K.Energy insulated wall panel system - PGA Consultants

K.Energy insulated wall panel system - PGA Consultants

K.Energy insulated wall panel system - PGA Consultants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

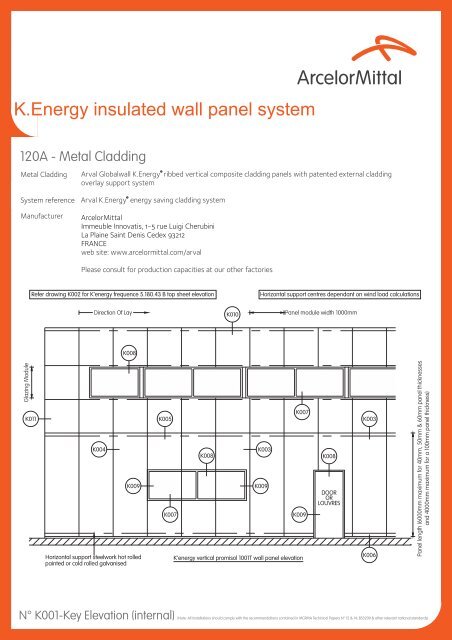

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

R<br />

Metal Cladding Arval Global<strong>wall</strong> K.<strong>Energy</strong> ribbed vertical composite cladding <strong>panel</strong>s with patented external cladding<br />

overlay support <strong>system</strong><br />

System reference<br />

Manufacturer<br />

R<br />

Arval K.<strong>Energy</strong> energy saving cladding <strong>system</strong><br />

ArcelorMittal<br />

Immeuble Innovatis, 1-5 rue Luigi Cherubini<br />

La Plaine Saint Denis Cedex 93212<br />

FRANCE<br />

web site: www.arcelormittal.com/arval<br />

Please consult for production capacities at our other factories<br />

Refer drawing K002 for K'energy frequence 5.180.43 B top sheet elevation<br />

Horizontal support centres dependant on wind load calculations<br />

Direction Of Lay<br />

K010<br />

Panel module width 1000mm<br />

K008<br />

Glazing Module<br />

K011<br />

K004<br />

K009<br />

Horizontal support steelwork hot rolled<br />

painted or cold rolled galvanised<br />

K007<br />

K005<br />

K003<br />

K008<br />

K009<br />

K007<br />

K009<br />

K'energy vertical promisol 1001T <strong>wall</strong> <strong>panel</strong> elevation<br />

K008<br />

DOOR<br />

OR<br />

LOUVRES<br />

K003<br />

K006<br />

Panel length (6000mm maximum for 40mm, 50mm & 60mm <strong>panel</strong> thicknesses<br />

and 4000mm maximum for a 100mm <strong>panel</strong> thickness)<br />

N° K001-Key Elevation (internal) (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 & other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

R<br />

Metal Cladding Arval Global<strong>wall</strong> K.<strong>Energy</strong> ribbed vertical composite cladding <strong>panel</strong>s with patented external cladding<br />

overlay support <strong>system</strong><br />

System reference<br />

Manufacturer<br />

R<br />

Arval K.<strong>Energy</strong> energy saving cladding <strong>system</strong><br />

ArcelorMittal<br />

Immeuble Innovatis, 1-5 rue Luigi Cherubini<br />

La Plaine Saint Denis Cedex 93212<br />

FRANCE<br />

web site: www.arcelormittal.com/arval<br />

Please consult for production capacities at our other factories<br />

Refer drawing K001 for K'energy vertical promisol 1001T <strong>wall</strong> <strong>panel</strong> elevation<br />

Ondafix vertical support rails fixed to promisol 1001T vertical <strong>wall</strong> <strong>panel</strong> modules at centres dependant on wind load calculations<br />

