Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CARBON 48 (2010) 4289– 4300<br />

available at www.sciencedirect.com<br />

journal homepage: www.elsevier.com/locate/<str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g><br />

<str<strong>on</strong>g>Synergetic</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>ibers <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g><br />

<strong>on</strong> <strong>the</strong> mechanical <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture properties <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy resin<br />

G. Zhang a, *, J. Karger-Kocsis b ,J.Zou a<br />

a Institute for Composite Materials, University <str<strong>on</strong>g>of</str<strong>on</strong>g> Kaiserslautern, 67663 Kaiserslautern, Germany<br />

b Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Polymer Technology, Faculty <str<strong>on</strong>g>of</str<strong>on</strong>g> Engineering <str<strong>on</strong>g>and</str<strong>on</strong>g> Built Envir<strong>on</strong>ment, Tshwane University <str<strong>on</strong>g>of</str<strong>on</strong>g> Technology, Pretoria 0001,<br />

South Africa<br />

ARTICLE<br />

INFO<br />

ABSTRACT<br />

Article history:<br />

Received 27 April 2010<br />

Accepted 22 July 2010<br />

Available <strong>on</strong>line 27 July 2010<br />

The <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>ibers (CNFs) <str<strong>on</strong>g>and</str<strong>on</strong>g> combinati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs with microsized <str<strong>on</strong>g>short</str<strong>on</strong>g><br />

<str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> (SCFs) <strong>on</strong> <strong>the</strong> mechanical <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture properties <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy resin were investigated.<br />

The combined use <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> SCFs leads to significant synergy in <strong>the</strong> mechanical<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> fracture properties. The composites reinforced with <strong>the</strong> combined multiscale fillers<br />

exhibit much higher modulus, strength <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness than <strong>the</strong> composites reinforced<br />

solely with ei<strong>the</strong>r micro- or nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers. The mechanisms <str<strong>on</strong>g>of</str<strong>on</strong>g> such synergism were<br />

analyzed by fracture studies using scanning electr<strong>on</strong> microscopy. The release <str<strong>on</strong>g>of</str<strong>on</strong>g> overstresses<br />

near to SCFs by stress transfer <str<strong>on</strong>g>and</str<strong>on</strong>g> redistributi<strong>on</strong>, realized by CNFs, was traced to <strong>the</strong><br />

synergistic <str<strong>on</strong>g>effect</str<strong>on</strong>g>s observed.<br />

Ó 2010 Elsevier Ltd. All rights reserved.<br />

1. Introducti<strong>on</strong><br />

Epoxy resins (EPs) are being more <str<strong>on</strong>g>and</str<strong>on</strong>g> more used as matrices<br />

in state-<str<strong>on</strong>g>of</str<strong>on</strong>g>-<strong>the</strong>-art applicati<strong>on</strong>s due to many useful properties<br />

such as high modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> strength, high <strong>the</strong>rmal resistance,<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> resistance to creep. However, EP displays also a highly<br />

undesirable property, i.e. poor resistance to crack initiati<strong>on</strong><br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> propagati<strong>on</strong>. To simultaneously enhance <strong>the</strong> mechanical<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> fracture properties <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy is <str<strong>on</strong>g>of</str<strong>on</strong>g> great importance.<br />

Microsized rigid inorganic particles [1–4] <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g><br />

[5–9] were proven suitable for this task. More recently, EP<br />

composites which are reinforced with nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers gained<br />

extensive <str<strong>on</strong>g>and</str<strong>on</strong>g> intensive interests both in <strong>the</strong> academia <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

industries.<br />

Carb<strong>on</strong> nanotube (CNT), more specifically a single-walled<br />

<str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> nanotube (SWCNT), can be c<strong>on</strong>sidered as a graphene<br />

sheet rolled into a cylinder, where multiple c<strong>on</strong>centric<br />

sheets create a multiwalled <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> nanotube (MWCNT). Carb<strong>on</strong><br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>ibers (CNFs), are a class <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>se materials that<br />

have curved graphene layers or nanoc<strong>on</strong>es stacked to form<br />

a quasi-<strong>on</strong>e-dimensi<strong>on</strong>al filament, whose internal structure<br />

can be characterized by <strong>the</strong> angle between <strong>the</strong> graphene layers<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> fiber axis [10]. Due to <strong>the</strong>ir excepti<strong>on</strong>ally excellent<br />

<strong>the</strong>rmal, electrical properties <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>ir high specific<br />

stiffness <str<strong>on</strong>g>and</str<strong>on</strong>g> strength <str<strong>on</strong>g>and</str<strong>on</strong>g> very large aspect ratios (length/<br />

diameter), CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNTs hold great potential for developing<br />

advanced polymer composites for both structural <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

functi<strong>on</strong>al applicati<strong>on</strong>s. CNFs typically have diameters <strong>on</strong><br />

<strong>the</strong> order <str<strong>on</strong>g>of</str<strong>on</strong>g> 50–200 nm [11]. CNFs are now produced at high<br />

rates <str<strong>on</strong>g>and</str<strong>on</strong>g> reas<strong>on</strong>ably lower cost than CNTs, <str<strong>on</strong>g>and</str<strong>on</strong>g> thus <strong>the</strong>y<br />

become potential c<str<strong>on</strong>g>and</str<strong>on</strong>g>idates for high-volume applicati<strong>on</strong>s.<br />

Extensive researches were carried out to reinforce polymer<br />

matrices by CNTs or CNFs introducing <strong>the</strong>m in low<br />

amounts. Note that due to <strong>the</strong> small sizes <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

CNTs, <strong>the</strong> properties <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>se nanoreinforcements can <strong>on</strong>ly<br />

be exploited if <strong>the</strong>y are homogeneously dispersed in <strong>the</strong> related<br />

matrices. How to achieve a homogeneous dispersi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers in polymers is a challenging task receiving<br />

* Corresp<strong>on</strong>ding author: Fax: +49 631 2017 196.<br />

E-mail address: ga.zhang@ivw.uni-kl.de (G. Zhang).<br />

0008-6223/$ - see fr<strong>on</strong>t matter Ó 2010 Elsevier Ltd. All rights reserved.<br />

doi:10.1016/j.<str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g>.2010.07.040

4290 CARBON 48 (2010) 4289– 4300<br />

c<strong>on</strong>siderable attenti<strong>on</strong>. Different dispersing techniques for<br />

CNTs were documented in recent review papers [12,13].<br />

CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNTs were proven to stiffen <str<strong>on</strong>g>and</str<strong>on</strong>g> toughen EPs even<br />

at <strong>the</strong>ir extremely low c<strong>on</strong>tents [14–17]. To reinforce EP with<br />

low-loading CNFs or CNTs is <str<strong>on</strong>g>of</str<strong>on</strong>g> practical interest because<br />

<strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> resin can be kept <strong>on</strong> an acceptable level.<br />

The large aspect ratios <str<strong>on</strong>g>and</str<strong>on</strong>g> huge specific surface areas <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CNTs or CNFs guarantee an efficient matrix/filler stress<br />

transfer. Available literatures to date <str<strong>on</strong>g>of</str<strong>on</strong>g>fer evidence str<strong>on</strong>g<br />

CNT–polymer interacti<strong>on</strong>s. Efficient stress transfer between<br />

