your complete guide to outstanding outdoor areas - PlaceMakers

your complete guide to outstanding outdoor areas - PlaceMakers

your complete guide to outstanding outdoor areas - PlaceMakers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

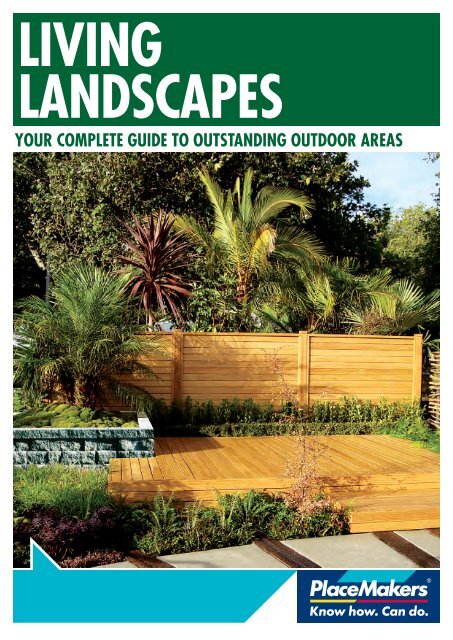

LIVING<br />

LANDSCAPES<br />

YOUR COMPLETE GUIDE TO OUTSTANDING OUTDOOR AREAS

INTRODUCTION<br />

S & J Mackay Builders Ltd; Silver Award<br />

and Category Winner – Welling<strong>to</strong>n Region,<br />

Sustainable Homes $500,000 – $1 million.<br />

QUALITY BRANDS AND<br />

PRODUCTS TO BUILD A<br />

QUALITY OUTDOOR AREA<br />

At <strong>PlaceMakers</strong> we are well equipped <strong>to</strong> help<br />

you turn <strong>your</strong> landscaping dream in<strong>to</strong> a reality.<br />

As well as a comprehensive supply of the<br />

materials and <strong>to</strong>ols you will need, we also offer<br />

sound advice. We know landscaping and are<br />

eager <strong>to</strong> share our knowledge <strong>to</strong> ensure you<br />

achieve the best result.<br />

Check out our large range of How To Guides<br />

in-s<strong>to</strong>re or at www.placemakers.co.nz<br />

These step-by-step instructions will take the<br />

mystery out of many landscaping projects.<br />

THINKING OF EXTENDING<br />

KNOW<br />

HOW<br />

CARD<br />

SPEND *<br />

$<br />

250<br />

GET A<br />

$<br />

25<br />

*Terms and conditions apply.<br />

BONUS<br />

VOUCHER<br />

EARN BONUS VOUCHERS<br />

WITH A KNOW HOW CARD<br />

<strong>PlaceMakers</strong> has everything you need <strong>to</strong> get<br />

the job done, and with a Know How Card<br />

you’ll earn a $25 Bonus Voucher with every<br />

$250 you spend*.<br />

For example, spend $10,000 on <strong>your</strong><br />

decking project and you’ll get a whopping<br />

$1,000 of Bonus Vouchers …that’s a new<br />

BBQ right there!<br />

If you don’t have <strong>your</strong> free Know How Card,<br />

apply at any <strong>PlaceMakers</strong> s<strong>to</strong>re or sign up<br />

online at placemakers.co.nz/knowhowcard<br />

* Know How Card terms and conditions apply.<br />

See www.placemakers.co.nz for details. Bonus Vouchers are<br />

not awarded on purchases using a GE CreditLine card.<br />

Please Note: While the advice and recommendations<br />

contained in this catalogue have been produced with<br />

proper care, they are offered only with the objective of<br />

assisting those interested in home improvement projects.<br />

<strong>PlaceMakers</strong> does not accept responsibility for the<br />

advice, recommendations, etc. contained herein.<br />

Front Cover: Verda Pre-finished Decking and<br />

Verda Pre-finished Fence Panels as shown at 2010<br />

Ellerslie Garden Show Gold winning exhibit.<br />

2

YOUR LIVING OUTDOORS<br />

CONTENTS<br />

4 – 5<br />

DECKING<br />

6 – 7<br />

PAVING - DRYCAST<br />

8 – 9<br />

PAVING - WETCAST & STONE<br />

10 – 11<br />

TIMBER RETAINING WALLS<br />

12 – 13<br />

RETAINING BLOCKS<br />

14 – 15<br />

TIMBER FENCING<br />

16<br />

TIMBER FENCING SYSTEMS<br />

17<br />

METAL FENCING SYSTEMS<br />

18<br />

CLEAR FENCING<br />

19<br />

TRELLIS<br />

20<br />

WIRE FENCING & NETTING<br />

21<br />

TRANSLUCENT ROOFING<br />

22 – 23<br />

LANDSCAPING AGGREGATES<br />

24<br />

OUTDOOR FABRIC SHEETING<br />

25<br />

TIMBER TREATMENT<br />

26 – 27<br />

DRICON, PASLODE & WATTYL<br />

FORESTWOOD PRODUCT GUIDES<br />

THE GROUND RULES<br />

Before you start any project, be<br />

sure the finished job will comply<br />

with the Building Code and council<br />

regulations. For full information,<br />

consult <strong>your</strong> local council.<br />

EXTRA SERVICES<br />

We make every project easier with<br />

these services:<br />

• Free estimates and quotes<br />

• Delivery <strong>to</strong> site or free loan trailer<br />

• 15% off at Hirepool on specialist<br />

<strong>to</strong>ols when you present <strong>your</strong><br />

<strong>PlaceMakers</strong> Know How Card<br />

• Free How To Guides available<br />

in-s<strong>to</strong>re or online at<br />

www.placemakers.co.nz<br />

3

DECKING<br />

NATURAL LIVING<br />

Wood from sustainably managed<br />

forests is the ultimate sustainable<br />

building material. As a tree grows,<br />

it removes and s<strong>to</strong>res carbon dioxide<br />

from the air, helping reduce carbon<br />

levels in the atmosphere. Harvesting<br />

and using the timber locks away<br />

carbon and prevents its release back<br />

in<strong>to</strong> the atmosphere. Replanting the<br />

forests continues the cycle of removal<br />

and s<strong>to</strong>rage.<br />

<strong>PlaceMakers</strong> s<strong>to</strong>cks radiata pine<br />

timber products from sawmills<br />

which source their logs from<br />

New Zealand’s sustainably managed<br />

forests. <strong>PlaceMakers</strong> also offers<br />

hardwood decking options from<br />

legally verified sources including<br />

Forest Stewardship Council<br />

(FSC). Please see our website,<br />

www.placemakers.co.nz for<br />

more details.<br />

Deck Bearers<br />

• H4 or H5 treated radiata<br />

• Planer gauge or rough sawn finish<br />

• SG8 wet graded timber<br />

• Available in 100 x 75mm, 100 x 100mm or 150 x 50mm<br />

Deck Joist<br />

• H3.2 treated radiata<br />

• Planer gauge or rough sawn finish<br />

• SG8 wet graded timber<br />

• Available in 150 x 50mm or 200 x 50mm<br />

FOREST<br />

STEWARDSHIP<br />

COUNCIL<br />

Dricon HandiCrete ®<br />

• Quality concrete with a<br />

super smooth finish<br />

• Formulated <strong>to</strong> reach a target<br />

strength of 20MPa in 28<br />

days<br />

• Ideal for paths, foundations,<br />

mowing strips, letter boxes<br />

and block fill<br />

Deck Balustrades<br />

• H3.2 treated radiata<br />

• Planer gauge or rough<br />

sawn finish<br />

• No.1 or SG8 wet<br />

graded timber<br />

• Available in 50 x 40mm<br />

or 50 x 50mm<br />

FSC is an independent,<br />

non-governmental, not for profit<br />

organisation established <strong>to</strong> promote<br />

the responsible management of the<br />

world’s forests. It is represented in<br />

more than 50 countries.<br />

FSC’s certification system is<br />

recognised internationally, and<br />

when you buy timber with the FSC<br />

label, you know you’re making a<br />

responsible choice.<br />

Merch Decking<br />

NZ grown radiata pine. Standard<br />

decking where cost is more<br />

important than appearance.<br />

Contains some knots and may be<br />

liable <strong>to</strong> dis<strong>to</strong>rtion.<br />

• Graded best face <strong>to</strong> grip<br />

tread profile<br />

• H3.2 treated radiata<br />

• Available in 100 x 25mm or<br />

100 x 40mm<br />

Premium Decking<br />

NZ grown radiata pine. Quality<br />

product with minimal defects,<br />

specially selected for a high-class<br />

fi n i s h .<br />

• Graded best face <strong>to</strong> grip<br />

tread profile<br />

• H3.2 treated radiata<br />

• Available in 100 x 25mm or<br />

100 x 40mm<br />

Verda Prefinished Decking<br />

NZ grown radiata pine. Superior <strong>to</strong> standard<br />

radiata, clear grade and knot-free. Graded<br />

<strong>to</strong> smooth face. Non-bleeding/leaching.<br />

• TanE treatment – 25 year guarantee<br />

against rot and insect attack*<br />

• Available in 100 x 25mm or 100 x 40mm<br />

• Available colours Honey Gold, Natural<br />

Amber and Antique Grey<br />

Available colours<br />

* Subject <strong>to</strong> conditions – see<br />

guarantee on www.verda.co.nz<br />

for more details<br />

4<br />

Whilst every care has been taken <strong>to</strong> obtain an accurate representation, the colours shown here are subject <strong>to</strong> the limitations of the<br />

colour reproduction process. Visit <strong>your</strong> nearest <strong>PlaceMakers</strong> <strong>to</strong> view samples prior <strong>to</strong> ordering.

