Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

Synergetic effect of carbon nanofibers and short carbon fibers on the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CARBON 48 (2010) 4289– 4300 4295<br />

As a result, <strong>the</strong> E-modulus <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs/EP is much improved with<br />

<strong>the</strong> additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> low-loading CNFs. The homogenized stress<br />

field in <strong>the</strong> matrix between SCFs enhances not <strong>on</strong>ly <strong>the</strong> E-<br />

modulus (Fig. 3c), but also <strong>the</strong> ductility (el<strong>on</strong>gati<strong>on</strong> at break)<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites. The data in Fig. 3e indicates, however,<br />

small enhancement in el<strong>on</strong>gati<strong>on</strong> at break. The reas<strong>on</strong><br />

behind is <strong>the</strong> multiple microcracking (cf. Fig. 6) which is<br />

accompanied with an inherently small change in <strong>the</strong> el<strong>on</strong>gati<strong>on</strong><br />

at break.<br />

Comparing to combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> SiO 2 nanoparticles with<br />

SCFs [27], <strong>the</strong> synergetic roles <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs with SCFs are more<br />

prominent. For example, in order to achieve comparable modulus<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> strength as 10CF0.75NF, at least adding <str<strong>on</strong>g>of</str<strong>on</strong>g> 3 vol.%<br />

nano-SiO 2 is required to <strong>the</strong> EP with <strong>the</strong> same amount <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs<br />

(i.e. 10 vol.%). The high aspect ratio <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs allows efficient<br />

stress transfer <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>reby, reduces more <str<strong>on</strong>g>effect</str<strong>on</strong>g>ively <strong>the</strong> overstress<br />

<strong>on</strong> SCFs. This is assumed to be <strong>the</strong> major reas<strong>on</strong> for <strong>the</strong><br />

synergetic acti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs <str<strong>on</strong>g>and</str<strong>on</strong>g> SCFs <strong>on</strong> <strong>the</strong> tensile properties.<br />

3.4. Fracture toughness<br />

Fig. 5 – Tensile fracture surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF (a) <str<strong>on</strong>g>and</str<strong>on</strong>g> 10CF0.75NF<br />

(b).<br />

plane <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> SCF/EP composite (10CF). Fig. 6b <str<strong>on</strong>g>and</str<strong>on</strong>g> c shows,<br />

respectively, <strong>the</strong> micrographs <str<strong>on</strong>g>of</str<strong>on</strong>g> 10CF0.5NF <str<strong>on</strong>g>and</str<strong>on</strong>g> 10CF0.75NF.<br />

Multiple matrix cracks are observed under <strong>the</strong> fracture planes<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/CNF/EP composites (<strong>the</strong> multiple cracking becomes<br />

less sharp <strong>on</strong> <strong>the</strong> graphs due to polishment reas<strong>on</strong>). In <strong>the</strong><br />

composites filled both with SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs <strong>the</strong> stress field<br />

in <strong>the</strong> matrix between SCFs was ‘‘homogenized’’ by <strong>the</strong> presence<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers. Stress field homogenizati<strong>on</strong> means<br />

that between <strong>the</strong> SCFs now well distributed nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers (i.e.<br />

CNFs) are present in <strong>the</strong> matrix <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>y work for efficient<br />

additi<strong>on</strong>al stress transfer <str<strong>on</strong>g>and</str<strong>on</strong>g> redistributi<strong>on</strong>.<br />

The stress transfer from matrix to CNFs, followed by <strong>the</strong><br />

sub-critical CNF-related failures, is assumed to relieve <strong>the</strong><br />

overstress <strong>on</strong> SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> reduce <strong>the</strong> occurrence <str<strong>on</strong>g>of</str<strong>on</strong>g> SCF/matrix<br />

interfacial failures. The formati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> sub-critical cracks<br />

due to CNF-related failure events is supposed to be <strong>the</strong> major<br />

reas<strong>on</strong> for <strong>the</strong> enhanced ‘‘strain-s<str<strong>on</strong>g>of</str<strong>on</strong>g>tening’’ at a high strain as<br />

revealed above.<br />

For <strong>the</strong> composites filled <strong>on</strong>ly with SCFs <strong>the</strong> extra stress in<br />

<strong>the</strong> regi<strong>on</strong>s adjacent to a fiber end is associated with large local<br />

strain [7,9,35]. Compared with <strong>the</strong> composites filled <strong>on</strong>ly<br />

with SCFs, CNFs are supposed to relieve <strong>the</strong> stress c<strong>on</strong>centrati<strong>on</strong>s<br />

at <strong>the</strong> ends <str<strong>on</strong>g>of</str<strong>on</strong>g> SCFs. Therefore, <strong>the</strong> large local strain<br />

adjacent to SCF ends can be reduced. By this way <strong>the</strong> neighboring<br />