CNTs <str<strong>on</strong>g>and</str<strong>on</strong>g> polymer matrix was evidenced in [18–20] <str<strong>on</strong>g>and</str<strong>on</strong>g> simulated<br />

in [21–23]. The stress transfer efficiency between<br />

nanotube <str<strong>on</strong>g>and</str<strong>on</strong>g> matrix was estimated to be at least <strong>on</strong>e order<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> magnitude larger than in c<strong>on</strong>venti<strong>on</strong>al fiber-based composites<br />

[20].<br />

Direct comparis<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> mechanical properties between<br />

micr<str<strong>on</strong>g>of</str<strong>on</strong>g>iller- <str<strong>on</strong>g>and</str<strong>on</strong>g> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced composites are scarce.<br />

A definite answer is still lacking to <strong>the</strong> basic questi<strong>on</strong>: do<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced composites always display superior<br />

mechanical properties to micr<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced composites<br />

Microsized particles or <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> (micro-scale in diameter<br />

or/<str<strong>on</strong>g>and</str<strong>on</strong>g> in length) were proven to <str<strong>on</strong>g>effect</str<strong>on</strong>g>ively stiffen <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

toughen EP matrix. However, <strong>the</strong>y str<strong>on</strong>gly lower <strong>the</strong> ductility<br />

due to <strong>the</strong> highly c<strong>on</strong>strained deformability <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EP matrix<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> stress c<strong>on</strong>centrati<strong>on</strong> occurring near <strong>the</strong> microsized<br />

filler [7–9,24,25]. Obvious stress c<strong>on</strong>centrati<strong>on</strong> near <strong>the</strong> fillers<br />

can induce critical failure <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composite system. Thus, in<br />

many cases, <strong>the</strong> strength <str<strong>on</strong>g>of</str<strong>on</strong>g> EP can <strong>on</strong>ly be moderately improved<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> even decreased with <strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> microsized<br />

fillers. Unlike micr<str<strong>on</strong>g>of</str<strong>on</strong>g>illers, <strong>the</strong> much smaller size <str<strong>on</strong>g>of</str<strong>on</strong>g> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers<br />

might guarantees a good integrati<strong>on</strong> with <strong>the</strong> matrix<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> avoid obvious stress c<strong>on</strong>centrati<strong>on</strong> [25]. The incorporati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> low-loading nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers makes it possible a simultaneous<br />

improvement in E-modulus, strength <str<strong>on</strong>g>and</str<strong>on</strong>g> toughness<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> EP [15,25,26]. Despite <strong>the</strong> fact that nan<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced<br />

polymer composites attracted great attenti<strong>on</strong>s in <strong>the</strong> last<br />

two decades, with low-loading nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers such as nanoparticles<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> CNTs, <strong>the</strong> mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> EP matrix can<br />

<strong>on</strong>ly be moderately improved [15,25,26]. However, our previous<br />

work [27] revealed that a combined utilizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> microsized<br />

<str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> (SCFs) <str<strong>on</strong>g>and</str<strong>on</strong>g> low-loading nano-silica<br />

particles leads to significant synergisms <strong>on</strong> <strong>the</strong> mechanical<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> EP. Combined utilizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> differently<br />

scaled fillers seems to be a promising route to greatly<br />

enhance <strong>the</strong> modulus, strength <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

EP simultaneously.<br />

In this work, we systematically compare <strong>the</strong> mechanical<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> fracture properties <str<strong>on</strong>g>of</str<strong>on</strong>g> three series <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy composites,<br />

i.e. c<strong>on</strong>venti<strong>on</strong>al composites reinforced with microsized SCFs<br />

(SCF/EP composites), composites reinforced with CNFs at low<br />

c<strong>on</strong>centrati<strong>on</strong>s (CNF/EP composites), <str<strong>on</strong>g>and</str<strong>on</strong>g> composites reinforced<br />

with both SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs (SCF/CNF/EP composites).<br />

The main aims <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> present work are to deepen <strong>the</strong> underst<str<strong>on</strong>g>and</str<strong>on</strong>g>ing<br />

<strong>on</strong> <strong>the</strong> structure–property relati<strong>on</strong>ship <str<strong>on</strong>g>of</str<strong>on</strong>g> EP composites<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> to investigate how <strong>the</strong> combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g>s, i.e. combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs, affects<br />

<strong>the</strong> mechanical properties <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

EP. By revealing <strong>the</strong> synergetic acti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g><br />

fillers, we propose a promising composite formulati<strong>on</strong> route<br />

for high-performance applicati<strong>on</strong>s.<br />

2. Experimental<br />

2.1. Materials <str<strong>on</strong>g>and</str<strong>on</strong>g> preparati<strong>on</strong><br />

All materials used in <strong>the</strong> present work were prepared <strong>on</strong> <strong>the</strong><br />

basis <str<strong>on</strong>g>of</str<strong>on</strong>g> a commercially available epoxy resin (DER331 by<br />

DOW) with an epoxide equivalent weight 182–192 g/equiv.<br />

Cycloaliphatic amine hardener (HY 2954; Huntsman) was used<br />

to cure <strong>the</strong> epoxy materials. Milled PAN-based <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g><br />

(Tenax â A-385) were supplied by Tenax GmbH (Germany).<br />

The diameter <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> length <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> are, respectively,<br />

7 lm <str<strong>on</strong>g>and</str<strong>on</strong>g> 40–70 lm. The SCFs were supplied without sizing<br />

treatment <str<strong>on</strong>g>and</str<strong>on</strong>g> were used as-received. CNFs (GANF1) were supplied<br />

by Grupo Antolin (Spain). The CNFs have diameters in<br />

<strong>the</strong> range <str<strong>on</strong>g>of</str<strong>on</strong>g> 20–80 nm <str<strong>on</strong>g>and</str<strong>on</strong>g> lengths larger than 30 lm. The <strong>the</strong>oretical<br />

E-modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNFs is 230 GPa <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> <strong>the</strong>oretical<br />

strength is 2.7 GPa. Fumed spherical silica nanoparticles<br />

(Aerosil R8200) with hexamethyldisilazane modificati<strong>on</strong> were<br />

supplied by Ev<strong>on</strong>ik GmbH (Germany).<br />

Three series <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy composites, i.e. CNF-filled EP composites<br />

(CNF/EP), composites reinforced with <strong>the</strong> combined<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers, i.e. nano-SiO 2 <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs (CNF/nano-SiO 2 /EP), <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

composites reinforced with <strong>the</strong> combined multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g>s,<br />

i.e. SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs (SCF/CNF/EP), were prepared in <strong>the</strong> present<br />

work. Pure EP <str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>venti<strong>on</strong>al composites filled uniquely<br />

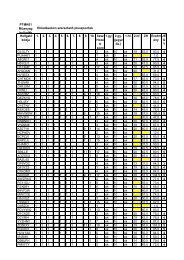

with SCFs were used for references. The loading <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNFs<br />

varied from 0.125 to 0.75 vol.%. The detailed compositi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> materials are disclosed in Table 1. The volume fracti<strong>on</strong>s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> all <strong>the</strong> fillers were calculated by c<strong>on</strong>sidering <strong>the</strong>ir weights<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> (bulk) densities. For simplificati<strong>on</strong> purpose, <strong>the</strong> composite<br />

materials were referenced according to <strong>the</strong> type <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> fillers as shown in <strong>the</strong> left column <str<strong>on</strong>g>of</str<strong>on</strong>g> Table 1.<br />