“The most renewable natural resource” for more information visit our<br />

website www.nzwood.co.nz<br />

Please Note:<br />

Whilst the advice and recommendations contained in this brochure<br />

have been produced with proper care, they are offered only with the<br />

objective of assisting those interested in home improvement projects<br />

and <strong>PlaceMakers</strong> does not accept responsibility for the advice,<br />

recommendations, etc. contained herein.<br />

Updated: July 2008 (BSPG110116)<br />

www.placemakers.co.nz<br />

0800 KNOW HOW (0800 566 946)<br />

The piles in this example deck are 125 x 125mm H5 radiata pine piles, spaced at<br />

a maximum of 1200mm in each direction. The front row of piles is also set back<br />

from the front edge of the deck <strong>to</strong> allow it <strong>to</strong> overhang the piles and bearers.<br />

This provides a neater finish <strong>to</strong> the front of the deck, but the construction<br />

details used and the ‘best’ way are ultimately a personal preference. The piles<br />

themselves can also continue up through the deck <strong>to</strong> support a handrail or<br />

overhead pergola. A pergola may require a building consent. The construction<br />

methods used at this stage must be modified <strong>to</strong> suit any of these alternatives.<br />

(See Illustration 3).<br />

Illustration 3<br />

If you are running the piles up<br />

through the deck <strong>to</strong> form part of<br />

the handrail, or support an<br />

overhead pergola, fix the bearer<br />

by bolting it in place<br />

Nail a small wooden block <strong>to</strong> the<br />

pile or use a G Clamp <strong>to</strong> support<br />

the bearer in the correct position<br />

while you drill the hole. Remember<br />

<strong>to</strong> treat the holes with a timber<br />

preservative.<br />

If you are running the piles up through the deck <strong>to</strong> form part of the handrail,<br />

or <strong>to</strong> support an overhead pergola, fix the bearer by bolting it in place. Nail a<br />

small wooden block <strong>to</strong> the pile or use a G Clamp <strong>to</strong> support the bearer in the<br />

correct position while you drill the hole. Remember <strong>to</strong> treat the holes with a<br />

timber preservative.<br />

The concrete pads need <strong>to</strong> be at least 300mm in diameter or 300 x 300mm<br />

square and, for a low deck, 300mm deep. After you’ve dug the holes, insert the<br />

piles <strong>to</strong> check there will be at least 100mm of concrete all around each pile,<br />

including underneath.<br />

You have a choice about when <strong>to</strong> set the piles in concrete.<br />

Option 1<br />

Cover the bot<strong>to</strong>m of the hole with 100mm of concrete. Place the pile back in the<br />

hole with the cut end up. Pour a further 200mm of concrete and position the<br />

pile. Brace the pile in the correct position and leave <strong>to</strong> set for at least 24 hours.<br />

Then trim the piles <strong>to</strong> height and continue building the deck on <strong>to</strong>p. This option<br />

requires you set the posts exactly in place before the bearers are there <strong>to</strong> give<br />

you a line <strong>to</strong> work <strong>to</strong>.<br />

Option 2<br />

Hang the piles 100mm above the bot<strong>to</strong>m of the holes, and brace them in<br />

all directions very firmly. Trim the piles <strong>to</strong> height, and build and fix <strong>your</strong> deck<br />

framing on <strong>to</strong>p, supporting it with props of timber.<br />

Illustration 4: Bearers and Piles<br />

When the framing (bearers and joists) is fitted and fixed <strong>to</strong>gether <strong>to</strong> the piles,<br />

check that everything is straight, level and square, and then pour concrete in<strong>to</strong><br />

the holes.<br />

(Leave <strong>your</strong> concrete slightly lower than the <strong>to</strong>p of the hole <strong>to</strong> allow lawn or<br />

<strong>to</strong>psoil <strong>to</strong> cover it up.)<br />

When the concrete has set, nail down the decking, removing the temporary<br />

props at any stage.<br />

An alternative <strong>to</strong> setting the piles in concrete is using a Bowmac post bracket.<br />

These require less concrete, but provide little lateral bracing compared with<br />

posts set in concrete. (See Illustration 5).<br />

Trimming hint:<br />

Mark the piles on three<br />

sides before cutting.<br />

With Bowmac<br />

Illustration 5: Post Setting Detail<br />

Ledger<br />

With post<br />

embedded<br />

The piles are trimmed off <strong>to</strong> the underside of the bearers. (See Illustration 4 & 5).<br />

The ledger on the wall is actually a bearer. Level a stringline from under that, or<br />

a straight bearer held against it, <strong>to</strong> give you the trim-off height of the piles. Mark<br />

the cut around three sides of the pile with <strong>your</strong> square before cutting.<br />

This deck uses two 100 x 50mm nailed <strong>to</strong>gether as bearers. Nail at 300mm<br />

centres from opposite faces. Fix <strong>to</strong> each pile with two nails skewed (angle nailed)<br />

from each face. The piles at each end should also be connected <strong>to</strong> the bearer with<br />

a stainless steel ‘Nailon’ plate on each face.<br />

SPACING BETWEEN PILES ALONG THE BEARER<br />

Maximum span of joist<br />

Bearer size<br />

1.45m 100 x 75mm<br />

2.00m 100 x 100mm or two 100 x 50mm<br />

3.20m 125 x 100mm or two 125 x 50mm<br />

4.65m 150 x 100 or two 150 x 50mm<br />

Fitting the Joists<br />

You can see from Illustration 6 that the deck cantilevers over the last bearer <strong>to</strong><br />

produce an overhanging deck.<br />

Illustration 6: Cantilevered Deck Construction<br />

The joists should be spaced at maximum centres according <strong>to</strong> the table below.<br />

The spacing depends on the thickness of decking used.<br />

JOIST SELECTION CHART<br />

Joist size: mm Maximum Span of Joists<br />

Joist Spacings<br />

400mm<br />

450mm 600mm<br />

100 x 50 1.45m 1.40m 1.25m<br />

125 x 50 1.85m 1.80m 1.60m<br />

150 x 50 2.60m 2.40m 2.00m<br />

200 x 50 3.50m 3.35m 2.85m<br />

250 x 50 4.40m 4.25m 3.60m<br />

300 x 50 5.20m 5.05m 4.30m<br />

When you rest each joist on the ledger on the side of the house, leave a 10mm<br />

gap between the end of each joist and the wall. That s<strong>to</strong>ps moisture becoming<br />

trapped and causing decay. Fix each joist <strong>to</strong> every bearer with two nails through<br />

each face at every crossing. Let the end of each joist overlap <strong>your</strong> profile strings.<br />

Trim them all at once later, using the line and a square <strong>to</strong> accurately mark each<br />

joist. Fit a boundary joist <strong>to</strong> the ends of the main joists <strong>to</strong> give the edge of <strong>your</strong><br />

deck a neat finish.<br />

Decking<br />

Gap between<br />

joist and wall<br />

Gap between<br />

decking and wall<br />

150mm Step<br />

Decking height<br />

Joist<br />

Deck joist depth<br />

Ledger<br />

Packer<br />

Illustration 7<br />

DECKING MATERIAL SELECTION CHART<br />

Joist Spacing<br />

Decking Material<br />

400mm<br />

25mm thick Radiata Timber<br />

450mm<br />

25mm thick imported Hardwood<br />

600mm<br />

40mm thick Radiata Timber<br />

Start laying timber decking from the house in a full length board. Make sure that,<br />

like the joists, there’s a gap left between the first board and the wall. If joins are<br />

necessary they should be made on the joists and staggered at random between<br />

rows. An overhang of 10mm <strong>to</strong> 20mm at each end is usually preferred. The first<br />

two boards should be cut <strong>to</strong> this size before fixing with galvanized nails: • 60mm<br />

Galvanized Nails for 19mm decking • 75mm Galvanized Nails for 30mm decking.<br />

Check the boards are true and in a straight line as you fix them. Also check the<br />

distance <strong>to</strong> the outside bearer remains constant. Make up a spacer of 3mm <strong>to</strong><br />

5mm <strong>to</strong> ensure an even gap. Move it along as you nail. Small variations can be<br />

adjusted slightly as each board is fixed. Don’t cut the rest of the decking <strong>to</strong> length<br />

(apart from the first two). Let them overhang the end joists. Then trim them all off<br />

<strong>to</strong>gether by nailing a board <strong>to</strong> the deck as a <strong>guide</strong> for <strong>your</strong> circular saw.<br />

