Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4290 CARBON 48 (2010) 4289– 4300<br />

c<strong>on</strong>siderable attenti<strong>on</strong>. Different dispersing techniques for<br />

CNTs were documented in recent review papers [12,13].<br />

CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNTs were proven to stiffen <str<strong>on</strong>g>and</str<strong>on</strong>g> toughen EPs even<br />

at <strong>the</strong>ir extremely low c<strong>on</strong>tents [14–17]. To reinforce EP with<br />

low-loading CNFs or CNTs is <str<strong>on</strong>g>of</str<strong>on</strong>g> practical interest because<br />

<strong>the</strong> viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> resin can be kept <strong>on</strong> an acceptable level.<br />

The large aspect ratios <str<strong>on</strong>g>and</str<strong>on</strong>g> huge specific surface areas <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CNTs or CNFs guarantee an efficient matrix/filler stress<br />

transfer. Available literatures to date <str<strong>on</strong>g>of</str<strong>on</strong>g>fer evidence str<strong>on</strong>g<br />

CNT–polymer interacti<strong>on</strong>s. Efficient stress transfer between<br />

CNTs <str<strong>on</strong>g>and</str<strong>on</strong>g> polymer matrix was evidenced in [18–20] <str<strong>on</strong>g>and</str<strong>on</strong>g> simulated<br />

in [21–23]. The stress transfer efficiency between<br />

nanotube <str<strong>on</strong>g>and</str<strong>on</strong>g> matrix was estimated to be at least <strong>on</strong>e order<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> magnitude larger than in c<strong>on</strong>venti<strong>on</strong>al fiber-based composites<br />

[20].<br />

Direct comparis<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> mechanical properties between<br />

micr<str<strong>on</strong>g>of</str<strong>on</strong>g>iller- <str<strong>on</strong>g>and</str<strong>on</strong>g> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced composites are scarce.<br />

A definite answer is still lacking to <strong>the</strong> basic questi<strong>on</strong>: do<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced composites always display superior<br />

mechanical properties to micr<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced composites<br />

Microsized particles or <str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> (micro-scale in diameter<br />

or/<str<strong>on</strong>g>and</str<strong>on</strong>g> in length) were proven to <str<strong>on</strong>g>effect</str<strong>on</strong>g>ively stiffen <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

toughen EP matrix. However, <strong>the</strong>y str<strong>on</strong>gly lower <strong>the</strong> ductility<br />

due to <strong>the</strong> highly c<strong>on</strong>strained deformability <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> EP matrix<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> stress c<strong>on</strong>centrati<strong>on</strong> occurring near <strong>the</strong> microsized<br />

filler [7–9,24,25]. Obvious stress c<strong>on</strong>centrati<strong>on</strong> near <strong>the</strong> fillers<br />

can induce critical failure <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composite system. Thus, in<br />

many cases, <strong>the</strong> strength <str<strong>on</strong>g>of</str<strong>on</strong>g> EP can <strong>on</strong>ly be moderately improved<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> even decreased with <strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> microsized<br />

fillers. Unlike micr<str<strong>on</strong>g>of</str<strong>on</strong>g>illers, <strong>the</strong> much smaller size <str<strong>on</strong>g>of</str<strong>on</strong>g> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers<br />

might guarantees a good integrati<strong>on</strong> with <strong>the</strong> matrix<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> avoid obvious stress c<strong>on</strong>centrati<strong>on</strong> [25]. The incorporati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> low-loading nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers makes it possible a simultaneous<br />

improvement in E-modulus, strength <str<strong>on</strong>g>and</str<strong>on</strong>g> toughness<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> EP [15,25,26]. Despite <strong>the</strong> fact that nan<str<strong>on</strong>g>of</str<strong>on</strong>g>iller-reinforced<br />

polymer composites attracted great attenti<strong>on</strong>s in <strong>the</strong> last<br />

two decades, with low-loading nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers such as nanoparticles<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> CNTs, <strong>the</strong> mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> EP matrix can<br />

