Improved Fischer-Tropsch Economics Enabled by Microchannel ...

Improved Fischer-Tropsch Economics Enabled by Microchannel ...

Improved Fischer-Tropsch Economics Enabled by Microchannel ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

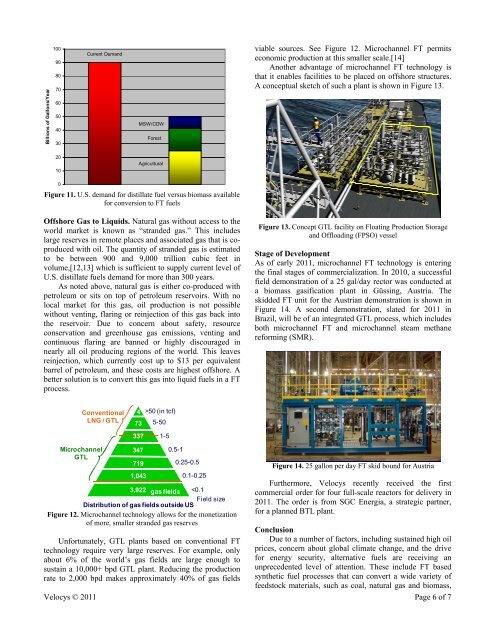

Billions of Gallons/Year<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

Current Demand<br />

MSW/CDW<br />

Forest<br />

viable sources. See Figure 12. <strong>Microchannel</strong> FT permits<br />

economic production at this smaller scale.[14]<br />

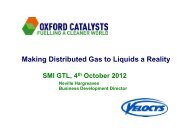

Another advantage of microchannel FT technology is<br />

that it enables facilities to be placed on offshore structures.<br />

A conceptual sketch of such a plant is shown in Figure 13.<br />

20<br />

10<br />

Agricultural<br />

0<br />

Figure 11. U.S. demand for distillate fuel versus biomass available<br />

for conversion to FT fuels<br />

Offshore Gas to Liquids. Natural gas without access to the<br />

world market is known as “stranded gas.” This includes<br />

large reserves in remote places and associated gas that is coproduced<br />

with oil. The quantity of stranded gas is estimated<br />

to be between 900 and 9,000 trillion cubic feet in<br />

volume,[12,13] which is sufficient to supply current level of<br />

U.S. distillate fuels demand for more than 300 years.<br />

As noted above, natural gas is either co-produced with<br />

petroleum or sits on top of petroleum reservoirs. With no<br />

local market for this gas, oil production is not possible<br />

without venting, flaring or reinjection of this gas back into<br />

the reservoir. Due to concern about safety, resource<br />

conservation and greenhouse gas emissions, venting and<br />

continuous flaring are banned or highly discouraged in<br />

nearly all oil producing regions of the world. This leaves<br />

reinjection, which currently cost up to $13 per equivalent<br />

barrel of petroleum, and these costs are highest offshore. A<br />

better solution is to convert this gas into liquid fuels in a FT<br />

process.<br />

Figure 13. Concept GTL facility on Floating Production Storage<br />

and Offloading (FPSO) vessel<br />

Stage of Development<br />

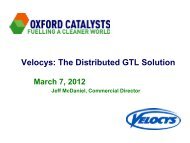

As of early 2011, microchannel FT technology is entering<br />

the final stages of commercialization. In 2010, a successful<br />

field demonstration of a 25 gal/day rector was conducted at<br />

a biomass gasification plant in Güssing, Austria. The<br />

skidded FT unit for the Austrian demonstration is shown in<br />

Figure 14. A second demonstration, slated for 2011 in<br />

Brazil, will be of an integrated GTL process, which includes<br />

both microchannel FT and microchannel steam methane<br />

reforming (SMR).<br />

Conventional<br />

LNG / GTL<br />

4 >50 (in tcf)<br />

73 5-50<br />

337 1-5<br />

<strong>Microchannel</strong><br />

GTL<br />

347<br />

719<br />

1,043<br />

0.5-1<br />

0.25-0.5<br />

0.1-0.25<br />

3,922 gas fields