Kitset steps of various lengths are available from <strong>PlaceMakers</strong>. These are<br />

easily fitted <strong>to</strong> <strong>your</strong> deck. If the deck gives access <strong>to</strong> a building the steps must<br />

comply with the New Zealand Building Code Access requirements.<br />

There are various types of interior stains available, oilbased<br />

pigmented, solvent-based dye stain and waterbased<br />

dye stains. They all allow the grain of the timber <strong>to</strong><br />

show through. Stains are designed <strong>to</strong> be applied <strong>to</strong> raw or<br />

new timber only and all interior stains must be over coated<br />

with a clear finish <strong>to</strong> protect the colour from rubbing off<br />

due <strong>to</strong> excess handling.<br />

Clear finishes are available in water-based, oil-based and solvent-based<br />

formulations. Most are only suitable for interior surfaces; <strong>to</strong> protect, enhance and<br />

highlight the timber being coated.<br />

Oil-based clears will give timber a ‘golden’ look whereas water-based preparations<br />

will keep the timber looking natural without discolouration.<br />

Prior <strong>to</strong> staining/clear coating interior timbers, it is essential<br />

that all timber is clean, dry and free from contamination.<br />

The right preparation can greatly enhance the natural grains on the timber surface<br />

and while sanding may be tedious it is an important step in preparing the surface.<br />

Timber should be sanded smooth <strong>to</strong> allow the penetration of the stain/clear<br />

coating. If this is not carried out the product will not penetrate the timber surface<br />

creating adhesion problems. Sand out any marks, including planer ripples. Sand<br />

with the grain, starting with coarse sandpaper and working up <strong>to</strong> fine. Overfill any<br />

cracks or holes with appropriate filler then sand back levelling with the surrounding<br />

timber. Wood dust from sanding will cause problems if it is not removed properly.<br />

Ensure that the surface has been properly cleaned and free of contaminants.<br />

Always check the colour of the stain prior <strong>to</strong> commencement <strong>to</strong> see if the colour<br />

is correct as it is difficult <strong>to</strong> remove the stain from the timber fibres once staining<br />

has been <strong>complete</strong>d.<br />

Apply one coat of stain with a rag, following the grain of<br />

Please Note:<br />

Whilst the advice the and timber. recommendations contained in this brochure<br />

have been produced with proper care, they are offered only with the<br />

objective of assisting Oil-based those interested pigmented in home stains improvement projects<br />

and <strong>PlaceMakers</strong> Oil-based does not pigmented accept stains responsibility are designed for the for advice, use on light timbers such as Pine,<br />

recommendations, Ash etc. and contained Tawa. They herein. are applied in a circular motion on larger <strong>areas</strong> or following<br />

Updated: July 2008 the grain (BSPG110116) on smaller <strong>areas</strong>. Avoid applying <strong>to</strong>o much stain as this can lead <strong>to</strong><br />

excess film build and premature failure.<br />

Solvent-based dye stains<br />

Solvent-based dye stains are designed for harder exotic timbers. They penetrate<br />

and dye the fibres of the timber and give crisp colours allowing the natural beauty<br />

of the timber grain <strong>to</strong> show through.<br />

Water-based gel stains<br />

Water-based gel stains tend <strong>to</strong> be the easiest <strong>to</strong> use. They can be applied direct <strong>to</strong><br />

vertical surfaces without the stain running down the surface, are quicker drying,<br />

low odour, have good clarity and are suitable for all timber types.<br />

All rags used for staining must be disposed of correctly by soaking in water <strong>to</strong><br />

neutralise any oil/solvent content present. If this is not carried out the rags can<br />

become combustible and ignite, causing fires.<br />

Polyurethane clear coatings are available in oil-based,<br />

water-based and moisture cured finishes. They are normally<br />

available in gloss, satin and matt finishes. A clear coat will<br />

enhance and protect the natural beauty and colour of the<br />

timber and protect any stained surface from excess wear.<br />

Gloss products are preferred for floors as the lower gloss<br />

levels may polish up in high traffic <strong>areas</strong>.<br />

When clear coating Rimu, Totara and Matai timbers, avoid using oil-based<br />

finishes as these can react with the oils in the timber causing drying problems.<br />

Water-based is recommended for these timbers as a first coat.<br />

Surfaces must be in good, clean, dry condition, free from wax, grease and dust<br />

prior <strong>to</strong> clear coating. Sanding the surface smooth <strong>to</strong> remove any defects or<br />

damaged <strong>areas</strong> will give you a better look. Remember that clear coating over<br />

such defects will highlight them making them stand out. If the coating is left longer<br />

than 48 hours, a light sanding is required between coats <strong>to</strong> aid adhesion.<br />

Polyurethanes can be applied by brush or speed brush. Do not apply <strong>to</strong>o much<br />

at once, keep an even coating and wet edge. This will enable you <strong>to</strong> continue<br />

blending the coating in on larger <strong>areas</strong>. When coating <strong>to</strong>ngue and groove, <strong>complete</strong><br />

each board from one end <strong>to</strong> the other, this will help <strong>to</strong> maintain an even coating.<br />

The use of sanding sealer is recommended prior <strong>to</strong> clear coating; this helps seal<br />

porous timber and gives a greater film build on finishing coats.<br />

A minimum of 2 coats is recommended with a light sanding between coats <strong>to</strong> give<br />

you a smoother finish.<br />

For an exceptionally hard-wearing finish on floors, bench <strong>to</strong>ps, labora<strong>to</strong>ry and<br />

kitchen benches, moisture cured polyurethane is recommended. It is a single<br />

pack clear coating which cures by absorbing water from the atmosphere.<br />

All polyurethanes start as a gloss finish. A flattening agent is added <strong>to</strong> lower the<br />

gloss level, therefore it is very important that satin and matt finishes are stirred<br />

well with a flat stick <strong>to</strong> bind the agent and give a uniform gloss level.<br />

YOUR COMPLETE KNOW HOW GUIDE<br />

Deck piles<br />

• H5 treated radiata<br />

• 125 x 125mm available<br />

in various lengths from<br />

600mm <strong>to</strong> 3.6M<br />

SPACING THE PILES<br />

DIGGING THE HOLES<br />

PILES & BEARERS<br />

PILES & BEARERS<br />

FIXING THE BEARERS<br />

JOISTS & DECKING<br />

CONCRETING THE PILES<br />

Deck Railings<br />

TRIMMING THE PILES (If using option 1)<br />

• H3.2 treated radiata<br />

• Planer gauge or rough sawn finish<br />

• No.1 or SG8 wet graded timber<br />

• Available in 75 x 50mm or 100 x 50mm<br />

PILES & BEARERS / JOISTS & DECKING<br />

FITTING THE DECKING<br />

STEPS<br />

JOISTS & DECKING<br />

Interior Stains & Clears<br />

BUILDING A<br />

TIMBER<br />

DECK<br />

YOUR COMPLETE HOW TO GUIDE<br />

Preparation<br />

Staining<br />

CHOOSING YOUR<br />

DECKING<br />

TIMBER<br />

Clear Coating<br />

YOUR COMPLETE HOW TO GUIDE<br />

HOW TO GUIDES<br />

PUTTING UP A<br />

TIMBER<br />

STAINS<br />

AND CLEARS<br />

For help choosing <strong>your</strong> decking timber<br />

and instructions on how <strong>to</strong> build and<br />

stain <strong>your</strong> deck see these how <strong>to</strong><br />

<strong>guide</strong>s, available in-s<strong>to</strong>re or online at<br />

www.placemakers.co.nz<br />

KNOW<br />

HOW<br />

CARD<br />

SPEND *<br />

$<br />

250<br />

GET A<br />

$<br />

25<br />

*Terms and conditions apply.<br />

BONUS<br />

VOUCHER<br />

Don’t forget <strong>to</strong> use <strong>your</strong> Know How<br />

Card with every purchase.<br />

Stair Stringers<br />

• H4 treated radiata<br />

• 1-15 step sizes available<br />

*Steps purchased<br />

separately <strong>to</strong><br />

preferred width<br />

Metalex Timber<br />

Preservative<br />

Treat all timber cut ends <strong>to</strong><br />

protect against rotting and<br />

mildew growth.<br />

• Water resistant finish<br />

• Protects fibrous substrates<br />

• Easy <strong>to</strong> apply<br />

• Available in clear or green<br />

PROJECT CHECK LIST<br />

Materials<br />

• Timber pegs • Decking • Joists<br />

• Bearers • Stringers • Nails<br />

• Concrete • Fixings and brackets<br />

• Timber Preservative<br />

Tools<br />

• Stringline • Tape measure<br />

• Spirit level • Circular saw<br />

• Hammer • Hand saw<br />

• Electric drill • Set square<br />

Makita 1050W<br />

185mm Circular<br />

Saw 5030425<br />

Vitex Decking<br />

A medium-density, naturally stable<br />

and durable hardwood harvested<br />

as “community production” from the<br />

Solomon Islands, it silvers off <strong>to</strong> a<br />

fine even finish.<br />

• Available in 100 x 25mm<br />

or 150 x 25mm<br />

Purple Heart Decking<br />

Purple Heart hardwood is superior<br />

quality decking. It provides class 1<br />

durability for decking, with minimal<br />

leaching/bleeding.<br />

• Available in 100 x 25mm<br />

or 150 x 25mm<br />

Massa Decking<br />

Sustainably harvested heavy<br />

hardwood, kiln-dried, stable and<br />

extremely strong with a Class 1<br />

durability rating. A proven<br />

performer for decking, fl ooring<br />

beams and exterior joinery.<br />

Non-bleeding/leaching.<br />

• Available in 100 x 25mm<br />

or 150 x 25mm<br />

Composite Decking<br />

– Hybrideck<br />

This new generation composite<br />

decking is extremely stylish, looks<br />

and feels like timber. Made from<br />

recycled wood and plastic materials,<br />

it won’t warp, crack or splinter.<br />

• Available in finished sizes of<br />

130 x 19mm or 140 x 25mm<br />

Available colours<br />

All decking sizes quoted are nominal. FSC timber only available from selected s<strong>to</strong>res.<br />