<strong>on</strong>ly be moderately improved [15,25,26]. However, our previous<br />

work [27] revealed that a combined utilizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> microsized<br />

<str<strong>on</strong>g>short</str<strong>on</strong>g> <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> (SCFs) <str<strong>on</strong>g>and</str<strong>on</strong>g> low-loading nano-silica<br />

particles leads to significant synergisms <strong>on</strong> <strong>the</strong> mechanical<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> EP. Combined utilizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> differently<br />

scaled fillers seems to be a promising route to greatly<br />

enhance <strong>the</strong> modulus, strength <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

EP simultaneously.<br />

In this work, we systematically compare <strong>the</strong> mechanical<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> fracture properties <str<strong>on</strong>g>of</str<strong>on</strong>g> three series <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy composites,<br />

i.e. c<strong>on</strong>venti<strong>on</strong>al composites reinforced with microsized SCFs<br />

(SCF/EP composites), composites reinforced with CNFs at low<br />

c<strong>on</strong>centrati<strong>on</strong>s (CNF/EP composites), <str<strong>on</strong>g>and</str<strong>on</strong>g> composites reinforced<br />

with both SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs (SCF/CNF/EP composites).<br />

The main aims <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> present work are to deepen <strong>the</strong> underst<str<strong>on</strong>g>and</str<strong>on</strong>g>ing<br />

<strong>on</strong> <strong>the</strong> structure–property relati<strong>on</strong>ship <str<strong>on</strong>g>of</str<strong>on</strong>g> EP composites<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> to investigate how <strong>the</strong> combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g>s, i.e. combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs, affects<br />

<strong>the</strong> mechanical properties <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

EP. By revealing <strong>the</strong> synergetic acti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g><br />

fillers, we propose a promising composite formulati<strong>on</strong> route<br />

for high-performance applicati<strong>on</strong>s.<br />

2. Experimental<br />

2.1. Materials <str<strong>on</strong>g>and</str<strong>on</strong>g> preparati<strong>on</strong><br />

All materials used in <strong>the</strong> present work were prepared <strong>on</strong> <strong>the</strong><br />

basis <str<strong>on</strong>g>of</str<strong>on</strong>g> a commercially available epoxy resin (DER331 by<br />

DOW) with an epoxide equivalent weight 182–192 g/equiv.<br />

Cycloaliphatic amine hardener (HY 2954; Huntsman) was used<br />

to cure <strong>the</strong> epoxy materials. Milled PAN-based <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>fibers</str<strong>on</strong>g><br />

(Tenax â A-385) were supplied by Tenax GmbH (Germany).<br />

The diameter <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> length <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> <str<strong>on</strong>g>fibers</str<strong>on</strong>g> are, respectively,<br />

7 lm <str<strong>on</strong>g>and</str<strong>on</strong>g> 40–70 lm. The SCFs were supplied without sizing<br />

treatment <str<strong>on</strong>g>and</str<strong>on</strong>g> were used as-received. CNFs (GANF1) were supplied<br />

by Grupo Antolin (Spain). The CNFs have diameters in<br />

<strong>the</strong> range <str<strong>on</strong>g>of</str<strong>on</strong>g> 20–80 nm <str<strong>on</strong>g>and</str<strong>on</strong>g> lengths larger than 30 lm. The <strong>the</strong>oretical<br />

E-modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNFs is 230 GPa <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> <strong>the</strong>oretical<br />

strength is 2.7 GPa. Fumed spherical silica nanoparticles<br />

(Aerosil R8200) with hexamethyldisilazane modificati<strong>on</strong> were<br />

supplied by Ev<strong>on</strong>ik GmbH (Germany).<br />

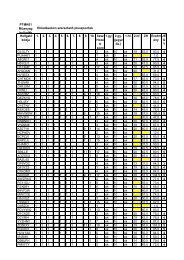

Three series <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy composites, i.e. CNF-filled EP composites<br />

