Souvenir Containing Abstracts - YMCA University of Science ...

Souvenir Containing Abstracts - YMCA University of Science ...

Souvenir Containing Abstracts - YMCA University of Science ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Join Today!<br />

To Enjoy the Benefits Tomorrow!<br />

Learn Catia/Ug/Solidworks/Proe/Autocad<br />

ROBOTICS / MECHATRONICS KITS<br />

ARE ALSO AVAILABLE FOR<br />

ENGINEERING STUDENTS<br />

Contact 9654702637/9818047027

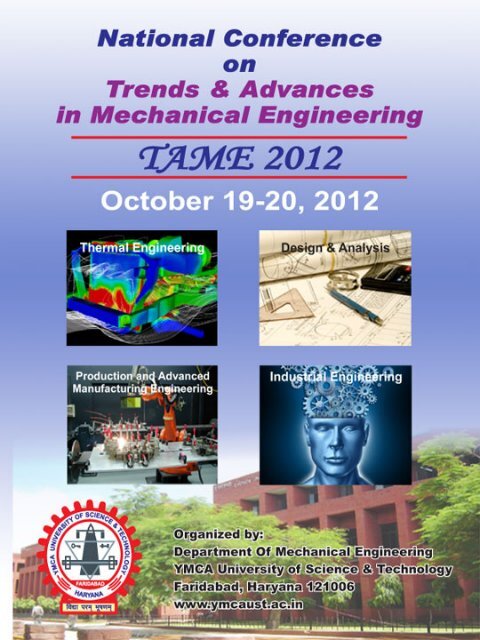

NATIONAL CONFERENCE<br />

ON<br />

TRENDS AND ADVANCES IN MECHANICAL ENGINEERING<br />

TAME 2012<br />

October 19-20, 2012<br />

Chief Patron<br />

H.E. Sh. Jagannath Pahadia Ji<br />

Governor <strong>of</strong> Haryana<br />

Patron<br />

Lt. Gen. (Retd.) K. S. Yadava<br />

PVSM, AVSM,SM,VSM<br />

Vice Chancellor, <strong>YMCA</strong> UST<br />

Co-Patron<br />

Mrs Shimla<br />

Registrar, <strong>YMCA</strong> UST<br />

Conference Chair<br />

Dr. Sandeep Grover<br />

Chairman & Pr<strong>of</strong>essor<br />

Mech. Engg.<br />

Convener<br />

Dr. Raj Kumar<br />

Pr<strong>of</strong>essor<br />

Mech. Engg<br />

Co-Convener<br />

Dr. Navdeep Malhotra<br />

Pr<strong>of</strong>essor<br />

Mech. Engg<br />

Organizing Secretary<br />

Dr. Vikram Singh<br />

Associate Pr<strong>of</strong>essor<br />

Mech. Engg<br />

Editors<br />

Pr<strong>of</strong>. Navdeep Malhotra<br />

Dr. Rajeev Saha<br />

Department <strong>of</strong> Mechanical Engineering,<br />

<strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology,<br />

Faridabad, Haryana. 121006<br />

www.ymcaust.ac.in

National Conference on Trends and Advances in Mechanical Engineering<br />

PREFACE<br />

TAME-2012<br />

OCT 19-20, 2012<br />

New developments bring change that usher the mankind to a better future. Technological innovations<br />

have reached a stage that incorporates the integration <strong>of</strong> different fields for the holistic developments.<br />

With innumerable specializations in the field <strong>of</strong> mechanical engineering, it becomes obligatory for<br />

pr<strong>of</strong>essionals and researchers to confer and transform their thoughts into more meaningful<br />

developments.<br />

To comply with such dynamic requirements, national conference on Trends and Advances in<br />

Mechanical Engineering (TAME 2012) is being organised on October 19-20, 2012. The conference is<br />

aimed at providing a common platform to researchers, industry personnel, academicians, students and<br />

participating pr<strong>of</strong>essionals to interact and discuss about the trends and advances made in the various<br />

areas <strong>of</strong> Mechanical Engineering.<br />

Conference Themes: Suggested themes include, but are not restricted to:<br />

Theme I: Thermal Engineering<br />

Heat Transfer, Fluid Dynamics, Alternative Refrigerants, Thermal Systems, Turbo Machinery,<br />

Renewable Energy, Energy conservation, Refrigeration & A/C<br />

Theme II: Design and Analysis<br />

CAD/CAE, Robotics, Mechatronics, Vibration Analysis, Condition Monitoring, Machine Design and<br />

Dynamics, Mechanisms, Tribology, Fracture Mechanics.<br />

Theme III: Production and Advanced Manufacturing Engineering<br />

CIM, E- Manufacturing, Group Technology, Rapid Prototyping and Reverse Engineering, Mechanical<br />

Metallurgy, Welding, Non Conventional Machining, Material testing, Smart Materials, Nano<br />

Materials, Composite Materials, Plastics, Fibre Reinforced Plastics, Flexible Manufacturing Systems.<br />

Theme IV: Industrial Engineering<br />

TQM, JIT, Reliability, Waste Management, Engineering, Concurrent Engineering, Operation<br />

Research, Ergonomics, SCM, ERP, Factories <strong>of</strong> Future, Production, Role <strong>of</strong> Computers in Mechanical<br />

Engineering, Planning and Control.<br />

TAME 2012 is being organized by Department <strong>of</strong> Mechanical Engineering with ever encouraging<br />

response from the management and whole hearted support from different quarters in the <strong>University</strong> and<br />

outside. The teamwork <strong>of</strong> students and faculty equally would lead to the success <strong>of</strong> conference.<br />

i<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

NATIONAL ADVISORY COMMITTEE<br />

TAME-2012<br />

OCT 19-20, 2012<br />

Pr<strong>of</strong>. B. John. Davies, Editor in chief, IJAMT, Springer<br />

Pr<strong>of</strong>. Pradeep Kumar, IIT, Roorkee<br />

Pr<strong>of</strong>. S. C Kaushik, IIT, Delhi<br />

Pr<strong>of</strong>. O P Gandhi, IIT, Delhi<br />

Pr<strong>of</strong>. Narendra K. Sharma, IIT Kanpur<br />

Pr<strong>of</strong>. Sunil Pandey, Director, SLIET, Longowal<br />

Pr<strong>of</strong>. S.K Sharma, NIT, Kurkshetra<br />

Pr<strong>of</strong>. H.K Rawal, NIT, Surat<br />

Pr<strong>of</strong>. M D Singh, MNIT, Allahabad<br />

Pr<strong>of</strong>. S. K. Mohapatra, TU, Patiala<br />

Pr<strong>of</strong>. I A Khan, JMI, New Delhi<br />

Pr<strong>of</strong>. Hari Singh, NIT, Kurukshetra<br />

Pr<strong>of</strong>. Keyur Desai, NIT, Surat<br />

Pr<strong>of</strong>. V.P Aggarwal, TU, Patiala<br />

Mr. Raj Bhatia, MD Bony polymers, FBD, President Alumni Association <strong>YMCA</strong> (MOB)<br />

Er. Ravikiran N K, Scientist, ISRO, Bangalore<br />

Dr. B R Ananda Murthy, ISRO, Bangalore<br />

Pr<strong>of</strong>. Dharmender Kumar, GJU, Hissar<br />

Dr. Sona Rani, UIET, K.U., Kurukshetra<br />

Mr. R. M. Mishra, CIPET, Lucknow<br />

Mr. Naveen Sood, MD, VEEGEE Industries, Faridabad<br />

Mr. Sukhdev Singh, Hind Hydraulics, Faridabad<br />

Mr. M.R. Salan, CIHT, Jalandhar<br />

Dr. U. Chandersekhar, Executive Convener RPSI, Bangalore<br />

Dr. A. Selvam, Executive Secretary, FRP Institute, Chennai<br />

Er. Manvinder Singh, MD, Bhiwadi Cylinders<br />

Mr. Praveen Khanna – Promoter <strong>of</strong> Suvidha Engineers<br />

Mr. Ramneek Bawa – Director & CEO <strong>of</strong> DS Construction Ltd.<br />

Mr Ashok Madan – GM (Projects) at HCL Technologies<br />

INTERNAL ADVISORY COMMITTEE<br />

Dr. A. K. Sharma, Pr<strong>of</strong>. and Dean, Engg & Tech.<br />

Dr. Sandeep Grover, Pr<strong>of</strong>. and Chairman, Mech Engg.<br />

Dr. Tilak Raj, Pr<strong>of</strong>essor (Mech. Engg.)<br />

Dr. M. L. Aggarwal, Pr<strong>of</strong>essor (Mech. Engg.)<br />

Dr. Raj Kumar, Pr<strong>of</strong>essor (Mech. Engg.)<br />

Dr. Navdeep Malhotra, Pr<strong>of</strong>essor (Mech. Engg.)<br />

ii<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

ABOUT THE UNIVERSITY<br />

TAME-2012<br />

OCT 19-20, 2012<br />

The <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad, erstwhile, '<strong>YMCA</strong><br />

Institute <strong>of</strong> Engineering, the Institute has been granted <strong>University</strong> status since 1st<br />

December, 2009 (Established by Haryana State Legislative Act No. 21 <strong>of</strong> 2009 and<br />

recognized by UGC Act 1956 u/s 22 to Confer Degrees). The <strong>University</strong> has recently<br />

been accorded 12B status by <strong>University</strong> Grant Commission (UGC).<br />

