protea - PGA Consultants

protea - PGA Consultants

protea - PGA Consultants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

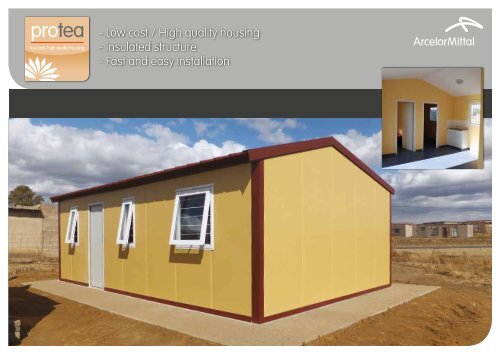

<strong>protea</strong><br />

low cost, high quality housing<br />

- Low cost / High quality housing<br />

- Insulated structure<br />

- Fast and easy installation

PROTEA | Affordable quality housing<br />

PROTEA® is a modular construction system.<br />

Standardised components are entirely prefabricated<br />

in factories, packed in protective<br />

containers and delivered on-site, ready<br />

South Africa<br />

to be assembled in 4 days by 4 local people.<br />

The PROTEA® building system ensures<br />

long term living conditions with respect to<br />

safety, insulation, health and comfort.<br />

Newcastle, South Africa<br />

Colours: Opale 4936 for walls,<br />

Bordeau 4802 for roof<br />

Mounting walls<br />

Newcastle, South Africa - Colours: Sand 4102 for walls, Bordeau 4802 for roof<br />

2<br />

Internal finishing with plasterboard

France<br />

Dubai<br />

Contrisson, France<br />

Colours: Opale 4936<br />

Contrisson, France<br />

Colours: Stone 4703 for walls,<br />

Abyss 4505 for roof<br />

PROTEA 40m² - 5 projects<br />

These five different projects illustrate<br />

the numerous implementation possibilities<br />

and options of PROTEA in terms of:<br />

- Colours<br />

- Floors (concrete slab or steel deck)<br />

- Integration of solar panels<br />

- Doors and windows<br />

- Interior finishing and equipment<br />

Mounting on a dry steel deck<br />

Mounting walls<br />

Photovoltaic panels<br />

Internal finishing with plasterboard<br />

3<br />

Dubai, United Arab Emirates<br />

Colours: Opale 4936 for walls,<br />

Bordeau 4802 for roof

PROTEA | Four days for one house<br />

Four workers can complete the construction,<br />

including doors and windows, in just 4 days.<br />

• Assembly is kept simple by using screw connections<br />

only.<br />

• An installation guide is provided, making the<br />

installation fast and easy.<br />

• The components, prefabricated in factories, are<br />

packed conveniently in protective containers and<br />

delivered on site ready to be assembled.<br />

• Three 40m² PROTEA kits can be stored in one<br />

40’ container.<br />

Phase 1: Reception of kits on site<br />

Day 1<br />

PROTEA Kit delivered to prepared foundation (concrete slab or dry steel<br />

deck) and elements are unpacked for assembly.<br />

Phase 3: Walls and partitions assembly<br />

Phase 2: Preparation of the ground - implementation<br />

Day 1<br />

U-profile elements, which will join the foundation with the wall panels,<br />

are fixed on the foundation. First two panels are assembled in the corner.<br />

Phase 4: Two last wall panels<br />

Day 2<br />

Mounting of pre-fabricated wall and partition elements is sequenced to<br />

build rigid subsets and so ensure stability during construction, especially<br />

in case of strong winds.<br />

Phase 5: Wall and roof joined by a U profile<br />

Day 2<br />

Wall construction is finalised by the connection of the two last panels at<br />

the opposite corner.<br />

Phase 6: Finishing accessories<br />

Kits in container on truck<br />

Day 3<br />

U-profile elements to join walls and roof panels are fixed to<br />

the top of all the wall panels.<br />

4<br />

Day 4<br />

Assembly of the roofing panels including finishing (mono and duo-pitch<br />

ridge, edge,...)

