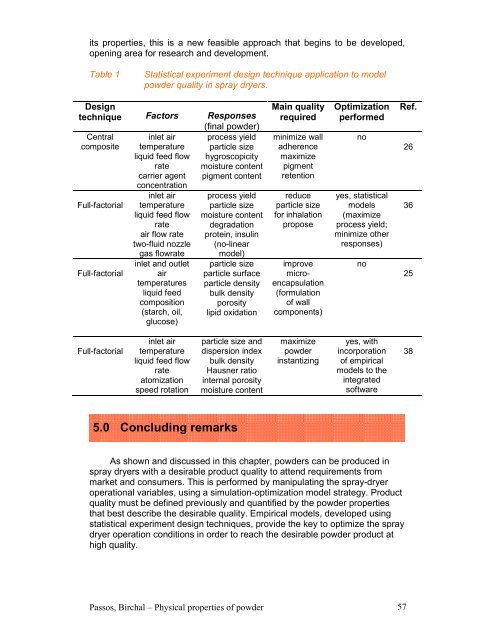

its properties, this is a new feasible approach that begins to be developed, opening area for research and development. Table 1 Statistical experiment design technique application to model powder quality in spray dryers. Design technique Factors Responses (final powder) Central composite Full-factorial Full-factorial inlet air temperature liquid feed flow rate carrier agent concentration inlet air temperature liquid feed flow rate air flow rate two-fluid nozzle gas flowrate inlet and outlet air temperatures liquid feed composition (starch, oil, glucose) process yield particle size hygroscopicity moisture content pigment content process yield particle size moisture content degradation protein, insulin (no-linear model) particle size particle surface particle density bulk density porosity lipid oxidation Main quality required minimize wall adherence maximize pigment retention reduce particle size for inhalation propose improve microencapsulation (formulation <strong>of</strong> wall components) Optimization performed no yes, statistical models (maximize process yield; minimize other responses) no Ref. 26 36 25 Full-factorial inlet air temperature liquid feed flow rate atomization speed rotation particle size and dispersion index bulk density Hausner ratio internal porosity moisture content maximize powder instantizing yes, with incorporation <strong>of</strong> empirical models to the integrated s<strong>of</strong>tware 38 5.0 Concluding remarks As shown and discussed in this chapter, powders can be produced in spray dryers with a desirable product quality to attend requirements from market and consumers. This is performed by manipulating the spray-dryer operational variables, using a simulation-optimization model strategy. Product quality must be defined previously and quantified by the powder properties that best describe the desirable quality. Empirical models, developed using statistical experiment design techniques, provide the key to optimize the spray dryer operation conditions in order to reach the desirable powder product at high quality. Passos, Birchal – Physical properties <strong>of</strong> powder 57

6.0 References 1. Filková, I.; Mujumdar, A. S. Industrial spray drying systems. In Handbook <strong>of</strong> Industrial <strong>Drying</strong>, 3 rd edition, Mujumdar, A. S., Ed.; CRC Press Taylor and Francis Group, Boca Raton, Fl, 2006; pp.215-256. 2. Pisecky, J. Evaporation and spray drying in the dairy industry. In Handbook <strong>of</strong> Industrial <strong>Drying</strong>, 2 rd edition, Mujumdar, A. S., Ed.; Marcel Dekker Inc.; New York, NY, 1995; pp.715-742. 3. Birchal, V.S.; Passos, M. L. Modeling and simulation <strong>of</strong> milk emulsion drying in spray dyers. Braz. J. Cem. Eng. 2005, 22, 293-302. 4. Mezhericher, M.; Levy, A.; Borde, I. Theoretical drying model <strong>of</strong> single droplets containing insoluble or dissolved solids. <strong>Drying</strong> Techn. 2007, 25(6), 1.025-1032 5. Kim, E.H.J.; Chen, X. D.; Pearce, D. On the mechanisms <strong>of</strong> surface formation and the surface compositions <strong>of</strong> industrial milk powders. <strong>Drying</strong> Technol. 2003, 21(2), 265-278. 6. Charlesworth, D. H.; Marshall Jr., W. R. Evaporating from drops containing dissolved solids. A. I. Ch. E. Journal 1960, 6(1), 9-23. 7. Nešić, S. The evaporation <strong>of</strong> single droplets - Experiments and modelling. In <strong>Drying</strong>’89, Mujumdar, A.S., Ed.; Hemisphere Publishing Corp., New York, NY, 1990; pp.386–393. 8. Seydel, P.; Blömer, J.; Bertling, J. Modeling particle formation at spray drying using population balances. <strong>Drying</strong> Techn. 2006, 24, 137-146. 9. Refstrup, E. Recent advances in agglomeration during spray drying. http://niroinc.com/ drying_dairy_food/recent_advances_agglomeration.asp (accessed March 30, 2010). 10. King, C. J.; Kieckbusch, T. G.; Greenwald, C. G. Food-quality factors in spray drying. In Advances in <strong>Drying</strong>, vol. 3, Mujumdar, A. S., Ed.; Hemisphere Publishing Corp., New York, NY, 1984, pp. 71-120. 11. Knegt, R.J.; Brink, H. van den. Improvement <strong>of</strong> the drying oven method for the determination <strong>of</strong> the moisture content <strong>of</strong> milk powder. Int. Dairy J. 1998, 8, 733-738. 12. Beuchat, L. Microbial stability as affected by water activity. Cereal Foods World 1981, 26, 345-351. 13. Decagon Inc. AquaSorp - moisture sorption isotherm generator. Operator’s Manual, version 3.0. http://www.decagon.com/<strong>pdf</strong>s/manuals/AquaSorp_v3.<strong>pdf</strong> (accessed March 30, 2010). 14. Passos, M. L.; Mujumdar, A. S. Mathematical models for improving spray drying processes for foods. Stewart Postharvest Review. 2005, 1(4), 6:1- 12. 15. Masters, K. <strong>Spray</strong> <strong>Drying</strong> Handbook, 5 th ed.; Longman Group: Harlow, Essex, 1991. 16. Ré, M. I. Formulating drug delivery systems by spray drying. <strong>Drying</strong> Technol. 2006, 24, 433-446. 17. Medeiros, U. K. L.; Medeiros, M. F. D.; Passos, M. L. Goat milk production in small agro-cooperatives. In Innovation in Food Engineering New Techniques and Products, Passos, M. L. and Ribeiro, C. P., Eds.; CRC Press Taylor and Francis Group, Boca Raton, Fl, 2010; pp.539-578. Passos, Birchal – Physical properties <strong>of</strong> powder 58