(CNF/EP), composites reinforced with <strong>the</strong> combined<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers, i.e. nano-SiO 2 <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs (CNF/nano-SiO 2 /EP), <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

composites reinforced with <strong>the</strong> combined multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g>s,<br />

i.e. SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs (SCF/CNF/EP), were prepared in <strong>the</strong> present<br />

work. Pure EP <str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>venti<strong>on</strong>al composites filled uniquely<br />

with SCFs were used for references. The loading <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNFs<br />

varied from 0.125 to 0.75 vol.%. The detailed compositi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> materials are disclosed in Table 1. The volume fracti<strong>on</strong>s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> all <strong>the</strong> fillers were calculated by c<strong>on</strong>sidering <strong>the</strong>ir weights<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> (bulk) densities. For simplificati<strong>on</strong> purpose, <strong>the</strong> composite<br />

materials were referenced according to <strong>the</strong> type <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong><br />

fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> fillers as shown in <strong>the</strong> left column <str<strong>on</strong>g>of</str<strong>on</strong>g> Table 1.<br />

For example, 10CF0.5NF refers to <strong>the</strong> composite filled with<br />

10 vol.% SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> 0.5 vol.% CNFs.<br />

A master batch <str<strong>on</strong>g>of</str<strong>on</strong>g> CNF-filled epoxy resin was firstly prepared<br />

by dispersing a CNF/epoxy mixture with a three roll calender<br />

(Exakt 80 E, Exakt GmbH, Germany). Three roll calender<br />

was firstly introduced for dispersing CNTs by Gojny et al. in<br />

2004 [14] <str<strong>on</strong>g>and</str<strong>on</strong>g> received intensive attenti<strong>on</strong>s in recent years.<br />

Interestingly, this dispersi<strong>on</strong> technique is well established in<br />

<strong>the</strong> praxis – for example nano-SiO 2 is traditi<strong>on</strong>ally dispersed<br />

in dental composites by such calendering process. The small<br />

gap between <strong>the</strong> rolls <str<strong>on</strong>g>and</str<strong>on</strong>g> a mismatch in rolling speed can result<br />

in enormous shear forces, which can <str<strong>on</strong>g>effect</str<strong>on</strong>g>ively disentangle<br />

CNTs or CNFs agglomerates without significantly reducing<br />

<strong>the</strong>ir aspect ratios. The mismatch between <strong>the</strong> angular velocity<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> adjacent rolls was fixed at x 1 :x 2 :x 3 = 1:3:9. The gap distance<br />

between <strong>the</strong> rolls was adjusted to be 50 lm for<br />

beginning <str<strong>on</strong>g>and</str<strong>on</strong>g> was reduced to 25 lm for <strong>the</strong> sec<strong>on</strong>d pass <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

finally to 5 lm for <strong>the</strong> third pass. With regard to <strong>the</strong> SCF/<br />

CNF/EP composites, required amounts <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs were mixed<br />

into <strong>the</strong> diluted CNF master batch using a vacuum dissolver<br />

(Dispermat, VMA-Getzmann GmbH, Germany). The CNF/<br />

nano-SiO 2 /EP composites were prepared by mixing <str<strong>on</strong>g>and</str<strong>on</strong>g> diluting<br />

<strong>the</strong> CNF/EP master batch with <strong>the</strong> nano-silica/EP master<br />

batch formulati<strong>on</strong>. The nano-silica master batch is prepared<br />

by using <strong>the</strong> dissolver with an extremely high rotati<strong>on</strong> speed<br />

(5800 rpm). Afterwards, <strong>the</strong> compounds were blended<br />

with <strong>the</strong> curing agent HY2954 by stirring in <strong>the</strong> dissolver<br />

for 15 min. Finally <strong>the</strong> mixture was poured into release