You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

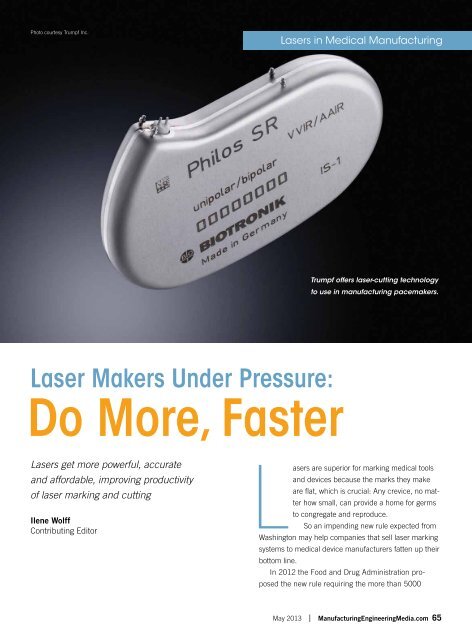

Photo courtesy Trumpf Inc.<br />

Lasers in Medical Manufacturing<br />

Trumpf offers laser-cutting technology<br />

to use in manufacturing pacemakers.<br />

Laser Makers Under Pressure:<br />

Do More, Faster<br />

Lasers get more powerful, accurate<br />

and af<strong>for</strong>dable, improving productivity<br />

of laser marking and cutting<br />

Ilene Wolff<br />

Contributing Editor<br />

Lasers are superior <strong>for</strong> marking medical tools<br />

and devices because the marks they make<br />

are flat, which is crucial: Any crevice, no matter<br />

how small, can provide a home <strong>for</strong> germs<br />

to congregate and reproduce.<br />

So an impending new rule expected from<br />

Washington may help companies that sell laser marking<br />

systems to medical device manufacturers fatten up their<br />

bottom line.<br />

In 2012 the Food and Drug Administration proposed<br />

the new rule requiring the more than 5000<br />

May 2013 | ManufacturingEngineeringMedia.com 65

Lasers in Medical Manufacturing<br />

Photo courtesy Miyachi Unitek Corp.<br />

This sample shows high-speed tube banding using the<br />

Miyachi Unitek LMF3500-HP laser marker.<br />

domestic medical device manufacturers and their <strong>for</strong>eign<br />

counterparts to add a unique device identification—a numeric<br />

or alphanumeric identifier—to some of the 1700 different<br />

types of devices used in the US. Examples of devices<br />

that would have to bear a UDI are implants and multi-use<br />

surgical instruments.<br />

A final rule isn’t expected until June. But if implemented,<br />

the rule could mean much more business <strong>for</strong> medical device<br />

makers, even if it means $132–$176 million a year in extra<br />

costs <strong>for</strong> the domestic and <strong>for</strong>eign medical device industry.<br />

The rule is designed to help improve device safety and the<br />

reporting of device-related adverse events.<br />

“It will improve how tools and devices are used and help<br />

define the life cycle of a device,” said Alex Boffi, key account<br />

manager <strong>for</strong> Techni<strong>for</strong>, a GravoTech Inc. company (Duluth,<br />

GA). His company offers a wide range of laser and other solutions<br />

<strong>for</strong> medical application UDI marking compliance. “At the<br />

end of the day, it comes down to safety.”<br />

66 ManufacturingEngineeringMedia.com | May 2013

Lasers in Medical Manufacturing<br />

Prima Power Laserdyne LLC reduced the price of its<br />

Laserdyne 430 by making the work envelope’s size more<br />

compatible with medical device applications.<br />

But even as the FDA creates additional costs <strong>for</strong> medical<br />

device manufacturers, insurance companies and the Centers<br />

<strong>for</strong> Medicare & Medicaid Services—who pay <strong>for</strong> their products,<br />