5

PAVING-<br />

DRYCAST<br />

At <strong>PlaceMakers</strong> you will find an<br />

extensive range of contemporary<br />

paving that will transform <strong>your</strong><br />

<strong>outdoor</strong> living spaces in<strong>to</strong><br />

statements of <strong>your</strong> individual style.<br />

With so many options available<br />

there is a selection of colours,<br />

shapes and sizes in classic masonry<br />

through <strong>to</strong> handcrafted large-format<br />

wet-cast pavers.<br />

Laying paving is a very achievable<br />

DIY project with <strong>PlaceMakers</strong><br />

providing the materials and Know<br />

How, or choose a professional<br />

contrac<strong>to</strong>r <strong>to</strong> transform <strong>your</strong><br />

<strong>outdoor</strong> living <strong>areas</strong>.<br />

Dricon PaveLock ®<br />

Dricon PaveLock ® is a stabilised<br />

jointing sand that enhances the<br />

durability and appearance of<br />

paved surfaces.<br />

• Provides long term locked<br />

in strength and durability<br />

• Resistant <strong>to</strong> weed growth<br />

and insect infestation<br />

• Ideal for paving joints in<br />

driveways and footpaths<br />

Dricon PaveSand TM<br />

• Essential <strong>to</strong> ensure the<br />

overall performance and<br />

quality<br />

• Ideal for paving joints in<br />

footpaths, domestic<br />

and industrial driveways<br />

• Flows easily in<strong>to</strong> paving<br />

joints providing strength<br />

maximising the long term<br />

performance of paving<br />

WHICH PAVERS<br />

Our range will help you create<br />

stylish patios, courtyards, paths,<br />

driveways and parking <strong>areas</strong>.<br />

Typically, pavers used for traffic<br />

<strong>areas</strong> will be smaller format and<br />

thicker <strong>to</strong> withstand the weight,<br />

while pedestrian <strong>areas</strong> only<br />

requires a thinner paver for ease<br />

of installation.<br />

Then, there’s the shape, size, colour<br />

and laying patterns which effect the<br />

overall look and performance.<br />

<strong>PlaceMakers</strong> can advise you<br />

which pavers are best suited <strong>to</strong><br />

<strong>your</strong> requirements.<br />

Firth Holland Paver<br />

The clean lines of the Holland Paver<br />

offer a flexible and stylish paving<br />

solution. Built-in spacer nibs allow<br />

for easy and accurate laying.<br />

• Ideal for domestic driveways and<br />

parking <strong>areas</strong><br />

• 200 x 100 x 50mm<br />

• 50 pavers per M 2<br />

Firth Walkway Paver<br />

With their traditional look, Walkway<br />

Pavers are an economical option for<br />

paving different <strong>areas</strong> around <strong>your</strong><br />

home.<br />

• Ideal for paths, pool surrounds,<br />

courtyards and patios<br />

• 230 x 190 x 45mm<br />

• 22 pavers per M 2<br />

Firth Classic<br />

Cobbles<strong>to</strong>ne Paver<br />

The Classic Cobbles<strong>to</strong>ne provides<br />

the look and feel of a traditional old<br />

world cobbles<strong>to</strong>ne for a variety of<br />

residential applications.<br />

• Ideal for domestic driveways,<br />

residential patios and pathways<br />

• 230 x 219 x 60mm<br />

• 22 pavers per M 2<br />

Available colours Available colours Available colours<br />

6<br />

Whilst every care has been taken <strong>to</strong> obtain an accurate representation, the colours shown here are subject <strong>to</strong> the limitations of the colour reproduction process.<br />

Visit <strong>your</strong> nearest <strong>PlaceMakers</strong> <strong>to</strong> view samples prior <strong>to</strong> ordering.

suB GraDe testiNG<br />

Sub-grade Weak moderate Strong<br />

Strength<br />

Walking & Walking Heel Neither walking<br />

heel test leaves distinct leaves an nor heel leaves<br />

footprints footprints impression an impression<br />

Driveways 175mm base 125mm base 75mm base<br />

(light vehicle material material material<br />

traffic only)<br />

Pedestrian 75mm base 50mm base No base<br />

use only material material material required,<br />

just sand<br />

exCavatioN exaMple<br />

Paver thickness (driveway)<br />

60 mm<br />

Bedding sand (compacted)<br />

30 mm<br />

Base Course (moderate sub-grade firmness) 125 mm<br />

= <strong>to</strong>tal exCavatioN Depth<br />

(below finished paving level)<br />

215mm<br />

Base Course Material<br />

• Should be crushed rock including particles of all sizes.<br />

• No particles should have a diameter more than one third of the<br />

thickness of the required base course layer.<br />

• It should contain no soil or plant material.<br />

• Lay geotextile fabric first where soft clay which might push in<strong>to</strong><br />

and through the base course material.<br />

• For layers of 100mm thick or more, use 40mm all in aggregate.<br />

This should also be laid in layers no thicker than 100mm and compacted <strong>to</strong> a<br />

uniform dense condition, especially around manholes and kerbs. The finished<br />

texture of the base course should not allow bedding sand <strong>to</strong> filter through. The<br />

final surface of the base course should match the con<strong>to</strong>ur of <strong>your</strong> finished<br />

paving with no bumps, and no holes deeper than 10mm.<br />

Edging is important <strong>to</strong> prevent sideways movement of pavers, and <strong>to</strong> s<strong>to</strong>p<br />

bedding sand leaking out.<br />

edging options<br />

• Soldier course of either standing or flat pavers (See Illustration 3)<br />

• Paving kerb – segmented raised kerbing<br />

• Paving edge – concealed, underground PVC strip<br />

• Haunching – concealed concrete strip. (See Illustration 4)<br />

Concrete<br />

Soldier Course<br />

Subgrade<br />

Illustration 3: Soldier course of standing pavers<br />

Concrete Haunching<br />

Soldier Course<br />

100mm<br />

Min<br />

Illustration 4: Concealed haunching<br />

Bedding sand supports <strong>your</strong> pavers, but will not hide irregularities in the base<br />

course. It should be coarse river sand (not beach sand), and damp but not wet.<br />

1. Don’t compact bedding sand directly. It compacts under the pavers. To test<br />

how much the thickness will reduce, spread some sand over a small area.<br />

Lay a paver on <strong>to</strong>p, and thump that with a rubber hammer. The resulting<br />

reduction in sand thickness will tell you how much <strong>your</strong> sand compacts.<br />

2. Pave in manageable sized <strong>areas</strong>. Spread sand only over an area you know<br />

you can finish in one session, and get <strong>to</strong> without walking on. Spread the<br />

sand <strong>to</strong> slightly more than the depth <strong>your</strong> rubber hammer test indicated<br />

would produce a compacted sand depth of between 20mm and 30mm. You<br />

will usually need <strong>to</strong> start with the uncompacted sand bed between 5mm<br />

and 10mm thicker than its compacted depth. (See Illustration 5A)<br />

3. Screed the sand <strong>to</strong> a uniform level. As with any screeding, you need<br />

temporary <strong>guide</strong>s or runners at each side <strong>to</strong> run <strong>your</strong> screed board on.<br />

If you have already laid a soldier or kerb course, you may be able <strong>to</strong> use<br />

that <strong>to</strong> support <strong>your</strong> runners. If the area <strong>to</strong> be paved is <strong>to</strong>o wide you’ll<br />

need <strong>to</strong> drive pegs, and fix <strong>your</strong> runners <strong>to</strong> them, just like concrete boxing.<br />

(See Illustration 5B)<br />

1. Start from the straightest convenient edge, and lay <strong>your</strong> pavers with a<br />

space of 2mm <strong>to</strong> 4mm between them. Some pavers have spacer nibs<br />

which achieve that au<strong>to</strong>matically. The space allows joint sand <strong>to</strong> penetrate<br />

around the pavers. Always start at the bot<strong>to</strong>m of sloped <strong>areas</strong>.<br />

