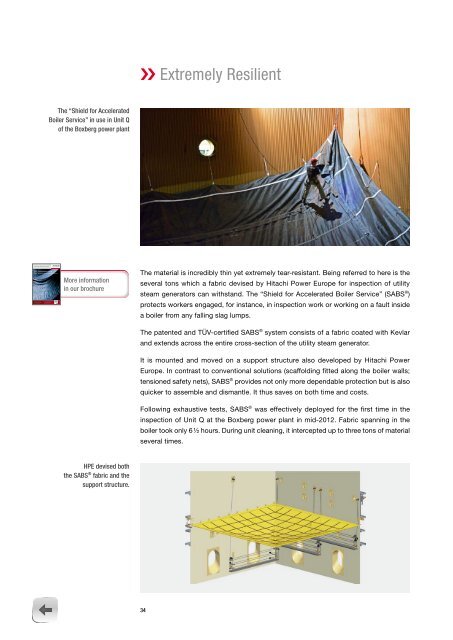

The “Shield for Accelerated<br />

Boiler Service” in use in Unit Q<br />

of the Boxberg power plant<br />

SABS ® Sicherheits abschottung<br />

SABS ® Shield for Accelerated Boiler Service<br />

More information<br />

in our brochure<br />

The material is incredibly thin yet extremely tear-resistant. Being referred to here is the<br />

several tons which a fabric devised by <strong>Hitachi</strong> <strong>Power</strong> <strong>Europe</strong> for inspection of utility<br />

steam generators can withstand. The “Shield for Accelerated Boiler Service” (SABS ® )<br />

protects workers engaged, for instance, in inspection work or working on a fault inside<br />

a boiler from any falling slag lumps.<br />

The patented and TÜV-certified SABS ® system consists of a fabric coated with Kevlar<br />

and extends across the entire cross-section of the utility steam generator.<br />

It is mounted and moved on a support structure also developed by <strong>Hitachi</strong> <strong>Power</strong><br />

<strong>Europe</strong>. In contrast to conventional solutions (scaffolding fitted along the boiler walls;<br />

tensioned safety nets), SABS ® provides not only more dependable protection but is also<br />

quicker to assemble and dismantle. It thus saves on both time and costs.<br />

Following exhaustive tests, SABS ® was effectively deployed for the first time in the<br />

inspection of Unit Q at the Boxberg power plant in mid-2012. Fabric spanning in the<br />

boiler took only 6 ½ hours. During unit cleaning, it intercepted up to three tons of material<br />

several times.<br />

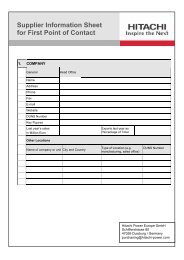

HPE devised both<br />

the SABS ® fabric and the<br />

support structure.<br />

34