The <strong>University</strong> is situated right on the National Highway No.2 (Mathura Road) 32 Kms.<br />

from the National Capital New Delhi on way to the Taj Mahal, Agra. The <strong>University</strong> has<br />

its own Campus on a plot area <strong>of</strong> 20 acres. It is located in the growing and sprawling<br />

Faridabad Ballabgarh Industrial Complex <strong>of</strong> Haryana. The <strong>University</strong> is well connected<br />

with rail transport from New Delhi.<br />

<strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> & Technology is a pioneer Institution that has been<br />

providing qualified, trained manpower to the industry since its inception. It has produced<br />

large number <strong>of</strong> entrepreneurs who are actively contributing to the socio – economical<br />

development <strong>of</strong> the country in general and the state <strong>of</strong> Haryana in particular. The<br />

<strong>University</strong> has contributed immensely in the field <strong>of</strong> technical education and plays an<br />

important role in creating highly skilled technical manpower which is employable in an<br />

equally competitive market.<br />

The <strong>University</strong> <strong>of</strong>fers 4-year B.Tech. degree course in six disciplines i.e. Mechanical,<br />

Information Technology, Computers, Electronics - Communication, Electrical and<br />

Electronics-Instrumentation & Control.<br />

The <strong>University</strong> also <strong>of</strong>fers Post Graduate courses viz. M.Tech. in Mechanical Engg /<br />

Electrical Engg / Electronics Engg / Computers/ Networking / Information Technology,<br />

MBA, MCA, MSc, and Ph.D. in all streams.<br />

iii<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

ABOUT THE DEPARTMENT<br />

TAME-2012<br />

OCT 19-20, 2012<br />

The Department <strong>of</strong> Mechanical Engineering <strong>of</strong>fers courses at UG and PG level. At UG<br />

level, B.Tech. course in Mech. Engg., started in 1997 has an intake <strong>of</strong> 120 students.<br />

M.Tech. programme in Mech. Engg. with specialization in Manufacturing Technology<br />

and Automation was started from the academic year 2003-04 and has an intake <strong>of</strong> 18<br />

students. The <strong>University</strong> has started PhD Course since 2010 and 53 students have<br />

registered themselves for the PhD programme in the department.<br />

The Department <strong>of</strong> Mechanical Engineering has a distinguished record in both<br />

teaching and research. The department was shifted to the new building in January 2009<br />

with modern facilities and a dedicated technical and <strong>of</strong>fice staff to support the academic<br />

programs and research.<br />

The department is actively engaged in research work in the broad area <strong>of</strong> Design<br />

<strong>of</strong> Mechanical Equipment, Design & Manufacturing, Thermal, Energy conservation,<br />

TQM, Product and Service Quality, Computer Integrated Manufacturing, E-<br />

Manufacturing, Computer Aided Engineering, Just in Time, etc.<br />

The departmental facilities include 16 labs, 3 workshops (Machine Tools,<br />

Refrigeration & Air conditioning, Fabrication & Sheet Metal Technology), 8 lecture<br />

halls, 1 conference room and 1 seminar hall with internet connectivity <strong>of</strong> 1Mbps.<br />

The department has highly qualified and experienced faculty including 5<br />

pr<strong>of</strong>essors, 9 Associate pr<strong>of</strong>essors and 16 Assistant Pr<strong>of</strong>essors. 15 <strong>of</strong> the faculty<br />

members are PhD holders with average experience <strong>of</strong> faculty members being<br />

approximately 13years.<br />

The department also sponsors its faculty for short term courses and conferences on<br />

regular basis. During last 3 years, faculty members have published approximately 200<br />

papers in various national and international journals and conferences <strong>of</strong> repute.<br />

The department is also highly active in co-curricular and technical activities. Two<br />

<strong>of</strong> its club namely MechNext Club and SAE India <strong>YMCA</strong> Collegiate Club are actively<br />

engaged in practising latest developments in concerned engineering field.<br />

Dr. Sandeep Grover<br />

Pr<strong>of</strong>essor & Chairman<br />

Department <strong>of</strong> Mechanical Engg.<br />

iv<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

DEPARTMENT OF MECHANICAL ENGINEERING<br />

S. No. Name Designation Qualification<br />

1 Dr. Sandeep Grover Pr<strong>of</strong>essor & Chairman PhD<br />

2 Dr. M.L. Aggarwal Pr<strong>of</strong>essor PhD<br />

3 Dr. Tilak Raj Pr<strong>of</strong>essor PhD<br />

4 Dr. Raj Kumar Pr<strong>of</strong>essor PhD<br />

5 Dr. Navdeep Malhotra Pr<strong>of</strong>essor PhD<br />

6 Mr. Naresh Yadav Workshop Supdt. M.E.<br />

7 Dr. Vikram Singh Associate Pr<strong>of</strong>. PhD<br />

8 Dr. Arvind Gupta Associate Pr<strong>of</strong>. PhD<br />

9 Mr. Hari Om Associate Pr<strong>of</strong>. M.E.<br />

10 Dr. Vikas Turk Associate Pr<strong>of</strong>. PhD<br />

11 Mr. Lakhwinder Singh Associate Pr<strong>of</strong>. M.E.<br />

12 Dr. Niranjan Mangla Associate Pr<strong>of</strong>. PhD<br />

13 Dr. Sanjeev Kumar Associate Pr<strong>of</strong>. PhD<br />

14 Mr. Surinder Raina Associate Pr<strong>of</strong>. M.Tech.<br />

15 Mr. Mukesh Gupta Asst. Pr<strong>of</strong>. M.Tech.<br />

16 Dr. Vasdev Malhotra Asst. Pr<strong>of</strong>. PhD<br />

17 Ms. Sandhya Dixit Asst. Pr<strong>of</strong>. M.Tech.<br />

18 Dr. Sanjeev Goyal Asst. Pr<strong>of</strong>. PhD<br />

19 Dr. Rajeev Saha Asst. Pr<strong>of</strong>. PhD<br />

20 Dr. Kamal Jangra Asst. Pr<strong>of</strong>. PhD<br />

21 Mr. Bhaskar Nagar Asst. Pr<strong>of</strong>. M.E.<br />

22 Mr. Nikhil Dev Asst. Pr<strong>of</strong>. M.E.<br />

23 Mr. Rajesh Kumar Attri Asst. Pr<strong>of</strong>. M.Tech.<br />

24 Mr. Krishan Verma Asst. Pr<strong>of</strong>. M.Tech.<br />

25 Mr. Mahesh Chand Asst. Pr<strong>of</strong>. M.E.<br />

26 Mr. Om Prakash Mishra Asst. Pr<strong>of</strong>. M.Tech.<br />

27 Mr. Surender Singh Asst. Pr<strong>of</strong> M.Tech.<br />

28 Mr. Bhupender Singh Asst. Pr<strong>of</strong>. M.Tech.<br />

29 Ms. Shefali Trivedi Asst. Pr<strong>of</strong>. M.Tech.<br />

30 Mr. Sanjay Kumar Asst. Pr<strong>of</strong> M.E.<br />

31 Mr. Manmohan Kakkar Technical Support Staff M.Tech.<br />

32 Mr. Dinesh Arora Support Staff<br />

v<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad<br />

TAME-2012<br />

OCT 19-20, 2012

MESSAGE<br />

It gives me immense pleasure to note that <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> & Technology,<br />

Faridabad is organizing a National Conference on "Trends and advances in<br />

Mechanical Engineering (Tame 2006)" during October 19th - 20th 2012.<br />

The Conference aims at providing a common platform to researchers, industry<br />

personnel, academicians, pr<strong>of</strong>essionals and other participants to interact and discuss<br />

the latest trends and advances in different fields in Mechanical Engineering, I am sure<br />

that the Conference will enthuse and inspire students and members <strong>of</strong> teaching faculty<br />

to actively participate and gain new insight in this field. I hope the outcomes and<br />

recommendations <strong>of</strong> this Conference will be utilized for promotion <strong>of</strong> research and<br />

development in the relevant field in market and industry and also by the academicians.<br />

I wish the organizers all success for the Conference.<br />

Sh. Dhanpat Singh, IAS,<br />

Principal Secretary to Govt. <strong>of</strong> Haryana,<br />

Technical Education Department,<br />

Room No. 606, 6th Floor,<br />

New Haryana Civil Secretariat Building,<br />

Sector- 17, Chandigarh.