2. Lay all full pavers first: then cut and lay any pieces. Cut pavers with a<br />

diamond concrete saw, paver splitter (both available from hire centres) or,<br />

for small <strong>areas</strong>, a bolster.<br />

3. Don’t run vehicles over the paving until it’s <strong>complete</strong>ly finished. To get a<br />

loaded wheelbarrow across, lay heavy planks down as running boards.<br />

Soldier Course<br />

on Concrete<br />

Illustration 5A: Screed on Runners<br />

Screed<br />

Sand<br />

Basecourse<br />

Subgrade<br />

Illustration 5B: (Detail) Not <strong>to</strong> scale<br />

Timber Screed<br />

Subgrade<br />

Guide Cleats<br />

Fixed <strong>to</strong> Screed<br />

Timber Runner<br />

Fixed <strong>to</strong> Peg<br />

Guide cleats<br />

fixed <strong>to</strong> screed<br />

Timber runner at<br />

correct height fixed<br />

<strong>to</strong> pegs<br />

Peg<br />

Your pavers now need <strong>to</strong> be consistently compacted over the whole area. Include<br />

a minimum of three passes with compac<strong>to</strong>r each at 90 degrees <strong>to</strong> each other.<br />

1. For a small area, use a rubber hammer on a short length of heavy timber:<br />

say a piece of 150 x 50mm. For most other jobs, use a plate compac<strong>to</strong>r.<br />

2. When the pavers are all compacted, sweep joint sand over the whole area<br />

and compact again. The compac<strong>to</strong>r will drive the sand in<strong>to</strong> the joints. Keep<br />

sweeping and compacting until all joints are filled.<br />

3. Joint sand should be fine dry plaster sand with angular particles that lock<br />

well <strong>to</strong>gether. It is also sold as paving sand and some types incorporate a<br />

weed preventative.<br />

In most cases maintenance will be minimal. If some pavers settle unevenly, or<br />

if underground services need <strong>to</strong> be exposed, <strong>your</strong> paving may require re-laying.<br />

To do this simply follow the procedures given above. It would pay <strong>to</strong> add a<br />

layer of weed matting below the sand layer <strong>to</strong> s<strong>to</strong>p any weeds that could grow<br />

up and between <strong>your</strong> pavers. Where paving is cleaned or has water running<br />

across it the joint sand may require <strong>to</strong>pping up periodically. To enhance the<br />

appearance of <strong>your</strong> paving special sealers are available, and these may require<br />

reapplication over time. Ask about these at <strong>your</strong> <strong>PlaceMakers</strong> Firth Centre.<br />

note: Building or landscaping work has <strong>to</strong> comply with the new Zealand<br />

Building code and <strong>your</strong> local council requirements. talk <strong>to</strong> the building<br />

inspec<strong>to</strong>rs at <strong>your</strong> council. they can provide helpful details of such<br />

matters and say whether or not a permit is required for the work you wish<br />

<strong>to</strong> do.<br />

Choose <strong>your</strong> site carefully, watch and compensate for potential problems such<br />

as drains, trees and electrical wiring.<br />

Check the height of the surface <strong>to</strong> be paved, take measurements and draw design<br />

plans <strong>to</strong> allow for the paving’s <strong>to</strong> be below the floor level and slightly sloped away<br />

from the house or <strong>areas</strong> that you would want <strong>to</strong> keep water away from.<br />

Choose <strong>your</strong> pavers and design…measure up and order.<br />

If the ground is firm and well compacted excavate <strong>to</strong> a depth of 75 mm, then<br />

move <strong>to</strong> next step. If soft or a filled site, excavate 75-100mm deeper and add<br />

75-100mm of <strong>to</strong>p course, compact well with a plate compacter.<br />

Now set up string lines <strong>to</strong> give you lines <strong>to</strong> follow for both height and gapping.<br />

now you can choose 1 of 2 laying methods:<br />

1. Spread and level a fine loose bedding sand, dampen and lightly compact.<br />

Then screed level and choose <strong>your</strong> laying pattern. (This method is quick<br />

easy and if the leveling is done well gives a great finish).<br />

2. Mix up a mix of sand and cement with water <strong>to</strong> make a wet mix that you<br />

put on the base, roughly level and then tamp <strong>your</strong> pavers down in<strong>to</strong> it,<br />

remember where they sit is where they stay. (This method requires more<br />

work, precision laying as it is far less forgiving, once the sand and cement<br />

mix hardens <strong>your</strong> pavers are not able <strong>to</strong> be easily lifted or moved).<br />

nB: It is critical you allow a gap between pavers of a minimum of 8mm,<br />

although 10-15mm is gap is recommended.<br />

This gap allows you <strong>to</strong> have some flexibility if there are any minor height<br />

discrepancies and also remove the effect of any slight size variation that occurs<br />

in hand made pavers.<br />

Some pavers may need cutting, you can hire a suitable saw from hire centres<br />

or use an angle grinder with a masonry blade installed. Remember <strong>your</strong> safety<br />

equipment.<br />

do not uSe comPActIon eQuIPment over PAverS<br />

Hose off pavers, let them dry, then use either pave joint sand, mortar pointing, or<br />

pavelock grouting sand…remember follow the product directions, if compaction<br />

is required, go over pavers tapping with a rubber mallet.<br />

Use dry sand and cement mix, <strong>to</strong> trowel an edge from the <strong>to</strong>p of the paver<br />

away at a 45 degree angle <strong>to</strong> give the pavers a border or haunch <strong>to</strong> hold them<br />

in place.<br />

Remember, if at any stage you are unsure of what you are doing or need further<br />

advice, seek professional help.<br />

Firth Grass Paver<br />

Ideal for driveways or<br />

parking <strong>areas</strong><br />

• Suitable for light vehicle<br />

traffic<br />

• Widely spaced openings<br />

let grass growth through<br />

• 400 x 400 x 80mm<br />

• 6 pavers per M 2<br />

3. PrePArIng the BASe<br />

courSe<br />

4. PlAcIng the edgIng<br />

installation instructions<br />

Firth Gobi Block<br />

Ideal for turning or<br />

5. PrePArIng the BeddIng<br />

parking<br />

SAnd BASe<br />

<strong>areas</strong> for boats<br />

and caravans<br />

• Provides superior<br />

traction, even on<br />

6. lAyIng the PAverS<br />

sloping surfaces<br />

• 200 x 200 x 100mm<br />

• 25 pavers per M 2<br />

installation instructions<br />

7. comPActIng the PAverS<br />

mAIntenAnce<br />

installation instructions / maintenance<br />

Wet cASt PAvIng<br />

wet cast paving<br />

LAYING<br />

PAVING<br />

STONES<br />

<strong>your</strong> <strong>complete</strong> how <strong>to</strong> <strong>guide</strong><br />

HOW TO GUIDE<br />

For instructions on how <strong>to</strong><br />

lay <strong>your</strong> pavers, see our<br />

How To Guide available<br />

in-s<strong>to</strong>re or online at<br />

www.placemakers.co.nz<br />

KNOW<br />

HOW<br />

CARD<br />

SPEND *<br />

$<br />

250<br />

GET A<br />

$<br />

25<br />

*Terms and conditions apply.<br />

BONUS<br />

VOUCHER<br />

Don’t forget <strong>to</strong> use <strong>your</strong> Know How<br />

Card with every purchase.<br />

PROJECT CHECKLIST<br />

Materials<br />

• Pavers • Dricon PaveLock<br />

• Base course • Sika Pave Sealant<br />

• Weed matting • Dricon PaveSand<br />

• Concrete<br />

Tools<br />

• Tape measure • Pencil • Stringline<br />

• Spirit level • Spade • Shovel<br />

• Screed board • Plate compac<strong>to</strong>r<br />

• Rake • Broom<br />

• Concrete saw/paver splitter/bolster<br />

Stanley FatMax<br />

Extreme 1200mm Level<br />

• Magnified centre vial for improved visibility<br />

4861609<br />

Firth Boulevard Paver<br />

These pavers are larger format<br />

pavers robust enough for heavy foot<br />

and light vehicular traffic.<br />

• Ideal for <strong>outdoor</strong> uses such as<br />

domestic driveways, patios and<br />

pathways<br />

• 297 x 297 x 60mm<br />

• 11 pavers per M 2<br />

Firth Chancery Paver<br />

Large format pavers provide a<br />

contemporary designer look for<br />

<strong>outdoor</strong> <strong>areas</strong>.<br />

• Ideal for patios, garden terraces<br />

and paths<br />

• 497 x 497 x 50mm<br />

• 4 pavers per M 2<br />

Not suitable for <strong>areas</strong> carrying heavy foot traffic or vehicles<br />

Firth Courtyard Flags<strong>to</strong>ne Paver<br />

Classically attractive paving option for<br />

<strong>your</strong> larger <strong>outdoor</strong> <strong>areas</strong>.<br />

• Ideal for pathways, formal garden<br />

or patio settings<br />

• 450 x 450 x 50mm<br />

• 5 pavers per M 2<br />

Not suitable for <strong>areas</strong> carrying heavy foot traffic or vehicles<br />