250<br />

250<br />

250<br />

250<br />

40<br />

275<br />

Panel<br />

female<br />

side<br />

250<br />

250<br />

40 40<br />

275 165 250 250 275 165<br />

Panel<br />

Panel<br />

female<br />

female<br />

side<br />

side<br />

40 40<br />

40 40<br />

275 165 250 250 275 165 250 250 275 165 250 250 275 165 250 250 275<br />

208,5 208,5 208,5 208,5 208,5 208,5 208,5 208,5 208,5 208,5 208,5 208,5 208,5 208,5<br />

40<br />

201,5 201,5 201,5 201,5 201,5 201,5 201,5 201,5 201,5 201,5 201,5 201,5 201,5<br />

40<br />

213 213 213 213 213 213 213 213 213<br />

40 40<br />

165<br />

250<br />

250<br />

40<br />

275<br />

Panel<br />

female<br />

side<br />

165<br />

250<br />

500<br />

250<br />

275<br />

Panel<br />

female<br />

side<br />

40<br />

275<br />

Panel<br />

female<br />

side<br />

170<br />

250<br />

250<br />

40<br />

275<br />

Panel<br />

female<br />

side<br />

165<br />

40<br />

275 165<br />

Panel<br />

female<br />

side<br />

250<br />

250<br />

250<br />

250<br />

40<br />

275<br />

Panel<br />

female<br />

side<br />

120<br />

275<br />

Panel<br />

female<br />

side<br />

165<br />

500<br />

275<br />

Panel<br />

female<br />

side<br />

165<br />

165<br />

250<br />

250<br />

40<br />

275<br />

Panel<br />

female<br />

side<br />

165<br />

250<br />

250<br />

275<br />

Panel<br />

female<br />

side<br />

40<br />

250 250 275 165 250 250 275<br />

Panel<br />

Panel<br />

female<br />

female<br />

side<br />

side<br />

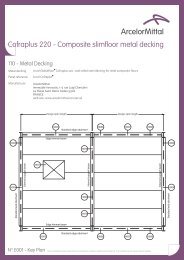

PROTEA | Installation guide abstract<br />

Each PROTEA kit comes with complete assembly<br />

instructions. Two documents detail all the different<br />

steps in the construction process.<br />

1 - Construction manual<br />

In this first document, the following points are<br />

covered:<br />

Necessary tools:<br />

Description of the needed equipment.<br />

Layout of the elements<br />

Installation plans giving laying order and position for<br />

each element:<br />

2<br />

7<br />

1 3 4 5 22 23 24 26<br />

6<br />

25<br />

Bedroom 2 Kitchen Bathroom<br />

/<br />

Bedroom3<br />

12<br />

32<br />

9 10 11 31 30<br />

33<br />

8<br />

13<br />

14<br />

Bedroom 1<br />

18<br />

Lounge<br />

27<br />

28<br />

29<br />

36<br />

2 - Fastenings plans<br />

This second document contains a complete range of<br />

drawings showing the number and precise position of<br />

all the different fastenings.<br />

600 600 600<br />

30<br />

215<br />

210<br />

210<br />

215 100 235<br />

230<br />

230<br />

235 100 280<br />

30<br />

30 30<br />

340 100 235 230 230 235 100 200 195 195 200<br />

15<br />

16<br />

19<br />

17 20 21 34 35 38 39<br />

37<br />

Panel<br />

Panel<br />

Panel<br />

Panel<br />

Panel<br />

female<br />

female<br />

female<br />

female<br />

female<br />

side<br />

side<br />

side<br />

side<br />

side<br />

1-38: Laying order : male side of panels<br />

Nomenclature:<br />

Extensive nomenclature of the kit contents.<br />

Connection details:<br />

How specific connections are treated<br />

Screw<br />

Wall panel<br />

Floor rail<br />

Screw<br />

600 600 600<br />

Site preparation:<br />

How to prepare the construction site prior to<br />

beginning<br />

8500<br />

Pattern L<br />

Reservations<br />

5600<br />

Floor<br />

Tightness joint<br />

Openings:<br />