MESSAGE<br />

I am pleased to learn that the Department <strong>of</strong> Mechanical Engineering <strong>of</strong> our <strong>University</strong><br />

is organizing a National Conference on "Trends and Advances in Mechanical<br />

Engineering (TAME 2012)" during October 19th - 20th, 2012.<br />

In recent years the advancement in Information Technology and computer sciences<br />

has brought a sea change in Mechanical Engineering. The integration <strong>of</strong> different<br />

engineering branches has resulted in tremendous technological advances in<br />

Mechanical Engineering. This is a proper time for Indian researchers to meet their<br />

counterparts and discuss various aspects <strong>of</strong> resources and utilization for increased<br />

productivity.<br />

I trust that this conference would also inspire the participants to develop and introduce<br />

new research activities for the future corporate world. These researches will also be <strong>of</strong><br />

great and incredible value to the humankind.<br />

My warm felicitations to the organizers, to all the participating delegates and best<br />

wishes for success <strong>of</strong> the National Conference, TAME 2012.<br />

Lt. Gen.(Retd.) K.S. Yadava<br />

PVSM, AVSM, SM, VSM<br />

Vice-Chancellor<br />

<strong>YMCA</strong>UST, Faridabad

MESSAGE<br />

It is a matter <strong>of</strong> great and elated feeling that a National Conference on "Trends &<br />

Advances in Mechanical Engineering" is being organized by the Department <strong>of</strong><br />

Mechanical Engineering <strong>of</strong> <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> & Technology, Faridabad from<br />

19th & 20th October, 2012. It is a great stride for the department in the direction <strong>of</strong><br />

achieving excellence in the field <strong>of</strong> mechanical engineering and indeed a proud<br />

moment for all <strong>of</strong> us in the <strong>University</strong>.<br />

Such Conferences provide an opportunity to the scholars and pr<strong>of</strong>essionals who have<br />

propensity towards research, to explore and share the research findings with the<br />

academic fraternity. The organizers have put their best efforts in going in a very<br />

systematic way and out reaching to the researchers countrywide. The result has been<br />

excellent.<br />

More than 150 research papers have been received from far and wide, exhibiting keen<br />

interest in sharing the new trends and advances in the area <strong>of</strong> mechanical<br />

engineering.<br />

The endeavour to bring out the selected papers in the form <strong>of</strong> a souvenir is really<br />

commendable.<br />

I, on behalf <strong>of</strong> the <strong>University</strong> administration and on my own behalf extend a very warm<br />

welcome to all the participants as our esteemed guests to the <strong>University</strong> Campus.<br />

I extend my whole hearted support and best wishes to the organizing Department, coordinators<br />

and participants in their efforts.<br />

I trust that the Conference is going to be a resounding success and provide a vibrant<br />

platform for learning and sharing <strong>of</strong> latest trends in this important area as well as<br />

strengthen the linkage between the academia and industry.<br />

My best wishes<br />

Mrs. Shimla<br />

Registrar<br />

<strong>YMCA</strong>UST, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

TAME-2012<br />

OCT 19-20, 2012<br />

Sr. Paper Title Authors Page<br />

No<br />

No<br />

THEME I – THERMAL ENGINEERING<br />

01 Study <strong>of</strong> Solar Water Heaters Based on Exergy Analysis Dilip Johari 1<br />

Ashok Yadav<br />

Ravi Verma<br />

02 Green Vehicle: Pollution Control Through Catalytic Converter Pankaj Agarwal 1<br />

and Performance Analysis <strong>of</strong> the SAME<br />

Manish Jain<br />

03 Performance Investigation <strong>of</strong> a Compact Tri-Generation System Dr. Raj Kumar 2<br />

Based on Renewable Energy Power Plant Exhaust Gas Waste Heat Anil Kumar<br />

Utilization<br />

04 Decomposition <strong>of</strong> Energy Consumption In India: A Discussion in Ponnala Vimal Mosahari 2<br />

Context to Index Decomposition Analysis (IDA)<br />

D. Ganeshwar Rao<br />

Rajeev Satsangi<br />

05 Thermo-Economic Optimization <strong>of</strong> Work Consuming Devices Rajesh Arora 2<br />

06 Clean Coal Technologies for Power Generation in India A near Siddhartha 3<br />

Zero emission plant approach<br />

Dr. Navdeep Malhotra<br />

07 Limitations <strong>of</strong> Energy Utilization <strong>of</strong> Solid Waste due to it's Poor Desh Deepak Johri 3<br />

Quality<br />

Manish Gaur<br />

Sachin Rathod<br />

08 A Feasibility Study on Waste Heat Recovery in An IC Engine S.N.Srinivasa Dhaya Prasad 4<br />

Using Electro Turbo Generation<br />

N.Parameshwari<br />

09 Reducing Battery Discharging Rate Using Photo-Electric Effect Jeet Kumar Gaur 4<br />

Abhinav Mittal<br />

Bikash Chandra Maurya<br />

10 Thermodynamic Modelling <strong>of</strong> Ground Source Heat Pump for Rajeev Satsangi 4<br />

Space Heating<br />

Ashok Yadav<br />

Ponnala Vimal Mosahari<br />

11 Alternatives to R134 A (CF3CH2F) Refrigerant- A Review Gaurav 5<br />

Dr. Raj Kumar<br />

12 A Review <strong>of</strong> Combined Cycle Power Plant Thermodynamic Cycles Nikhil Dev 5<br />

Samsher<br />

S. S. Kachhwaha<br />

Rajesh Attri<br />

13 A Review on Parabolic Trough Type Solar Collectors: Innovation, Devander Kumar Lamba 5<br />

Applications and Thermal Energy Storage<br />

14 Study <strong>of</strong> Flow and Heat Transfer in Plate Fin Heat Exchanger at Pardeep Yadav 6<br />

Varying Reynold's Number<br />

Pawan Kumar<br />

15 Performance Improvement <strong>of</strong> a Control Valve Using Computational K Thanigavelmurugan 6<br />

Fluid Dynamics<br />

N.V. Mahalakshmi<br />

S. Mohan Das<br />

D. Venkates<br />

16 CFD Application in Passive Building Designs Ali A. F. Al-Hamadani 7<br />

S. K. Shukla<br />

Alok K.Dwivedi<br />

17 Energy Audit <strong>of</strong> 250 MW Thermal Power Stations, PTPS, Panipat Vikrant Bhardwaj 7<br />

Rohit Garg<br />

Mandeep Chahal<br />

Baljeet Singh<br />

a<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

18 Thermodynamic Analysis <strong>of</strong> Ground Source Heat Pump for Space Surender Nain 7<br />

Heating Using R-22<br />

Sanjeev Kumar<br />

Vikrant Bhardwaj<br />

Narender Mann<br />

Parveen Kumar<br />

19 Effect <strong>of</strong> Roughness on Secondary Flow in a Rectilinear Turbine Vinod Kumar Singoria 8<br />

Cascade<br />

Deepika Sharma<br />

Dr. Samsher<br />

20 An Overall Evaluation <strong>of</strong> Flow Characteristics and Performance Netrapal Singh 8<br />

Parameters <strong>of</strong> Y-Shaped Diffusing Duct with Same Angle <strong>of</strong> Turn Abdur Rahim<br />

and Different Centerline Length and Radius <strong>of</strong> Curvature<br />

Md. Islam<br />

21 Review <strong>of</strong> Different Technologies in the Solar Absorption Vinod Sehrawat 8<br />

Air-Conditioning Systems<br />

Tarun Gupta<br />

Dr. Raj Kumar<br />

22 Energy Method for Performance Evaluation <strong>of</strong> a Boiler in a Coal Mukesh Gupta 9<br />

Fired Thermal Power Plant: A Review<br />

Raj Kumar<br />

23 Shell Side CFD Analysis <strong>of</strong> a Small Shell-and-Tube Heat Exchanger Abdur Rahim 9<br />

Considering the Effects <strong>of</strong> Baffle Inclination on Fluid Flow<br />

S.M.Saad Jameel<br />

24 Performance Based Comparative Analysis <strong>of</strong> Thermal Power Manmohan Kakkar 10<br />

Plant: A Review<br />

Raj Kumar<br />

25 Exergetic Analysis <strong>of</strong> Combustion Chamber <strong>of</strong> a Combined Nikhil Dev 10<br />

Heat and Power System<br />

Rajesh Attri<br />

26 Applications <strong>of</strong> Artificial Neural Network in Solar Thermal Naveen Sharma 10<br />

Systems: A Review<br />

Manish Kumar Chauhan<br />

Rajesh Kumar<br />

27 Thermodynamic Analysis for Improvement in Thermal Performance Shyam Agarwal 11<br />

<strong>of</strong> A Simple Gas Turbine Cycle Through Retr<strong>of</strong>itting Techniques R.S. Mishra<br />

(Inlet Air Evaporative Cooling, Steam Injection and Combined<br />

IAC and STIG)<br />

28 Time Dependent Analysis <strong>of</strong> Cooling Load Using FDM Approach Sachin Gupta 11<br />

Arvind Gupta<br />

29 Use <strong>of</strong> Biogas for Cooking Purpose in a Technical Institute: A View Point Indraj Singh 12<br />

30 CFD Modeling for Pneumatic Conveying Arvind Kumar 12<br />

D.R. Kaushal<br />

Navneet Kumar<br />

31 Electronic Waste Management in India Abhinav Kumar Shrivastava 12<br />

Sorabh<br />

32 Alternatives <strong>of</strong> Freons Praveen 13<br />

33 Waste to Energy: Using MSW <strong>of</strong> Katra Town for Electricity Sona Rani 13<br />

Generation<br />

Prabhat Shankar<br />

Navdeep Malhotra<br />

Munish Kohli<br />

THEME II – DESIGN & ANALYSIS<br />

TAME-2012<br />

OCT 19-20, 2012<br />

34 Path Synthesis <strong>of</strong> 4-Bar Linkages with Joint Clearances Using De Ruby Mishra 14<br />

Algorithm<br />

T.K.Naskar<br />

Sanjib Acharya<br />

35 Stochastic Thermal Buckling Response <strong>of</strong> Laminated Composite Rajiv Kumar 14<br />

Plate Resting on Elastic Foundation Based on Micromechanical Amit Sharma<br />

Model<br />

Rajesh Kumar<br />

b<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

TAME-2012<br />

OCT 19-20, 2012<br />

36 An Introduction to Structural Health Monitoring: A Smart Solution Vikash Kumar 14<br />

Dr. Sanjeev Kumar<br />

Dr. Vikram Singh<br />

37 Predicting Wind Turbine Design Parameter Using Actuator Hari Pal Dhariwal 15<br />

Disk Theory as a Rotational Basis<br />

Barun Kumar Roy<br />

Bhupender Yadav<br />

38 Shape Optimization to Utilize Pressure Difference at Front and Rear Amit Chauhan 15<br />

<strong>of</strong> the Body<br />

Nadish Saini<br />

Shivam<br />

Udit Dureja<br />

Narender Panwar<br />

39 Investigations <strong>of</strong> the Variation <strong>of</strong> Bush Temperature <strong>of</strong> an Offset-Halves Ami Chauhan 15<br />