- Page 1 and 2:

Spray Drying Technology Volume One

- Page 3 and 4:

List of Authors Arun Sadashiv Mujum

- Page 5 and 6:

Content Preface Page i List of Auth

- Page 7 and 8:

1.0 Introduction The CFD technique

- Page 9 and 10:

Transient or steady simulation The

- Page 11 and 12: Initial conditions Steady state sol

- Page 13 and 14: flow structures; limiting any possi

- Page 15 and 16: ( ρ − ρ) du g P X P = FD ( u

- Page 17 and 18: Group of particles with the same ma

- Page 19 and 20: vortex in the region below the disk

- Page 21 and 22: Another development is in the use o

- Page 23 and 24: modulus, can be obtained to be used

- Page 25 and 26: 3.1 Quantitative and qualitative ai

- Page 27 and 28: 3.4 Residence time measurements The

- Page 29 and 30: velocities at nozzle exit are fixed

- Page 31 and 32: Figure 13 a b Spray dryer considere

- Page 33 and 34: atomizer was operated at a higher c

- Page 35 and 36: 6.0 Concluding remarks This chapter

- Page 37 and 38: dryers. Chemical Product and Proces

- Page 39 and 40: 56. Adhikari, B.; Howes, T.; Lecomt

- Page 41 and 42: Woo, Huang, Mujumdar, Daud - CFD mo

- Page 43 and 44: Since the current market requires f

- Page 45 and 46: dryer operation conditions to those

- Page 47 and 48: SPRAY DRYER DESIGN: • spray dryer

- Page 49 and 50: spray-dried powders. This lognormal

- Page 51 and 52: permeability, as the ESA (envelope

- Page 53 and 54: Therefore, the ρ p determination d

- Page 55 and 56: that can be universally accepted as

- Page 57 and 58: inhalation. For that, product quali

- Page 59 and 60: 4.1 Experimental design for empiric

- Page 61: X 1 X 3 X 2 Figure 8 Rotational Cen

- Page 65 and 66: 38. Birchal, V.S.; Passos, M. L.; W

- Page 67 and 68: 1.1 Effect on particle-wall deposit

- Page 69 and 70: These considerations regarding the

- Page 71 and 72: eported by Keey & Pham [19]. This a

- Page 73 and 74: ⎛ ρ 1000 ⎞ pi − d p = d pi

- Page 75 and 76: 2.5 Particulate drying kinetics Cor

- Page 77 and 78: may be the solid material that is s

- Page 79 and 80: 10. Pokharkar, V.B.; Mandpe, L.P.;

