A push for cleaner industrial production - EEB

A push for cleaner industrial production - EEB

A push for cleaner industrial production - EEB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

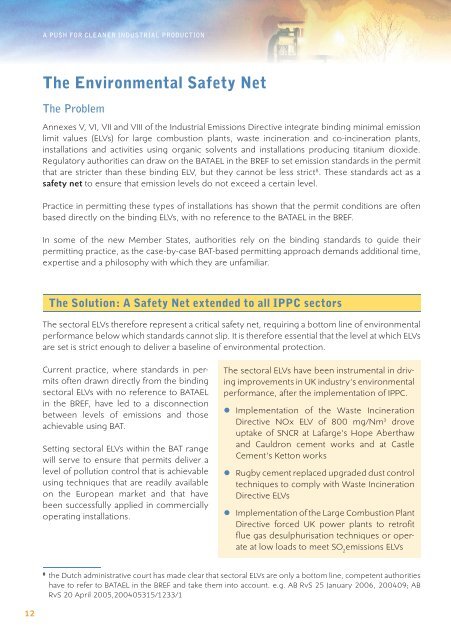

A PUSH FOR CLEANER INDUSTRIAL PRODUCTION<br />

The Environmental Safety Net<br />

The Problem<br />

Annexes V, VI, VII and VIII of the Industrial Emissions Directive integrate binding minimal emission<br />

limit values (ELVs) <strong>for</strong> large combustion plants, waste incineration and co-incineration plants,<br />

installations and activities using organic solvents and installations producing titanium dioxide.<br />

Regulatory authorities can draw on the BATAEL in the BREF to set emission standards in the permit<br />

that are stricter than these binding ELV, but they cannot be less strict 8 . These standards act as a<br />

safety net to ensure that emission levels do not exceed a certain level.<br />

Practice in permitting these types of installations has shown that the permit conditions are often<br />

based directly on the binding ELVs, with no reference to the BATAEL in the BREF.<br />

In some of the new Member States, authorities rely on the binding standards to guide their<br />

permitting practice, as the case-by-case BAT-based permitting approach demands additional time,<br />

expertise and a philosophy with which they are unfamiliar.<br />

The Solution: A Safety Net extended to all IPPC sectors<br />

The sectoral ELVs there<strong>for</strong>e represent a critical safety net, requiring a bottom line of environmental<br />

per<strong>for</strong>mance below which standards cannot slip. It is there<strong>for</strong>e essential that the level at which ELVs<br />

are set is strict enough to deliver a baseline of environmental protection.<br />

Current practice, where standards in permits<br />

often drawn directly from the binding<br />

sectoral ELVs with no reference to BATAEL<br />

in the BREF, have led to a disconnection<br />

between levels of emissions and those<br />

achievable using BAT.<br />

Setting sectoral ELVs within the BAT range<br />

will serve to ensure that permits deliver a<br />

level of pollution control that is achievable<br />

using techniques that are readily available<br />

on the European market and that have<br />

been successfully applied in commercially<br />

operating installations.<br />

The sectoral ELVs have been instrumental in driving<br />

improvements in UK industry‘s environmental<br />

per<strong>for</strong>mance, after the implementation of IPPC.<br />

• Implementation of the Waste Incineration<br />

Directive NOx ELV of 800 mg/Nm 3 drove<br />

uptake of SNCR at Lafarge’s Hope Aberthaw<br />

and Cauldron cement works and at Castle<br />

Cement’s Ketton works<br />

• Rugby cement replaced upgraded dust control<br />

techniques to comply with Waste Incineration<br />

Directive ELVs<br />

• Implementation of the Large Combustion Plant<br />

Directive <strong>for</strong>ced UK power plants to retrofit<br />

flue gas desulphurisation techniques or operate<br />

at low loads to meet SO 2<br />

emissions ELVs<br />

8<br />

the Dutch administrative court has made clear that sectoral ELVs are only a bottom line, competent authorities<br />

have to refer to BATAEL in the BREF and take them into account. e.g. AB RvS 25 January 2006, 200409; AB<br />

RvS 20 April 2005,200405315/1233/1<br />

12