Journal Bearing Pr<strong>of</strong>ile<br />

40 Navigation Control and Localization <strong>of</strong> Mobile Robot Meghana S 16<br />

Dr. D.N Drakshayani<br />

41 Fuzzy Control <strong>of</strong> Semi-Active Quarter Car Suspension System Devdutt 16<br />

with MR Damper<br />

Dr. M.L. Aggarwal<br />

42 Stress Distribution Analysis <strong>of</strong> A Rotating Hyperelastic Vane with Pratik D Upadhyay 16<br />

the Finite Element Method<br />

Akshay J Patel<br />

43 Study <strong>of</strong> Uncoiling in Suspension Springs and its Effects Kushal A Jolapara 17<br />

Adhip Puttaraj<br />

Abhishek Chatterjee<br />

44 Factors Affecting the Automatic Rain Sensing Wiper System Rahul Sindhwani 17<br />

Vasdev Malhotra<br />

45 Failure Analysis and Counter Measure <strong>of</strong> Capacitor Leads Used Santoshkumar Joshi 18<br />

in Automotive PCBs<br />

Dr. D. N. Shivappa<br />

Venkatesh Madhyastha<br />

46 Analysis <strong>of</strong> Brake Spongy Defect in Passenger Vehicle and M. Chethan 18<br />

Developing the Counter Measures – QI Case Study<br />

Dr D N Shivappa<br />

Santosh S Navada<br />

47 Virtual Reality in Design: User Training and Evaluation: Harish Pungotra 19<br />

48 Slab Width Measurement Technique Using Manipulator in Anand S. Srivastava 19<br />

Plate Rolling Mill <strong>of</strong> Bhilai Steel Plant (Sail)<br />

Krishna K. Saxena<br />

49 FEM Analysis <strong>of</strong> Copper Using Equal Channel Angular Pressing Neeraj Saraswat 19<br />

Rahul Jain<br />

Rajnish Saxena<br />

50 Solar Electric Vehicle: A Sustainable Mode <strong>of</strong> Transport Dr Samsher Gautam 20<br />

Team Solaris<br />

51 Deflection and Stress Analysis <strong>of</strong> Brake Disc Using Finite Atul Sharma 20<br />

Element Method<br />

M.L. Aggarwal<br />

52 To Eliminate Big End Over Size Rejection by Sizing Plug Gauge Aditya Singh 21<br />

on Connecting Rod Honing Machine: A Case Study<br />

Rajeev Saha<br />

53 Design <strong>of</strong> IIR Band Pass Filter Using Time Domain Approach Ruchika Singh 21<br />

Munish Vashisht<br />

54 Finite Element Analysis <strong>of</strong> Beam Hasan Zakir Jafri 21<br />

Pr<strong>of</strong>. I.A. Khan<br />

S.M. Muzakkir<br />

55 Design and Optimisation <strong>of</strong> Robotic Gripper : A Review Vaibhav Raghav 22<br />

Jitender Kumar<br />

Shailesh S.Senger<br />

c<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

THEME III – PRODUCTION ENGINEERING<br />

56 Electrical Discharge Machining <strong>of</strong> Aluminium Metal Matrix Bhaskar Chandra Kandpal 23<br />

Composites- A Review<br />

Jatinder Kumar<br />

Hari Singh<br />

57 Modelling <strong>of</strong> Surface Roughness in WEDM for HSLA Using Neeraj Sharma 23<br />

Response Surface Methodology<br />

Kamal Jangra<br />

58 E-Manufacturing Concept : A Review Naveen Virmani 24<br />

Dr. Rajeev Saha<br />

59 Investigation <strong>of</strong> the Effect <strong>of</strong> Process Parameters on Surface Dharmender 24<br />

Roughness in Wire Electric Discharge Machining <strong>of</strong> En31 Tool Steel Rajeev Kumar<br />

Anmol Bhatia<br />

60 Flexible Manufacturing Systems: Recent Development and Trends Neeraj Lamba 24<br />

61 Computer Integrated Manufacturing: A Powerful Technique for Neeraj Lamba 25<br />

Improving Productivity<br />

62 Influence <strong>of</strong> Drilling Parameters on Thrust Force in Drilling <strong>of</strong> A. Muniaraj 25<br />

SiC and Graphite Reinforced Aluminium Matrix Composites by Sushil Lal Das<br />

Step Drill<br />

K. Palanikumar<br />

63 Modelling for Machining Speed in WEDM <strong>of</strong> Wc-5.3%Co Composite Kamal Jangra 26<br />

Using Response Surface Methodology<br />

Sandeep Grover<br />

64 Effect <strong>of</strong> Tool Shape on Tensile Strength in Single and Sequential Vinod Kumar 26<br />

Double Sided Friction Stir Weld on AA1100 Aluminum Alloy<br />

Kamal Jangra<br />

Vikas Kumar<br />

65 Study <strong>of</strong> Various Mechanical Properties <strong>of</strong> Fiber Reinforced Cast Iron Sanjay Kumar 27<br />

Vasdev Malhotra<br />

Vikas Kumar<br />

66 Application <strong>of</strong> Fiber Reinforced Plastics or Polymers in Civil Meeta Verma 27<br />

Engineering Structures<br />

67 Analysis <strong>of</strong> the Depth <strong>of</strong> Penetration Using Automatic Robotic Anees Ahmed 27<br />

Arc Welding System<br />

Dr. Sanjeev Kumar<br />

Ruchika Singh<br />

68 Application <strong>of</strong> Taguchi Method and Grey Relational Analysis in<br />

Optimization <strong>of</strong> Machining Processes: A Review<br />

TAME-2012<br />

OCT 19-20, 2012<br />

Parveen Kamboj 28<br />

Sunil Kumar<br />

Kamal Jangra<br />

69 To Study the Effect <strong>of</strong> Polarity and Current During Electric Discharge Naveen Beri 28<br />

Machining <strong>of</strong> Inconel 718 with CuW Powder Metallurgy Electrode Harish Pungotra<br />

Anil Kumar<br />

70 Experimental Evaluations on Surface Quality Improvement in Anil Kumar 29<br />

Aluminium Powder Mixed AEDM <strong>of</strong> Nickel Based Super Alloy 718 Naveen Beri<br />

with Cryogenically Treated Copper Electrode<br />

Harish Pungotra<br />

71 Design and Development <strong>of</strong> Cellular Layout for Machining Bommireddy G.K 29<br />

Axle Housing and Carrier Component<br />

Dr D N Shivappa<br />

Chethan C N<br />

72 Effect <strong>of</strong> Inclusion on Fracture Behavior <strong>of</strong> Viscoelastic Materials Dharya Partap singh 29<br />

Varun Chhabra<br />

Mahesh Chand<br />

73 Compound Casting - A Literature Review Rajender Kumar Tayal 30<br />

Vikram Singh<br />

Sudhir Kumar<br />

Rohit Garg<br />

d<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

74 Effect <strong>of</strong> WEDM Parameters on Machinability <strong>of</strong> Nimonic-90 Vinod Kumar 30<br />

Kamal Jangra<br />

Vikas Kumar<br />

75 Evaluation <strong>of</strong> Electro Discharge Sawing, A Modified Electro Discharge Kalley Harinarayana 31<br />

Machining Process<br />

T.Raghavender Reddy<br />

Dr.N.Nagabhushana Ramesh<br />

Dr.B.Balu Naik<br />

76 Analysis on the Study <strong>of</strong> Changes In Mechanical Properties <strong>of</strong> Mandeep singh 31<br />

Al6063-SiC<br />

Jaspreet Singh<br />

Dipak Narang<br />

77 Friction Stir Welding <strong>of</strong> Aluminium Alloy and its Tensile Properties Sandhya Dixit 31<br />

M.L.Aggarwal<br />

78 Investigation and Analysis for The Wrinkling Behaviour <strong>of</strong> Deep Surya Prakash 32<br />

Drawn Die Sheet Metal Component by Using Fast Form<br />

Dinesh Kumar<br />

79 Modeling <strong>of</strong> Al-20wt.% SiCp Metal Matrix Composite Using Shyam Sunder 32<br />

Surface-Electrical Discharge Diamond Grinding Process<br />

Vinod Yadava<br />

80<br />

TAME-2012<br />

OCT 19-20, 2012<br />

Role <strong>of</strong> IT in Manufacturing Sector Amandeep Singh Wadhwa 33<br />

81 Optimizing Surface Roughness <strong>of</strong> High Die Steel H13 in CNC Milling Mandeep Chahal 33<br />

Using Taguchi Technique<br />

Vikram Singh<br />

Rohit Garg<br />

Sudhir Kumar<br />

82 A review on Process Parameter Optimization techniques for Advanced S. Kumar 33<br />

Machining Processes<br />

83 An Analysis <strong>of</strong> Surface Roughness and Machinability <strong>of</strong> Al-Fe-Si Kanwar Pal Sombir Sharma 34<br />

