BAYPREG Brosch GB neu_A4.fh11 - BaySystems - customized ...

BAYPREG Brosch GB neu_A4.fh11 - BaySystems - customized ...

BAYPREG Brosch GB neu_A4.fh11 - BaySystems - customized ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4<br />

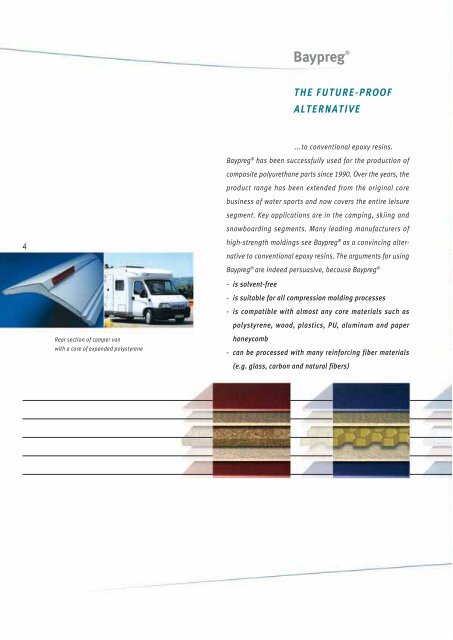

Rear section of camper van<br />

with a core of expanded polystyrene<br />

THE FUTURE-PROOF<br />

ALTERNATIVE<br />

...to conventional epoxy resins.<br />

Baypreg ® has been successfully used for the production of<br />

composite polyurethane parts since 1990. Over the years, the<br />

product range has been extended from the original core<br />

business of water sports and now covers the entire leisure<br />

segment. Key applications are in the camping, skiing and<br />

snowboarding segments. Many leading manufacturers of<br />

high-strength moldings see Baypreg ® as a convincing alternative<br />

to conventional epoxy resins. The arguments for using<br />

Baypreg ® are indeed persuasive, because Baypreg ®<br />

- is solvent-free<br />

- is suitable for all compression molding processes<br />

- is compatible with almost any core materials such as<br />

polystyrene, wood, plastics, PU, aluminum and paper<br />

honeycomb<br />

- can be processed with many reinforcing fiber materials<br />

(e.g. glass, carbon and natural fibers)