I R 1 2 3 4 5 6 7 8 9 10 11 12 13 T 14 15 A - SDP/SI

I R 1 2 3 4 5 6 7 8 9 10 11 12 13 T 14 15 A - SDP/SI

I R 1 2 3 4 5 6 7 8 9 10 11 12 13 T 14 15 A - SDP/SI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

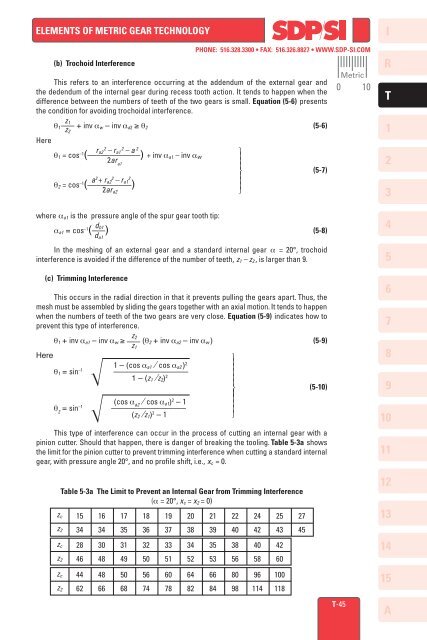

ELEMENTS OF METRIC GEAR TECHNOLOGY<br />

(b) Trochoid Interference<br />

PHONE: 516.328.3300 • FAX: 516.326.8827 • WWW.<strong>SDP</strong>-<strong>SI</strong>.COM<br />

This refers to an interference occurring at the addendum of the external gear and<br />

the dedendum of the internal gear during recess tooth action. It tends to happen when the<br />

difference between the numbers of teeth of the two gears is small. Equation (5-6) presents<br />

the condition for avoiding trochoidal interference.<br />

z<br />

θ 1<br />

1 ––– + inv α w<br />

z<br />

– inv α a2 ≥ θ 2 (5-6)<br />

2<br />

Here<br />

2 2<br />

r a2 – r a1 – a 2<br />

⎫<br />

θ 1 = cos –1 (––––––––––––) + inv α a1 – inv α w<br />

2ar a1<br />

⎪ ⎪⎬ (5-7)<br />

a 2 2 2<br />

+ r a2 – r a1 θ 2 = cos –1 (––––––––––)<br />

⎪<br />

2ar a2<br />

⎭<br />

where α a1 is the pressure angle of the spur gear tooth tip:<br />

d<br />

α b1<br />

a1 = cos –1 (–––) (5-8)<br />

d a1<br />

In the meshing of an external gear and a standard internal gear α = 20°, trochoid<br />

interference is avoided if the difference of the number of teeth, z 1 – z 2 , is larger than 9.<br />

(c) Trimming Interference<br />

This occurs in the radial direction in that it prevents pulling the gears apart. Thus, the<br />

mesh must be assembled by sliding the gears together with an axial motion. It tends to happen<br />

when the numbers of teeth of the two gears are very close. Equation (5-9) indicates how to<br />

prevent this type of interference.<br />

z<br />

q 2<br />

1 + inv α a1 – inv α w ≥ ––– (θ 2 + inv α a2 – inv α<br />

z w ) (5-9)<br />

1<br />

Here<br />

⎫ 1 – (cos α ⁄ θ a1 cos α a2 )2 1 = sin –1 ––––––––––––––––– 1 – (z 1 ⁄z 2 ) 2 ⎪ ⎪⎬ (5-<strong>10</strong>)<br />

(cos α a2 ⁄ cos α a1 ) 2 – 1<br />

θ 2<br />

= sin –1 ––––––––––––––––– ⎪<br />

(z 2 ⁄z 1 ) 2 – 1 ⎭<br />

This type of interference can occur in the process of cutting an internal gear with a<br />

pinion cutter. Should that happen, there is danger of breaking the tooling. Table 5-3a shows<br />

the limit for the pinion cutter to prevent trimming interference when cutting a standard internal<br />

gear, with pressure angle 20°, and no profile shift, i.e., x c = 0.<br />

z c<br />

Table 5-3a The Limit to Prevent an Internal Gear from Trimming Interference<br />

(α = 20°, x c = x 2 = 0)<br />

z 2<br />

z c<br />

z 2<br />

z c<br />

z 2<br />

<strong>15</strong><br />

34<br />

28<br />

46<br />

44<br />

62<br />

16<br />

34<br />

30<br />

48<br />

48<br />

66<br />

17<br />

35<br />

31<br />

49<br />

50<br />

68<br />

18<br />

36<br />

32<br />

50<br />

56<br />

74<br />

19<br />

37<br />

33<br />

51<br />

60<br />

78<br />

20<br />

38<br />

34<br />

52<br />

64<br />

82<br />

21<br />

39<br />

35<br />

53<br />

66<br />

84<br />

22<br />

40<br />

38<br />

56<br />

80<br />

98<br />

24<br />

42<br />

40<br />

58<br />

96<br />

<strong>11</strong>4<br />

25<br />

43<br />

42<br />

60<br />

<strong>10</strong>0<br />

<strong>11</strong>8<br />

27<br />

45<br />

Metric<br />

0 <strong>10</strong><br />

T-45<br />

I<br />

R<br />

T<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

<strong>10</strong><br />

<strong>11</strong><br />

<strong>12</strong><br />

<strong>13</strong><br />

<strong>14</strong><br />

<strong>15</strong><br />

A