Alloys<br />

B. N. Pathak<br />

Arvind Kumar<br />

84 Machining Characteristics <strong>of</strong> Borosilicate Glass Using Traveling Basanta Kumar Bhuyan 34<br />

Wire Electro-Chemical Spark Machining (TW-ECSM) Process Vinod Yadava<br />

85 Mechanical Properties <strong>of</strong> Friction Stir Welded Dissimilar Metals Ratnesh Kumar Raj Singh 35<br />

Rajesh Prasad<br />

Sunil Pandey<br />

86 Microstructure and Weldability Evaluation <strong>of</strong> Dissimilar Metal Joint Dinesh Rathod 35<br />

Using Paste Technique for Buttering Layers<br />

Hariom Choudhary<br />

Sunil Pandey<br />

87 Electrical Discharge Grinding (EDG): A Review Ravindra Nath Yadav 35<br />

Vinod Yadava<br />

88 Effect <strong>of</strong> Ni-20mg Treatment <strong>of</strong> Al-2Fe-1V-1Si Alloy on its B. N. Pathak 36<br />

Microstructure and Mechanical Properties<br />

Dr. K. L. Sahoo<br />

Dr. M. N. Mishra<br />

89 Impact <strong>of</strong> Shot Peening and Heat Treatment Process on Surface Lakhwinder Singh 36<br />

Hardening <strong>of</strong> Welded 304l Austenitic Stainless Steel<br />

R.A. Khan<br />

M.L. Aggarwal<br />

90 Sensitive Analysis <strong>of</strong> EDM Process Using Digraph Method Madan Gopal 37<br />

Naresh Yadav<br />

Bhupender Singh<br />

91 Mathematical Modeling <strong>of</strong> HAZ in Submerged Arc Welding Process Hari Om 37<br />

Using Factorial Design Technique<br />

Sunil Pandey<br />

Dinesh Rathod<br />

92 Consumption and Manufacturing for the Future Challenges – Subrata Kumar Patra 37<br />

The Sustainable Way<br />

Tilak Raj<br />

93 Finite Element Modelling <strong>of</strong> Tube Hydr<strong>of</strong>orming Process Using Pure Dhairya Pratap Singh 38<br />