For example, 10CF0.5NF refers to <strong>the</strong> composite filled with<br />

10 vol.% SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> 0.5 vol.% CNFs.<br />

A master batch <str<strong>on</strong>g>of</str<strong>on</strong>g> CNF-filled epoxy resin was firstly prepared<br />

by dispersing a CNF/epoxy mixture with a three roll calender<br />

(Exakt 80 E, Exakt GmbH, Germany). Three roll calender<br />

was firstly introduced for dispersing CNTs by Gojny et al. in<br />

2004 [14] <str<strong>on</strong>g>and</str<strong>on</strong>g> received intensive attenti<strong>on</strong>s in recent years.<br />

Interestingly, this dispersi<strong>on</strong> technique is well established in<br />

<strong>the</strong> praxis – for example nano-SiO 2 is traditi<strong>on</strong>ally dispersed<br />

in dental composites by such calendering process. The small<br />

gap between <strong>the</strong> rolls <str<strong>on</strong>g>and</str<strong>on</strong>g> a mismatch in rolling speed can result<br />

in enormous shear forces, which can <str<strong>on</strong>g>effect</str<strong>on</strong>g>ively disentangle<br />

CNTs or CNFs agglomerates without significantly reducing<br />

<strong>the</strong>ir aspect ratios. The mismatch between <strong>the</strong> angular velocity<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> adjacent rolls was fixed at x 1 :x 2 :x 3 = 1:3:9. The gap distance<br />

between <strong>the</strong> rolls was adjusted to be 50 lm for<br />

beginning <str<strong>on</strong>g>and</str<strong>on</strong>g> was reduced to 25 lm for <strong>the</strong> sec<strong>on</strong>d pass <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

finally to 5 lm for <strong>the</strong> third pass. With regard to <strong>the</strong> SCF/<br />

CNF/EP composites, required amounts <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs were mixed<br />

into <strong>the</strong> diluted CNF master batch using a vacuum dissolver<br />

(Dispermat, VMA-Getzmann GmbH, Germany). The CNF/<br />

nano-SiO 2 /EP composites were prepared by mixing <str<strong>on</strong>g>and</str<strong>on</strong>g> diluting<br />

<strong>the</strong> CNF/EP master batch with <strong>the</strong> nano-silica/EP master<br />

batch formulati<strong>on</strong>. The nano-silica master batch is prepared<br />

by using <strong>the</strong> dissolver with an extremely high rotati<strong>on</strong> speed<br />

(5800 rpm). Afterwards, <strong>the</strong> compounds were blended<br />

with <strong>the</strong> curing agent HY2954 by stirring in <strong>the</strong> dissolver<br />

for 15 min. Finally <strong>the</strong> mixture was poured into release

CARBON 48 (2010) 4289– 4300 4291<br />

Table 1 – Compositi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> materials studied.<br />

Series Material codes Matrix (vol.%) SCF (vol.%) CNFs Nano-SiO 2 (vol.%)<br />

Neat epoxy EP 100 – – –<br />

SCF/EP composites 5CF 95 5 – –<br />

10CF 90 10 – –<br />

15CF 85 15 – –<br />

CNF/EP composites 0.125NF 99.875 – 0.125 –<br />

0.25NF 99.75 – 0.25 –<br />

0.5NF 99.5 – 0.5 –<br />

0.75NF 99.25 – 0.75 –<br />

CNF/nano-SiO 2 /EP composites 0.25NF1Si 98.75 0.25 1<br />

0.25NF3Si 96.75 0.25 3<br />

SCF/CNF/EP composites 10CF0.125NF 89.875 10 0.125 –<br />

10CF0.25NF 89.75 10 0.25 –<br />

10CF0.5NF 89.5 10 0.5 –<br />

10CF0.75NF 89.25 10 0.75 –<br />

agent-coated metallic molds <str<strong>on</strong>g>and</str<strong>on</strong>g> cured at 70 °C for 8 h,<br />

followed by 8 h at 120 °C.<br />

2.2. Characterizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNF network in SCF/CNF/EP<br />

composites<br />

In order to examine <strong>the</strong> CNF dispersi<strong>on</strong> state <str<strong>on</strong>g>and</str<strong>on</strong>g> CNF network<br />

in <strong>the</strong> SCF/CNF/EP composites, scanning electr<strong>on</strong><br />

microscopy (SEM, Zeiss Supra TM 40VP) was utilized to examine<br />

<strong>the</strong> fracture surface <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF0.75NF. No c<strong>on</strong>ductive coating was<br />

sputtered <strong>on</strong> <strong>the</strong> sample surface, in order to avoid any mask<br />

over <strong>the</strong> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> to allow possible charge c<strong>on</strong>trast imaging<br />

between <strong>the</strong> c<strong>on</strong>ductive CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> EP matrix. Due to <strong>the</strong><br />

charge c<strong>on</strong>trast, <strong>the</strong> overall distributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNTs or CNFs<br />

can be easily distinguished because <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> high c<strong>on</strong>trast (in<br />

brightness) between <strong>the</strong> c<strong>on</strong>ductive fillers <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> EP matrix<br />

[28–31]. A low accelerati<strong>on</strong> voltage <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.5 kV was utilized in order<br />

to reduce electr<strong>on</strong> penetrati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> to view dispersi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CNFs <strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>on</strong>ly slightly below <strong>the</strong> specimen surface.<br />

2.3. Glass transiti<strong>on</strong> temperature<br />

Glass transiti<strong>on</strong> temperatures, T g , <str<strong>on</strong>g>of</str<strong>on</strong>g> CNF composites <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

SCF/CNF/EP composites were measured by differential scanning<br />

calorimetry (DSC) using a DSC821 apparatus (Mettler-<br />

Toledo GmbH, Switzerl<str<strong>on</strong>g>and</str<strong>on</strong>g>). All tests were performed in<br />

nitrogen atmosphere with a sample mass <str<strong>on</strong>g>of</str<strong>on</strong>g> about 20 mg.<br />

The sample was heated from 20 °C to 200 °C at a rate <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

10 °C/min.<br />

2.4. Tensile tests<br />

Tensile tests were performed at room temperature (21 °C) <strong>on</strong> a<br />

Zwick 1474 universal testing machine at a c<strong>on</strong>stant crosshead<br />

speed <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.5 mm/min. The measurements followed DIN EN<br />

ISO 527 using dumbbell shaped specimens. The specimens<br />

having a 4 mm thickness were machined from <strong>the</strong> molded<br />

plates. The displacement <str<strong>on</strong>g>of</str<strong>on</strong>g> each specimen during tensi<strong>on</strong><br />

was accurately measured by an extensometer with an initial<br />

gage length <str<strong>on</strong>g>of</str<strong>on</strong>g> 20 mm. E-moduli were calculated by c<strong>on</strong>sidering<br />

<strong>the</strong> load in <strong>the</strong> 0.05–0.25% strain range. All presented data<br />

corresp<strong>on</strong>ds to <strong>the</strong> average <str<strong>on</strong>g>of</str<strong>on</strong>g> at least five measurements.<br />