SCFs can now fulfill <strong>the</strong>ir reinforcing role accordingly.<br />

Typical load-line displacement curves measured <strong>on</strong> <strong>the</strong> CT<br />

specimens <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> materials studied are displayed in Fig. 7a.<br />

The curves dem<strong>on</strong>strate that <strong>the</strong> incorporati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> microor<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers increases both <strong>the</strong> modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness.<br />

The modulus <str<strong>on</strong>g>and</str<strong>on</strong>g> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composite<br />

with <strong>the</strong> multiscale <str<strong>on</strong>g>carb<strong>on</strong></str<strong>on</strong>g> fillers are markedly higher than<br />

those <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites filled solely with <strong>the</strong> micro- or<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers.<br />

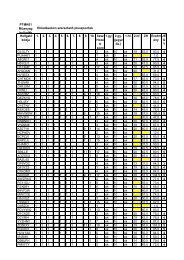

The fracture toughness, K IC , <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> critical energy release<br />

rate, G IC , <str<strong>on</strong>g>of</str<strong>on</strong>g> all materials studied are compared in Fig. 7b <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

c, respectively. CNFs at low c<strong>on</strong>centrati<strong>on</strong>s moderately increase<br />

<strong>the</strong> K IC <str<strong>on</strong>g>and</str<strong>on</strong>g> G IC <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> parent EP. With 0.125 vol.% CNFs,<br />

<strong>the</strong> fracture toughness is increased from 0.62 to 0.70 MPam 1/2 .<br />

With increasing <strong>the</strong> CNF-loading to 0.25 vol.%, <strong>the</strong> fracture<br />

toughness is enhanced to 0.74 MPam 1/2 . Never<strong>the</strong>less, fur<strong>the</strong>r<br />

increase in <strong>the</strong> CNF-loading till 0.75 vol.% does not lead to significant<br />

change in fracture toughness. The toughening <str<strong>on</strong>g>effect</str<strong>on</strong>g><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> CNF in this work is in good agreement with that realized<br />

by CNT, dispersed in a similar EP resin by a three roll calender<br />

[14]. The combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs with nano-SiO 2 also <strong>on</strong>ly leads<br />

to moderate improvement in fracture toughness (cf. Fig. 7b<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> c). By comparing <strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> CNF/<br />

nano-SiO 2 /EP composites to that <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites filled solely<br />

with CNFs or nano-Al 2 O 3 particles [25], no obvious synergetic<br />

roles are noticed between <strong>the</strong> two ‘‘size-similar’’<br />

nan<str<strong>on</strong>g>of</str<strong>on</strong>g>illers.<br />

The microsized SCFs significantly improve <strong>the</strong> K IC <str<strong>on</strong>g>and</str<strong>on</strong>g> G IC<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> EP (cf. Fig. 7b <str<strong>on</strong>g>and</str<strong>on</strong>g> c). The additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> 10 vol.% SCFs doubles<br />

<strong>the</strong> fracture toughness. In <strong>the</strong> studied range, <strong>the</strong> fracture<br />

toughness increases with increasing SCF c<strong>on</strong>tent. Compared<br />

to CNF, SCF increases more <strong>the</strong> fracture toughness.<br />

The K IC <str<strong>on</strong>g>and</str<strong>on</strong>g> G IC <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> SCF/CNF/EP composites are enhanced<br />

with increasing loading <str<strong>on</strong>g>of</str<strong>on</strong>g> CNFs. The composites with<br />

10 vol.% SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> CNFs with more than 0.5 vol.% possess significantly<br />

higher fracture toughness <str<strong>on</strong>g>and</str<strong>on</strong>g> critical energy release<br />

rate than <strong>the</strong> superpositi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> separate<br />

c<strong>on</strong>tributi<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> two respective fillers (cf. Fig. 7b <str<strong>on</strong>g>and</str<strong>on</strong>g> c).<br />

The combined use <str<strong>on</strong>g>of</str<strong>on</strong>g> 10 vol.% SCFs <str<strong>on</strong>g>and</str<strong>on</strong>g> 0.75 vol.% CNFs increases<br />

<strong>the</strong> fracture toughness <str<strong>on</strong>g>of</str<strong>on</strong>g> epoxy by about 210%. By