How to install and fasten doors and windows<br />

130<br />

325<br />

325<br />

325<br />

325<br />

325<br />

325<br />

325<br />

325<br />

150<br />

20<br />

283<br />

Ridge<br />

Eaves<br />

diameter Ø<br />

Welded wire reinforcement. L=150mm, and Ø=8mm<br />

Recommendations, preliminary operations:<br />

For example about checking panels verticality.<br />

Safety recommendations<br />

Take extra care of safety on the working site. All<br />

workers must wear all necessary safety equipment,<br />

which is gloves, safety shoes, helmet, safety glasses.<br />

5

PROTEA | Designs<br />

12 m² shelter<br />

4058<br />

Main room<br />

~12m²<br />

3169<br />

1m<br />

Outside perspective<br />

Top view<br />

Floor plan<br />

20m² cottage<br />

5168<br />

Room2<br />

~10m²<br />

Room1<br />

~10m²<br />

4060<br />

1m<br />

Outside perspective<br />

Top view<br />

6<br />

Floor plan

PROTEA | Designs<br />

30m² family house<br />

6057<br />

Bedroom 2<br />

~7.5m²<br />

Kitchen / Lounge<br />

~15m²<br />

5168<br />

Bedroom 1<br />

~7.5m²<br />

1m<br />

Outside perspective<br />

Top view<br />

Floor plan<br />

40m² family house<br />

8052<br />

Bedroom 2<br />

~7.5m²<br />

Bath<br />

~5m²<br />

Kitchen / Lounge<br />

~20m²<br />

5164<br />

Bedroom 1<br />

~7.5m²<br />

Outside perspective<br />

Top view<br />

1m<br />

Floor plan<br />

7

PROTEA | Designs<br />

55m² residence<br />

998<br />

9053<br />

8055<br />

Bedroom1<br />

~13m²<br />

Entrance Hall<br />

~2m²<br />

Kitchen / Lounge<br />

~21m²<br />

Corridor<br />

~2m²<br />

Bedroom2<br />

~13m²<br />

Bathroom<br />

~5m²<br />

3654 3588<br />

7242<br />

Canopy<br />

~9m²<br />

1m<br />

Outside perspective<br />

Top view<br />

Floor plan<br />

71m² residence<br />

9059<br />

Bedroom 1<br />

~11m²<br />

Bathroom<br />

~5m²<br />

Bedroom 2<br />

~12m²<br />

WC<br />

~2m²<br />

8178<br />

Bedroom 3<br />

~12m²<br />

Kitchen / Lounge<br />

~29m²<br />

1m<br />

Canopy<br />

~12m²<br />

Outside perspective<br />

Top view<br />

Floor plan<br />

8

PROTEA | Designs<br />

100m² residence<br />

12128<br />

Bedroom 3<br />

~8.5m²<br />

Bathroom<br />

~5.5m²<br />

Bedroom 1<br />

~12m²<br />

Access<br />

~1m²<br />

WC<br />

~2m²<br />

Kitchen<br />

~10m²<br />

8178<br />

Bedroom 2<br />

~12m²<br />

Lounge<br />

~34m²<br />

Bedroom 4<br />

~12m²<br />

13074<br />

1m<br />

Canopy<br />

~12m²<br />

Outside perspective<br />

Internal finishing<br />

Inside the house, PROTEA panels can be covered with<br />

a plasterboard to perform:<br />

- Aesthetic finishing<br />

- Fire resistance<br />

Plasterboard are not included in the PROTEA kit, and<br />

must be purchased locally.<br />

Top view<br />

Floor plan<br />

Plasterboard can be screwed directly onto the steel<br />

sheet panels and folded parts.<br />

The type and thickness of the plasterboard must be<br />

determined according to local regulations.<br />

Plasterboard<br />

9<br />

Plasterboard<br />

Wall aspect:<br />

with and without plasterboard

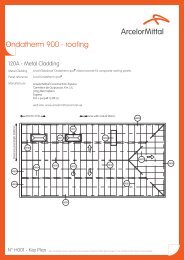

PROTEA | Kit offer & components characteristics<br />

Wall panels:<br />

• Insulated, structural panels<br />

• PUR foam thickness: 60mm (standard)<br />

• Steel sheet thickness:<br />

-interior: 0,50mm (standard)<br />

-exterior: 0,63mm (standard)<br />

8mm<br />

0.25mm<br />

Overall width: 1016mm<br />