Direction Of Lay<br />

K010<br />

Sheet length dependant on wind load calculations<br />

K008<br />

Glazing Module<br />

K011<br />

K005<br />

K007<br />

K012<br />

900mm cover width<br />

K004<br />

K008<br />

K012<br />

K008<br />

K009<br />

K009<br />

DOOR<br />

OR<br />

LOUVRES<br />

K007<br />

K009<br />

Ondafix vertical support rails fixed to promisol<br />

1001T vertical <strong>wall</strong> <strong>panel</strong> modules<br />

K'energy frequence 5.180.43 B top sheet elevation<br />

(Illustrative only - may be replaced by any suitable<br />

external steel or aluminium profile, "hi-tec"<br />

<strong>panel</strong>ling, timber cladding or reconstituted stone)<br />

K006<br />

N° K002-Key Elevation (external) (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 & other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

External facing material<br />

0.63mm or 0.75mm gauge galvanized cold rolled steel sheet<br />

grade S220 G to EN10326 & EN10346<br />

Finish/colour<br />

Internal facing material<br />

Finish/colour<br />

Colorissme range (we recommend using light colours) to EN10169<br />

0.5mm or 0.63mm gauge galvanized cold rolled steel sheet<br />

grade S220 G to EN10326 & EN10346<br />

Interior 912 to EN10169<br />

3<br />

Core insulation HCFC free rigid polyurethane foam, density 40kg/m giving i [W/(m.K)]<br />

on stated overall K.<strong>Energy</strong> thickness module:<br />

140mm - 0.37; 160mm - 0.28; 180mm - 0.23; 200mm - 0.19; 220mm - 0.17.<br />

Please contact our Technical Department for further information/individual project assessment<br />

1000 Cover width<br />

333.3mm<br />

Promisol 1001T vertically laid <strong>wall</strong> <strong>panel</strong><br />

Panel thickness<br />

Main <strong>panel</strong> fixing in accordance to the specification of <strong>panel</strong> thickness<br />

Horizontal steelwork sheeting rail<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

10mm minimum<br />

Side lap fixing screw at<br />

maximum 450mm centres<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

50<br />

6x5mm butyl rubber sealant (site applied)<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

200<br />

End lap stitcher screw at<br />

every crown<br />

End lap detail<br />

50<br />

10mm nominal 20mm maximum<br />

3 Rows of 6x5mm butyl rubber<br />

sealant (site applied)<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Side lap detail<br />

6mm diameter butyl rubber sealant<br />

Vapour seal when required (site applied)<br />

Direction of lay<br />

N° K003 - Panel Arrangement (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Primary cladding fasteners Self tapping and self drilling screws (galvanized carbon steel) .<br />

Number and location of<br />

fasteners<br />

Fixing Cladding<br />

210G Structure<br />

1 N° fastener at every support rail fixed through <strong>panel</strong> trough plus side lap fasteners at 450mm<br />

minimum centers or as required by project specific calculations.<br />

Fixing of outer cladding <strong>system</strong> to be in accordance with NBS applicable to <strong>system</strong> selected.<br />

Check that the structure is in a suitable state to receive the cladding before commencing fixing. Subcontractor must<br />

confirm acceptance to main contractor.<br />

215 Structure Do not fix cladding until final coats of paint have been applied to all contact surfaces of supporting structure, and<br />

remove all dust and foreign matter before finally fixing <strong>panel</strong>s into position.<br />

Drill all holes and install fasteners at regular intervals in straight lines, centered on support bearings.<br />

Install fastners to correct tightness using special tools recommended by the fastener manufacturer. When used,<br />

screw guns must be fitted with depth sensitive devices and be used at the correct speed.<br />

Check fasteners on completion and adjust as necessary to ensure that they are watertight and sheeting is secure<br />

but not buckled or distorted.<br />

Horizontal steelwork sheeting rail<br />

6mm diameter butyl rubber sealant<br />

Vapour seal when required (site applied)<br />

77 insulation<br />

zone<br />

6x5mm butyl rubber sealant (site applied)<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong> vertically laid<br />

43<br />

Panel thickness<br />

Ondafix vertical support rail<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

Fixing at 450 centres<br />

Profiled foam fillers<br />

0.75mm thick closer feature fin<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet horizontally laid<br />

May be replaced by any suitable external steel or aluminium profile,<br />

"hi-tec" <strong>panel</strong>ling, timber cladding or reconstituted stone<br />

Refer drawing K012 for the 4 No end lap options of the frequence 5.180.43 B <strong>wall</strong> sheet<br />