Aluminium (Al 99)<br />

e<br />

Jitendra Kumar Verma<br />

Dilip Johari<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

94 Nano-materials, Synthesis, Characterization and Photoluminescent Avni Khatkar 38<br />

Properties <strong>of</strong> Ca V O : Eu Nanomaterials<br />

S.P. Khatkar<br />

2 2 7<br />

95 A Study <strong>of</strong> Recent Trends in Friction Stir Welding Rajan 39<br />

Shailesh S. Sengar<br />

Jitender Kumar<br />

96 Thermal Modeling and Finite Element Analysis <strong>of</strong> Electro- Gaurav Kumar Sharma 39<br />

Chemical Spark Machining (ECSM)<br />

Audhesh Narayan<br />

97 A Detailed Review <strong>of</strong> the Current Research Trends in Electrical Sumit Ganguly 39<br />

Discharge Machining (EDM)<br />

98 Hardness Improvement <strong>of</strong> Dissimilar metal Stainless Steel (A304) Rakesh Kumar 40<br />

and Mild Steel by TIG Welding<br />

Manmeet Shergill<br />

THEME IV – INDUSTRIAL ENGINEERING<br />

TAME-2012<br />

OCT 19-20, 2012<br />

99 Concurrent Engineering Dr. S.P.Tayal 41<br />

100 Implementation <strong>of</strong> NSGA-II to Reduce the Occupational Health Ruchi Chaudhary 41<br />

Hazards <strong>of</strong> Workers in Glass Making Industry<br />

Ajit<br />

Manisha Verma<br />

Dr. Rk Srivastava<br />

101 Study <strong>of</strong> Manual Material Handling Tasks Using Taguchi Technique Jaswinder Singh 42<br />

P Kalra<br />

R S Walia<br />

102 Manual Material Handling Tasks Process Optimization Using Jaswinder Singh 42<br />

Physiological Technique<br />

P Kalra<br />

R S Walia<br />

103 Office Efficiency Enhancement Through TPM : An Empirical Study Rajender Kumar 42<br />

Dr. Vikas Kumar<br />

Dr. Sultan Singh<br />

S. K.Gupta<br />

104 Enhancing Productivity by Strategic Improvement in Throughput- S.K. Gupta 43<br />

Time on Assembly Line: A Case Study<br />

Dr. V.K. Mahna<br />

Dr. R.V. Singh<br />

Rajender Kumar<br />

105 Application <strong>of</strong> Taguchi Method in Process Optimization Shyam Kumar Karna 43<br />

Dr. Ran Vijay Singh<br />

Dr. Rajeshwar Sahai<br />

106 A Review <strong>of</strong> Literature on Worker Allocation Problem in FMS Lalit Kumar 44<br />

Mohit Bansal<br />

Sanjeev Goyal<br />

107 To Study the Implementation <strong>of</strong> Pareto Analysis in SME Indian Kailash Attri 44<br />

Industries By Using Cause and Effect Diagram: A Case Study<br />

Dr. Rajeev Saha<br />

108 Lean Manufacturing System: An Overview Rakesh Kumar 44<br />

Vikas Kumar<br />

109 Lean Manufacturing: Elements and its Benefits for Manufacturing Rakesh Kumar 45<br />

Industry<br />

Vikas Kumar<br />

110 Criticality <strong>of</strong> Supply Chain in Indian Auto Industry Dharamvir Mangal 45<br />

Tarun Gupta<br />

111 Intensity <strong>of</strong> Critical Factors Effecting Technical Institution Victor Gambhir 46<br />

Evaluation-An ANP Approach<br />

Dr N.C. Wadhwa<br />

Dr. Sandeep Grover<br />

f<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

112 Effects <strong>of</strong> Road Traffic Noise on Traffic Constable in Ghaziabad Region Rakesh Mishra 46<br />

,<br />

Sachin Rathore<br />

Nitin Sharma<br />

D.D.Johri<br />

Z Mallick<br />

113 Optimization <strong>of</strong> Inventory Model for Decaying Item with Variable Ankit Prakash Tyagi 47<br />

Holding Cost and Power Demand<br />

Rama Kant Pandey<br />

Shivraj Singh<br />

114<br />

TAME-2012<br />

OCT 19-20, 2012<br />

Application <strong>of</strong> Graph Theory: A Review Ravi Kalra 47<br />

Sunil Kumar<br />

Kamal Jangra<br />

115 Evaluation <strong>of</strong> Ideas for Panel Body Assembly by Decision Matrix Narender Kumar 47<br />

Vineet Jain<br />

116 Lean Manufacturing Strategy –A Remedy for Tough Times Naveen Kumar 48<br />

Dr S.K Sharma<br />

117 Enablers <strong>of</strong> Technology Management: An ISM Approach<br />

Sarvesh Kumar 48<br />

Javed Khan<br />

Abid Haleem<br />

118 Establishing Time Standards for Fixing Body Size Panel to the Chassi Vikram K V 49<br />

in Assembly Line Using MOST<br />

Dr. D. N. Shivappa<br />

Jaganur Sangamesh<br />

119 Establishing Time Standards for Assembly Activity in Chassis Harish. H 49<br />

Preparation Area Using MOST<br />

Dr. D. N. Shivappa<br />

Jaganur Sangamesh<br />

120 Metaheuristic Design for Calculating Makespan <strong>of</strong> Comprehensive Sunil Kumar 49<br />

Scheduling Problems<br />

Rajender Kumar Tayal<br />

121 An Efficient Approach <strong>of</strong> Good Manufacturing Flexibility by FMS Virender Chahal 50<br />

and RMS With Minimizing the Overall Wastage by JIT<br />

122 Modern Trends, Problems, Solutions and Ethics in Mechanical Engineering Dr. Niranjan Lal Mangla 50<br />

123 Stratagem Progress <strong>of</strong> Lean Manufacturing Implementation in Shop Floor Dharmender Kumar 51<br />

Dr. Navdeep Malhotra<br />

124 Tools and Techniques for Quality Management in Manufacturing Mohit Singh 51<br />

Industries<br />

Dr. I.A. Khan<br />

Dr. Sandeep Grover<br />

125 Simulation Based Analysis <strong>of</strong> the Bullwhip Effect Under Different B.A. Mir 51<br />

Information Sharing Strategies<br />

A. Jayant<br />

A. Singh<br />

126 Supplier Manufacturer Relationship in Supply Chain Management: Vikramjeet Singh 52<br />

A Review<br />

Arvind Jayant<br />

127 A Generic Model <strong>of</strong> Multi-Echelon Reverse Logistics Network for S. Bansal 52<br />

Product Returns<br />

A.Jayant<br />

P. Gupta<br />

S. K. Garg<br />

128 Supplier Quality Assurance in Supply Chain Management (SCM) P.P. Shah 53<br />

Through Quality Tools and Techniques<br />

Dr. R.L. Shrivastava<br />

129 Critical Issues for Indian Small and Medium Enterprises for A. Anand 53<br />

Adopting Knowledge Management<br />

M. D. Singh<br />

R. Kant<br />

130 JIT Supply Chain Management: An Introduction O P Mishra 53<br />

Vikas Kumar<br />

Dixit Garg<br />

g<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

TAME-2012<br />

OCT 19-20, 2012<br />

131 Intensity <strong>of</strong> Critical Factors for Implementing AMT– An ANP Approach Sanjeev Goyal 54<br />

Sandeep Grover<br />

132 A View <strong>of</strong> Queue Analysis with Customer Behaviour, Balking Neetu Gupta 54<br />

and Reneging<br />

Reena Garg<br />

133 Improving the Organisation Through 5S Methodology Ravinder Kumar Panchal 54<br />

134 Applying Six Sigma Methodology in a Brick Kiln Industry Thereby Akhil Khajuria 55<br />

Reducing Defect Level<br />

Kapil Singh<br />

Khalid Sheikh<br />

Dr. Navdeep Malhotra<br />

135 Role <strong>of</strong> Operation Research Applications in Financial Markets- Ashok Kumar 55<br />

A Literature Review<br />

Jyotsana chawla<br />

Neha Goyal<br />

136 Quest for Environmental Protection by Integrated Green Sandeep Handa 56<br />

Manufacturing System<br />

Dr. Tilak Raj<br />

Dr. Sandeep Grover<br />

137 A Review on JIT Implementation Aspects in Service Sector Sandeep Phogat 56<br />

Dr. A. K. Gupta<br />

138 Genetic Algorithms: A Problem Solving Approach Jyoti 56<br />

Dr. Neetu Gupta<br />

139 A Systematic Review <strong>of</strong> Literature on Benchmarking Bhupender Singh 57<br />

Dr. Sandeep Grover<br />

Dr. Vikram Singh<br />

140 Systematic Model Development to Analyze Service Quality in Supply Tarun Kumar Gupta 57<br />

Chain for a Manufacturing Organization<br />

Vikram Singh<br />

Full text <strong>of</strong> the papers is published in the e-proceeding <strong>of</strong> the conference (ISBN 978-93-5087-574-2)<br />

h<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

THEME-I<br />

THERMAL ENGINEERING<br />

TAME-2012<br />

OCT 19-20, 2012<br />

STUDY OF SOLAR WATER HEATERS BASED ON EXERGY ANALYSIS<br />

1 2 3<br />

Dilip Johari , Ashok Yadav , Ravi Verma<br />

1 2 3<br />

M.Tech Student, Asst. Pr<strong>of</strong>., Asst. Pr<strong>of</strong>.<br />

1,2<br />

Department <strong>of</strong> Mechanical Engineering, Dayalbagh Educational <strong>University</strong>, Agra, U.P.,<br />

Department <strong>of</strong> Mechanical Engineering, Graphic Era <strong>University</strong>, Dehradun, Uttrakhand<br />

1 2 3<br />

Email: dilipjohari@gmail.com, ashokyadavaca@gmail.com, raviverma2020@gmail.com<br />

Energy application from the sun to heat water is well known. Solar water heater is a device which is used for heating the<br />

water for domestic and industrial purposes by utilizing the solar energy. Solar energy is the energy which is coming from sun<br />

in the form <strong>of</strong> solar radiations in infinite amount, when these solar radiations fall on absorbing surface, then they gets<br />

converted into heat. This heat is used for heating the water.<br />

This paper presents the study based on three procedure theory. Exergy analysis is conducted with the aim <strong>of</strong> providing some<br />

methods to save cost and keep the efficiency <strong>of</strong> solar water heater to desired extent and at the same time figuring out related<br />

exergy losses. In the Exergy analysis <strong>of</strong> solar water heater systems, the conversion <strong>of</strong> solar radiation is typically included<br />

within the analysis. Exergy analysis has been widely used for the optimisation and allocation <strong>of</strong> losses in energy systems.<br />

Exergy is the expression for loss <strong>of</strong> available energy due to the creation <strong>of</strong> entropy in irreversible systems or processes. The<br />

exergy loss in a system or component is determined by multiplying the absolute temperature <strong>of</strong> the surroundings by the<br />

entropy increase. Exergy is also a measure <strong>of</strong> the maximum useful work that can be done by a system interacting with an<br />

environment. It has been widely used in the design, simulation and performance evaluation <strong>of</strong> energy systems.<br />

Keywords: Solar water heater, Laws <strong>of</strong> Thermodynamics, Exergy Analysis, Three procedure theory.<br />

***<br />

GREEN VEHICLE: POLLUTION CONTROL THROUGH CATALYTIC CONVERTER<br />

AND PERFORMANCE ANALYSIS OF THE SAME<br />

1 2<br />

Pankaj Agarwal , Manish Jain<br />

1<br />

M.Tech (Pur.), Jagannath <strong>University</strong>, Jaipur, Email:mr.pankajagarwal@gmail.com<br />

2<br />

PhD Scholar, JECRC <strong>University</strong>, Jaipur, Email:<br />

Regardless <strong>of</strong> how perfect engine is operating, there will always be some harmful byproducts <strong>of</strong> combustion. When the<br />

combustion <strong>of</strong> fuel takes place in an engine <strong>of</strong> an automobile in the presence <strong>of</strong> air, following reaction takes place:<br />

Hydrocarbons<br />

xCO 2+yH2O+Heat<br />

Fumes <strong>of</strong> un-burnt hydrocarbons produce a number <strong>of</strong> petrochemical oxidants & photochemical smog with O 2 & N 2<br />

which causes adverse effects on physiological activities <strong>of</strong> living beings. Emissions from gasoline powered vehicles are<br />

generally the hydrocarbons like CO, NOx, SO 2, etc.<br />

Catalytic converter is a device which treats the exhaust emission and converts them into the less harmful substances. This<br />

device is located in-line with the exhaust system and is used to cause a desirable chemical reaction to take place in the<br />

exhaust flow. In this paper the various aspects <strong>of</strong> design, construction, working and performance analysis <strong>of</strong> a catalytic<br />

converter are discussed. The converter performance is simulated by considering chemical reactions and heat transfer<br />

phenomena as the exhaust gases flow through the catalyst.<br />

Keywords: Green Vehicle, Pollution control<br />

***<br />

1<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

PERFORMANCE INVESTIGATION OF A COMPACT TRI-GENERATION SYSTEM<br />

BASED ON RENEWABLE ENERGY POWER PLANT EXHAUST GAS WASTE HEAT<br />

UTILIZATION<br />

1 2<br />

Dr. Raj Kumar , Anil Kumar<br />

1<br />

Pr<strong>of</strong>essor (Mechanical Engineering Department)<br />

2<br />

Ph.D.scholar, mech_annu@rediffmail.com<br />

<strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> & Technology, Faridabad,<br />

This paper presents a compact tri-generation system in order to cover the electric and thermal power demand <strong>of</strong> small rural<br />

areas using the renewable energy. The gasifier generator coupled power plants are being widely used in rural communities<br />

where electric network doesn't exist. The recovery <strong>of</strong> the exhaust gases makes the system very attractive. Apart from it, there<br />

is the performance study <strong>of</strong> a compact power plant and a tri-generation plant. The stack gases from internal combustion<br />

engine are directed to a 25 kW ammonia-water absorption refrigeration chiller. In the power plant,31.25% is the electric<br />

power generation <strong>of</strong> the total fuel gas input and same amount <strong>of</strong> stack gases at temperature 400 0 C just at out let <strong>of</strong> engine is<br />

0<br />

used to operate absorption chiller machine which is having COP <strong>of</strong> 0.517. The temperature <strong>of</strong> cold storage was between 0 C-<br />

5 C at 15kW cooling capacity. The engine water jacket was used for heating purpose and the temperature gain was between<br />

0 0<br />

60 C -63.5 C.<br />

Keywords: Tri-generation, renewable energy, exhaust gas waste.<br />

***<br />

DECOMPOSITION OF ENERGY CONSUMPTION IN INDIA: A DISCUSSION IN THE<br />

CONTEXT OF INDEX DECOMPOSITION ANALYSIS (IDA)<br />

1* 2 3<br />

Ponnala Vimal Mosahari , D. Ganeshwar Rao , Rajeev Satsangi<br />

1,2<br />

Department <strong>of</strong> Mechanical Engineering, Faculty <strong>of</strong> Engineering, Dayalbagh Educational Institute ), Dayalbagh, Agra<br />

* 1<br />

Corresponding Author: pvimalmosahari@gmail.com<br />

India is a developing country with enormous growth in the Industrial sector. A major concern however lies in the limited<br />

energy resources which are the driving force <strong>of</strong> any industry or country as a whole. Hence, it becomes important to focus on<br />

the energy consumption pattern <strong>of</strong> the country and to identify where optimization is needed. Energy consumption is also<br />

related to the environment i.e. CHG emissions and therefore CHG monitoring is also important to check the emissions.<br />

Index Decomposition Analysis (IDA) is an analytical tool based on the Index Number Theory used in Economics and<br />

Statistics. It is at present a much sought after research area to analyse the energy consumption pattern or to decompose<br />

energy indicators. IDA is widely used to disentangle and separate changes in energy consumption, energy intensity and<br />

CHG emissions in energy and environmental field. In the present work an attempt has been made to review the energy<br />

consumption in India and discuss IDA.<br />

Keywords: IDA, CHG<br />

***<br />

THERMO-ECONOMIC OPTIMIZATION OF WORK CONSUMING DEVICES<br />

Rajesh Arora<br />

Associate Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Engineering,<br />

Dronacharya College <strong>of</strong> Engineering, Khentawas (FarrukhNagar), Gurgaon<br />

Email: - rajesharora1219@rediffmail.com<br />

The finite-time and finite size are considered to be the major constraints in the optimization <strong>of</strong> the real systems. In classical<br />

thermodynamic analysis, these constraints are not considered because <strong>of</strong> the inherent assumption <strong>of</strong> reversibility. Finite<br />

Time Thermodynamics provide a fundamental starting point for the optimization <strong>of</strong> real systems. The optimization studies<br />