- Page 81 and 82: Langrish - Spray drying and crystal

- Page 83 and 84: 1.0 Introduction Spray modeling has

- Page 85 and 86: As for the small-scale phenomena, c

- Page 87 and 88: Figure 5 Lagrangian approach for de

- Page 89 and 90: 2.1 Particle size distribution In c

- Page 91 and 92: Figure 8 Property variations in par

- Page 93 and 94: More sophisticated treatments could

- Page 95 and 96: ⎛⎛ 1 1 ⎞ ln( P / P ) = −h

- Page 97 and 98: 3/2 3/2 3/4 k 2 k µ or T L = e C C

- Page 99 and 100: ρ u − u C σ C µ dy m = m − m

- Page 101 and 102: 3 ⎛ 8K ρlr( t) 6K − 5 rp ( t +

- Page 103 and 104: Where 2χ 2bsin β −γ B = = d +

- Page 105 and 106: This Eq. (31) distinguishes the reg

- Page 107 and 108: f γ = γ − 2.4γ + 2.7γ represe

- Page 109 and 110: ⎛ new 6m ⎞ t dl = ⎜ πρ ⎟

- Page 111 and 112: in air. Park et al. [98] used the b

- Page 113 and 114:

5. Batchelor ,G.K. Collected Works

- Page 115 and 116:

59. Ranz, W.E.; Marshall, W.R.; Eva

- Page 117 and 118:

112. Xu, L.; Zhang, W.W.; Nagel, S.

- Page 119 and 120:

1.0 Introduction Spray drying is a

- Page 121 and 122:

3.0 Relevant physical-chemical prop

- Page 123 and 124:

the rapid drying of the liquid feed

- Page 125 and 126:

degradation of the product during s

- Page 127 and 128:

Cyclodextrins are ‘bucketlike’

- Page 129 and 130:

were used as drying carriers. Their

- Page 131 and 132:

continuation Lime T in = 135 - 160

- Page 133 and 134:

herbal materials (leaves, roots, se

- Page 135 and 136:

taken in account simultaneously dur

- Page 137 and 138:

6.3 Microencapsulation of essential

- Page 139 and 140:

in mixtures of gum arabic and malto

- Page 141 and 142:

and to examine their physicochemica

- Page 143 and 144:

Ersus and Yurdagel [135] investigat

- Page 145 and 146:

dried be cooled down to 30 °C or l

- Page 147 and 148:

Table 4 Miscellaneous food products

- Page 149 and 150:

8.0 Nomenclature Cs solid concentra

- Page 151 and 152:

24. Reineccius, G.A; Multiple-core

- Page 153 and 154:

57. Roustapour, O.R.; Hosseinalipou

- Page 155 and 156:

85. Cacace, J.E.; Mazza, G. Pressur

- Page 157 and 158:

110. Souza, C.R.F.; Schiavetto, I.A

- Page 159 and 160:

139. Shu, B.; Yu, W.; Zhao, Y.; Liu

- Page 161 and 162:

Oliveira, Souza, Kurozawa, Park - F

- Page 163 and 164:

1. Preparation and formulation step

- Page 165 and 166:

There are three fundamental stages

- Page 167 and 168:

2.0 Spray freeze drying Spray freez

- Page 169 and 170:

procaine hydrochloride, was success

- Page 171 and 172:

where ρ p is the particle density

- Page 173 and 174:

to be negligible [7,37,39] . The pa

- Page 175 and 176:

Figure 2 (a) Diagram of a material

- Page 177 and 178:

In Eq.(27), T interf , denotes the

- Page 179 and 180:

( z= Z t ) pw = f T at z = Z( t) ,

- Page 181 and 182:

The current studies have shown that

- Page 183 and 184:

22. Yin, W.; Yates, M.Z. Encapsulat

- Page 185 and 186:

k des rate constant in the desorpti

- Page 187 and 188:

Sadikoglu - Spray freeze drying 182

- Page 189 and 190:

However, there is no report on an e

- Page 191 and 192:

• Fine powder transport air tempe

- Page 193 and 194:

Nominal main process air flowrate (

- Page 195 and 196:

4.2 Mass balance Similar to the hea

- Page 197 and 198:

obtained from established correlati

- Page 199 and 200:

droplet surface vapour concentratio

- Page 201 and 202:

5. Patel, K.C.; Chen, X. D.; Lin, S

- Page 203 and 204:

1.0 Introduction The demand of food

- Page 205 and 206:

2.3 Particle shape All geometrical

- Page 207 and 208:

factors such as the solvent tempera

- Page 209 and 210:

A B Stereomicroscope (Nikon SMZ1500

- Page 211 and 212:

4.4 Conventional and environmental

- Page 213 and 214:

neutral networks that have as a com

- Page 215 and 216:

Wen-Shiung et al. [44] . FDt was ca

- Page 217 and 218:

Morphological parameters of powder

- Page 219 and 220:

Figure 7 Sample B of powder milk. a

- Page 221 and 222:

8.0 References 1. Hogekamp, S.; Sch

- Page 223 and 224:

35. Peighambardoust, S.H.; Dadpour,

- Page 225 and 226:

Diameter change correlation, 194 Di

- Page 227 and 228:

Phenolic compounds, 114 Phytochemic

- Page 230:

Spray drying is a ubiquitous indust