N° K004/1 - Fasteners 1 (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Primary cladding fasteners Self tapping and self drilling screws (galvanized carbon steel) .<br />

Number and location of<br />

fasteners<br />

Sealing Cladding<br />

550A Seals<br />

1 N° fastener at every support rail fixed through <strong>panel</strong> trough plus intermediate fasteners<br />

at 450mm centers or as required by project specific calculations.<br />

.<br />

Horizontal - Rolled steel full interlocking male/female edges giving weather tight overlap joint.<br />

Vertical - Extended top profile with foam core and bottom profile cut back to give a fully sealed<br />

overlap joint (200mm) complete with 3 continuous rows of 6mm x 5mm butyl rubber sealant.<br />

554A Vapour seals<br />

Sealant tape: 20mm x 5mm closed cell foam vapour strip positioned in straight unbroken lines at <strong>panel</strong><br />

supports, parallel to and slightly back from end of <strong>panel</strong>. Do not allow tape to be stretched into position.<br />

Ensure continuity and effectiveness of seal, especially at sheet corners. Ensure adequate over-compression<br />

to achieve required vapour seal.<br />

Sealing of outer cladding <strong>system</strong> to be in accordance with NBS applicable to <strong>system</strong> selected<br />

Horizontal steelwork sheeting rail<br />

6mm diameter butyl rubber sealant<br />

Vapour seal when required (site applied)<br />

77 insulation<br />

zone<br />

6x5mm butyl rubber sealant (site applied)<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong> vertically laid<br />

43<br />

Panel thickness<br />

Ondafix vertical support rail<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

Fixing at 450 centres<br />

Profiled foam fillers<br />

0.75mm thick closer feature fin<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet horizontally laid<br />

May be replaced by any suitable external steel or aluminium profile,<br />

"hi-tec" <strong>panel</strong>ling, timber cladding or reconstituted stone<br />

Refer drawing K012 for the 4 No end lap options of the frequence 5.180.43 B <strong>wall</strong> sheet<br />

N° K004/2 - Sealing Joints 1 (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Primary cladding fasteners Self tapping and self drilling screws (galvanized carbon steel) .<br />

Number and location of<br />

fasteners<br />

Fixing Cladding<br />

210G Structure<br />

1 N° fastener at every support rail fixed through <strong>panel</strong> trough plus side lap fasteners at 450mm<br />

minimum centers or as required by project specific calculations.<br />

Fixing of outer cladding <strong>system</strong> to be in accordance with NBS applicable to <strong>system</strong> selected.<br />

Check that the structure is in a suitable state to receive the cladding before commencing fixing. Subcontractor must<br />

confirm acceptance to main contractor.<br />

215 Structure Do not fix cladding until final coats of paint have been applied to all contact surfaces of supporting structure, and<br />

remove all dust and foreign matter before finally fixing <strong>panel</strong>s into position.<br />

Drill all holes and install fasteners at regular intervals in straight lines, centered on support bearings.<br />

Install fastners to correct tightness using special tools recommended by the fastener manufacturer. When used,<br />

screw guns must be fitted with depth sensitive devices and be used at the correct speed.<br />

Check fasteners on completion and adjust as necessary to ensure that they are watertight and sheeting is secure<br />

but not buckled or distorted.<br />

43<br />

77<br />

Panel thickness<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Ondafix vertical support rail<br />

Horizontal steelwork sheeting rail<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Monobond butyl<br />

3 Rows of 6x5mm butyl rubber<br />

sealant (site applied)<br />

Top sheet stitcher fixing<br />

at 450 centres<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

N° K005/1 - Fasteners 2 (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Primary cladding fasteners Self tapping and self drilling screws (galvanized carbon steel) .<br />

Number and location of<br />

fasteners<br />

Sealing Cladding<br />

550A Seals<br />

1 N° fastener at every support rail fixed through <strong>panel</strong> trough plus intermediate fasteners<br />

at 450mm centers or as required by project specific calculations.<br />

.<br />

Horizontal - Rolled steel full interlocking male/female edges giving weather tight overlap joint.<br />

Vertical - Extended top profile with foam core and bottom profile cut back to give a fully sealed<br />

overlap joint (200mm) complete with 3 continuous rows of 6mm x 5mm butyl rubber sealant.<br />

