The voice of concrete products - British Precast

The voice of concrete products - British Precast

The voice of concrete products - British Precast

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BRITISH PRECAST BEST PRACTICE AWARDS 2008<br />

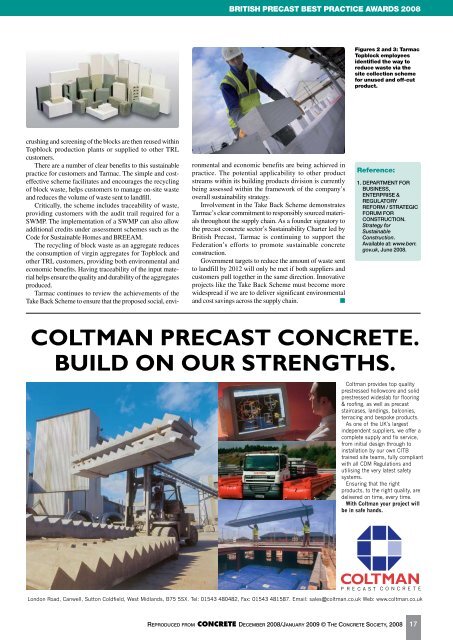

Figures 2 and 3: Tarmac<br />

Topblock employees<br />

identified the way to<br />

reduce waste via the<br />

site collection scheme<br />

for unused and <strong>of</strong>f-cut<br />

product.<br />

crushing and screening <strong>of</strong> the blocks are then reused within<br />

Topblock production plants or supplied to other TRL<br />

customers.<br />

<strong>The</strong>re are a number <strong>of</strong> clear benefits to this sustainable<br />

practice for customers and Tarmac. <strong>The</strong> simple and costeffective<br />

scheme facilitates and encourages the recycling<br />

<strong>of</strong> block waste, helps customers to manage on-site waste<br />

and reduces the volume <strong>of</strong> waste sent to landfill.<br />

Critically, the scheme includes traceability <strong>of</strong> waste,<br />

providing customers with the audit trail required for a<br />

SWMP. <strong>The</strong> implementation <strong>of</strong> a SWMP can also allow<br />

additional credits under assessment schemes such as the<br />

Code for Sustainable Homes and BREEAM.<br />

<strong>The</strong> recycling <strong>of</strong> block waste as an aggregate reduces<br />

the consumption <strong>of</strong> virgin aggregates for Topblock and<br />

other TRL customers, providing both environmental and<br />

economic benefits. Having traceability <strong>of</strong> the input material<br />

helps ensure the quality and durability <strong>of</strong> the aggregates<br />

produced.<br />

Tarmac continues to review the achievements <strong>of</strong> the<br />

Take Back Scheme to ensure that the proposed social, envi-<br />

cpc 78 186x130 20/5/08 16:17 Page 1<br />

ronmental and economic benefits are being achieved in<br />

practice. <strong>The</strong> potential applicability to other product<br />

streams within its building <strong>products</strong> division is currently<br />

being assessed within the framework <strong>of</strong> the company’s<br />

overall sustainability strategy.<br />

Involvement in the Take Back Scheme demonstrates<br />

Tarmac’s clear commitment to responsibly sourced materials<br />

throughout the supply chain. As a founder signatory to<br />

the precast <strong>concrete</strong> sector’s Sustainability Charter led by<br />

<strong>British</strong> <strong>Precast</strong>, Tarmac is continuing to support the<br />

Federation’s efforts to promote sustainable <strong>concrete</strong><br />

construction.<br />

Government targets to reduce the amount <strong>of</strong> waste sent<br />

to landfill by 2012 will only be met if both suppliers and<br />

customers pull together in the same direction. Innovative<br />

projects like the Take Back Scheme must become more<br />

widespread if we are to deliver significant environmental<br />

and cost savings across the supply chain.<br />

n<br />

Reference:<br />

1. DEPARTMENT FOR<br />

BUSINESS,<br />

ENTERPRISE &<br />

REGULATORY<br />

REFORM / STRATEGIC<br />

FORUM FOR<br />

CONSTRUCTION.<br />

Strategy for<br />

Sustainable<br />

Construction.<br />

Available at: www.berr.<br />

gov.uk, June 2008.<br />

COLTMAN PRECAST CONCRETE.<br />

BUILD ON OUR STRENGTHS.<br />

Coltman provides top quality<br />

prestressed hollowcore and solid<br />

prestressed wideslab for flooring<br />

& ro<strong>of</strong>ing, as well as precast<br />

staircases, landings, balconies,<br />

terracing and bespoke <strong>products</strong>.<br />

As one <strong>of</strong> the UK’s largest<br />

independent suppliers, we <strong>of</strong>fer a<br />

complete supply and fix service,<br />

from initial design through to<br />

installation by our own CITB<br />

trained site teams, fully compliant<br />

with all CDM Regulations and<br />

utilising the very latest safety<br />

systems.<br />

Ensuring that the right<br />

<strong>products</strong>, to the right quality, are<br />

delivered on time, every time.<br />

With Coltman your project will<br />

be in safe hands.<br />

London Road, Canwell, Sutton Coldfield, West Midlands, B75 5SX. Tel: 01543 480482, Fax: 01543 481587. Email: sales@coltman.co.uk Web: www.coltman.co.uk<br />

Reproduced f ro m CONCRETE December 2008/January 2009 © <strong>The</strong> Concrete So c i e t y, 2008 17