Useful width: 1000mm<br />

Exterior microribbed face<br />

60mm<br />

Roof panels:<br />

• Insulated, structural panels<br />

• PUR foam thickness: 40mm (standard)<br />

• Steel sheet thickness<br />

-interior: 0,50mm (standard)<br />

-exterior: 0,63mm (standard)<br />

Overall width: 1078mm<br />

Useful width: 1000mm<br />

40mm<br />

Included in the kit<br />

- Walls, partitions and roof in sandwich panels with all accessories<br />

- Technical guide for all elements and installation guide<br />

- Technical drawings and Performance Guarantee<br />

- Screws & rivets compatible in shape and colors with wall<br />

and roof panels<br />

Options<br />

- Dry steel deck<br />

- Doors and windows<br />

- Solar panel system<br />

- Plumbing and electricity<br />

- Supervision training and technical assistance during construction,<br />

to be discussed case by case.<br />

Wall panels interlocking<br />

Roof panels interlocking<br />

Not included<br />

- Concrete slab<br />

- Plasterboard<br />

- Floor finishing<br />

- External finishing<br />

These elements should be subcontracted to local companies.<br />

Equivalence of insulation power between polyurethane (PUR) and some other common materials:<br />

PUR foam 60mm<br />

Polystyrene 100mm<br />

Mineral wool 110mm<br />

Wood<br />

460mm<br />

Bricks<br />

1870mm<br />

Stone<br />

4080mm<br />

Concrete<br />

5830mm<br />

Steel characteristics<br />

-Steel grade: S350GD<br />

-Hot dip galvanised Z275<br />

-25μm prepainted steel coating (standard)<br />

-A dedicated coating will be selected in regions with agressive<br />

climatic conditions (sea shore...)<br />

Adaptability<br />

Any specific design can be investigated on a case by case<br />

basis by the ArcelorMittal Construction Design & Engineering<br />

team.<br />

10

Colours<br />

Type of coating: thermosetting polyester resin.<br />

- Good corrosion resistance<br />

- Good colour and appearance stability<br />

- Good external sustainability<br />

- Good metal forming suitability<br />

Doors and<br />

windows (option)<br />

Steel deck (option)<br />

Walls<br />

Roof<br />

Sand 4102<br />

Ral 1002<br />

Stone 4703<br />

Ral 7032<br />

Bordeau 4802<br />

Ral 8012<br />

Abyss 4505<br />

Ral 5008<br />

A kit comprising doors and windows can be provided.<br />

Exterior doors are insulated, and windows feature<br />

double glazing. All doors and windows are made of<br />

PVC, except for the exterior doors frames, which are<br />

made of aluminium.<br />

Opale 4936<br />

Ral 9010<br />

Other colours can be investigated case by case by ArcelorMittal<br />

Top coat: 20 microns<br />

Primer: 5 microns<br />

Zinc (hot dip galvanizing S275GD)<br />

Steel<br />

(guaranteed minimum yield stress)<br />

Zinc (hot dip galvanizing S275GD)<br />

Back coat reinforced<br />

For protection, all windows can be equipped with anti<br />

intrusion bars.<br />

11<br />

A steel deck can be provided for each type of house<br />

(12, 20, 30, 40, 55, 71 and 100m²).<br />

It is delivered ready to be assembled, with all fastenings<br />

and connection parts, including connections<br />

between the structure and the concrete pads.<br />

Depending on the house type, the number of concrete<br />

pads will vary.<br />

This solution allows a good evenness of the floor, even<br />

on a uneven soil, and is a must in terms of protection<br />

in case of torrential rains.

