You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Lasers in Medical Manufacturing<br />

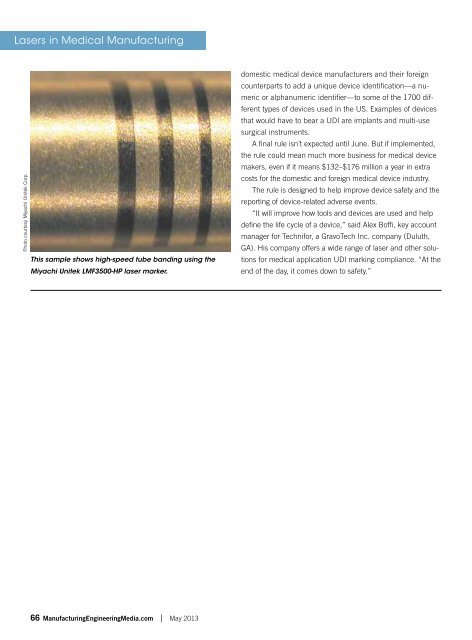

Photo courtesy Miyachi Unitek Corp.<br />

This sample shows high-speed tube banding using the<br />

Miyachi Unitek LMF3500-HP laser marker.<br />

domestic medical device manufacturers and their <strong>for</strong>eign<br />

counterparts to add a unique device identification—a numeric<br />

or alphanumeric identifier—to some of the 1700 different<br />

types of devices used in the US. Examples of devices<br />

that would have to bear a UDI are implants and multi-use<br />

surgical instruments.<br />

A final rule isn’t expected until June. But if implemented,<br />

the rule could mean much more business <strong>for</strong> medical device<br />

makers, even if it means $132–$176 million a year in extra<br />

costs <strong>for</strong> the domestic and <strong>for</strong>eign medical device industry.<br />

The rule is designed to help improve device safety and the<br />

reporting of device-related adverse events.<br />

“It will improve how tools and devices are used and help<br />

define the life cycle of a device,” said Alex Boffi, key account<br />

manager <strong>for</strong> Techni<strong>for</strong>, a GravoTech Inc. company (Duluth,<br />

GA). His company offers a wide range of laser and other solutions<br />

<strong>for</strong> medical application UDI marking compliance. “At the<br />

end of the day, it comes down to safety.”<br />

66 ManufacturingEngineeringMedia.com | May 2013