Firth Palermo Paver †<br />

Stylish modular, larger format paver<br />

with a distinctive polished finish.<br />

• Ideal for patios, courtyards<br />

and light pedestrian <strong>areas</strong><br />

• 450 x 450 x 50mm • 5 pavers per M 2<br />

Not suitable for <strong>areas</strong> carrying heavy foot traffic or vehicles<br />

† Palermo Paver must be sealed once laid as it is a honed<br />

product, all Palermo pavers are delivered unsealed. It is<br />

the responsibility of the installer <strong>to</strong> seal Palermo Pavers.<br />

Available colours Available colours Available colours Available colours<br />

7

PAVING-<br />

WETCAST<br />

& STONE<br />

With our range of stylish, quality<br />

wetcast pavers you can create an<br />

exceptional <strong>outdoor</strong> living area that<br />

stands the test of time.<br />

<strong>PlaceMakers</strong> offers wetcast paving<br />

in a range of textures, sizes and<br />

colours that will suit any <strong>outdoor</strong><br />

space. A key aspect of wetcast<br />

paving is the finish or texture of the<br />

paver. From our range, you can<br />

select pavers that have a smooth,<br />

glossy finish or ones that are highly<br />

textured which give the look and<br />

feel of natural s<strong>to</strong>ne.<br />

Natural Split Paving<br />

Create a stunning patio<br />

with the unrivalled,<br />

natural beauty of schist<br />

s<strong>to</strong>ne paving<br />

• Fast and easy <strong>to</strong> lay<br />

• Extremely durable<br />

• Low maintenance<br />

Must be laid on on full<br />

concrete bed<br />

Waterworn S<strong>to</strong>nes<br />

Create a natural<br />

pathway with these<br />

beautiful s<strong>to</strong>nes<br />

• Fast and easy <strong>to</strong> lay<br />

• Extremely durable<br />

• Low maintenance<br />

Wetcast pavers suit a number of<br />

applications and are particularly<br />

ideal for patios, pool <strong>areas</strong>, paths,<br />

entranceways and garden edging.<br />

Wetcast pavers generally come in<br />

a larger format than most traditional<br />

pavers. Many of the pavers in the<br />

wetcast range feature slip resistant<br />

qualities which reduce accidents<br />

around pool <strong>areas</strong> and other parts<br />

of the home.<br />

Milano Paver<br />

The Milano is an elegant smooth style<br />

paver perfect for every application<br />

from classic <strong>to</strong> modern contemporary.<br />

It has a slightly etched finish creating a<br />

more slip resistant surface.<br />

• Available in 300 x 300, 450 x 450,<br />

600 x 150, 600 x 300 or 600 x 600mm<br />

Romani Paver<br />

The Romani creates a timeless look<br />

with a beautiful, softly textured<br />

surface that ties in perfectly with<br />

almost any style of house and<br />

landscape.<br />

• Available in 300 x 300, 450 x 450,<br />

600 x 300 or 600 x 600mm<br />

Vil<strong>to</strong>rio Paver<br />

A smooth bevelled edge lends the<br />

Vil<strong>to</strong>rio true class. The diamond facet<br />

surface pattern makes it an excellent<br />

choice for entrance ways and other<br />

<strong>areas</strong> where safety is a priority.<br />

• Available in 600 x 600mm<br />

Available colours Available colours Available colours<br />

8<br />

Whilst every care has been taken <strong>to</strong> obtain an accurate representation, the colours shown here are subject <strong>to</strong> the limitations of the colour reproduction process.<br />

Visit <strong>your</strong> nearest <strong>PlaceMakers</strong> <strong>to</strong> view samples prior <strong>to</strong> ordering.

suB GraDe testiNG<br />

Sub-grade Weak moderate Strong<br />

Strength<br />

Walking & Walking Heel Neither walking<br />

heel test leaves distinct leaves an nor heel leaves<br />

footprints footprints impression an impression<br />

Driveways 175mm base 125mm base 75mm base<br />

(light vehicle material material material<br />

traffic only)<br />

Pedestrian 75mm base 50mm base No base<br />

use only material material material required,<br />

just sand<br />

exCavatioN exaMple<br />

Paver thickness (driveway)<br />

60 mm<br />

Bedding sand (compacted)<br />

30 mm<br />

Base Course (moderate sub-grade firmness) 125 mm<br />

= <strong>to</strong>tal exCavatioN Depth<br />

(below finished paving level)<br />

215mm<br />

Base Course Material<br />

• Should be crushed rock including particles of all sizes.<br />

• No particles should have a diameter more than one third of the<br />

thickness of the required base course layer.<br />

• It should contain no soil or plant material.<br />

• Lay geotextile fabric first where soft clay which might push in<strong>to</strong><br />

and through the base course material.<br />

• For layers of 100mm thick or more, use 40mm all in aggregate.<br />

This should also be laid in layers no thicker than 100mm and compacted <strong>to</strong> a<br />

uniform dense condition, especially around manholes and kerbs. The finished<br />

texture of the base course should not allow bedding sand <strong>to</strong> filter through. The<br />

final surface of the base course should match the con<strong>to</strong>ur of <strong>your</strong> finished<br />

paving with no bumps, and no holes deeper than 10mm.<br />

Edging is important <strong>to</strong> prevent sideways movement of pavers, and <strong>to</strong> s<strong>to</strong>p<br />

bedding sand leaking out.<br />

edging options<br />

• Soldier course of either standing or flat pavers (See Illustration 3)<br />

• Paving kerb – segmented raised kerbing<br />

• Paving edge – concealed, underground PVC strip<br />

• Haunching – concealed concrete strip. (See Illustration 4)<br />

Concrete<br />

Soldier Course<br />

Subgrade<br />

Illustration 3: Soldier course of standing pavers<br />

Concrete Haunching<br />

Soldier Course<br />

100mm<br />

Min<br />

Illustration 4: Concealed haunching<br />

Bedding sand supports <strong>your</strong> pavers, but will not hide irregularities in the base<br />

course. It should be coarse river sand (not beach sand), and damp but not wet.<br />

1. Don’t compact bedding sand directly. It compacts under the pavers. To test<br />

how much the thickness will reduce, spread some sand over a small area.<br />

Lay a paver on <strong>to</strong>p, and thump that with a rubber hammer. The resulting<br />

reduction in sand thickness will tell you how much <strong>your</strong> sand compacts.<br />

2. Pave in manageable sized <strong>areas</strong>. Spread sand only over an area you know<br />

you can finish in one session, and get <strong>to</strong> without walking on. Spread the<br />

sand <strong>to</strong> slightly more than the depth <strong>your</strong> rubber hammer test indicated<br />

would produce a compacted sand depth of between 20mm and 30mm. You<br />

will usually need <strong>to</strong> start with the uncompacted sand bed between 5mm<br />

and 10mm thicker than its compacted depth. (See Illustration 5A)<br />

3. Screed the sand <strong>to</strong> a uniform level. As with any screeding, you need<br />

temporary <strong>guide</strong>s or runners at each side <strong>to</strong> run <strong>your</strong> screed board on.<br />

If you have already laid a soldier or kerb course, you may be able <strong>to</strong> use<br />

that <strong>to</strong> support <strong>your</strong> runners. If the area <strong>to</strong> be paved is <strong>to</strong>o wide you’ll<br />

need <strong>to</strong> drive pegs, and fix <strong>your</strong> runners <strong>to</strong> them, just like concrete boxing.<br />

(See Illustration 5B)<br />

1. Start from the straightest convenient edge, and lay <strong>your</strong> pavers with a<br />

space of 2mm <strong>to</strong> 4mm between them. Some pavers have spacer nibs<br />

which achieve that au<strong>to</strong>matically. The space allows joint sand <strong>to</strong> penetrate<br />

around the pavers. Always start at the bot<strong>to</strong>m of sloped <strong>areas</strong>.<br />

2. Lay all full pavers first: then cut and lay any pieces. Cut pavers with a<br />

diamond concrete saw, paver splitter (both available from hire centres) or,<br />

for small <strong>areas</strong>, a bolster.<br />

3. Don’t run vehicles over the paving until it’s <strong>complete</strong>ly finished. To get a<br />

loaded wheelbarrow across, lay heavy planks down as running boards.<br />

Soldier Course<br />

on Concrete<br />

Illustration 5A: Screed on Runners<br />

Screed<br />

Sand<br />

Basecourse<br />

Subgrade<br />

Illustration 5B: (Detail) Not <strong>to</strong> scale<br />

Timber Screed<br />

Subgrade<br />

Guide Cleats<br />

Fixed <strong>to</strong> Screed<br />

Timber Runner<br />

Fixed <strong>to</strong> Peg<br />

Guide cleats<br />

fixed <strong>to</strong> screed<br />

Timber runner at<br />

correct height fixed<br />

<strong>to</strong> pegs<br />

Peg<br />

Your pavers now need <strong>to</strong> be consistently compacted over the whole area. Include<br />

a minimum of three passes with compac<strong>to</strong>r each at 90 degrees <strong>to</strong> each other.<br />