554A Vapour seals<br />

Sealant tape: 20mm x 5mm closed cell foam vapour strip positioned in straight unbroken lines at <strong>panel</strong><br />

supports, parallel to and slightly back from end of <strong>panel</strong>. Do not allow tape to be stretched into position.<br />

Ensure continuity and effectiveness of seal, especially at sheet corners. Ensure adequate over-compression<br />

to achieve required vapour seal.<br />

Sealing of outer cladding <strong>system</strong> to be in accordance with NBS applicable to <strong>system</strong> selected<br />

43<br />

77<br />

Panel thickness<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Ondafix vertical support rail<br />

Horizontal steelwork sheeting rail<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Monobond butyl<br />

3 Rows of 6x5mm butyl rubber<br />

sealant (site applied)<br />

Top sheet stitcher fixing<br />

at 450 centres<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

N° K005/2 - Sealing Joints 2 (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

Fittings and accessories generally<br />

221 Accessories Cappings, closure pieces, flashings, trims cills, gutters, fillers, spacers, tapes, sealants, fixings etc, where not<br />

specified, are to be types as recommended by ArcelorMittal - Arval.<br />

223 Isolating Tape A type recommended for the purpose by ArcelorMittal - Arval. Apply to those surfaces of supports which<br />

would otherwise be in contact with cladding or accessories after fixing.<br />

310A Purpose made<br />

cold formed<br />

metal<br />

accessories<br />

Material:<br />

Thickness/gauge:<br />

Finish/colour:<br />

43<br />

Galvanized cold rolled steel sheet grade S320 GD.<br />

0.75mm minimum.<br />

External - Colorissime range.<br />

Internal - Interior 912<br />

Workmanship as NBS Standard Section Z22.<br />

R<br />

Fix to K.<strong>Energy</strong> and/or Structure with 4.8mm stitcher screws (or rivets) at 450mm<br />

nominal centers.<br />

77<br />

Panel thickness<br />

Ondafix vertical support rail<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Horizontal steelwork sheeting rail<br />

6mm diameter bead of gun grade sealant<br />

Gun grade silicone fillet<br />

Cill flashing by others<br />

Note: These details are for guidance only.<br />

The individual building designer must<br />

satisfy him/herself of any and all cold<br />

bridging issues and adjust the final<br />

design layout accordingly.<br />

Closure flashing by others<br />

Brickwork<br />

N° K006 - Base Drip (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

Fittings and accessories generally<br />

221 Accessories Cappings, closure pieces, flashings, trims cills, gutters, fillers, spacers, tapes, sealants, fixings etc, where not<br />

specified, are to be types as recommended by ArcelorMittal - Arval.<br />

223 Isolating Tape A type recommended for the purpose by ArcelorMittal - Arval. Apply to those surfaces of supports which<br />

would otherwise be in contact with cladding or accessories after fixing.<br />

310A Purpose made<br />

cold formed<br />

metal<br />

accessories<br />

Material:<br />

Thickness/gauge:<br />

Finish/colour:<br />

Galvanized cold rolled steel sheet grade S320 GD.<br />

0.75mm minimum.<br />

External - Colorissime range.<br />

Internal - Interior 912<br />

Workmanship as NBS Standard Section Z22.<br />

R<br />

Fix to K.<strong>Energy</strong> and/or Structure with 4.8mm stitcher screws (or rivets) at 450mm<br />

nominal centers.<br />

Glazing by others<br />

Closure flashing by others<br />

4mm diameter butyl<br />

rubber sealant<br />

Cill flashing by others<br />

Mastic sealant by others<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

PIR board insulation<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

6mm diameter bead of gun grade sealant to provide air seal<br />

Ondafix vertical<br />

support rail<br />

Horizontal steelwork by others<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