<strong>of</strong> refrigeration and heat pump systems that consider various objective functions based on Finite Time Thermodynamics and<br />

thermo-economics are reviewed here.<br />

Keywords: FTT, Endo-reversible, Refrigerator, Heat Pump, Heat Reservoir<br />

2<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad<br />

TAME-2012<br />

OCT 19-20, 2012

National Conference on Trends and Advances in Mechanical Engineering<br />

***<br />

CLEAN COAL TECHNOLOGIES FOR POWER GENERATION IN INDIA<br />

A NEAR ZERO EMISSION PLANT APPROACH<br />

1 2<br />

Siddhartha , Pr<strong>of</strong>.(Dr.)Navdeep Malhotra<br />

1<br />

MTech.Mechanical <strong>YMCA</strong>UST, ,Faridabad<br />

Certified Energy Manager , BEE-INDIA and Life Member IE(India)<br />

Mobile : 0918527243948, E-Mail : mailsiddhartha08@gmail.com<br />

2<br />

Ph.D.,Pr<strong>of</strong>essor <strong>YMCA</strong>UST,ZakirNagar,Faridabad<br />

LMISTE,LMIE,MSAE,LMMRIS,LMISAMPE,LMSME,LMFRPI<br />

Mobile :0919466175277, E-Mail: navdeep_malhotra2001@yahoo.com<br />

Coal is chemically and physically a complex and heterogeneous material, consisting <strong>of</strong> organic and inorganic<br />

constituents from its origin .Concerted efforts are needed to reduce “ash-forming” inorganic elements and to develop<br />

clean methods <strong>of</strong> using coal.A combined-cycle gas turbine power plant consists <strong>of</strong> one or more gas turbine generators<br />

equipped with heat recovery steam generators to capture heat from the gas turbine exhaust. Steam produced in the heat<br />

recovery steam generators powers a steam turbine generator to produce additional electric power. Gas-fired combined-cycle<br />

plants produce less carbon dioxide per unit energy output than other fossil fuel technologies because <strong>of</strong> the relatively high<br />

thermal efficiency <strong>of</strong> the technology .Grate firing was the first combustion system used for solid fuels followed by<br />

pulverized and fluidized bed firing. The concept <strong>of</strong> burning coal that has been pulverized into a fine powder stems from<br />

the belief that if the coal is made fine enough ,it will burn almost as easily and efficiently as gas. Various scrubbing<br />

processes have been proposed to remove carbon dioxide from air or flue gases. In contrast to wet scrubbers which apply<br />

energy directly to the flowing fluid medium, an ESP applies energy only to the particulate matter being collected and<br />

therefore is very efficient in its consumption <strong>of</strong> energy (in the form <strong>of</strong> electricity). Most FGD systems employ two stages:<br />

one for fly ash removal and the other for SO2 removal. However, these systems experienced severe maintenance problems<br />

and low removal efficiency. In wet scrubbing systems, the flue gases normally passes first through a fly ash removal device,<br />

either an electrostatic precipitator or a wet scrubber, and then into the SO2-absorber. However, in dry injection or spray<br />

drying operations, the SO2 is first reacted with the sorbent, and then the flue gas passes through a particulate control device.<br />

Another important design consideration associated with wet FGD systems is that the flue gas exiting the absorber is<br />

saturated with water and still contains some SO2. These gases are highly corrosive to any downstream equipment such as<br />

fans, ducts, and stacks. Usage <strong>of</strong> supercritical and ultrasupercritical pulverised coal technologies along with<br />

Circulating Fluidised Bed Combustion besides IGCC has been discussed as Clean Coal Technologies for power<br />

generation. Hence the paper Clean Coal Technologies for Power Generation in India : A Near Zero Emission Plant<br />

Approach is limited to the study <strong>of</strong> various technologies to reduce emissions/greenhouse gases by coal combustion.<br />

Keywords: Coal Beneficiation, Coal Gasification, Fluidised Bed Combustion, Integrated Gasification Combined Cycle,<br />

Flue Gas Desulphurisation, Electrostatic Precipitator, Carbon Capture and Storage.<br />

***<br />

LIMITATIONS OF ENERGY UTILIZATION OF SOLID WASTE DUE TO IT'S POOR<br />

QUALITY<br />

1 2 3<br />

Desh Deepak Johri, Manish Gaur, Sachin Rathod<br />

1<br />

Associate Pr<strong>of</strong>essor, Deptt. <strong>of</strong> Mech. Engg., ABESIT, Ghaziabad<br />

2,3<br />

Assistant Pr<strong>of</strong>essor, Deptt. <strong>of</strong> Mech. Engg., KIET, Ghaziabad<br />

1<br />

E mail: ddjohri@gmail.com<br />

TAME-2012<br />

OCT 19-20, 2012<br />

The increasing problem <strong>of</strong> continuous population growth in the metro cities and subsequent increase in solid waste disposal<br />

has created a severe problem as well as its hazardous effects may not be overlooked. The major utilization <strong>of</strong> this solid waste<br />

in India is limited to composting only. The amount <strong>of</strong> solid waste in Delhi alone is nearly 9000 MT / day. The quality <strong>of</strong><br />

compost is not appropriate because <strong>of</strong> mixed solid waste and its poor quality .The compost thus produced is not salable in the<br />

market. In domestic solid waste if the organic content is collected separately the food stuff waste content can be utilized for<br />

compost which shall be <strong>of</strong> good quality. Again the content in the form <strong>of</strong> Plastic and paper is suitable for the purpose <strong>of</strong><br />

energy.<br />

Keywords:-Sanitary Land Fills (SLF), Waste to Energy Generation (WTE), Municipal Solid Waste (MSW)<br />

***<br />

3<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

A FEASIBILITY STUDY ON WASTE HEAT RECOVERY IN AN IC ENGINE USING<br />

ELECTRO TURBO GENERATION<br />

1 2<br />

S.N.Srinivasa Dhaya Prasad , N.Parameshwari<br />

1<br />

Assistant Pr<strong>of</strong>essor, Department <strong>of</strong> Automobile Engg., SACS MAVMM Engg. College,<br />

Madurai, Tamilnadu. E-mail: iamdhaya77@gmail.com<br />

2<br />

Asst. Pr<strong>of</strong>. /Research Scholar, Department <strong>of</strong> Automobile Engg, SACS MAVMM Engineering College,<br />

E-mail: paramspraba@gmail.com<br />

In a conventional IC engine a considerable heat is carried away by exhaust gases. To recover the waste heat, various methods<br />

are being adopted. One <strong>of</strong> them is turbo charging. In this project an attempt has been made to explore the various possibilities<br />

<strong>of</strong> waste heat / energy recovery methods in conventional commercial two wheeler and four wheelers. In this context, a new<br />

concept <strong>of</strong> hybrid engine has also been discussed. The heat energy contained in the exhaust gases are recovered in three<br />

different methodologies.<br />

Firstly, by introducing an auxiliary combustion chamber and injecting an additional suitable fuel and then allowing it to<br />

expand in a turbine which forms the part <strong>of</strong> turbo charger unit. Thus the waste heat energy is utilized to burn an additional<br />

amount <strong>of</strong> fuel. The second stage contains a thermoelectric generator which produces electrical energy by utilizing the high<br />

heat <strong>of</strong> exhaust gases. The third stage energy recovery is done by coupling a compressor and an alternator. Both being<br />

coupled to the turbine shaft, produces electrical energy and compressed air which can be accumulated and used effectively<br />

for running any auto auxiliaries. Thus the principle <strong>of</strong> electro turbo generation has been adopted for waste heat recovery In<br />

order to use the aforesaid combination <strong>of</strong> waste energy recovery systems a matrix has also been suggested.<br />

REDUCING BATTERY DISCHARGING RATE USING PHOTO-ELECTRIC EFFECT<br />

***<br />

1* 2 3<br />

Jeet Kumar Gaur , Abhinav Mittal ,Bikash Chandra Maurya<br />

1,2,3<br />

B.tech, Student 3rd year, Mechanical Engineering, KIET, Ghaziabad, India<br />

Corresponding author Email:* jeetkumargaur@gmail.com, Ph-+91-8909518527<br />

To make the battery work longer once charged the electrons can be made to get over the negative terminal <strong>of</strong> the battery<br />

using the photon energy by the use <strong>of</strong> a low wave length ultra violet lamp [1].In process forms a circuit that acts as the<br />

charging circuit <strong>of</strong> the battery. Thus the rate <strong>of</strong> discharge <strong>of</strong> the battery reduces and battery life increases. Such an<br />

arrangement if used with the battery will tend to recharge the battery when it's being used. Thus the net discharging rate <strong>of</strong><br />

the battery is reduced.<br />

Keywords: Electrons, photons, photo-electric effect, Work function, Ultra Violet Lamp.<br />

***<br />

THERMODYNAMIC MODELLING OF GROUND SOURCE HEAT PUMP FOR SPACE<br />

HEATING<br />

1 2 3<br />

Rajeev Satsangi , Ashok Yadav ,Ponnala Vimal Mosahari<br />

1,2,3<br />

Department <strong>of</strong> Mechanical Engineering, Faculty <strong>of</strong> Engineering, Dayalbagh Educational Institute<br />