1. For a small area, use a rubber hammer on a short length of heavy timber:<br />

say a piece of 150 x 50mm. For most other jobs, use a plate compac<strong>to</strong>r.<br />

2. When the pavers are all compacted, sweep joint sand over the whole area<br />

and compact again. The compac<strong>to</strong>r will drive the sand in<strong>to</strong> the joints. Keep<br />

sweeping and compacting until all joints are filled.<br />

3. Joint sand should be fine dry plaster sand with angular particles that lock<br />

well <strong>to</strong>gether. It is also sold as paving sand and some types incorporate a<br />

weed preventative.<br />

In most cases maintenance will be minimal. If some pavers settle unevenly, or<br />

if underground services need <strong>to</strong> be exposed, <strong>your</strong> paving may require re-laying.<br />

To do this simply follow the procedures given above. It would pay <strong>to</strong> add a<br />

layer of weed matting below the sand layer <strong>to</strong> s<strong>to</strong>p any weeds that could grow<br />

up and between <strong>your</strong> pavers. Where paving is cleaned or has water running<br />

across it the joint sand may require <strong>to</strong>pping up periodically. To enhance the<br />

appearance of <strong>your</strong> paving special sealers are available, and these may require<br />

reapplication over time. Ask about these at <strong>your</strong> <strong>PlaceMakers</strong> Firth Centre.<br />

note: Building or landscaping work has <strong>to</strong> comply with the new Zealand<br />

Building code and <strong>your</strong> local council requirements. talk <strong>to</strong> the building<br />

inspec<strong>to</strong>rs at <strong>your</strong> council. they can provide helpful details of such<br />

matters and say whether or not a permit is required for the work you wish<br />

<strong>to</strong> do.<br />

Choose <strong>your</strong> site carefully, watch and compensate for potential problems such<br />

as drains, trees and electrical wiring.<br />

Check the height of the surface <strong>to</strong> be paved, take measurements and draw design<br />

plans <strong>to</strong> allow for the paving’s <strong>to</strong> be below the floor level and slightly sloped away<br />

from the house or <strong>areas</strong> that you would want <strong>to</strong> keep water away from.<br />

Choose <strong>your</strong> pavers and design…measure up and order.<br />

If the ground is firm and well compacted excavate <strong>to</strong> a depth of 75 mm, then<br />

move <strong>to</strong> next step. If soft or a filled site, excavate 75-100mm deeper and add<br />

75-100mm of <strong>to</strong>p course, compact well with a plate compacter.<br />

Now set up string lines <strong>to</strong> give you lines <strong>to</strong> follow for both height and gapping.<br />

now you can choose 1 of 2 laying methods:<br />

1. Spread and level a fine loose bedding sand, dampen and lightly compact.<br />

Then screed level and choose <strong>your</strong> laying pattern. (This method is quick<br />

easy and if the leveling is done well gives a great finish).<br />

2. Mix up a mix of sand and cement with water <strong>to</strong> make a wet mix that you<br />

put on the base, roughly level and then tamp <strong>your</strong> pavers down in<strong>to</strong> it,<br />

remember where they sit is where they stay. (This method requires more<br />

work, precision laying as it is far less forgiving, once the sand and cement<br />

mix hardens <strong>your</strong> pavers are not able <strong>to</strong> be easily lifted or moved).<br />

nB: It is critical you allow a gap between pavers of a minimum of 8mm,<br />

although 10-15mm is gap is recommended.<br />

This gap allows you <strong>to</strong> have some flexibility if there are any minor height<br />

discrepancies and also remove the effect of any slight size variation that occurs<br />

in hand made pavers.<br />

Some pavers may need cutting, you can hire a suitable saw from hire centres<br />

or use an angle grinder with a masonry blade installed. Remember <strong>your</strong> safety<br />

equipment.<br />

do not uSe comPActIon eQuIPment over PAverS<br />

Hose off pavers, let them dry, then use either pave joint sand, mortar pointing, or<br />

pavelock grouting sand…remember follow the product directions, if compaction<br />

is required, go over pavers tapping with a rubber mallet.<br />

Use dry sand and cement mix, <strong>to</strong> trowel an edge from the <strong>to</strong>p of the paver<br />

away at a 45 degree angle <strong>to</strong> give the pavers a border or haunch <strong>to</strong> hold them<br />

in place.<br />

Remember, if at any stage you are unsure of what you are doing or need further<br />

advice, seek professional help.<br />

Garden Edging<br />

With a sharp, stylish profile,<br />

garden edging is perfect<br />

for framing <strong>your</strong> paving or<br />

garden area.<br />

• Fast and easy <strong>to</strong> lay<br />

• Available in a variety of<br />

shapes and sizes that<br />

allow you <strong>to</strong> create almost<br />

any shape garden or<br />

mowing edge<br />

Green Plus Matting<br />

Green Plus matting is designed <strong>to</strong><br />

5. PrePArIng the BeddIng<br />

allow for damage SAnd BASe free vehicle<br />

7. comPActIng the PAverS<br />

access or parking on or across<br />

lawns, driveways and playing fields.<br />

mAIntenAnce<br />

It is virtually invisible when<br />

6. lAyIng the PAverS<br />

it is installed.<br />

• Suitable for parking or access<br />

for cars, 4x4 vehicles, light<br />

trucks, caravans, trailer boats<br />

• Available in 387 x 387 x 50mm<br />

3. PrePArIng the BASe<br />

courSe<br />

4. PlAcIng the edgIng<br />

installation instructions<br />

installation instructions<br />

installation instructions / maintenance<br />

Wet cASt PAvIng<br />

wet cast paving<br />

LAYING<br />

PAVING<br />

STONES<br />

<strong>your</strong> <strong>complete</strong> how <strong>to</strong> <strong>guide</strong><br />

