You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNICAL<br />

up to 15,000 PSI (1000 Bar)<br />

CONNECTION TYPES<br />

Several connection types are used at pressures of 15,000 psi (1000 bar) and<br />

below. The purpose of this section is to allow users to identify the connections<br />

needed and provide information on the features and proper use of each.<br />

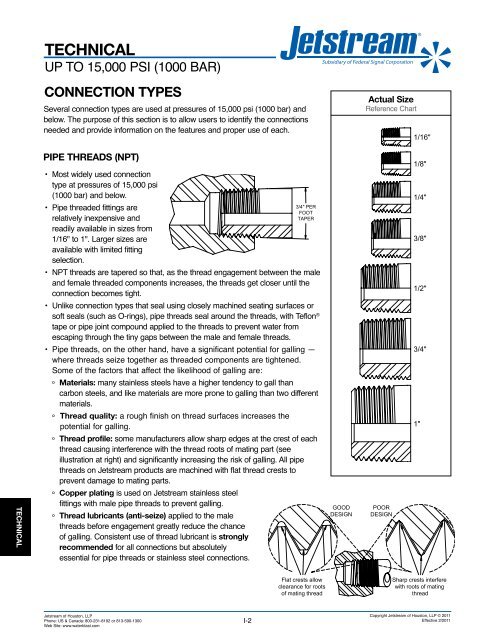

Actual Size<br />

Reference Chart<br />

Pipe threads (npt)<br />

TECHNICAL<br />

• Most widely used connection<br />

type at pressures of 15,000 psi<br />

(1000 bar) and below.<br />

• Pipe threaded fittings are<br />

relatively inexpensive and<br />

readily available in sizes from<br />

1/16" to 1". Larger sizes are<br />

available with limited fitting<br />

selection.<br />

• NPT threads are tapered so that, as the thread engagement between the male<br />

and female threaded components increases, the threads get closer until the<br />

connection becomes tight.<br />

• Unlike connection types that seal using closely machined seating surfaces or<br />

soft seals (such as O-rings), pipe threads seal around the threads, with Teflon ®<br />

tape or pipe joint compound applied to the threads to prevent water from<br />

escaping through the tiny gaps between the male and female threads.<br />

• Pipe threads, on the other hand, have a significant potential for galling —<br />

where threads seize together as threaded components are tightened.<br />

Some of the factors that affect the likelihood of galling are:<br />

° Materials: many stainless steels have a higher tendency to gall than<br />

carbon steels, and like materials are more prone to galling than two different<br />

materials.<br />

° Thread quality: a rough finish on thread surfaces increases the<br />

potential for galling.<br />

° Thread profile: some manufacturers allow sharp edges at the crest of each<br />

thread causing interference with the thread roots of mating part (see<br />

illustration at right) and significantly increasing the risk of galling. All pipe<br />

threads on <strong>Jetstream</strong> products are machined with flat thread crests to<br />

prevent damage to mating parts.<br />

° Copper plating is used on <strong>Jetstream</strong> stainless steel<br />

fittings with male pipe threads to prevent galling.<br />

° Thread lubricants (anti-seize) applied to the male<br />

threads before engagement greatly reduce the chance<br />

of galling. Consistent use of thread lubricant is strongly<br />

recommended for all connections but absolutely<br />

essential for pipe threads or stainless steel connections.<br />

<strong>Jetstream</strong> of Houston, LLP<br />

Phone: US & Canada: 800-231-8192 or 813-590-1300<br />

Web Site: www.waterblast.com<br />

I-2<br />

Copyright <strong>Jetstream</strong> of Houston, LLP © 2011<br />

Effective 2/2011