Extension kit<br />

(option)<br />

Rainwater<br />

system (option)<br />

A gutter system allowing the harvesting of rainwater<br />

can be provided. The system includes gutters, gutter<br />

stops, down pipe connections and down pipes,<br />

elbows, junctions and brackets<br />

Photovoltaic<br />

panels (option)<br />

A system of rails able to support various types of<br />

photovoltaic modules can be provided.<br />

Down<br />

pipe<br />

Gutter<br />

A 15m² extension kit is available, for the following<br />

house types: 20m², 30m² and 40m².<br />

Detail of the mechanical<br />

testing of the rail<br />

8052 3028<br />

Water tank (not provided)<br />

Roof example with 7 rails and 6 solar modules:<br />

Bedroom 2<br />

~7.5m²<br />

Bath<br />

~5m²<br />

Bedroom 4<br />

~7.5m²<br />

Kitchen / Lounge<br />

~20m²<br />

5164<br />

Bedroom 1<br />

~7.5m²<br />

Bedroom 3<br />

~7.5m²<br />

Rails<br />

Solar modules<br />

1m<br />

40m².<br />

15m².<br />

55m².<br />

Extension example with the 40m² house<br />

Concerning the photovoltaic panels, a study can be<br />

done to match your specific needs.<br />

12

PROTEA | Excellent performances<br />

Technical agreement:<br />

ArcelorMittal complies with local construction regulations<br />

in countries where PROTEA is erected.<br />

Fire performance:<br />

The CSIR* in South Africa performed a fire resistance<br />

test on the 60mm wall panel, with a 15mm Firestop<br />

plasterboard on the exposed side. The complex achieved<br />

a Fire Resistance Rating (FRR) of 30 minutes.<br />

*Council for Scientific and Industrial Research<br />

Fire test in South Africa<br />

Structural performance:<br />

The PROTEA structural performance has been assessed.<br />

The house structure is essentially ensured by<br />

self bearing panels.<br />

Example: the 55m² house and its maximal<br />

calculated horizontal deflection<br />

Wind forces:<br />

The calculation shows that the PROTEA house is able<br />

to resist to winds up to 36m/s (130km/h) with peaks<br />

up to 50m/s (180km/h).<br />

Simulation of wind action (confirmed the calculation model)<br />

Seismic forces:<br />

Moreover, steel is known to behave well in an earthquake.<br />

Global failures and huge numbers of casualties<br />

are mostly associated with structures made from<br />

other materials.<br />

This is mainly due to three major qualities of steel:<br />

- Light weight:<br />

Steel structures are generally lighter than those using<br />

other materials. Some steel structures are sufficiently<br />

light so that seismic design is not critical.<br />

- Flexibility:<br />

Steel structures are generally more flexible than other<br />

types of structure. Constraints in the structure and its<br />

foundations are therefore lower.<br />

- Ductility:<br />

Unlike other materials, steel’s failure mode is ductile;<br />

this means that when submitted to strong forces,<br />

steel doesn’t break but dissipates energy by plastic<br />

deformation.<br />

13<br />

Thermal performance calculation:<br />

The PROTEA thermal performance has been assessed<br />

by thermal calculation.<br />

temperature (°C)<br />

42<br />

40<br />

38<br />

36<br />

34<br />

32<br />

30<br />

28<br />

26<br />

24<br />

22<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

As a result, this calculation shows that the PROTEA<br />

house provides better summer comfort compared to a<br />

traditional brick and mortar house (up to 5°C cooler).<br />

Thermal performance measurement:<br />

A thermography measurement was performed on a<br />

prototype, showing good thermal insulation and air<br />

tightness.<br />

Infrared images<br />

Indoor<br />

Comparison of indoor temperatures between PROTEA and standard<br />

south-african house, during the hottest week in climate zone 1<br />

(Bloemfontein)<br />

time (from 1/25 to 1/31)<br />

Comfort temperature PROTEA External Temperature Comfort temperature standard SA house<br />