2.5. Fracture toughness<br />

The fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> materials studied was determined<br />

by means <str<strong>on</strong>g>of</str<strong>on</strong>g> compact tensi<strong>on</strong> (CT) tests following <strong>the</strong><br />

st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard ISO 13586 <strong>on</strong> at least five specimens at a crosshead<br />

speed <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.5 mm/min. The CT specimens were cured in a<br />

metallic mold <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>n both sides were polished by abrasive<br />

papers until all visible marks disappeared. A notch was machined<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>n sharpened by tapping a fresh razor blade<br />

(tip radius: 2 lm) into <strong>the</strong> material, so that a sufficiently sharp<br />

crack was initiated. The thickness <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> width <str<strong>on</strong>g>of</str<strong>on</strong>g> specimens<br />

were 4 mm <str<strong>on</strong>g>and</str<strong>on</strong>g> 30 mm, respectively. In order to analyze<br />

failure mechanisms, <strong>the</strong> fracture surfaces after tensile <str<strong>on</strong>g>and</str<strong>on</strong>g> CT<br />

tests were inspected using SEM after being coated a thin gold<br />

layer.<br />

3. Results <str<strong>on</strong>g>and</str<strong>on</strong>g> discussi<strong>on</strong>s<br />

3.1. Dispersi<strong>on</strong> state <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> structure <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP<br />

composites<br />

Fig. 1 displays at different magnificati<strong>on</strong>s SEM images <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

n<strong>on</strong>-coated fracture surface <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF0.75NF. From Fig. 1a <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

b, it is seen that CNFs are globally well distributed in <strong>the</strong> EP<br />

matrix between SCFs. With a low magnificati<strong>on</strong> (cf. Fig. 1a<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> b), <strong>the</strong> overall structure <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> SCF/CNF/EP composite<br />

is clear due to <strong>the</strong> high c<strong>on</strong>trast between CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> EP.<br />

The high c<strong>on</strong>trast between CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> EP matrix is related<br />

to a charge c<strong>on</strong>trast <str<strong>on</strong>g>effect</str<strong>on</strong>g> [28–31], besides topography c<strong>on</strong>trast.<br />

With respect to <strong>the</strong> micr<strong>on</strong> SCFs which protrudes from<br />

<strong>the</strong> fractured EP surface, <strong>the</strong> topography c<strong>on</strong>trast is believed<br />

to be important. Charge c<strong>on</strong>trast mechanisms are currently<br />

under investigati<strong>on</strong>. Fig. 1c illustrates <strong>the</strong> fracture surface<br />

with a high magnificati<strong>on</strong>, with some <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNFs indicated<br />

by arrows <strong>on</strong> <strong>the</strong> surface. Besides discretely dispersed CNFs,<br />

small bundles <str<strong>on</strong>g>and</str<strong>on</strong>g> agglomerates <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs can be resolved<br />

locally.

4292 CARBON 48 (2010) 4289– 4300<br />

144<br />

140<br />

136<br />

T g<br />

( o C)<br />

132<br />

128<br />

124<br />

EP + CNFs<br />

EP + SCFs + CNFs<br />

120<br />

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8<br />

C<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs (vol.%)<br />

Fig. 2 – Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> CNF-loading <strong>on</strong> <strong>the</strong> T g <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs/EP <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs/<br />

SCF/EP composites.<br />

Fig. 1 – SEM images <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> n<strong>on</strong>-coated fracture surface <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

10CF0.75NF.<br />

As reviewed in a recent paper [32], widespread <str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>tradictory<br />

results regarding <strong>the</strong> glass transiti<strong>on</strong> temperature <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CNTs or CNFs filled EP were reported by different researchers.<br />

The mechanisms how CNTs or CNFs modify <strong>the</strong> T g are ra<strong>the</strong>r<br />

complex <str<strong>on</strong>g>and</str<strong>on</strong>g> remain unclear. It is generally believed that <strong>the</strong><br />

change in T g can be related to some restricti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> polymer<br />

chains’ movements <str<strong>on</strong>g>and</str<strong>on</strong>g> to changes in <strong>the</strong> cure degree<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EP in <strong>the</strong> corresp<strong>on</strong>ding interphase. Due to <strong>the</strong> large<br />

matrix/filler interface area, <strong>the</strong> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers could limit <strong>the</strong><br />

mobility <str<strong>on</strong>g>of</str<strong>on</strong>g> polymer chains <str<strong>on</strong>g>and</str<strong>on</strong>g> provide an increment in T g .<br />

Moreover, a higher cure degree can enhance <strong>the</strong> T g <str<strong>on</strong>g>and</str<strong>on</strong>g> vice<br />

versa. The additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs could earlier initiate <strong>the</strong> crosslinking<br />

reacti<strong>on</strong> due to <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> catalyst particles or<br />

hydrogen-b<strong>on</strong>d d<strong>on</strong>or molecules <strong>on</strong> CNF [32,33]. However,a<br />

higher c<strong>on</strong>versi<strong>on</strong> obtained in <strong>the</strong> interphase may be associated<br />

with a decrease <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> final cure in <strong>the</strong> following diffusi<strong>on</strong>-c<strong>on</strong>trolled<br />

stage [32,33]. Note that selective absorpti<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> resin or <strong>the</strong> hardener at nan<str<strong>on</strong>g>of</str<strong>on</strong>g>iller surface can lead to<br />

an <str<strong>on</strong>g>of</str<strong>on</strong>g>f-stoichiometry in <strong>the</strong> interphase which str<strong>on</strong>gly affects<br />

<strong>the</strong> T g . The mechanisms, how CNF c<strong>on</strong>tent influences <strong>the</strong> T g s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> EP <str<strong>on</strong>g>and</str<strong>on</strong>g> SCF/EP, cannot be clarified by <strong>the</strong> present work.<br />

However, it is assumed that <strong>the</strong> c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs can influence<br />

<strong>the</strong> weighting <str<strong>on</strong>g>of</str<strong>on</strong>g> aforementi<strong>on</strong>ed competing factors. Thus,<br />

<strong>the</strong> trend <str<strong>on</strong>g>of</str<strong>on</strong>g> T g with CNF c<strong>on</strong>tent is <strong>the</strong> outcome <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> abovementi<strong>on</strong>ed<br />

competing factors.<br />

3.3. Tensile properties<br />

3.2. Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <strong>on</strong> T g<br />

Fig. 2 shows <strong>the</strong> T g <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNF/EP composites <str<strong>on</strong>g>and</str<strong>on</strong>g> SCF/CNF/EP<br />

composites as a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNF-loading. The increase <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CNF-loading first leads to a slight enhancement in T g . When<br />

<strong>the</strong> CNF-loading is increased from 0.5 to 0.75 vol.%, <strong>the</strong> T g declines.<br />

Whereas, in <strong>the</strong> whole range studied <strong>the</strong> CNFs gives<br />

rise to <strong>the</strong> T g in comparis<strong>on</strong> to pure EP. The SCF/CNF/EP composites<br />

present slightly lower T g than <strong>the</strong> CNF/EP composites.<br />

With respect to <strong>the</strong> SCF/CNF/EP composites, <strong>the</strong> CNFs slightly<br />

increase <strong>the</strong> T g .<br />

Fig. 3a shows representative stress–strain curves <str<strong>on</strong>g>of</str<strong>on</strong>g> materials<br />

studied, i.e. pure EP, CNF/EP composites, SCF/EP composites<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> SCF/CNF/EP composites. Pure EP first exhibits a c<strong>on</strong>stant<br />

stiffness z<strong>on</strong>e (stain 0–0.3%) with <strong>the</strong> initial modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> about<br />