HOW TO GUIDE<br />

For instructions on how <strong>to</strong><br />

lay <strong>your</strong> pavers, see our<br />

How To Guide available<br />

in-s<strong>to</strong>re or online at<br />

www.placemakers.co.nz<br />

KNOW<br />

HOW<br />

CARD<br />

SPEND *<br />

$<br />

250<br />

GET A<br />

$<br />

25<br />

*Terms and conditions apply.<br />

BONUS<br />

VOUCHER<br />

Don’t forget <strong>to</strong> use <strong>your</strong> Know How<br />

Card with every purchase.<br />

PROJECT CHECKLIST<br />

Materials<br />

• Pavers • Base course material<br />

• Mortar mix • Sweep in grout<br />

Tools<br />

• Shovel<br />

• Spade<br />

• Rubber mallet • Tape measure<br />

• Spirit level • Rake<br />

• Compac<strong>to</strong>r • Wheel barrow<br />

• Screed board • Soft broom<br />

• Stakes and stringline<br />

• Gloves and earmuffs<br />

• Paving saw <strong>to</strong> cut paver<br />

• Acid wash <strong>to</strong> clean pavers<br />

when laid<br />

Leathers<strong>to</strong>ne Paver<br />

Distinctive pavers that look like leather,<br />

with a low skid surface.<br />

• Pinstripe edging gives the pavers a<br />

tile-like look when they are grouted<br />

• Available in 450 x 450 x 45mm<br />

Sawns<strong>to</strong>ne Paver<br />

Square pavers with a finish similar <strong>to</strong> that<br />

of cut limes<strong>to</strong>ne, with bandsaw cut marks<br />

across the surface. This provides a soft<br />

sawn limes<strong>to</strong>ne effect with the durability<br />

of concrete.<br />

• Available in 360 x 360 or 450 x 450mm<br />

Exposed Aggregate Paver<br />

The exposed aggregate range has an<br />

important place in landscaping which<br />

gives a traditional yet ageless look.<br />

• Slip resistant for really wet <strong>areas</strong><br />

• Available in 300 x 300, 450 x 450,<br />

500 x 500 or 600 x 600mm<br />

Indian Sands<strong>to</strong>ne Paver<br />

Indian Sands<strong>to</strong>ne will introduce a<br />

timeless aspect of quality and longevity<br />

<strong>to</strong> any <strong>outdoor</strong> area.<br />

• Can be used for patios, paths and<br />

pool surrounds<br />

• Available in 100 x 100, 300 x 300,<br />

600 x 300, 600 x 600, 900 x 600<br />

or 900 x 900mm<br />

Available colours Available colours Available colours Available colours<br />

9

TIMBER<br />

RETAINING<br />

WALLS<br />

In recent times retaining walls have<br />

become an integral part of any<br />

garden design. They are perfect<br />

for creating a focal point in <strong>your</strong><br />

garden, highlighting a special<br />

feature or levelling off <strong>areas</strong> <strong>to</strong><br />

create a flat lawn.<br />

Retaining walls are great for<br />

creating terracing and raised<br />

gardens where space is limited.<br />

On a steep site, they give <strong>your</strong><br />

garden structure, highlight natural<br />

features and help control soil<br />

erosion. Best of all, they’re low<br />

maintenance, easy <strong>to</strong> build and<br />

they last for years.<br />

Wattyl Forestwood<br />

Aquatech Oil<br />

Stain 5L<br />

• Water clean up<br />

• Penetrates, whilst<br />

adding natural colour<br />

<strong>to</strong> timber<br />

• Available in a range<br />

of colours<br />

Dricon High<br />

Strength HandiCrete ®<br />

High strength concrete mix,<br />

formulated <strong>to</strong> reach a target<br />

strength of 40MPa in 28 days<br />

• Ideal for foundations, heavy<br />

duty paths, bridge repair<br />

work, bollards and block fill<br />

SLEEPERS<br />

There are a variety of sleepers<br />

available with the most common<br />

being Hardwood, Macrocarpa and<br />

Radiata Pine. It is vital <strong>to</strong> assess if<br />

the sleeper application is purely<br />

aesthetic in which case any species<br />

will do, accepting that untreated<br />

sleepers will breakdown over time.<br />

However, if the use is for more<br />

structural retaining application<br />

and longevity is required then it is<br />

recommended that treated Radiata<br />

Pine sleepers are used.<br />

Rough Sawn<br />

Retaining Timber<br />

Visually graded radiata pine with<br />

rough sawn finish on both faces.<br />

Used <strong>to</strong> construct a retaining structure<br />

both residentially and commercially.<br />

• H4 treated radiata No.2<br />

• Available in 150 x 50mm or<br />

200 x 50mm<br />

Retaining Cap<br />

• Helps prevent erosion<br />

and water damage<br />

• Ideal for a finishing<br />

<strong>to</strong>uch <strong>to</strong> any<br />

retaining wall<br />

construction<br />

Edged Half Round<br />

Retaining Timber<br />

Can be used <strong>to</strong> construct a retaining<br />

wall, also looks good when making a<br />

raised garden.<br />

• H4 treated radiata<br />

• Available in 150mm<br />

& 175mm widths<br />

H4 Retaining Post<br />

• H4 treated radiata<br />

• Available in 100 x 75mm or<br />

100 x 100mm<br />

• Lengths 1.8, 2.4, 2.7 or 3M<br />

Larger dimension posts and dressed<br />

are available on request.<br />

Tongue & Groove<br />

Retaining Timber<br />

With a refined <strong>to</strong>ngue and groove<br />

profile, you can transform an<br />

unwanted sloping area in<strong>to</strong> a flat<br />

garden or lawn.<br />

• H4 treated radiata No.2<br />

• Available in 150 x 50mm<br />

or 200 x 50mm<br />

10

Drainage Coil<br />

Designed for the<br />

economic removal of<br />

excess ground water<br />

• Ideal for effluent<br />

soakage fields, retaining<br />

wall drainage and<br />

s<strong>to</strong>rmwater diversion<br />

• Available in diameters<br />

of 65, 110 & 150mm<br />

Scoria<br />

Ideal for bedding under<br />

constructions such as<br />

paving <strong>areas</strong> or for<br />

drainage behind retaining<br />

walls and piping trenches<br />

HOW TO GUIDE<br />

For instructions on how<br />

<strong>to</strong> build <strong>your</strong> retaining<br />

wall, see our How To<br />

Guide available<br />

in-s<strong>to</strong>re or online at<br />

www.placemakers.co.nz<br />

KNOW<br />

HOW<br />

CARD<br />

SPEND *<br />

$<br />

250<br />

GET A<br />

$<br />

25<br />

*Terms and conditions apply.<br />

BONUS<br />

VOUCHER<br />

Don’t forget <strong>to</strong> use <strong>your</strong> Know How<br />

Card with every purchase.<br />

H5 Retaining Post<br />

• H5 treated radiata<br />

• Available in 100 x<br />

75mm or 100 x 100mm<br />

• Lengths 1.8, 2.4,<br />

2.7 or 3M<br />

Larger dimension posts and<br />

dressed are available on<br />

request.<br />

H5 Round Post<br />

• H5 treated radiata<br />

• Available in various sizes<br />

from 125mm <strong>to</strong> 300mm<br />

• Lengths from 900mm<br />

<strong>to</strong> 7M<br />

PROJECT CHECKLIST<br />

Materials<br />

• H5 treated post<br />

• H4 treated rough sawn or <strong>to</strong>ngue &<br />

groove rails. Alternatively use edged<br />

half rounds<br />

• Concrete • Timber preservative<br />

• Scoria • Nails<br />

• Pegs • Geotextile fabric<br />

• Drainage coil<br />

Tools<br />

• Stringline • Spirit level<br />

• Hammer • Old paintbrush<br />

• Shovel • Sledgehammer<br />

• Spade or post hole borer<br />

• Hand saw or circular saw<br />

• Tape, square and pencil<br />

Macrocarpa Sleepers<br />

Naturally durable and suitable for non<br />

structural landscaping projects. It will<br />

weather <strong>to</strong> a silvery grey colour or<br />

can be stained or painted.<br />

• Available in 150 x 100mm<br />

& 200 x 100mm<br />

Verda Pine Sleepers<br />

Sleepers are H4 treated for long term<br />

durability. Suitable for a wide range of<br />

landscaping applications.<br />

• Available in 200 x 100 x 2.1M<br />

• Available unstained or prestained<br />

Hardwood Sleeper<br />

Australian Hardwood is suitable<br />

for a wide range of landscaping<br />

applications such as garden edging<br />

or low retaining walls.<br />

• Available in 220 x 110 x 2.1M<br />

& 220 x 130mm x 2.1M<br />

DeWalt 305mm Slide<br />

Compound Mitre Saw DW718<br />

• 1600W belt drive mo<strong>to</strong>r<br />

• 4000rpm<br />

• 48° bevel left or right<br />

• Cuts up <strong>to</strong> 355mm x 50mm @ 90°<br />

5032174<br />

11

RETAINING<br />

BLOCKS<br />

Retaining block walls are perfect<br />

for creating boundary walls, a focal<br />

point or levelling off an area <strong>to</strong><br />

establish a lawn.<br />

There are many different looks you<br />

can create <strong>to</strong> establish interesting<br />

<strong>outdoor</strong> <strong>areas</strong> or “rooms” on a<br />

property. These will enhance <strong>your</strong><br />

overall design and add value <strong>to</strong><br />

<strong>your</strong> home.<br />

The new range of retaining wall<br />

products (available from December<br />

2011) are designed <strong>to</strong> add beauty<br />

and definition <strong>to</strong> <strong>your</strong> garden and<br />

larger structural projects.<br />

Dricon High<br />

Strength HandiCrete ®<br />

High strength concrete mix,<br />

formulated <strong>to</strong> reach a target<br />

strength of 40MPa in 28 days<br />

• Ideal for foundations, heavy<br />

duty paths, bridge repair<br />

work, bollards and block fill<br />

Drainage Coil<br />

Designed for the economic<br />

removal of excess ground<br />

water<br />

• Ideal for effluent soakage<br />

fields, retaining wall<br />

drainage and s<strong>to</strong>rmwater<br />

diversion<br />

• Available in diameters of<br />

65, 110 & 150mm<br />

HELPFUL HINTS<br />

• Terraced retaining walls will let<br />

more light in<strong>to</strong> an area rather<br />

than one high wall.<br />

• Raised beds showcase plants and<br />

are better for vegetable gardens<br />

in particular, as they improve<br />

drainage.<br />

• The modular shape and design of<br />

Firth retaining walls means you<br />

can install them <strong>your</strong>self<br />

• Retaining walls require little<br />

maintenance but if you need <strong>to</strong><br />

clean them, use a pre-emergent<br />

spray and low-pressure water<br />

Colours<br />

Available<br />

Rockface<br />

Granite<br />

Firth Ezi Wall<br />

Firth Keys<strong>to</strong>ne Sedona<br />

Retaining Block<br />

S<strong>to</strong>ne Retaining Block<br />

Easily constructed using the<br />

Virtually maintenance free.<br />

unique interlocking system<br />

Ideal for finishing <strong>your</strong> lawn<br />

• Suitable for low<br />

edge, for decorative tree<br />

freestanding retaining<br />

rings, planters or raised<br />

walls, garden edging or<br />

garden beds<br />

beds and tree wells<br />

• Builds wall up <strong>to</strong><br />

• Concave or convex curved<br />

300mm high<br />

walls up <strong>to</strong> 500mm high<br />

Colours<br />

• 5 units per lineal metre<br />

Available<br />

• 7 units per lineal metre or<br />

or 66 units per M 2<br />

57 units per M 2<br />

Rockface<br />

Granite<br />

Sands<strong>to</strong>ne<br />

Sands<strong>to</strong>ne<br />

New Range - Available in December 2011<br />

12<br />

Whilst every care has been taken <strong>to</strong> obtain an accurate representation, the colours shown here are subject <strong>to</strong> the limitations of the colour reproduction process.<br />

Visit <strong>your</strong> nearest <strong>PlaceMakers</strong> <strong>to</strong> view samples prior <strong>to</strong> ordering.

Grass Paver<br />

per m 2 =6<br />

Note; Available in<br />

natural only.<br />