a study on the performance of limestone roughing filter - ePrints@USM

a study on the performance of limestone roughing filter - ePrints@USM

a study on the performance of limestone roughing filter - ePrints@USM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

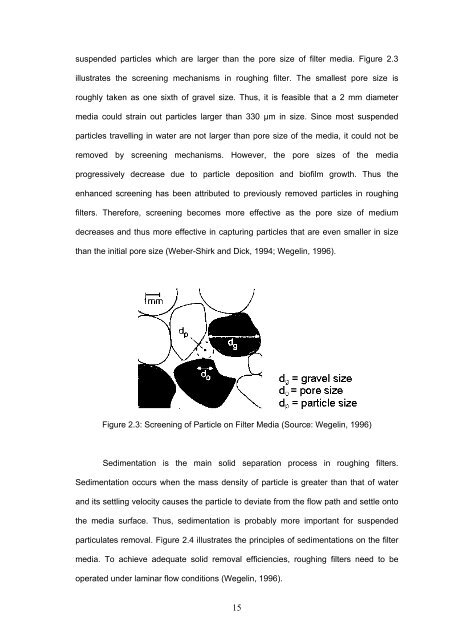

suspended particles which are larger than <strong>the</strong> pore size <strong>of</strong> <strong>filter</strong> media. Figure 2.3<br />

illustrates <strong>the</strong> screening mechanisms in <strong>roughing</strong> <strong>filter</strong>. The smallest pore size is<br />

roughly taken as <strong>on</strong>e sixth <strong>of</strong> gravel size. Thus, it is feasible that a 2 mm diameter<br />

media could strain out particles larger than 330 μm in size. Since most suspended<br />

particles travelling in water are not larger than pore size <strong>of</strong> <strong>the</strong> media, it could not be<br />

removed by screening mechanisms. However, <strong>the</strong> pore sizes <strong>of</strong> <strong>the</strong> media<br />

progressively decrease due to particle depositi<strong>on</strong> and bi<strong>of</strong>ilm growth. Thus <strong>the</strong><br />

enhanced screening has been attributed to previously removed particles in <strong>roughing</strong><br />

<strong>filter</strong>s. Therefore, screening becomes more effective as <strong>the</strong> pore size <strong>of</strong> medium<br />

decreases and thus more effective in capturing particles that are even smaller in size<br />

than <strong>the</strong> initial pore size (Weber-Shirk and Dick, 1994; Wegelin, 1996).<br />

Figure 2.3: Screening <strong>of</strong> Particle <strong>on</strong> Filter Media (Source: Wegelin, 1996)<br />

Sedimentati<strong>on</strong> is <strong>the</strong> main solid separati<strong>on</strong> process in <strong>roughing</strong> <strong>filter</strong>s.<br />

Sedimentati<strong>on</strong> occurs when <strong>the</strong> mass density <strong>of</strong> particle is greater than that <strong>of</strong> water<br />

and its settling velocity causes <strong>the</strong> particle to deviate from <strong>the</strong> flow path and settle <strong>on</strong>to<br />

<strong>the</strong> media surface. Thus, sedimentati<strong>on</strong> is probably more important for suspended<br />

particulates removal. Figure 2.4 illustrates <strong>the</strong> principles <strong>of</strong> sedimentati<strong>on</strong>s <strong>on</strong> <strong>the</strong> <strong>filter</strong><br />

media. To achieve adequate solid removal efficiencies, <strong>roughing</strong> <strong>filter</strong>s need to be<br />

operated under laminar flow c<strong>on</strong>diti<strong>on</strong>s (Wegelin, 1996).<br />

15