which are often cut with lasers—are <strong>for</strong>cing them to do<br />

more with less.<br />

“Produce more in less time <strong>for</strong> a lower cost per part” is<br />

what customers want from lasers and laser systems from<br />

Trumpf Inc. (Farmington, CT), said Sascha Weiler, microprocessing<br />

product manager.<br />

Geoff Shannon, laser technology manager at Miyachi<br />

Unitek Corporation (Los Angeles), agrees. He’s noticed a big<br />

cost-reduction drive among manufacturers who now operate<br />

smarter and leaner, compared with 10–15 years ago when<br />

money was no object.<br />

68 ManufacturingEngineeringMedia.com | May 2013

Lasers in Medical Manufacturing<br />

Prima Power Laserdyne LLC’s BeamDirector, a rotary and tilt axes<br />

laser beam positioning device, gives the Laserdyne 430 full 3D<br />

cutting capability.<br />

tricky part is how to use this power, and merge it<br />

with the capabilities of motion control.”<br />

That’s w<strong>here</strong> Aerotech Inc. (Pittsburgh)<br />

comes in. Aerotech manufactures extremely<br />

precise motion control systems <strong>for</strong> laser processing<br />

and micromachining.<br />

“Capabilities 10 years ago were normally<br />

limited to micron-level resolutions and accuracies,”<br />

said Scott Schmidt, laser processing<br />

and micromachining group manager. “Today<br />

we already offer standard products that function<br />

in the nanometer range, and we fully<br />

expect that 10 years from now many standard<br />

systems will be capable of picometer resolutions<br />

and accuracies.”<br />

Part of operating smarter may mean making more powerful<br />

lasers. “We are always working on increasing the laser’s<br />

power,” said Weiler, “but still maintaining high efficiency. The<br />

Making Their Mark<br />

G.T. Schmidt Marking Systems (Niles, IL) has several<br />

marking product lines, but since the turn of the century lasers<br />

have taken over.<br />

“We do see lasers as truly the future <strong>for</strong> GTS,” said Dave<br />

Noonan, product manager. Growth in Schmidt’s laser marking<br />

sales grew by about 50% in 2011 and 40% in 2012.<br />

Not only are lasers the future <strong>for</strong> Schmidt, the company<br />

will likely expand into systems <strong>for</strong> cutting and ablating as well<br />

as <strong>for</strong> marking, Noonan said.<br />

Schmidt’s laser systems include the scanning head, software<br />

and programmable controller in addition to the laser itself.<br />

Medical device makers use the system to add their corporate<br />

identifying names and logos, as well as serial numbers and 2D<br />

matrices to artificial joints, pacemakers and their nerve-stimulating<br />

cousins, catheters, tubing, and surgical tools.<br />

“About anything steel or plastic that needs to be marked,<br />

our lasers are marking,” said Noonan, whose customer base<br />

is mainly in the United States and Canada, with a few clients<br />

in South America, Europe, China and India. “Most of our<br />

customers are opting <strong>for</strong> the fiber laser these days due to its<br />

price and durability. The sources are rock solid and the design<br />

is well proven.<br />

“I think durability speaks <strong>for</strong> itself by simply looking at<br />

the expected life of the lasers,” Noonan said. “The fiber laser<br />

sources are projected to have a 100,000-hour life cycle while<br />

the diode laser sources are rated <strong>for</strong> 30,000 hours.”<br />

Fiber lasers are also becoming more powerful, up to 70<br />

W, and are more environmentally friendly because they’re air-<br />

70 ManufacturingEngineeringMedia.com | May 2013

cooled vs. water-cooled like CO 2 or YAG lasers. But they also<br />

have another distinctive advantage.<br />

“The nice thing about a fiber laser is that it’s compact,” said<br />

Bob Henry, product manager <strong>for</strong> Epilog Laser, (Golden, CO).<br />