2.71 GPa. The transiti<strong>on</strong> from linear to n<strong>on</strong>linear behavior was<br />

interpreted in terms <str<strong>on</strong>g>of</str<strong>on</strong>g> ‘‘strain-s<str<strong>on</strong>g>of</str<strong>on</strong>g>tening’’ [34,35]. The nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers<br />

do not significantly change <strong>the</strong> el<strong>on</strong>gati<strong>on</strong> rate at break<br />

while <strong>the</strong> micr<strong>on</strong> fillers significantly decrease <strong>the</strong> ultimate<br />

el<strong>on</strong>gati<strong>on</strong>. Compared with <strong>the</strong> composites filled <strong>on</strong>ly with<br />

SCFs, <strong>the</strong> SCF/CNF/EP composites show a tendency to yield.<br />

Fig. 3b shows <strong>the</strong> slopes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> local points <strong>on</strong> <strong>the</strong> curves in<br />

Fig. 3a as a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> strain, which was defined in [35] secant

CARBON 48 (2010) 4289– 4300 4293<br />

Stress (MPa)<br />

100<br />

90 a 10CF0.75NF<br />

0.75NF<br />

5<br />

b<br />

80<br />

10CF0.75NF<br />

10CF<br />

4 10CF<br />

EP<br />

70<br />

60<br />

3 0.75NF<br />

50<br />

40<br />

2 EP<br />

30<br />

1<br />

20<br />

10<br />

0<br />

0<br />

0 1 2 3 4 5 6 0 1 2 3 4 5 6 7<br />

Strain (%)<br />

Strain (%)<br />

E sm<br />

(GPa)<br />

Modulus (MPa)<br />

5500<br />

5000<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

c<br />

Neat Nanocomposites<br />

epoxy<br />

EP<br />

EP<br />

0.125NF<br />

0.25NF<br />

0.5NF<br />

0.75NF<br />

Microcomposites<br />

10SCF<br />

5CF<br />

10CF<br />

15CF<br />

10CF0.125NF<br />

Materials<br />

Multiscale<br />

composites<br />

10CF0.25NF<br />

10CF0.5NF<br />

10CF0.75NF<br />

Tensile strength (MPa)<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

d<br />

Neat<br />

epoxy<br />

EP<br />

EP<br />

0.125NF<br />

Nanocomposites<br />

0.25NF<br />

0.5NF<br />

0.75NF<br />

Microcomposites<br />

10SCF<br />

5CF<br />

10CF<br />

15CF<br />

Materials<br />

Multiscale<br />

composites<br />

10CF0.125NF<br />

10CF0.25NF<br />

10CF0.5NF<br />

10CF0.75NF<br />

Elogati<strong>on</strong> at break (%)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

e<br />

Neat<br />

epoxy<br />

EP<br />

Nanocomposites<br />

EP<br />

0.125NF<br />

0.25NF<br />

0.5NF<br />

0.75NF<br />

Microcomposites<br />

10SCF<br />

5CF<br />

10CF<br />

15CF<br />

10CF0.125NF<br />

Materials<br />

Multiscale<br />

composites<br />

10CF0.25NF<br />

10CF0.5NF<br />

10CF0.75NF<br />

Fig. 3 – (a) Stress–strain curves <str<strong>on</strong>g>of</str<strong>on</strong>g> typical materials studied, (b) secant moduli <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> materials in (a), <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> tensile<br />

characteristics: (c) E-modulus, (d) tensile strength <str<strong>on</strong>g>and</str<strong>on</strong>g> (e) el<strong>on</strong>gati<strong>on</strong> rate at break <str<strong>on</strong>g>of</str<strong>on</strong>g> EP composites. Dash lines in (c)–(e)<br />

indicating <strong>the</strong> levels <str<strong>on</strong>g>of</str<strong>on</strong>g> two reference materials, i.e. EP <str<strong>on</strong>g>and</str<strong>on</strong>g> SCFs/EP, are added for easier comparis<strong>on</strong>s.<br />

modulus E sm . The data with strain from 0% to 0.3% was not<br />

shown due to <strong>the</strong> scattering <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> data. The tendency <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> secant modulus is associated to <strong>the</strong> deb<strong>on</strong>ding <str<strong>on</strong>g>of</str<strong>on</strong>g> fillers<br />

from polymer matrix with certain pre-strains [35]. From<br />

Fig. 3b, at a low strain <strong>the</strong> secant modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNF/EP composite<br />

(0.75NF) is higher than that <str<strong>on</strong>g>of</str<strong>on</strong>g> EP. However, when <strong>the</strong><br />

strain is higher than 4.5%, <strong>the</strong> two materials have similar secant<br />

moduli. With respect to <strong>the</strong> SCF/EP composite, <strong>the</strong> secant<br />

modulus declines rapidly due to deb<strong>on</strong>ding <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs. The<br />

‘‘strain-s<str<strong>on</strong>g>of</str<strong>on</strong>g>tening’’ <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF0.75NF is enhanced compared to<br />

10CF.<br />

The E-moduli, tensile strengths <str<strong>on</strong>g>and</str<strong>on</strong>g> el<strong>on</strong>gati<strong>on</strong>s at break<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> pure EP, SCF/EP composites, CNF/EP composites, SCF/<br />

CNF/EP composites, are collated in Fig. 3c–e. The modulus <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

EP is <strong>on</strong>ly slightly increased (by less than 10%) by adding CNFs<br />

(cf. Fig. 3c). The tensile strength is moderately improved with<br />

<strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers (cf. Fig. 3d), whereas <strong>the</strong> el<strong>on</strong>gati<strong>on</strong><br />

at break is not changed significantly (cf. Fig. 3e). In

4294 CARBON 48 (2010) 4289– 4300<br />

<strong>the</strong> range studied, <strong>the</strong> c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs does not play an<br />

important role <strong>on</strong> <strong>the</strong> tensile properties <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNF/EP<br />

composites.<br />

Compared with <strong>the</strong> CNF/EP composites, <strong>the</strong> SCF/EP composites<br />

exhibit much higher E-moduli <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> modulus is linearly<br />

increased with increasing SCF c<strong>on</strong>tent (cf. Fig. 3c). With<br />

SCFs incorporati<strong>on</strong> <strong>the</strong> tensile strength decreased (Fig. 3d).<br />

The ultimate el<strong>on</strong>gati<strong>on</strong> is markedly lowered with <strong>the</strong> additi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> micr<str<strong>on</strong>g>of</str<strong>on</strong>g>illers (cf. Fig. 3e).<br />

A combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers, i.e. SCFs<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs, leads to impressive improvements in modulus<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> tensile strength (cf. Fig. 3c <str<strong>on</strong>g>and</str<strong>on</strong>g> d). The modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites increase steadily with<br />

increasing CNF-loading. For example, compared with <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al<br />

composite 10CF, incorporati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>on</strong>ly 0.75% CNFs<br />

into <strong>the</strong> matrix (10CF0.75NF) increases <strong>the</strong> modulus from<br />

3.70 to 5.03 GPa <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> tensile strength from 80.0 to<br />

