Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4294 CARBON 48 (2010) 4289– 4300<br />

<strong>the</strong> range studied, <strong>the</strong> c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs does not play an<br />

important role <strong>on</strong> <strong>the</strong> tensile properties <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNF/EP<br />

composites.<br />

Compared with <strong>the</strong> CNF/EP composites, <strong>the</strong> SCF/EP composites<br />

exhibit much higher E-moduli <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> modulus is linearly<br />

increased with increasing SCF c<strong>on</strong>tent (cf. Fig. 3c). With<br />

SCFs incorporati<strong>on</strong> <strong>the</strong> tensile strength decreased (Fig. 3d).<br />

The ultimate el<strong>on</strong>gati<strong>on</strong> is markedly lowered with <strong>the</strong> additi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> micr<str<strong>on</strong>g>of</str<strong>on</strong>g>illers (cf. Fig. 3e).<br />

A combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers, i.e. SCFs<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs, leads to impressive improvements in modulus<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> tensile strength (cf. Fig. 3c <str<strong>on</strong>g>and</str<strong>on</strong>g> d). The modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites increase steadily with<br />

increasing CNF-loading. For example, compared with <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al<br />

composite 10CF, incorporati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>on</strong>ly 0.75% CNFs<br />

into <strong>the</strong> matrix (10CF0.75NF) increases <strong>the</strong> modulus from<br />

3.70 to 5.03 GPa <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> tensile strength from 80.0 to<br />

91.4 MPa. It is interesting to note that with CNF c<strong>on</strong>tents higher<br />

than 0.25%, <strong>the</strong> enhancements in modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> strength<br />

achieved by <strong>the</strong> combined multiscale fillers are significantly<br />

higher than superpositi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> separate c<strong>on</strong>tributi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

two fillers, as realized in <strong>the</strong> SCF/EP <str<strong>on</strong>g>and</str<strong>on</strong>g> CNF/EP systems (cf.<br />

Fig. 3c <str<strong>on</strong>g>and</str<strong>on</strong>g> d). Therefore, <strong>the</strong> multiscale fillers play synergetic<br />

roles <strong>on</strong> stiffening <str<strong>on</strong>g>and</str<strong>on</strong>g> streng<strong>the</strong>ning <strong>the</strong> EP matrix. The el<strong>on</strong>gati<strong>on</strong><br />

at break values <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites are slightly<br />

higher than that <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composite filled solely with SCFs (cf.<br />

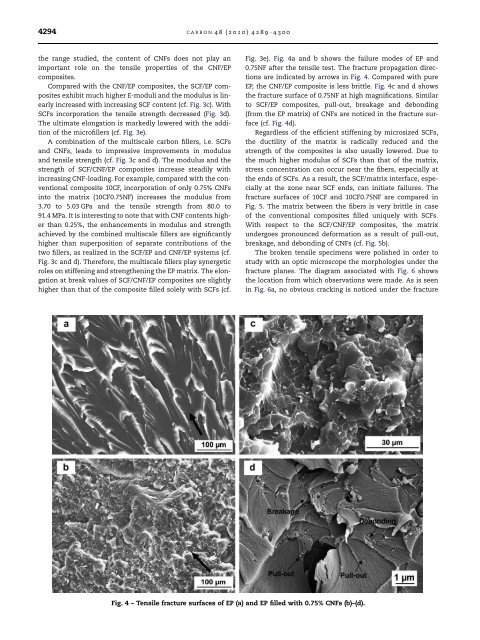

Fig. 3e). Fig. 4a <str<strong>on</strong>g>and</str<strong>on</strong>g> b shows <strong>the</strong> failure modes <str<strong>on</strong>g>of</str<strong>on</strong>g> EP <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

0.75NF after <strong>the</strong> tensile test. The fracture propagati<strong>on</strong> directi<strong>on</strong>s<br />

are indicated by arrows in Fig. 4. Compared with pure<br />

EP, <strong>the</strong> CNF/EP composite is less brittle. Fig. 4c <str<strong>on</strong>g>and</str<strong>on</strong>g> d shows<br />

<strong>the</strong> fracture surface <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.75NF at high magnificati<strong>on</strong>s. Similar<br />

to SCF/EP composites, pull-out, breakage <str<strong>on</strong>g>and</str<strong>on</strong>g> deb<strong>on</strong>ding<br />

(from <strong>the</strong> EP matrix) <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs are noticed in <strong>the</strong> fracture surface<br />

(cf. Fig. 4d).<br />

Regardless <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> efficient stiffening by microsized SCFs,<br />

<strong>the</strong> ductility <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> matrix is radically reduced <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites is also usually lowered. Due to<br />

<strong>the</strong> much higher modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs than that <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> matrix,<br />

stress c<strong>on</strong>centrati<strong>on</strong> can occur near <strong>the</strong> <str<strong>on</strong>g>fibers</str<strong>on</strong>g>, especially at<br />

<strong>the</strong> ends <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs. As a result, <strong>the</strong> SCF/matrix interface, especially<br />

at <strong>the</strong> z<strong>on</strong>e near SCF ends, can initiate failures. The<br />

fracture surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF <str<strong>on</strong>g>and</str<strong>on</strong>g> 10CF0.75NF are compared in<br />

Fig. 5. The matrix between <strong>the</strong> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> is very brittle in case<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al composites filled uniquely with SCFs.<br />

With respect to <strong>the</strong> SCF/CNF/EP composites, <strong>the</strong> matrix<br />

undergoes pr<strong>on</strong>ounced deformati<strong>on</strong> as a result <str<strong>on</strong>g>of</str<strong>on</strong>g> pull-out,<br />

breakage, <str<strong>on</strong>g>and</str<strong>on</strong>g> deb<strong>on</strong>ding <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs (cf. Fig. 5b).<br />

The broken tensile specimens were polished in order to<br />

study with an optic microscope <strong>the</strong> morphologies under <strong>the</strong><br />

fracture planes. The diagram associated with Fig. 6 shows<br />

<strong>the</strong> locati<strong>on</strong> from which observati<strong>on</strong>s were made. As is seen<br />

in Fig. 6a, no obvious cracking is noticed under <strong>the</strong> fracture<br />

Fig. 4 – Tensile fracture surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> EP (a) <str<strong>on</strong>g>and</str<strong>on</strong>g> EP filled with 0.75% CNFs (b)–(d).