4mm diameter butyl<br />

rubber sealant<br />

77<br />

Panel thickness<br />

Note: These details are for guidance only.<br />

The individual building designer must<br />

satisfy him/herself of any and all cold<br />

bridging issues and adjust the final<br />

design layout accordingly.<br />

N° K007 - Cills (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

Fittings and accessories generally<br />

221 Accessories Cappings, closure pieces, flashings, trims cills, gutters, fillers, spacers, tapes, sealants, fixings etc, where not<br />

specified, are to be types as recommended by ArcelorMittal - Arval.<br />

223 Isolating Tape A type recommended for the purpose by ArcelorMittal - Arval. Apply to those surfaces of supports which<br />

would otherwise be in contact with cladding or accessories after fixing.<br />

310A Purpose made<br />

cold formed<br />

metal<br />

accessories<br />

Material:<br />

Thickness/gauge:<br />

Finish/colour:<br />

Galvanized cold rolled steel sheet grade S320 GD.<br />

0.75mm minimum.<br />

External - Colorissime range.<br />

Internal - Interior 912<br />

Workmanship as NBS Standard Section Z22.<br />

R<br />

Fix to K.<strong>Energy</strong> and/or Structure with 4.8mm stitcher screws (or rivets) at 450mm<br />

nominal centers.<br />

43<br />

77<br />

Panel thickness<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

Ondafix vertical support rail<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Horizontal steelwork sheeting rail<br />

6mm diameter bead of gun grade sealant to provide air seal<br />

PIR board insulation<br />

Closure flashing by others<br />

Cill flashing by others<br />

Mastic sealant by others<br />

Closure flashing by others<br />

Note: These details are for guidance only.<br />

The individual building designer must<br />

satisfy him/herself of any and all cold<br />

bridging issues and adjust the final<br />

design layout accordingly.<br />

6mm diameter butyl<br />

rubber sealant<br />

Glazing by others<br />

N° K008 - Heads (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

Fittings and accessories generally<br />

221 Accessories Cappings, closure pieces, flashings, trims cills, gutters, fillers, spacers, tapes, sealants, fixings etc, where not<br />

specified, are to be types as recommended by ArcelorMittal - Arval.<br />

223 Isolating Tape A type recommended for the purpose by ArcelorMittal - Arval. Apply to those surfaces of supports which<br />

would otherwise be in contact with cladding or accessories after fixing.<br />

310A Purpose made<br />

cold formed<br />

metal<br />

accessories<br />

Material:<br />

Thickness/gauge:<br />

Finish/colour:<br />

Galvanized cold rolled steel sheet grade S320 GD.<br />

0.75mm minimum.<br />

External - Colorissime range.<br />

Internal - Interior 912<br />

Workmanship as NBS Standard Section Z22.<br />

R<br />

Fix to K.<strong>Energy</strong> and/or Structure with 4.8mm stitcher screws (or rivets) at 450mm<br />

nominal centers.<br />

Closure flashing by others<br />

Refer drawing K012 for the 4 No end lap options of the frequence 5.180.43 B <strong>wall</strong> sheet<br />

4mm diameter butyl<br />

rubber sealant<br />

Vertical steelwork by others<br />

Note: These details are for guidance only.<br />

The individual building designer must<br />

satisfy him/herself of any and all cold<br />

bridging issues and adjust the final<br />

design layout accordingly.<br />

6mm diameter bead of gun grade sealant to provide air seal<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Horizontal steelwork sheeting rail<br />

Glazing by others<br />

Mastic sealant by others<br />

PIR board insulation<br />

Panel thickness<br />

Jamb flashing by others<br />

4mm diameter butyl rubber sealant<br />

Ondafix vertical support rail<br />

Profiled foam fillers<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong> vertically laid<br />

43 77<br />

0.75mm thick closer feature fin Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

N° K009 - Jambs (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

Fittings and accessories generally<br />

221 Accessories Cappings, closure pieces, flashings, trims cills, gutters, fillers, spacers, tapes, sealants, fixings etc, where not<br />

specified, are to be types as recommended by ArcelorMittal - Arval.<br />

223 Isolating Tape A type recommended for the purpose by ArcelorMittal - Arval. Apply to those surfaces of supports which<br />