91.4 MPa. It is interesting to note that with CNF c<strong>on</strong>tents higher<br />

than 0.25%, <strong>the</strong> enhancements in modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> strength<br />

achieved by <strong>the</strong> combined multiscale fillers are significantly<br />

higher than superpositi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> separate c<strong>on</strong>tributi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

two fillers, as realized in <strong>the</strong> SCF/EP <str<strong>on</strong>g>and</str<strong>on</strong>g> CNF/EP systems (cf.<br />

Fig. 3c <str<strong>on</strong>g>and</str<strong>on</strong>g> d). Therefore, <strong>the</strong> multiscale fillers play synergetic<br />

roles <strong>on</strong> stiffening <str<strong>on</strong>g>and</str<strong>on</strong>g> streng<strong>the</strong>ning <strong>the</strong> EP matrix. The el<strong>on</strong>gati<strong>on</strong><br />

at break values <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites are slightly<br />

higher than that <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composite filled solely with SCFs (cf.<br />

Fig. 3e). Fig. 4a <str<strong>on</strong>g>and</str<strong>on</strong>g> b shows <strong>the</strong> failure modes <str<strong>on</strong>g>of</str<strong>on</strong>g> EP <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

0.75NF after <strong>the</strong> tensile test. The fracture propagati<strong>on</strong> directi<strong>on</strong>s<br />

are indicated by arrows in Fig. 4. Compared with pure<br />

EP, <strong>the</strong> CNF/EP composite is less brittle. Fig. 4c <str<strong>on</strong>g>and</str<strong>on</strong>g> d shows<br />

<strong>the</strong> fracture surface <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.75NF at high magnificati<strong>on</strong>s. Similar<br />

to SCF/EP composites, pull-out, breakage <str<strong>on</strong>g>and</str<strong>on</strong>g> deb<strong>on</strong>ding<br />

(from <strong>the</strong> EP matrix) <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs are noticed in <strong>the</strong> fracture surface<br />

(cf. Fig. 4d).<br />

Regardless <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> efficient stiffening by microsized SCFs,<br />

<strong>the</strong> ductility <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> matrix is radically reduced <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites is also usually lowered. Due to<br />

<strong>the</strong> much higher modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs than that <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> matrix,<br />

stress c<strong>on</strong>centrati<strong>on</strong> can occur near <strong>the</strong> <str<strong>on</strong>g>fibers</str<strong>on</strong>g>, especially at<br />

<strong>the</strong> ends <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs. As a result, <strong>the</strong> SCF/matrix interface, especially<br />

at <strong>the</strong> z<strong>on</strong>e near SCF ends, can initiate failures. The<br />

fracture surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF <str<strong>on</strong>g>and</str<strong>on</strong>g> 10CF0.75NF are compared in<br />

Fig. 5. The matrix between <strong>the</strong> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> is very brittle in case<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al composites filled uniquely with SCFs.<br />

With respect to <strong>the</strong> SCF/CNF/EP composites, <strong>the</strong> matrix<br />

undergoes pr<strong>on</strong>ounced deformati<strong>on</strong> as a result <str<strong>on</strong>g>of</str<strong>on</strong>g> pull-out,<br />

breakage, <str<strong>on</strong>g>and</str<strong>on</strong>g> deb<strong>on</strong>ding <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs (cf. Fig. 5b).<br />

The broken tensile specimens were polished in order to<br />

study with an optic microscope <strong>the</strong> morphologies under <strong>the</strong><br />

fracture planes. The diagram associated with Fig. 6 shows<br />

<strong>the</strong> locati<strong>on</strong> from which observati<strong>on</strong>s were made. As is seen<br />

in Fig. 6a, no obvious cracking is noticed under <strong>the</strong> fracture<br />

Fig. 4 – Tensile fracture surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> EP (a) <str<strong>on</strong>g>and</str<strong>on</strong>g> EP filled with 0.75% CNFs (b)–(d).

CARBON 48 (2010) 4289– 4300 4295<br />

As a result, <strong>the</strong> E-modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs/EP is much improved with<br />

<strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> low-loading CNFs. The homogenized stress<br />

field in <strong>the</strong> matrix between SCFs enhances not <strong>on</strong>ly <strong>the</strong> E-<br />

modulus (Fig. 3c), but also <strong>the</strong> ductility (el<strong>on</strong>gati<strong>on</strong> at break)<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites. The data in Fig. 3e indicates, however,<br />

small enhancement in el<strong>on</strong>gati<strong>on</strong> at break. The reas<strong>on</strong><br />

behind is <strong>the</strong> multiple microcracking (cf. Fig. 6) which is<br />

accompanied with an inherently small change in <strong>the</strong> el<strong>on</strong>gati<strong>on</strong><br />

at break.<br />

Comparing to combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> SiO 2 nanoparticles with<br />

SCFs [27], <strong>the</strong> synergetic roles <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs with SCFs are more<br />

prominent. For example, in order to achieve comparable modulus<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> strength as 10CF0.75NF, at least adding <str<strong>on</strong>g>of</str<strong>on</strong>g> 3 vol.%<br />

nano-SiO 2 is required to <strong>the</strong> EP with <strong>the</strong> same amount <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs<br />

(i.e. 10 vol.%). The high aspect ratio <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs allows efficient<br />

stress transfer <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>reby, reduces more <str<strong>on</strong>g>effect</str<strong>on</strong>g>ively <strong>the</strong> overstress<br />

<strong>on</strong> SCFs. This is assumed to be <strong>the</strong> major reas<strong>on</strong> for <strong>the</strong><br />

synergetic acti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> SCFs <strong>on</strong> <strong>the</strong> tensile properties.<br />

3.4. Fracture toughness<br />

Fig. 5 – Tensile fracture surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF (a) <str<strong>on</strong>g>and</str<strong>on</strong>g> 10CF0.75NF<br />

(b).<br />

plane <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> SCF/EP composite (10CF). Fig. 6b <str<strong>on</strong>g>and</str<strong>on</strong>g> c shows,<br />

respectively, <strong>the</strong> micrographs <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF0.5NF <str<strong>on</strong>g>and</str<strong>on</strong>g> 10CF0.75NF.<br />

Multiple matrix cracks are observed under <strong>the</strong> fracture planes<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites (<strong>the</strong> multiple cracking becomes<br />

less sharp <strong>on</strong> <strong>the</strong> graphs due to polishment reas<strong>on</strong>). In <strong>the</strong><br />

composites filled both with SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs <strong>the</strong> stress field<br />

in <strong>the</strong> matrix between SCFs was ‘‘homogenized’’ by <strong>the</strong> presence<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers. Stress field homogenizati<strong>on</strong> means<br />

that between <strong>the</strong> SCFs now well distributed nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers (i.e.<br />

CNFs) are present in <strong>the</strong> matrix <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>y work for efficient<br />

additi<strong>on</strong>al stress transfer <str<strong>on</strong>g>and</str<strong>on</strong>g> redistributi<strong>on</strong>.<br />

The stress transfer from matrix to CNFs, followed by <strong>the</strong><br />

sub-critical CNF-related failures, is assumed to relieve <strong>the</strong><br />

overstress <strong>on</strong> SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> reduce <strong>the</strong> occurrence <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/matrix<br />

interfacial failures. The formati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> sub-critical cracks<br />

due to CNF-related failure events is supposed to be <strong>the</strong> major<br />

reas<strong>on</strong> for <strong>the</strong> enhanced ‘‘strain-s<str<strong>on</strong>g>of</str<strong>on</strong>g>tening’’ at a high strain as<br />

revealed above.<br />

For <strong>the</strong> composites filled <strong>on</strong>ly with SCFs <strong>the</strong> extra stress in<br />