Outdoor

PROTEA | Made of safe, sustainable steel<br />

The advantages of steel are numerous and make it<br />

an ideal building material.<br />

Steel, a material coming from nature:<br />

Iron ore, its raw material, is one of Earth’s most abundant<br />

elements.<br />

Steel is sustainable, durable and solid:<br />

Today, steel can be effectively protected against corrosion, particularly<br />

through the galvanisation process.<br />

Sandwich panels recycling process:<br />

Different studies show that technical solutions to recover steel in<br />

buildings and to transform it in high quality scrap exist.<br />

Sandwich<br />

panels<br />

Rotary<br />

shear<br />

Magnetic<br />

drum<br />

Steel is clean; its manufacturing process as well:<br />

Steelworks have cut steel manufacturing’s energy consumption<br />

and CO 2<br />

emissions by half compared with 1960 levels.<br />

Steel is recyclable and recycled<br />

Steel is indefinitely and 100% recyclable. More than 40% of the<br />

world steel production comes from recycled steel.<br />

Scrap<br />

metal<br />

PUR foam<br />

flakes<br />

Steel reduces building site noise pollution and makes for<br />

clean and safe construction:<br />

Prefabricated materials are delivered, minimising waste and onsite<br />

storage and making building sites safe, dry and dust-free.<br />

Steel is earthquake-resistant:<br />

Steel increases building longevity in earthquake-prone areas and<br />

preserves human life through its resistance.<br />

The goal is to separate steel from polyurethane foam in such a<br />

way that each component will be pure enough to be easily recycled<br />

in its own process. Two different tools exist: a shredder<br />

commonly used to process end of life vehicles or household appliances,<br />

and a rotary shear commonly used to shred steel packaging.<br />

However, reusing the sandwich panels at the end of the house<br />

life could be a much simpler and cheaper solution of recycling.<br />

Cooperation between «Habitat for Humanity» Haïti and ArcelorMittal<br />

Construction Dominicana (steel roof sheets)<br />

For more information:<br />

http://www.arcelormittal.com<br />

14

PROTEA | Benefits<br />

Low cost<br />

Cheaper than traditional materials with<br />

higher performances<br />

Thermal insulation<br />

U wall<br />

=0.29-0.47W/m².K (100-60 mm)<br />

U roof<br />

= 0.28-0.58W/m².K (100-40mm)<br />

Fast installation<br />

- 4 days<br />

- 4 workers<br />

Industrial power<br />

Industrialised system available<br />

in very large quantities<br />

Sound insulation<br />

Walls (60mm): Rw (C; Ctr): 25(-1;-3) dB<br />

Roof (40mm): Rw (C; Ctr): 25(-1;-3) dB<br />

Easy installation kit<br />

Easy to assemble, construction<br />

guide provided<br />

Training for local contractors<br />

Supervision training and technical<br />

assistance during construction<br />

Corrosion resistance<br />

Validated by salt spray test and humidity<br />

resistance<br />

Dry and clean<br />

construction site<br />

No water nor concrete needed<br />

Environmentally friendly<br />

- Steel is indefinitely and 100% recyclable<br />

- Steel is sustainable, durable and solid<br />

UV resistance<br />

- ∆E ≤ 3<br />

- Gloss retention ≥ 60%<br />

National certificates<br />

ArcelorMittal Construction respects the<br />

national construction regulations<br />

Wind load<br />

Up to 50 m/s (180km/h)<br />

Seismic resistance<br />

Up to 10m/s²<br />

Reaction to fire<br />

SBI test with 10mm plasterboard: B s1 d0<br />

(EU norms)<br />

15

PROTEA | Fast and easy installation<br />

• Low cost, high quality housing<br />

• Dry and clean construction site<br />

• Watertight structure completed in just 4 days<br />

Day 1<br />

- Products reception and<br />

site preparation<br />

- Chalk line tracing<br />

- Preparing and installing<br />

the floor rails on the slab<br />

Day 2<br />

- Installing the walls and partitions<br />

Day 3&4<br />

- Installing the top rails<br />

- Installing the roof<br />

- Installing wall to roof junctions and<br />

finishing<br />

Version 3 | 03-2012<br />

Excellent technical performance of:<br />

- Thermal insulation<br />

- Resistance to fire<br />

(with plasterboard)<br />

Resistance to:<br />

- Earthquakes<br />

- Strong winds<br />

- UV rays<br />

Steel characteristics:<br />

- High Strength Steel: S350GD<br />

- Hot Dip Galvanised<br />

- Pre-painted Organic Coating<br />

E-mail:sales@pga-consultants.net<br />

This publication is not a contractual document. Due to a policy of continual product development, ArcelorMittal Construction reserves the right to alter any of the specifications given in this publication without prior notice.<br />

No responsibility for accuracy is accepted by ArcelorMittal Construction. All information contained within this document is the sole property of our company and any unauthorized use is strictly forbidden.<br />

Document printed on<br />

paper made 100%<br />

from recycled fibres