It’s not uncommon <strong>for</strong> visitors at<br />

medical device trade shows to approach<br />

Epilog’s booth and hand over a bag of<br />

jangling metal parts to mark, said Henry.<br />

“We love the challenge when people<br />

bring us materials,” said Henry. “We<br />

haven’t seen a metal yet that we can’t<br />

get a good mark on.<br />

“The trick is to get a nice, thick<br />

oxide layer that can stand up to passivation<br />

[a cleaning process] and<br />

autoclaving,” said Henry.<br />

software, such as Microsoft Word, Adobe Illustrator, Corel-<br />

DRAW or BarTender, control the system.<br />

“With our approach, you can use so many different approaches<br />

<strong>for</strong> printing,” said Henry.<br />

We are always working on<br />

increasing the laser’s power,<br />

but still maintaining<br />

high efficiency.<br />

Epilog’s latest products include<br />

the Fusion FiberMark Laser System.<br />

The FiberMark’s work area, at 640<br />

in. 2 (4129 cm 2 ), is more than double<br />

that of its predecessor, which has a<br />

288-in. 2 (1858-cm 2 ) work area. It also<br />

features bigger motors, an enhanced<br />

motion control system, a central<br />

processing unit on the laser motors, an<br />

all-new bearing assembly and steelrein<strong>for</strong>ced<br />

belts, and bidirectional<br />

communication between the computer<br />

and laser. The two-way communications,<br />

along with the operator’s ability<br />

to pause the system’s operations,<br />

make it handy <strong>for</strong> prototyping.<br />

Another handy feature <strong>for</strong> job shops is<br />

the Epilog systems’ time estimator, which<br />

is activated after an image is uploaded to<br />

its programmable logic controller.<br />

Epilog’s open-source software, along<br />

with off-the-shelf writing or graphics<br />

May 2013 | ManufacturingEngineeringMedia.com 71

Lasers in Medical Manufacturing<br />

Device manufacturers intent on cutting production costs<br />

not only want options, they want the process to be fast as well.<br />

Techni<strong>for</strong>’s TC 500 35-W CO 2 laser is fast enough to keep<br />

up with production of plastic-molded parts, said Boffi. Just out<br />

this year, the TC 500 is galvonometric-steered vs. gantry-based,<br />

easy to integrate, cost-competitive and extremely powerful. As a<br />

result, it offers a low cycle time and increases throughput.<br />

“We anticipate it’s going to be popular in the food and<br />

beverage industry, automotive, and <strong>for</strong> medical devices,” said<br />

key account manager Boffi.<br />

Also innovating to increase speed is Miyachi Unitek.<br />

“To make the commonly required dark, or so-called annealed<br />

mark, on stainless steel faster is a challenge, as it’s<br />

very easy to overheat the part,” said Shannon. “However,<br />

using the correct laser technology, this is possible, resulting in<br />

significant throughput gains.”<br />

Shannon said his firm’s new LMF 3500-HP laser marker<br />

cuts this type of marking time by up to half, compared with its<br />

previous technology.<br />

The trick is to get a nice, thick oxide<br />

layer that can stand up to passivation<br />

(a cleaning process) and autoclaving.<br />

Cutting Into the Business<br />

Faster marking is not the only innovation Miyachi Unitek<br />

has to offer. The company’s as-yet unnamed tooling option<br />

<strong>for</strong> its Sigma Tube Cutter can cut features in small-diameter<br />

nitinol tubing <strong>for</strong> neurovascular applications. Not only will the<br />

new technology cut tubing as small as 254 μm in diameter, it<br />

will immerse the part in an ultrasound bath that eliminates the<br />

need <strong>for</strong> electro-polish finishing.<br />

“If you can provide a cutting process that produces<br />

minimal need <strong>for</strong> postprocessing you can shave time off the<br />

72 ManufacturingEngineeringMedia.com | May 2013

Lasers in Medical Manufacturing<br />

manufacturing process and save money,” said Shannon. “We<br />

think we’ve come up with a nice, elegant solution.”<br />

For this particular application the Miyachi Unitek technology—with<br />

an estimated cost of $20,000–$25,000—can<br />

be used with a system that includes a $40,000 fiber laser<br />

to make acceptable cuts. Previously the process required a<br />

$250,000 ultra-fast laser, Shannon said.<br />

To make the commonly required dark, or<br />

so-called annealed mark, on stainless steel<br />

faster is a challenge, as it’s very easy to<br />

overheat the part.<br />

Joining Miyachi Unitek with new technology is Trumpf,<br />

with the second generation of its TruMicro Series, which was<br />

first offered in 2008. The TruMicro Series 5000 uses a hybrid<br />

design <strong>for</strong> laser-cutting metals and polymers. A fiber laser is<br />