would otherwise be in contact with cladding or accessories after fixing.<br />

310A Purpose made<br />

cold formed<br />

metal<br />

accessories<br />

Material:<br />

Thickness/gauge:<br />

Finish/colour:<br />

Galvanized cold rolled steel sheet grade S320 GD.<br />

0.75mm minimum.<br />

External - Colorissime range.<br />

Internal - Interior 912<br />

Workmanship as NBS Standard Section Z22.<br />

R<br />

Fix to K.<strong>Energy</strong> and/or Structure with 4.8mm stitcher screws (or rivets) at 450mm<br />

nominal centers.<br />

Parapet flashing by others<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

PIR board insulation<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

6mm diameter bead of gun grade sealant to provide air seal<br />

Ondafix vertical<br />

support rail<br />

Horizontal steelwork by others<br />

Profiled foam filler<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

4mm diameter butyl<br />

rubber sealant<br />

Internal parapet cladding by others<br />

77<br />

Panel thickness<br />

Note: These details are for guidance only.<br />

The individual building designer must<br />

satisfy him/herself of any and all cold<br />

bridging issues and adjust the final<br />

design layout accordingly.<br />

N° K010 - Parapets (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

Fittings and accessories generally<br />

221 Accessories Cappings, closure pieces, flashings, trims cills, gutters, fillers, spacers, tapes, sealants, fixings etc, where not<br />

specified, are to be types as recommended by ArcelorMittal - Arval.<br />

223 Isolating Tape A type recommended for the purpose by ArcelorMittal - Arval. Apply to those surfaces of supports which<br />

would otherwise be in contact with cladding or accessories after fixing.<br />

310A Purpose made<br />

cold formed<br />

metal<br />

accessories<br />

Material:<br />

Thickness/gauge:<br />

Finish/colour:<br />

Galvanized cold rolled steel sheet grade S320 GD.<br />

0.75mm minimum.<br />

External - Colorissime range.<br />

Internal - Interior 912<br />

Workmanship as NBS Standard Section Z22.<br />

R<br />

Fix to K.<strong>Energy</strong> and/or Structure with 4.8mm stitcher screws (or rivets) at 450mm<br />

nominal centers.<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

Note: These details are for guidance only.<br />

The individual building designer must<br />

satisfy him/herself of any and all cold<br />

bridging issues and adjust the final<br />

design layout accordingly.<br />

External corner flashing by others<br />

Ondafix vertical support rail<br />

Cleader angle by others<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Horizontal steelwork sheeting rail<br />

Panel thickness<br />

Fixing at 450 centres<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong> vertically laid<br />

43 77<br />

Profiled foam fillers<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet<br />

May be replaced by any suitable external steel or<br />

aluminium profile, "hi-tec" <strong>panel</strong>ling, timber<br />

cladding or reconstituted stone<br />

N° K011 - Corner (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

Fittings and accessories generally<br />

221 Accessories Cappings, closure pieces, flashings, trims cills, gutters, fillers, spacers, tapes, sealants, fixings etc, where not<br />

specified, are to be types as recommended by ArcelorMittal - Arval.<br />

223 Isolating Tape A type recommended for the purpose by ArcelorMittal - Arval. Apply to those surfaces of supports which<br />

would otherwise be in contact with cladding or accessories after fixing.<br />

310A Purpose made<br />

cold formed<br />

metal<br />

accessories<br />

43<br />

Material:<br />

Thickness/gauge:<br />

Finish/colour:<br />

Galvanized cold rolled steel sheet grade S320 GD.<br />

0.75mm minimum.<br />

External - Colorissime range.<br />

Internal - Interior 912<br />

Workmanship as NBS Standard Section Z22.<br />

R<br />

Fix to K.<strong>Energy</strong> and/or Structure with 4.8mm stitcher screws (or rivets) at 450mm<br />