<strong>the</strong> regi<strong>on</strong>s adjacent to a fiber end is associated with large local<br />

strain [7,9,35]. Compared with <strong>the</strong> composites filled <strong>on</strong>ly<br />

with SCFs, CNFs are supposed to relieve <strong>the</strong> stress c<strong>on</strong>centrati<strong>on</strong>s<br />

at <strong>the</strong> ends <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs. Therefore, <strong>the</strong> large local strain<br />

adjacent to SCF ends can be reduced. By this way <strong>the</strong> neighboring<br />

SCFs can now fulfill <strong>the</strong>ir reinforcing role accordingly.<br />

Typical load-line displacement curves measured <strong>on</strong> <strong>the</strong> CT<br />

specimens <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> materials studied are displayed in Fig. 7a.<br />

The curves dem<strong>on</strong>strate that <strong>the</strong> incorporati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> microor<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers increases both <strong>the</strong> modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness.<br />

The modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composite<br />

with <strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers are markedly higher than<br />

those <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites filled solely with <strong>the</strong> micro- or<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers.<br />

The fracture toughness, K IC , <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> critical energy release<br />

rate, G IC , <str<strong>on</strong>g>of</str<strong>on</strong>g> all materials studied are compared in Fig. 7b <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

c, respectively. CNFs at low c<strong>on</strong>centrati<strong>on</strong>s moderately increase<br />

<strong>the</strong> K IC <str<strong>on</strong>g>and</str<strong>on</strong>g> G IC <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> parent EP. With 0.125 vol.% CNFs,<br />

<strong>the</strong> fracture toughness is increased from 0.62 to 0.70 MPam 1/2 .<br />

With increasing <strong>the</strong> CNF-loading to 0.25 vol.%, <strong>the</strong> fracture<br />

toughness is enhanced to 0.74 MPam 1/2 . Never<strong>the</strong>less, fur<strong>the</strong>r<br />

increase in <strong>the</strong> CNF-loading till 0.75 vol.% does not lead to significant<br />

change in fracture toughness. The toughening <str<strong>on</strong>g>effect</str<strong>on</strong>g><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> CNF in this work is in good agreement with that realized<br />

by CNT, dispersed in a similar EP resin by a three roll calender<br />

[14]. The combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs with nano-SiO 2 also <strong>on</strong>ly leads<br />

to moderate improvement in fracture toughness (cf. Fig. 7b<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> c). By comparing <strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNF/<br />

nano-SiO 2 /EP composites to that <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites filled solely<br />

with CNFs or nano-Al 2 O 3 particles [25], no obvious synergetic<br />

roles are noticed between <strong>the</strong> two ‘‘size-similar’’<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers.<br />

The microsized SCFs significantly improve <strong>the</strong> K IC <str<strong>on</strong>g>and</str<strong>on</strong>g> G IC<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> EP (cf. Fig. 7b <str<strong>on</strong>g>and</str<strong>on</strong>g> c). The additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> 10 vol.% SCFs doubles<br />

<strong>the</strong> fracture toughness. In <strong>the</strong> studied range, <strong>the</strong> fracture<br />

toughness increases with increasing SCF c<strong>on</strong>tent. Compared<br />

to CNF, SCF increases more <strong>the</strong> fracture toughness.<br />

The K IC <str<strong>on</strong>g>and</str<strong>on</strong>g> G IC <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> SCF/CNF/EP composites are enhanced<br />

with increasing loading <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs. The composites with<br />

10 vol.% SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs with more than 0.5 vol.% possess significantly<br />

higher fracture toughness <str<strong>on</strong>g>and</str<strong>on</strong>g> critical energy release<br />

rate than <strong>the</strong> superpositi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> separate<br />

c<strong>on</strong>tributi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> two respective fillers (cf. Fig. 7b <str<strong>on</strong>g>and</str<strong>on</strong>g> c).<br />

The combined use <str<strong>on</strong>g>of</str<strong>on</strong>g> 10 vol.% SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> 0.75 vol.% CNFs increases<br />

<strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy by about 210%. By

4296 CARBON 48 (2010) 4289– 4300<br />

Fig. 6 – Optic micrographs <str<strong>on</strong>g>of</str<strong>on</strong>g> polished secti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> specimens after tensile tests, perpendicular <str<strong>on</strong>g>and</str<strong>on</strong>g> near to <strong>the</strong> fracture planes,<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF (a), 10CF0.5NF (b) <str<strong>on</strong>g>and</str<strong>on</strong>g> 10CF0.75NF (c); <strong>the</strong> diagram associated shows <strong>the</strong> locati<strong>on</strong> observed.<br />

c<strong>on</strong>trast <strong>the</strong> superpositi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> separate c<strong>on</strong>tributi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> two fillers to K IC , as, respectively, achieved in 10CF <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

0.75NF, result in a value <str<strong>on</strong>g>of</str<strong>on</strong>g> 120% (additive rule). With respect<br />

to G IC , <strong>the</strong> combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> two multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers<br />

leads to an improvement by 427%. Whereas, <strong>the</strong> superpositi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> separate c<strong>on</strong>tributi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> two fillers to G IC ,<br />

as, respectively, achieved in 10CF <str<strong>on</strong>g>and</str<strong>on</strong>g> 0.75NF, result in a value<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 232%. Based <strong>on</strong> <strong>the</strong> above results, it can be c<strong>on</strong>cluded that<br />

<strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers play synergetic roles <strong>on</strong> <strong>the</strong> linear<br />

elastic fracture mechanical parameters <str<strong>on</strong>g>of</str<strong>on</strong>g> EP.<br />

The fracture surface <str<strong>on</strong>g>of</str<strong>on</strong>g> pure EP is very smooth manifesting<br />

<strong>the</strong> brittle deformati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EP [25]. This explains why <strong>the</strong><br />

fracture toughness <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture energy <str<strong>on</strong>g>of</str<strong>on</strong>g> pure EP are low.<br />

Fig. 8a <str<strong>on</strong>g>and</str<strong>on</strong>g> b shows <strong>the</strong> fracture surface <str<strong>on</strong>g>of</str<strong>on</strong>g> a CNF/EP composite<br />

(0.75NF) with different magnificati<strong>on</strong>s. The fracture propagati<strong>on</strong><br />

directi<strong>on</strong> is downward as indicated by an arrow, which<br />

is identical to all <strong>the</strong> o<strong>the</strong>r CT fracture surfaces presented in<br />

this paper. Similar to <strong>the</strong> toughening mechanisms <str<strong>on</strong>g>of</str<strong>on</strong>g> microsized<br />

SCFs, pull-out, breakage <str<strong>on</strong>g>and</str<strong>on</strong>g> deb<strong>on</strong>ding <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs, as noticed<br />

in Fig. 8b, are assumed to be <strong>the</strong> major energy<br />

dissipati<strong>on</strong> mechanisms <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs. In additi<strong>on</strong>, some tiny<br />

CNF bundles or agglomerates cause crack pinning <str<strong>on</strong>g>effect</str<strong>on</strong>g> as<br />

evidenced by <strong>the</strong> ‘‘tail’’ formati<strong>on</strong> behind <strong>the</strong>m (cf. Fig. 8a<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> b).