amplified by a disk laser and uses six pico-second pulses <strong>for</strong><br />

cutting polymer stents and other materials that are sensitive<br />

and react to heat affect.<br />

Also offering revamped technology—and making it price<br />

competitive in the medical device market—is Prima Power<br />

Laserdyne LLC (Champlin, MN). Prima started selling its<br />

Laserdyne 430 just this year, but it’s based on laser system<br />

designs initially created 20 years ago and used since then<br />

primarily in the aerospace industry.<br />

Prima reduced the Laserdyne 430’s price by modifying its<br />

design: For example, the work area has been reduced to a<br />

cube that measures 23 × 16 × 20" (584 × 406 × 508 mm),<br />

a work envelope compatible with the size of medical device<br />

components to be laser processed. The cost of the control<br />

system has decreased as, <strong>for</strong> example, industrial computers<br />

have become less expensive, explains Terry VanderWert,<br />

company president.<br />

Also multi-generational is the system’s BeamDirector, a<br />

rotary and tilt axes laser beam positioning device that gives<br />

the 430 full 3D cutting capability.<br />

“It’s the cleanest head on the market today, without<br />

external cables and hoses that can interfere with parts being<br />

laser processed,” said VanderWert, who sees great potential<br />

<strong>for</strong> using the Laserdyne 430 to make orthopedic implants and<br />

process-<strong>for</strong>med and tube-based medical instruments.<br />

He also points out that his new technology can be used<br />

<strong>for</strong> laser drilling and welding as well as cutting, and promises<br />

quick company responses to users’ changing needs <strong>for</strong> the<br />

430’s operating program as the marketplace evolves.<br />

Essential to many cutting jobs is motion control that controls<br />

chattering, and that’s exactly what Aerotech focuses on<br />

with its VascuLathe Stent Manufacturing System and its Toric<br />

Lens Generator.<br />

“Potential users of the VascuLathe get the benefits of better<br />

quality stents, produced more quickly, with easier and quicker<br />

system start-up,” said Scott Schmidt, laser processing and<br />

micromachining group manager. He promises a two- to five-fold<br />

increase in vascular and neural stent throughput with VascuLathe.<br />

That’s because Aerotech, Schmidt explains, integrates<br />

VascuLathe’s linear-rotary system with material handling and<br />

wet-cutting capability.<br />

“Aerotech’s direct-drive and advanced control architecture<br />

also means better quality output,” Schmidt said.<br />

The Toric Lens Generator is designed specifically to create<br />

toric lens profiles (that correct <strong>for</strong> astigmatism as well as near<br />

and farsightedness) to manufacture contact lenses and intraocular<br />

(implantable) lenses.<br />

“By limiting the application scope of the product, the TLG<br />

provides a smaller, less costly solution than competitive products,”<br />

Schmidt said. ME<br />

Want More In<strong>for</strong>mation<br />

Aerotech Inc.<br />

Ph: 412-963-7470<br />

Web site: www.aerotech.com/<br />

Epilog Laser<br />

Ph: 303-277-1188<br />

Web site: www.epiloglaser.com/<br />

G.T. Schmidt Marking Systems<br />

Ph: 800-323-1332<br />

Web site: www.gtschmidt.com<br />

Miyachi Unitek Corp.<br />

Ph: 626-303-5676<br />

Web site: www.miyachiunitek.com<br />

Prima Power Laserdyne LLC<br />

Ph: 763-433-3700<br />

Web site: www.prima-na.com<br />

Techni<strong>for</strong> Inc.<br />

Ph: 704-525-5230<br />

Web site: www.techni<strong>for</strong>.us<br />

Trumpf Inc.<br />

Ph: 860-255-6000<br />

Web site: www.us.trumpf.com<br />

74 ManufacturingEngineeringMedia.com | May 2013