nominal centers.<br />

180<br />

55<br />

10<br />

Note: These details are for guidance only.<br />

The individual building designer must<br />

satisfy him/herself of any and all cold<br />

bridging issues and adjust the final<br />

design layout accordingly.<br />

Ondafix vertical support rail<br />

Steel butt straps colour<br />

coated profile<br />

900mm Profile cover width<br />

Frequence 5.180.43 B <strong>wall</strong> sheet<br />

Ondafix vertical support rail<br />

BCR 9mm x 3mm mastic<br />

between deck sheets<br />

Line of ondafix vertical<br />

support rail<br />

43<br />

43<br />

150 Min<br />

Monobond butyl<br />

Sleeved butted end lap detail<br />

Overlap joint end lap detail<br />

Ondafix vertical support rail<br />

Ondafix vertical support rail<br />

Top sheet stitcher fixing<br />

at 450 centres<br />

Profiled foam fillers<br />

Frequence 5.180.43 B <strong>wall</strong> sheet<br />

Profiled foam fillers<br />

0.75mm closer feature<br />

inverted tophat<br />

Illustrative only - Frequence 5.180.43 B<br />

<strong>wall</strong> sheet see note above<br />

43<br />

0.75mm closer<br />

feature fin<br />

43<br />

N° K012 - Assembly (illustrative) (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)<br />

Side lap detail<br />

Feature fin joint end lap detail<br />

Feature inverted tophat joint end lap detail

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

120A - Metal Cladding<br />

Accessories<br />

Fixing <strong>panel</strong>s generally<br />

R<br />

Matching flashings and support zeds. Ondafix rails (1.5mm)<br />

R<br />

410 Fixing Panels The use of K.<strong>Energy</strong> sandwich <strong>panel</strong>s requires accurate setting out, with due allowance for building<br />

expansion devices (these must not be built over). For fixing of external <strong>panel</strong>s refer to relevant NBS<br />

documentation for selected <strong>system</strong>.<br />

Before fitting the <strong>panel</strong>s, the cladding contractor must inspect the supporting structure using the<br />

criteria below listed, to ensure that the <strong>panel</strong>s do not take on any uneveness inherent in the support<br />

support <strong>system</strong>, thereby causing the finished surface of the facade to be out of true.<br />

The results of a bilateral inspection by the principal contractor and the supplier of the support <strong>system</strong><br />

should be duly recorded in any inspection report. In case of complaint in respect of ArcelorMittal - Arval<br />

products we will require production of the inspection report for the support structure.<br />

Any comosite <strong>panel</strong> <strong>system</strong> is aesthetically only as good as the framework to which it is fixed. It is<br />

essential therefore that the support <strong>system</strong> is true to line and plumb. We recommend that all<br />

R<br />

secondary steelwork to which K.<strong>Energy</strong> <strong>panel</strong>s are fixed be designed to be capable of adjustment<br />

during erection. ArcelorMittal - Arval recommend steelwork tolerances as listed below:-<br />

Vertical tolerance (full height of building) = 5mm maximum<br />

Alignment (adjacent vertical supports) = +/-2mm<br />

Horizontal tolerance (full length of building)<br />

= +/-5mm<br />

R<br />

K.<strong>Energy</strong> <strong>panel</strong>s are purpose-made to specific requirements. Site cutting is not normally required,<br />

if cutting is required the following should be observed:-<br />

Before cutting, masking tape must be laid on the cutting line to protect coating from damage.<br />

Cutting must be carried out with a jigsaw, blades are to have fine metal cutting serrations.<br />

Note - Angle grinders or similar type tools must not be used.<br />

Cut <strong>panel</strong>s on suitable supports to avoid de-lamination of metal skins by vibration.<br />

All exposed foam cut <strong>panel</strong> edges to be protected afterwards with self adhesive foil tape. Cut openings<br />

in <strong>panel</strong>s for outlets, vent pipes, flues, etc. to the minimum size necessary. Reinforce edges of openings<br />

with support angles/flashings.<br />

Drill all holes and install fasteners perpendicular to the surface of the <strong>panel</strong>s. Position the fasteners at<br />

regular intervals in straight lines, centred on the support bearings. Remove dust and any other foreign<br />

matter before finally fixing <strong>panel</strong>s into position.<br />

Protect <strong>panel</strong>s adequately during fixing and up to Completion against mechanical damage/disfigurement.<br />

Rectify any defects as quickly as practicable to minimise damage and nuisance. Cladding <strong>panel</strong>s and<br />

flashings must be cleaned down and swarf, rivet mandrels, debris, etc. must be removed on a day to day<br />

basis as work proceeds.<br />

Paint all cut edges to match face finish.<br />

N° K013 - Fixing Generally (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)