CARBON 48 (2010) 4289– 4300 4297<br />

Load (mm)<br />

K IC<br />

(MPa m 1/2 )<br />

G IC<br />

(KJ/m 2 )<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

a<br />

EP<br />

0.5NF<br />

10CF<br />

10CF0.5NF<br />

0<br />

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7<br />

2.0<br />

1.6<br />

1.2<br />

0.8<br />

0.4<br />

0.0<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

b<br />

EP<br />

EP<br />

EP<br />

c<br />

EP<br />

EP<br />

EP<br />

CNF/EP<br />

0.125NF<br />

0.25NF<br />

0.125NF<br />

0.25NF<br />

CNF/EP<br />

0.5NF<br />

0.75NF<br />

0.5NF<br />

Displacement (mm)<br />

CNF/<br />

nano-SiO 2<br />

/<br />

EP<br />

0.25NF1Si<br />

0.75NF<br />

0.25NF1Si<br />

0.25NF3Si<br />

SCF/EP<br />

10CF<br />

5CF<br />

10CF<br />

15CF<br />

Materials<br />

CNF/<br />

nano-SiO 2<br />

/<br />

EP<br />

0.25NF3Si<br />

10CF<br />

5CF<br />

Materials<br />

SCF/EP<br />

10CF<br />

15CF<br />

10CF0.125NF<br />

SCF/CNF/EP<br />

10CF0.25NF<br />

SCF/CNF/EP<br />

10CF0.125NF<br />

10CF0.25NF<br />

10CF0.5NF<br />

10CF0.5NF<br />

10CF0.75NF<br />

Fig. 7 – CT load–displacement curves <str<strong>on</strong>g>of</str<strong>on</strong>g> typical materials<br />

studied (a); fracture toughness, K IC , (b) <str<strong>on</strong>g>and</str<strong>on</strong>g> critical energy<br />

release rate, G IC , (c) <str<strong>on</strong>g>of</str<strong>on</strong>g> all materials studied. Dash lines in (b)<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> (c) indicating <strong>the</strong> levels <str<strong>on</strong>g>of</str<strong>on</strong>g> two reference materials, i.e.<br />

pure EP <str<strong>on</strong>g>and</str<strong>on</strong>g> EP + 10 vol.% SCFs, are added for easier<br />

comparis<strong>on</strong>s.<br />

10CF0.75NF<br />

The crack in SCF-filled composites produces a typical zigzag<br />

pattern, as was intensively analyzed by Karger-Kocsis<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> Friedrich [7–9]. Fig. 8c shows that <strong>the</strong> EP matrix fails in<br />

a brittle manner in <strong>the</strong> SCF/EP composite (10CF). With respect<br />

to <strong>the</strong> SCF/CNF/EP composite (i.e. 10CF0.75NF), <strong>the</strong> fracture<br />

plane <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> matrix is much rougher <str<strong>on</strong>g>and</str<strong>on</strong>g> numerous microcracks<br />

appear, as is seen from Fig. 8d. Fig. 8e <str<strong>on</strong>g>and</str<strong>on</strong>g> f dem<strong>on</strong>strates<br />

<strong>the</strong> fracture surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> SCF/CNF/EP composites<br />

at high magnificati<strong>on</strong>s. Extensive deformati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> matrix<br />

is observed <strong>on</strong> <strong>the</strong> fracture surface due to <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CNFs. For <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al composites filled with SCFs, due<br />

to <strong>the</strong> stress c<strong>on</strong>centrati<strong>on</strong> occurring near fiber ends a limited<br />

plastic z<strong>on</strong>e (also termed damage z<strong>on</strong>e) develops near <strong>the</strong><br />

fracture plane as schematized in Fig. 9a. The stress transfer<br />

realized by CNFs, followed by pull-out, breakage <str<strong>on</strong>g>and</str<strong>on</strong>g> deb<strong>on</strong>ding<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs, can participate in <strong>the</strong> stress redistributi<strong>on</strong> process<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> thus can relieve <strong>the</strong> overstress <strong>on</strong> SCF ends. In<br />

additi<strong>on</strong>, CNF-related failures trigger extensive microcracks<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> matrix in <strong>the</strong> CNF–CNF ligaments <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> CNF–SCF ligaments<br />

as a result <str<strong>on</strong>g>of</str<strong>on</strong>g> shear yielding <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> matrix. As a c<strong>on</strong>sequence,<br />

a larger plastic z<strong>on</strong>e develops because o<strong>the</strong>r SCFs can<br />

now be involved in <strong>the</strong> stress transfer, as schematically illustrated<br />

in Fig. 9b. This is assumed to be <strong>the</strong> major reas<strong>on</strong> for<br />

<strong>the</strong> synergetic roles <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers. In comparis<strong>on</strong><br />

to spherical nanoparticles (i.e. nano-SiO 2 as reported<br />

in [27]), <strong>the</strong> high aspect ratio CNF is more efficient to enhance<br />

<strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF-filled EP. That is, in order to get<br />

comparable fracture toughness, a smaller fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs<br />

(than spherical nanoparticles) is required to be combined<br />

with SCFs. This can be attributed to <strong>the</strong> high aspect ratio <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CNFs which allow an efficient stress transfer <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>reby,<br />

an efficient release <str<strong>on</strong>g>of</str<strong>on</strong>g> stress c<strong>on</strong>centrati<strong>on</strong>s occurring near<br />

to <strong>the</strong> SCF ends.<br />

4. C<strong>on</strong>clusi<strong>on</strong>s<br />

The <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs (nanosized), <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> SCFs (microsized) <strong>on</strong> <strong>the</strong> tensile <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture properties<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> EP were studied. The loading <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> SCFs varied from<br />

0.125 to 0.75 vol.% <str<strong>on</strong>g>and</str<strong>on</strong>g> from 5 to 15 vol.%, respectively. The<br />

tensile properties <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> fracture mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

SCF/EP, CNF/EP, <str<strong>on</strong>g>and</str<strong>on</strong>g> SCF/CNF/EP composites were compared.<br />

It was revealed that <strong>the</strong> SCF/CNF/EP composites exhibit much<br />

higher fracture toughness <str<strong>on</strong>g>and</str<strong>on</strong>g> much better mechanical properties<br />

than <strong>the</strong> composites filled uniquely with CNFs or SCFs.<br />

The multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers improved <strong>the</strong> tensile <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture<br />

mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> EP synergistically. Based <strong>on</strong><br />

<strong>the</strong> work d<strong>on</strong>e <strong>the</strong> following c<strong>on</strong>clusi<strong>on</strong>s can be drawn:<br />

1. Filled uniquely with CNFs, <strong>the</strong> E-modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EP was<br />

slightly increased. The tensile strength <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture<br />

toughness were moderately enhanced with <strong>the</strong> additi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs. Filled with microsized SCFs, <strong>the</strong> modulus <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

<strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> EP are str<strong>on</strong>gly improved. However,<br />

<strong>the</strong> tensile strength decreased with <strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

SCFs.<br />

2. The combined use <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> SCFs (multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g><br />

fillers) leads to significant synergetic <str<strong>on</strong>g>effect</str<strong>on</strong>g>s <strong>on</strong> <strong>the</strong><br />