You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

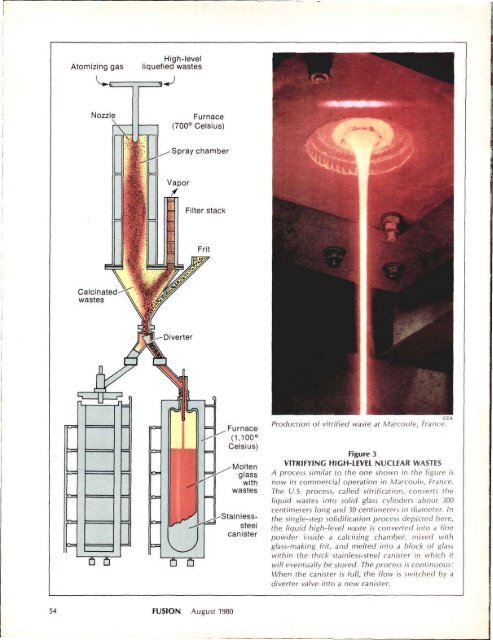

Production of vitrified waste at Marcoule,<br />

CEA<br />

France.<br />

Figure 3<br />

VITRIFYING HIGH-LEVEL NUCLEAR WASTES<br />

A process similar to the one shown in the figure is<br />

now in commercial operation in Marcoule, France.<br />

The U.S. process, called vitrification, converts the<br />

liquid wastes into solid glass cylinders about 300<br />

centimeters long and 30 centimeters in diameter. In<br />

the single-step solidification process depicted here,<br />

the liquid high-level waste is converted into a fine<br />

powder inside a calcining chamber, mixed with<br />

glass-making frit, and melted into a block of glass<br />

within the thick stainless-steel canister in which it<br />

will eventually be stored. The process is continuous:<br />

When the canister is full, the flow is switched by a<br />

diverter valve into a new canister.<br />

54 FUSION August 1980