(Deemed <strong>University</strong>), Dayalbagh, Agra<br />

Corresponding Author: rajeevsatsangi2008@gmail.com<br />

Fossil fuels are depleting day by day due to rapid industrialization and urbanization, so there are lot <strong>of</strong> effort made all over<br />

the world to use alternative energy resources. Ground Source Heat Pump is considered as one <strong>of</strong> the renewable energy<br />

resources used for heating and cooling purposes. In the present work, conservation equation for mass and energy are derived<br />

for a GSHP system with simple U Tube Ground heat exchanger. The performance characteristics <strong>of</strong> GSHP are computed in<br />

terms <strong>of</strong> COP and energetic aspect. After successful validation <strong>of</strong> the equation and procedure, the analysis has been<br />

performed for the application <strong>of</strong> GSHP for space heating load <strong>of</strong> 5KW for R 22 and R 134 a (Tetra fluoro ethane) refrigerants.<br />

4<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad<br />

TAME-2012<br />

OCT 19-20, 2012

National Conference on Trends and Advances in Mechanical Engineering<br />

TAME-2012<br />

OCT 19-20, 2012<br />

It has been seen that R 134 a have high COP than R 22. R134 a have no chlorine content and it can be considered as ec<strong>of</strong>riendly.<br />

Keyword – Ground Source Heat Pump, Energy Analysis, Mass flow rate, Coefficient <strong>of</strong> Performance<br />

***<br />

ALTERNATIVES TO R134A (CF CH F) REFRIGERANT- A REVIEW<br />

3 2<br />

1 2<br />

Gaurav , Dr. Raj Kumar<br />

1<br />

Assistant Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Engineering, Mewat Enginieering College, Mewat-122107,<br />

1<br />

Haryana,E-mail: gaurav.citm@gmail.com<br />

2<br />

Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> & Technology, Faridabad<br />

R134a (Hydr<strong>of</strong>luorocarbon refrigerant) is used in domestic refrigeration and other vapour compression system. R134a is<br />

having zero ozone depletion potential (ODP) and almost same thermodynamic properties as R12 (Chlor<strong>of</strong>lurocarbon<br />

refrigerant), but it has 1300 global warming potential (GWP) per year which is very high. So, there is a need to find out the<br />

alternatives to R134a from toxicity, flammability, thermodynamic, thermoeconomic and environment point <strong>of</strong> view. This<br />

review paper also represents the recent development done on alternatives to R134a.<br />

Keywords: Global warming, Ozone depletion, Alternative refrigerant, Flammability<br />

***<br />

A REVIEW OF COMBINED CYCLE POWER PLANT THERMODYNAMIC CYCLES<br />

1* 2 3 1<br />

Nikhil Dev , Samsher , S. S. Kachhwaha , Rajesh Attri<br />

1<br />

<strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad, Haryana<br />

2<br />

Delhi Technological <strong>University</strong>, Delhi<br />

3<br />

Pandit Deendayal Petroleum <strong>University</strong>, Gandhinagar<br />

nikhildevgarg@yahoo.com<br />

Simple cycle gas turbine engines suffer from limited efficiencies and consequential dominance <strong>of</strong> fuel prices on generation<br />

costs. Combined cycles, however, exploit the waste heat from exhaust gases to boost power output, resulting in overall<br />

efficiencies around 50%, which are significantly above those <strong>of</strong> steam power plants. This paper reviews various types <strong>of</strong><br />

combined cycles, including repowering, integrated gasification and other advanced systems.<br />

Keywords: Combined cycle power plant, gas turbine, HRSG<br />

***<br />

A REVIEW ON PARABOLIC TROUGH TYPE SOLAR COLLECTORS: INNOVATION,<br />

APPLICATIONS AND THERMAL ENERGY STORAGE<br />

Devander Kumar Lamba<br />

Mechanical Engg.,Deptt., TITS Bhiwani, India<br />

E-mail:- lambadev1@rediffmail.com<br />

The global demand for energy is growing and conventional energy sources like coal and petroleum are depleting, and<br />

renewable resources will play a crucial role in the future. This paper presents an overview about the parabolic trough solar<br />

collector which is one <strong>of</strong> the renewable source. Parabolic trough collector can supply the thermal energy up to 4000C ,<br />

mainly in steam power plant for electricity generation. Many applications <strong>of</strong> Parabolic Trough Collector, it's innovations<br />

and thermal energy storage materials has been discussed keeping in mind the environmental benefits. In India, the states <strong>of</strong><br />

Rajasthan and Gujarat have the potential for widespread application <strong>of</strong> PTC to harness the solar energy. The launch <strong>of</strong> The<br />

5<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

TAME-2012<br />

OCT 19-20, 2012<br />

Jawaharlal Nehru National Solar Mission (JNNSM) in 2008 by the Indian Government and its initiatives, complemented by<br />

state solar policy passed by the states <strong>of</strong> Rajasthan and Gujarat, will go a long way based on deployment <strong>of</strong> both solar PV<br />

projects and solar thermal projects in a ratio <strong>of</strong> 50:50, in MW terms to fulfilling India's upcoming energy needs.<br />

Keywords: - Parabolic Trough Collector (PTC), concentrated solar power (CSP), heat transfer fluid (HTF), Thermal<br />

energy storage.<br />

***<br />

STUDY OF FLOW AND HEAT TRANSFER IN PLATE FIN HEAT EXCHANGER AT<br />

VARYING REYNOLD'S NUMBER<br />

1 2<br />

Pardeep Yadav , Pawan Kumar ,<br />

1,2<br />

DAV College <strong>of</strong> Engg.& Technology,Kanina,(M.Garh) HR<br />

Heat transfer characteristics and flow structure in laminar and turbulent flows through a rectangular channel containing<br />

built in vortex generators have been analyzed by means <strong>of</strong> solutions <strong>of</strong> the full Navier-Stokes and energy equations The<br />

effects <strong>of</strong> two different shaped LVGs, rectangular winglet pair (RWP) and delta winglet pair (DWP) with two different<br />

congurations, common-ow-down (CFD) and common-ow-up (CFU), are studied. The numerical results indicate that the<br />

application <strong>of</strong> LVGs effectively enhances heat transfer <strong>of</strong> the channel. According to the performance evaluation<br />

parameter, (Nu/Nu 0)/(f/f 0), the channel with DWP has better overall performance than RWP; the CFD and CFU<br />

congurations <strong>of</strong> DWP have almost the same overall performance; the CFD conguration has a better overall performance<br />

than the CFU conguration for RWP. The basic mechanism <strong>of</strong> heat transfer enhancement by LVGs can be well described<br />

by the eld synergy principle. The main purpose <strong>of</strong> this study is to show the performance <strong>of</strong> delta winglet type vortex<br />

generators in improving heat transfer.<br />

Keywords: Vortex generator; Common ow up; Heat transfer enhancement; Plate-n & tube heat.<br />

***<br />

PERFORMANCE IMPROVEMENT OF A CONTROL VALVE USING COMPUTATIONAL<br />

FLUID DYNAMICS<br />

1 2 3 4<br />

K Thanigavelmurugan , N.V. Mahalakshmi , S. Mohan Das , D. Venkatesh<br />

1,2<br />

Department <strong>of</strong> Mechanical Engineering, Anna <strong>University</strong>,Chennai<br />

3,4<br />

Circor Flow Technologies,Coimbatore,India<br />

1<br />

thanigavel_murugan@yahoo.co.in<br />

This article describes the design and performance improvements <strong>of</strong> a high pressure turbine bypass valve Zick Twist trim<br />

(multi stage, multi path). For effective control <strong>of</strong> velocity, pressure and temperature, a trim designed to have a tortuous path<br />

was designed. Computational fluid dynamics and FEM analyses were used in the design process. The valve, which was<br />

installed with the designed trim, was tested. To evaluate its performance in the field, the valve was installed at a 225MW<br />

combined power plant system for two months. The results showed that the pressure letdown was successfully controlled by<br />

the designed trim, and the noise level was reduced below 85dB. The main objective <strong>of</strong> the work is to find the pressure drop,<br />

velocity variation, temperature distribution in the different stages <strong>of</strong> the turbine bypass valve using computational fluid<br />

dynamics. This is done to increase the performance <strong>of</strong> the valve.<br />

Keywords: Zick Twist trim (multi stage, multi path, tortuous path trim), turbine bypass valve, pressure control, velocity<br />

control, temperature control, disc stacks, computational fluid dynamics exchanger.<br />

***<br />

6<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad

National Conference on Trends and Advances in Mechanical Engineering<br />

CFD APPLICATION IN PASSIVE BUILDING DESIGNS<br />

TAME-2012<br />

OCT 19-20, 2012<br />

1 2 3<br />

Ali A. F. Al-Hamadani , S. K. Shukla , Alok K.Dwivedi<br />

1, 2<br />

Department <strong>of</strong> Mechanical Engineering,<br />

Indian Institute <strong>of</strong> Technology, Banaras Hindu <strong>University</strong> , Varansi<br />

3<br />

SHEAT College <strong>of</strong> Engineering, Babatpur, Varanasi<br />

2<br />

Corresponding Author; Telefax ; +91-0542-670285<br />

2<br />

Email: skshukla.mec@itbhu.ac.in<br />

The main factors which govern physical conditions and comfort are air temperature and air movement. These factors will<br />

assist the designer to know or to reach the suitable thermal comfort to attain the primitive knowledge, it used in passive<br />

building design. Thus, in this paper, simulation study has been performed to estimate the distribution <strong>of</strong> air temperature<br />

inside the common room with the direction <strong>of</strong> velocity and the indoor environment by using ANSYS Fluent 12.1. The<br />

simulation results show that radiation model assist better to understand the mixed convection, force convection with<br />

temperature in ventilated spaces.<br />

Keywords: CFD, Passive, Radiation, Building Design<br />

***<br />